Which Companies Offer Maintenance Services For Automatic Capsule Filling Machines?

At first glance, the idea of which companies offer maintenance services for automatic capsule filling machines might look like adding more investment.

After all, many big industries are already occupied with in-house engineers and experts for troubleshooting equipment. So why do you require maintenance services? However, if you look closer, the picture would be different. The automatic capsule filling machine is not a simple unit, a tablet press, or related machines.

There’s no doubt that machines itself are demanding and require expertise that is always present on site to run the system smoothly. Consequently, many companies offer maintenance services to avoid downtime, reducing batch loss and related issues.

Read up about the article on ‘Which companies offer maintenance services for automatic capsule filling machines?’ to learn setup and more professional tips and tricks you will love to know.

1.What is the importance of maintenance for automatic capsule filling machines?

Importance of Maintenance

The maintenance for automatic capsule filling machines is not the choice! It is requirement.

That’s why companies give prime importance to maintenance services to save the cost and limit downtime. The real world

machines with outstanding performance directly impacts on your businesses. Side by side, primary reasons for importance of maintenance are described below:

Positive Impact on Operational Dynamics

In today’s competitive world, a minor downtime can become prominent issue. Regular maintenance can protect cross-contamination, variation in dispensing, common capsules related problems, etc. For good profitability, timely maintenance has positive impacts on operational and business dynamics.

Meeting End User Demand

The maintenance of equipment is the only way to achieve ideal market emerging trends with consistent and high-quality production batches. This is the gateway that swiftly drives the machine with remarkable end-user demand and rise in expansion of production capacity.

A Key to Long-Lived Machine

Professional maintenance services for automatic capsule filling machines can optimize and safeguard the overall shelf life of the machine. Whether preventive or corrective maintenance, the timely follow up can not only reduce the unexpected problems but it maximizes efficiency, production goals and performance.

Complies With cGMP Regulations

Performing regular and pre-planned maintenance services not only keeps machine reliable and durable. It also makes equipment essential to meeting strict regulatory requirements set by good manufacturing practices (GMP).

Boosting Reliability & Cost Cutting

To analyze the equipment, restoring its settings, repairing, replacing of spare parts, maintaining the optimal properties of machines ensure everything in the machine is ready to work. The following safety protocols and execution of maintenance strictly can improve the reliability with no cost.

Case Study – From Bottleneck to Breakthrough

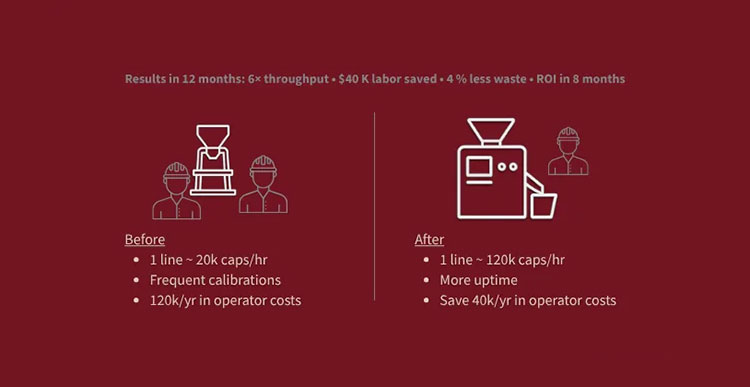

Case Study Demonstrates Infographic of Before And After Maintenance Progress- Picture Courtesy: INDEX

To describe the real impact of old and non-updated automatic capsule filling machine, the above infographic presentation tells major differences. In first, the data is from a nutraceutical company, where the machine yields with 20,000 capsule/hour. It is associated with low production capacity, continuous downtime issues, calibration problems and more cost. The estimated labor cost is around $120,000 annually.

After weekend, a professional team upgraded and followed updated maintenance plan for automatic capsule filling machine with servo drives with real-time monitoring authorized ±0.3 mg (fill-force precision) and passing by the requirement for manual calibration. It was observed that after 12 months the outcome rose by 6×. whereas labor costs were cut down by $40,000, and overfill waste of product was controlled by 4%, saving $20,000 in potent ingredients.

2.Why choose professional maintenance services over in-house maintenance?

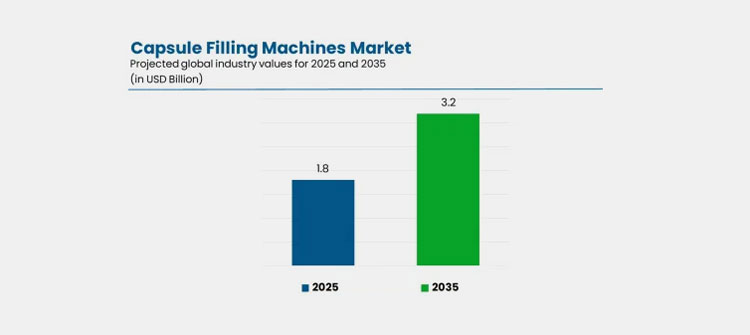

Capsule Filling Machine Market- Picture Courtesy: FMI

The issue of choosing professional maintenance services over in-house maintenance has long been a topic of debate. If you see the quick stats, its current capsule filling machine's current value is around USD 1.8 billion, which has to forecasted value of USD 3.2 billion. ignorance in minor cases can affect overall key revenue. Therefore, it is always a good decision to outsource professional maintenance experts to avail themselves of their own services. After all maintenance is not that easy.

Expertise And Specialization

Expertise And Specialization- Picture Courtesy: RainUK

The professional maintenance services are composed of highly specialized experts with prompt experience. They directly come to your facility to make you facilitate with their team. Despite efforts to make expertise skills, the in-house team may still lack the requisite know-how to attempt challenging tasks. In contrast, the professional services are way more cost-effective due to bypassing recruitment, training, salaries, etc. Professional knowledge goes beyond the scope compared to an in-house technical team for an automatic capsule filling machine.

Saving Your Money & Time

Saving Your Money & Time-Picture Courtesy: Well Ailment

The maintenance services are equipped with modern tools and spare parts for machines. In this case, you don’t need to purchase expensive parts, tools, and related formalities. The experts come and do their maintenance work fast, which ultimately saves your money, time, and energy.

Ideal for Business Core Objective

Ideal for Business Core Objective- Picture Courtesy: Uniza Group

There is no headache of looking at your staff, shifts, skills, etc. The professional services are ideal to limit the disruption operations with more managerial focus on your core business. The maintenance team is responsible for facilitating efficient tasks without redundant efforts and are clearer delineation of job responsibilities.

Quick and Familiar with Challenges

Quick and Familiar with Challenges- Picture Courtesy: Nutrition Insight

The professional services teams are more familiar with day-to-day challenges. They are holding more knowledge due to broad exposure to machines and techniques. It enables them to act quickly and perform things more precisely and efficiently. In turn, they can promptly address the baseline issues with technical expertise.

3.What does routine maintenance for automatic capsule filling machines involve?

Routine maintenance is crucial to achieve optimal efficiency from equipment and comply with regulatory requirements. According to the preventive maintenance article paper by Deloitte, through predictive maintenance 25% productivity can be achieved, with 70% reduced downtime and 25% maintenance cost. The maintenance routine of automatic capsule filling machine includes the following steps.

| Maintenance Item | Daily | Weekly | Bi-Monthly | Quarterly | Half-Yearly | Yearly |

| Maintenance cycle after machine operation | ☆ | ☆ | ☆ | ☆ | ☆ | ☆ |

| Components on worktable top | ☆ | |||||

| Clean upper and lower modules | ☆ | |||||

| Lubricate cams and rollers with grease | ☆ | |||||

| Lubricate moving parts inside turntable | ☆ | |||||

| Clean cams | ☆ | |||||

| Vacuum pump check | ☆ | |||||

| Thorough machine cleaning | ☆ | |||||

| Calibrate & check coaxially of upper/lower modules | ☆ | |||||

| Function check of jog, auto, press switches | ☆ |

4.What are the risks of neglecting regular maintenance?

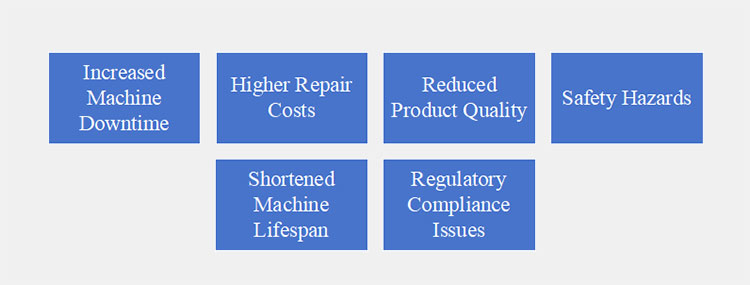

To neglecting the maintenance of automatic capsule machines can lead to inefficiency and affect overall production. Some of the key risks are mentioned below:

Ignoring Regular Maintenance can affect Regular Workflow

Increased Machine Downtime

Neglecting routine checks and overlooking calibration can result in worn components, lubrication issues and mechanical wear in equipment. These issues can quickly escalate and cause major breaks and increased downtime, disrupting operational efficiency.

Higher Repair Costs

Avoiding maintenance leads to equipment failure which is far more expensive than fixing a fault. It is important to detect and identify issues and fix them to avoid expensive repair costs.

Reduced Product Quality

Overlooking equipment maintenance impacts its functioning and performance, as a result affecting product quality and integrity. Performance faults include inconsistent fill weights in capsules, defective sealing and size variations. To avoid all of this, regular calibration and maintenance should be carried out.

Safety Hazards

Mechanical failures and equipment breakdowns pose a risk for handling operators. Unexpected malfunctioning of moving parts, electrical defects can cause accidents and serious harm. Proper maintenance ensures the machine is working properly and detects any fault to avoid the risk of accident, protecting both equipment and workers.

Shortened Machine Lifespan

Without proper maintenance, the machine parts face extra stress and degradation, causing machine breakdown, reducing its life span. It is essential to perform regular checks and maintenance, because when avoided, it will require replacement sooner than expected.

Regulatory Compliance Issues

In pharmaceutical industry, regulatory compliance is mandatory. Proper maintenance and calibration is one of the most important regulatory requirements. Ignoring regulatory compliance may lead to legal penalties, bad reputation and even production suspension.

5.What types of maintenance services do companies offer for automatic capsule filling machines?

Following are the types of maintenance services offered by companies for automatic capsule filling machines.

Preventive Maintenance

Preventive Maintenance

Preventive maintenance involves regular machine checks, inspections, cleaning and replacing worn parts in order to avoid downtime and outage.

In automatic capsule machines, the process of preventive maintenance typically involves vacuum system checks, lubrication of moving parts, cleaning and replacing the seals.

Reliable manufacturers prefer preventive maintenance in order to comply with GMP and ISO maintenance protocols to ensure optimal production volume and equipment safety.

Corrective Maintenance

Corrective maintenance- Picture Courtesy: Collidu

Corrective maintenance is performed when the fault has already been detected. Following the detection of fault, technicians review and identify the primary cause of problems which may include mechanical degradation, electric issues, software crash or operational faults.

It is necessary to document and maintain reports and deviation records for audits and regulatory compliance. The performing corrective action should be done on defective parts or areas to deal rectify the problem.

Predictive Maintenance

Predictive Maintenance- Picture Courtesy: SEEBURGER

Predictive maintenance is real-time monitoring through sensors, performance trends, and data analysis to predict when a component might fail, allowing maintenance on time.

For automatic capsule filling machine, vibration, temperature and motor current are monitored through sensors. Data analysis allows early detection of mechanical degradation. Predictive maintenance enhances operational and equipment functionality, allowing the maintenance only when required, to avoid unnecessary downtime.

Calibration and Adjustment Services

AIPAK Automatic Capsule Filling Machine Parts

Calibration and adjustments services ensure the equipment is working properly and consistently. In automatic capsule filling machine, calibration is performed by checking inconsistent weights, accurate dosing, vacuum pressure, sensors and other critical parameters to ensure their functional capacity. In pharmaceutical industry, equipment calibration is documented and recorded for audits and regulatory compliance.

6.Who are the top companies providing maintenance services for automatic capsule filling machines?

Major companies which provide maintenance support for automatic capsule machine includes global manufacturers are described as follows:

Top Companies Providing Maintenance Services for Automatic Capsule Filling Machines

Syntegon

Syntegon is a global manufacturing company with strategic approach and 160 years of experience with major focus on innovation and sustainable production. The company offers reliable maintenance support and after sales services.

IMA Group

IMA Group is a leading manufacturing company with a vast network across 80 countries, offering services in the production of automatic machines for pharmaceutical and other industries. The company emphasizes on improving quality of life through sustainable development and maintenance assistance.

AIPAK Pharma

AIPAK Pharma is a global supplier company with emphasize on equipment involved, manufacturing, filling, packaging, etc. With over 10 years of experience, AIPAK offers design customization of automatic capsule filling machine with remarkable maintenance support to customers. The primary serving companies are related to pharmaceutical, nutraceutical, biopharmaceutical, and biotechnology industries worldwide.

MG America

MG America is a well-known company providing European-designed machinery with strong focus on delivering customer-driven facilities such as sales support, machine trials, spare parts and field service to ensure effective production.

Harro Höfliger

Harro Höfliger offers sustainable solution and technologies for pharmaceutical and medical technology companies globally. The company is a member of UN global compact and science-based targets initiatives (SBTi) due to their commitment to sustainable production while offering extensive maintenance support.

7.What advantages do professional maintenance companies offer?

The advantages professional maintenance companies offer are discussed in:

Benefits of Approaching Professional Maintenance

On-Call Emergency Support

On-Call Services- Picture Courtesy: EviView

The regular problems, such as dose variation, vacuum problems, software disruptions, and others, are commonly occurring troubles. This can happen any time! With the help of professional maintenance companies, you can avail services just a call away. The immediate technical support with the help of experts can resolve the basic problem in a fraction of a minute.

Broad Range of Services

Broad Range of Services

The professional maintenance companies are not offering one or two services rather they keep up with a vast range of expertise. For instance, routine, weekly, corrective, preventive maintenance, wear and tear, replacement, repairing, calibration, etc., Therefore, your one call will open ideal solutions for many maintenance problems.

Improved Risk Management

Improved Risk Management

Maintenance of the automatic capsule filling machine is not just fixing the current issues—rather, this is helpful in the prevention of failures. The professional maintenance companies facilitate deep inspection to identify the issue or future occurrences.

For instance,

- Misalignment of the machine’s tooling

- Correction and prevention of electronic instabilities

- Reducing risk of cross-contamination

- Limiting the problems related to dose variations

- Addressing batch deviation problems

Energy Efficiency and Sustainable Operation

AIPAK Automatic Capsule Filling Machine

Today, modern and technically sound professional companies focus on limited energy consumption and more sustainable operations. This could be done by focusing:

- The running of motors is smooth and efficient

- Time-to-time calibrations

- Reducing air leakage

- Efficient vacuum units

- Updated software for effective processing

8.How do professional maintenance services help reduce long-term costs?

Professional Maintenance Services- Picture Courtesy: Syntegon

When you outsource, you’re actually relying on professional maintenance services that help to reduce the long-term costs. This means that improving the machine structure and performance can prevent regular ups and downs during working that ultimately boost lifespan.

When automatic capsule filling machine is validated with outstanding performance, the companies seldom meet with unplanned troubles. Therefore, well-structured maintenance plans always help to smoothen the process. To support this point, we have mentioned the real-world case story which is mainly inspired by professional maintenance services that results in reducing long term cost.

Case Story: How an Automatic Capsule Filling Machine Reduced 70% Maintenance Costs with AIPAK Professional Services

AIPAK pharma is a global company with over 10 years successful journey with professional supplying and customer service. Our customer from pharma company with own team and technicians are still stuck with constant issues of capsule rejections. Therefore, they contacted our advisory services and upon call out--we immediately took action to assess the scenario.

Key Strategy to Limit Cost

The real-time approach and suggestions are provided to customers to limit the cost by implementing the following points:

Always implement proactive approaches for maintenance to save the cost. This means, try following preventive maintenance prior after problem fixation.

Strictly follow schedule maintenance planning such as general maintenance, management of software, tracking inventory, to limit time wastes.

Keep spare parts in advanced to utilized on time when needed, prioritize them as an essential part of maintenance plan.

What has resulted in a few months?

From a real case study, it is documented that after spending quality amount on professional maintenance services can saves up to 70% of cost with more efficient working hours. This can be explained by:

Reduction in unwanted and unplanned problems

Reduction in general expenditure on maintenance (breakdown, spare parts, etc).

Limitation in capsule rejection, dose variation, batch withdrawals.

Extended machine’s life.

More accurate and professional filling and work.

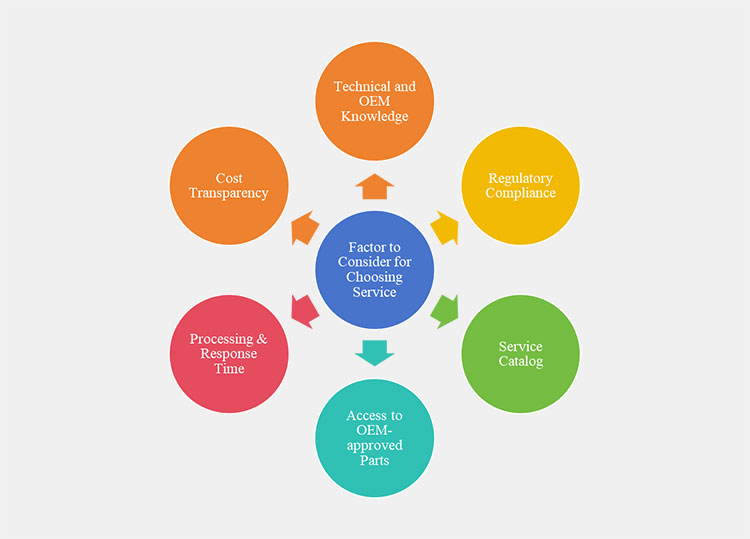

9.What factors should you consider when selecting an automatic capsule filling machine maintenance service provider?

Selecting a competent maintenance service provider for automatic capsule filling is imperative to develop a proper maintenance routine and ensure effective equipment performance. According to a featured story by Honey well, through proper maintenance, companies can prevent unexpected breakdowns and costly repairs. Therefore, it is important to select a credible service provider. Here are some key points to consider before selecting a maintenance service provider.

Points To Consider When Selecting Automatic Capsule Filling Machine

Technical and OEM Knowledge

Consider maintenance service provider who are OEM-trained and have proven experience with specific model. The supplier must have in-depth knowledge of tamping pins, dosing unit, sealing mechanism and vacuum system. OEM-trained service providers strictly adhere to quality system regulation by Annex 3; Good manufacturing practices.

Regulatory Compliance

Before making the purchase, ensure the service provider follow GMP protocols, proper documentation and safety practices. Non-compliance must be identified and addressed promptly. The service provider should also offer calibration services that meet the regulatory standards such as FDA, WHO, GMP etc.

Service Catalog

A reliable service provider should be able to effectively facilitate in preventive and predictive maintenance on daily, weekly, monthly or yearly basis. The supplier must offer annual overhaul service, which is quite critical for the effective maintenance of the equipment.

Access to OEM-approved Parts

Verify if the maintenance service provider supply OEM certified spare parts and maintenance kits. Reliable and OEM verified material in annual overhaul servicing and replacements is most likely reduce the downtime and optimize equipment efficiency.

Processing & Response Time

The response rate and dependability of maintenance service provider directly influence the continuity of operation and overall process; even minor downtime can affect the productivity largely. A reliable maintenance service provider ensures immediate response to emergency repairs.

Cost Transparency

Clear and accurate pricing is essential while selecting a maintenance service provider for automatic capsule filling machine. Cost transparency allows the company to evaluate direct and indirect cost, avoid cost elevations and plan budget according to the services covered in contract. AIPAK provide performance service plans which offers predictable cost to ensure cost transparency.

10.How can you ensure that the maintenance provider meets GMP (Good Manufacturing Practices) standards?

Good Manufacturing Practices

It is strictly required that the maintenance service provider meets the GMP standards in order to prevent non-compliance and legal penalties. Following are some important evaluations you can consider ensuring the service provider meet the regulatory standards.

Initial Audit and Assessment

Before selecting the maintenance service provide, verify their quality management system (QMS). Perform an on-site assessment and ensure the maintenance service provide follow their authentic SOPs for maintenance services, trainings and documentation. Check for calibration records and procedures.

Regulatory Compliance Verification

Ensure that the service provider is familiar and adhere to GMP standards during equipment maintenance. The service provider should demonstrate relevant experience and compliance during inspections and specific machine model maintenance.

Equipment Calibration and Validation

According to Quality System regulation, good manufacturing practices, the personnel carrying out the calibration and preventive maintenance should have relevant training and qualification. Ask and evaluate whether the maintenance service provider have appropriate knowledge and qualification for calibration.

OEM-Trained Maintenance

Ensure the maintenance service provider is OEM-trained and is using OEM-approved parts in maintenance service. Request official OEM training certificates and ask for prior maintenance performed under OEM guidelines. You can question the service provider about OEM procedures to ensure their reliability.

Documentation and Records

Proper documentation and records of maintenance are proof of regulatory compliance as documentation and validation is one of the most crucial requirements of GMP standards. Assess their maintenance records and evaluate inspection documentation, this will prove if they are following the regulatory guidelines.

Risk Assessment

Evaluate the service provider’s track record of maintenance and identify potential risk that could detect any non-compliance. Search for any incompetent maintenance records such as use of non-OEM parts, improper calibration or substandard documentation. This will provide the evidence that if the maintenance service provider follows GMP standards consistently.

Contamination Control

Ensure the maintenance service provider adheres to strict contamination control practices. Check the usage of sanitized and clean room-approved tools, use of PPEs, operator safety and appropriate handling of machine parts to reduce the risk of contamination and prevent microbial growth during maintenance procedures.

11.What real-world examples demonstrate the importance of professional maintenance?

The real-world examples demonstrate the importance of professional maintenance are discussed below:

Real World Example: Simple, Fast & Better Market

In this case study, the leading Italian company successfully conducted pellet filling in capsules with tremendous output. The client aimed to formulate the project with three variables of pellets with different release profiles.

Verifying accuracy and offering high production capacity were challenging for customized encapsulation. We, AIPAK experts, not only advised them on easy solutions but also transformed the entire operation into a real-time, optimized, and effective pattern.

AIPAK Solution

AIPAK Automatic Capsule Filling Machine

After assessing the challenging requirements of our clients, the AIPAK team found the alternative features and redesigned the capsule filling machine for pellets. Therefore, the machine is not only ideal for fractions of different formulation types but also offers a myriad of other benefits.

Easy sampling of individual pellet: when the machine was designed with a separate servo-driven machine. The individual sampling was successfully achieved.

Maintenance of Static Charge: With the help of static charge removal, the accurate dosing was accomplished noiselessly.

Outcome

We always feel special after catering to our clients to successfully resolve the issue. However, finding happy customers when we reach their expectations with desirable results is our goal. With our timely management and machines can ensure customers can work effortlessly with different formulation types in capsule filling production with high throughputs.

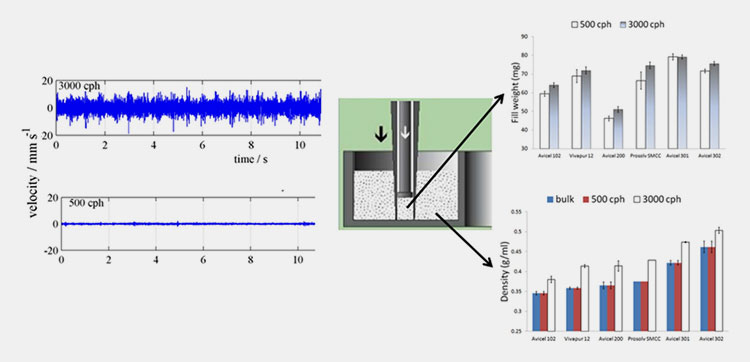

Real World Example: Impact of Vibration on Weight Variation

Effects of Vibration on Average Fill Variation- Picture Courtesy: Science Direct

According to a study published in the International Journal of Pharmaceutics, you can observe that the graph illustrates the effects of high-speed results in the vibration of machines. Due to vibrations, the powder densification or filling weight becomes more than you expect. This means that there’s unintentional high weight when the machine’s velocity is higher. Consequently, poor quality and batch inconsistencies.

Solution

The research study suggested possible solutions such as:

Implementation of the Quality-by-Design (QbD) strategy will always be helpful in the assessment of machine vibrations.

A Laser Doppler Vibrometer is a useful tool to trace the level of vibration produced by the machine during work.

Optimizing speed, regular maintenance is a great strategy for safe dispensing with reduced production of vibration.

Conclusion

Whether you are pharma based capsule manufacturer or planning to start up the business. There are always key rules to keep good knowledge to your project. As one of the world’s largest suppliers of automatic capsule filling machines, AIPAK has broad range and excellent security to offer our services almost everywhere around the globe. Together we can have a better future! Contact us to choose a better maintenance service partner.

Don't forget to share this post!

Capsule Filling Machine Related Posts

Capsule Filling Machine Related Products

Capsule Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine