What Is The Advantage Of Aluminium Foil Sealing?

Aluminium Foil Sealing-sourced: imimg

Aluminium foil is a good material for packaging as the lid to a pot, cover a bowl, and be used in the oven, backyard grill, slow cooker, and air fryer. Aluminium foil sealing is a common method now applying to the lid of different bottles and jars. What is the advantage of aluminium foil sealing? To know the advantage of aluminium foil sealing, you are better to read through this post. Let's start now!

1.What Is The Aluminium Foil Sealing?

Aluminium Foil Sealing-sourced: topack168

Aluminium foil sealing, also called as induction aluminium foil sealing, is a process of sealing and bonding thermoplastic materials through induction heating. This process involves the controlled heating of a conductive object (usually aluminum foil) through electromagnetic induction of heat generated in the object through eddy currents.

It is a special technique to use heat to seal bottle caps with aluminum foil liners or aluminum foil liners materials. The aluminium foil sealing offers a quick, cost effective and reliable method for sealing bottles caps.

2.What Are The Use Of Aluminium Foil Sealing?

Use Of Aluminium Foil Sealing-sourced: sigmacapseal

The aluminum foil sealing is used in many types of manufacturing, but probably the most common use is cap sealing. It is a non-contact method of heating the top of plastic and glass containers to achieve an airtight seal by heating the interior seal of the container.

Aluminum foil sealing has a wide range of uses. It can be used to seal plastic cups made of PP, PS or PET, or paper cups laminated with plastic film. The industries it is used in include:

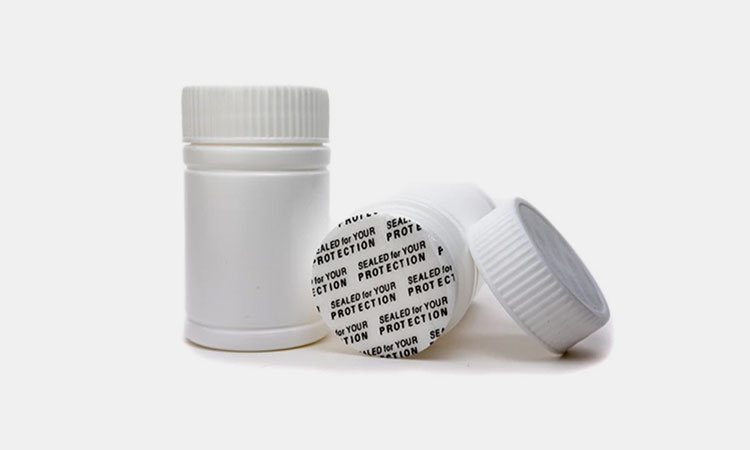

Pharmaceutical Industry

Pharmaceutical Industry-sourced: inductioncapsealingmachine

The aluminum foil sealing can be applied to the cap sealing of various veterinary supplies, medical supplies, powders, pills, pharmaceutical raw materials bottles and containers.

Food Industry

Food Industry-sourced: kramfc-2

In the food industry, aluminum foil sealing is used in many canned fruits, canned snacks, canned meat, sauces, canned prepared products, nutrition powder, honey, dry food (such as nuts, cereals, rice, etc.).

Beverage Industry

Beverage Industry-sourced: horizonfoil

Beverages like coffee, ice cream, jam, yogurt, water, milk, soft drinks, etc. can be applied by the aluminum foil sealing with good sealing effects and convenient for transportation.

Cosmetic Industry

Cosmetic Industry-sourced: enerconind

Various cosmetics and skin care products are using aluminum foil sealing for tubes, bottles and jars packaging. Liquid foundation, BB cream, concealer, eyebrow gel, makeup setting liquid, water, lotion, essence, eye cream, etc.

Daily Chemical Industry

Daily Chemical Industry-sourced: ptasia

Detergents, toiletries, hair care products, cleaning products, skin care products, etc. are all using aluminum foil sealing, including hand soap, shampoo, body wash, hair mask, toilet cleaner, dish soap, etc.

Chemical Industry

Chemical Industry-sourced: penglaichina-1

The chemical materials like cooking oil, lube oil, glue, paint, farm chemicals, cleaning liquid, ink and lacquers, nuclear waste and radioactive substances, automotive fluids (petrol, oil, and diesel) all can be applied by the aluminum foil sealing.

Agricultural Industry

Agricultural Industry-sourced: minipress

Aluminum foil sealing can be used for various pesticides and fertilizers, including herbicides, insecticides, nutrient solutions, rooting solutions, liquid fertilizers, etc.

3.What Is The Advantage Of Aluminium Foil Sealing?

The technical application of aluminum foil sealing has been very mature and extensive. The reason why aluminum foil sealing can be widely used is that it has many advantages.

For sealed products, the advantages are:

Good Sealing Effect

Good Sealing Effect-sourced: nanografix

The aluminum foil sealing can provide customers with clean, neat, safe and effective cap lid sealing with good sealing effect. Containers of different materials can be sealed safely and effectively.

Reduced Oxidation

Reduced Oxidation-sourced: kramfc

Especially in the cosmetics industry, many expensive skin creams and essences with active ingredients can be processed by aluminum foil sealing to reduce the oxidation of nutrients and the failure of active ingredients.

Easy To Peel

Easy To Peel-sourced: Urban

By heating, the wax oil on the cap liner is melted and pasted on the cap lid mouth. This operation also facilitates subsequent tearing.

Moisture-proof and Non-toxic

Moisture-proof and Non-toxic-sourced: nicevoteet

It has good waterproofing effect and can extend the storage time of the contents; it is non-toxic and improves the safety of consumable materials such as food and medicine.

Leak Prevention or Mold Proof

Leak Prevention or Mold Proof-sourced: ptasia

Using aluminum foil material can effectively prevent water, dust, moisture, dirt and odor from entering the tank and preventing product leakage. It can simultaneously prevent the product from growing moldy and maintain the microbial quality of the product.

Extend Storage Time

The aluminum foil sealing provides an airtight seal, preventing air, moisture and other contaminants from entering the container, thereby extending the shelf life of the product.

Block Light

Block Light-sourced: imimg

The aluminum foil sealing can help block part of the sunlight and help light-sensitive substances in the container avoid evaporation or chemical changes.

For sealed containers, the advantages are:

High Processability

The physical and thermal properties of aluminum foil make it a suitable material for foil sealing, increasing its compatibility with different sealing machines and sealed containers.

Protect Containers

Protect Containers-sourced: penglaichina

The entire sealing process will not damage the sealing layer, nor will it have a negative impact on the products in the container, protecting the container from being affected.

Tamper Proof

The aluminum foil sealing can provide a tamper-evident seal, showing whether the product has been tampered with, helping to ensure the integrity of the product within the container and protecting consumer safety.

Recyclable

Bottles and caps processed through aluminum foil sealing can still be recycled. It reduces the steps of classification and recycling and saves recycling costs.

For the sealing materials used, the advantages are:

Good Printing Effect

Good Printing Effect-sourced: sealfoil

Compared with materials such as paper and plastic, aluminum foil has good printing effects and good durability, which can bring excellent printing effects to different containers. It also reduces the amount of carbon printing and protects the environment.

Durable

Aluminum foil has high strength and hardens over time, making it not easily damaged and durable.

For aluminum foil sealing technology, the advantages are:

Versatility

Versatility-sourced: medpacking

The aluminum foil sealing can be used to seal a variety of containers, including plastic, glass and metal bottles and jars. And containers of different sizes can be sealed as long as they are within the diameter range of the machine's head.

It can also be used in a variety of products, including food, beverages, pharmaceuticals and personal care products.

High Production Efficiency

The aluminum foil sealing is tight and not affected by moisture, grease or powder contamination in the container mouth.

Short Time

The aluminum foil sealing is a fast and efficient method that generally takes a short time and usually only takes a few seconds to complete, depending on the specifications of the machine.

Cost Effective

Compared with other sealing materials, aluminum foil has low cost but high benefits, and is widely sought after.

Easy For Transportation

The aluminum foil sealing provides a tight seal, providing extra strength and security to the product's opening, preventing leakage and facilitating product transportation.

Low Maintenance

The aluminum foil sealing requires minimal maintenance, reducing downtime and increasing productivity.

Conclusion

With new technological breakthroughs in sealing non-round containers and lidless containers, the advantages of aluminum foil sealing can apply to almost any container. Through this "what is the advantage of aluminum foil sealing", you may have a more thorough understanding of this technology. Are you more curious about what kind of equipment or services can be used for aluminum foil sealing? Please contact us for more!

Don't forget to share this post!

Induction Sealing Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine