Top 10 Best Dryers Used In Pharmaceutical Industries

Drying is an important step in material processing, thus dryers are necessary for industries which have demands for material drying, especially in pharmaceutical industries. What’s the purpose of drying? It is to reduce the moisture content of your materials to let them be qualified for production.

There are many different types of dryers on the market which can be used in pharmaceutical industries, these dryers are based on different working principles, but their final purpose is the same. To help you select the proper type of dryer, next you will learn the top 10 best dryers used in pharmaceutical industries. Now please read on.

Table of Contents

Ⅰ.Fluid Bed Dryer

Fluid bed dryer, is a popular type of drying equipment in pharmaceutical industry, it is based on fluidization principle, suitable for drying powders and granules. This machine is widely applied in pharmaceutical, food processing, chemical, agriculture, ceramic, mineral, metal industries, etc.

There are many different types of fluid bed dryers on the market, such as static fluid bed dryer, vibratory fluid bed dryer, vertical fluid bed dryer, horizontal fluid bed dryer,etc.

Working Principle:

As is mentioned, the working principle of fluid bed dryer is fluidization, when the material is loaded into the machine, the air also starts to enter it, with the movement of air, the material is suspended. And then, the machine begins to heat the air and material, as the temperature rises, the material is gradually dried.

Benefits:

Benefits of Fluid Bed Dryer-Photo Credit:Tema Process

●Fluid bed dryer can provide fast and uniform drying, besides drying, it can also play a role in mixing.

●Compared with other types of dryers, fluid bed dryer will consume less energy.

●Fluid bed dryer has large production capacity, it is suitable for large volume production.

II.Spray Dryer

Spray dryer is another type of common drying equipment, it can realize drying and granulation operations at the same time. Don’t know what it is? Well, this dryer is to dry liquids or pastes and turn them into dry powder. You can often see spray dryer in sectors such as pharmaceutical, nutritional, biological, chemical, food, agriculture and plastic, etc.

In general, there are 4 types of spray dryers on the market, they are electric blast spray dryer, vacuum spray dryer, high-speed centrifugal spray dryer and sterile spray dryer.

Working Principle:

As the name implies, spray dryer is to spray the special liquid material onto the raw material to let it be atomizated. Next, the atomized material will directly contact with hot air, at this moment the purpose of drying is achieved.

Benefits:

- By using a spray dryer, you can get consistent quality product because it can control the particle size of the final product accurately.

- Spray dryer can increase the production efficiency and extend the storage time of products.

III.Vacuum Dryer

Vacuum dryer is a type of cryogenic equipment which is suitable for drying heat-sensitive agricultural products, health care products, food ,medicines, chemicals, etc. Vacuum dryers can be divided into two major categories, the static vacuum dryers and tumble vacuum dryers.

Working Principle:

Can you guess how does a vacuum dryer work? It works based on vacuum, during the working process, this machine will extract the air inside the container,and then remove the moisture content of the inner parts of the container when it is under a vacuum condition.

Benefits:

- The vacuum dryer can dry flammable and explosive dangerous goods, and can prevent the discharge of toxic and harmful substances in the dried materials.

- Vacuum dryer process products under a vacuum circumstance, thus it can prevent the products from deteriorating.

- Due to the particularity of the vacuum dryer, the machine can dryproducts with complex ingredients.

IV.Freeze Dryer

Can you image the function of freeze dryer through its name? That's right, this machine dries the material by freezing it, and the whole drying process will take place at extremely low temperatures, therefore, freeze dryer is suitable for drying products which are heat-labile.

Freeze dryer is mainly composed of refrigeration system, vacuum system, heating system and electrical instrument control system, can dry material in a short time.

Working Principle:

Freeze dryer works on the principle of sublimation, the material which needs to be dried will be quickly frozen under a low temperature. and then in a suitable vacuum environment, the frozen water molecules will be directly sublimated into water vapor to escape. At this moment, the material is perfectly dried.

Benefits:

- Since the material is frozen by freeze dryer, it is stored in a low temperature so that there will be no microorganisms and bacteria, therefore, the shelf life of the material will be extended.

- Freeze dryer can remain the nutritional value of the material in the largest degree, it won’t cause damage to the original characteristics of the material.

Ⅴ.Rotary Dryer

Rotary Dryer-Photo Credit:DARMAWAN

Rotary dryer uses the movement of air to dry the material, in this machine, the material contacts with hot air so that it can be quickly dried. The rotary dryer consists of a rotating cylinder, a drive mechanism and a supporting structure. This machine is widely applied in food, chemical, pharmaceutical, mineral industries and so on.

Working Principle:

Rotary dryer reduces the moisture content of materials by exposing them to hot air, during the working principle, the cylinder of the machine rotates constantly, therefore, the material and air also keep moving. The material continues to rise and fall, during this process, it contacts with the hot air and then by dried.

Benefits:

- The rotation design of rotary dryer let it be suitable for processing a wide range of materials and particle sizes.

- Rotary dryer has low energy consumption, and it is convenient to be integrated with other equipment.

- Rotary dryer is suitable for materials with higher moisture content and can provide fast evaporation without overheating them.

ⅤI.Tray Dryer

Tray Dryer-Photo Credit:Labconco

Compared with other types of dryers, tray dryer is a little different, as the picture shows, it has a heated chamber which is equipped with trays. That is, the material is placed on these trays during the drying process. The tray dryer is often used to dry powders, granules and other products, the drying process always occurs at controlled temperature and humidity conditions.

Working Principle:

The working or tray dryer is based on convection principle, the solid materials are placed at the trays, when the machine begins working, the whole chamber will be heated. During the working process of tray dryer, hot air will be circulated in the chamber, meanwhile, it can take away the moisture content of the material.

Benefits:

Benefits of Tray Dryer-Photo Credit:Yinda Machinery

- By using a tray dryer, you can easily control the parameters such as temperature and humidity according to different drying demands.

- You can load and unload the material precisely, without any leakage and wastage.

- The tray dryer is simple to operate, clean and maintain, ideal for operators who have less usage experience.

Ⅶ.Belt Dryer

Belt dryer is a type of continuous drying equipment which uses air, inert gas or flue gas to dry materials, it is suitable for drying flakes, strips and granular materials which have good gas permeability. Generally speaking, belt dryers adopt modular designs, there are many different types of belt dryers which include single-belt dryer, multi-stage dryer, multi-level dryer and multi-belt dryer.

The belt dryer has a wide range of applications, and it has already been used in the fields of pharmacy, food, biology, and chemical, etc.

Working Principle:

As is mentioned, belt dryer uses gas to dry material, as you can see in the picture, belt dryer is equipped with a conveyor belt which is in the horizontal direction. During the working process of belt dryer, the material is put on the conveyor belt and be delivered, then the gas is released, passes through the material and dries it.

Benefits:

- The belt dryer has the advantages of large production capacity, fast drying speed and high evaporation intensity.

- Belt dryer has high adaptability, it is suitable for drying a wide range of materials.

- Belt dryer is environmental protectiveand energy saving, during its production process, there will not be harmful gases such as carbon dioxide.

Ⅷ.Paddle Dryer

Paddle type dryer is a kind of low-speed stirring dryer with a stirring paddle installed inside the equipment, as a result, the wet material can totally contact with the heat carrier and the hot surface under the agitation of the paddle, so as to achieve the purpose of drying. The structure of paddle dryer is generally horizontal , two-axis or four-axis.

This machine is suitable for drying all kinds of paste, granule, powder and other materials with good thermal stability. It is widely used in food, pharmaceutical, chemical, petrochemical, dyestuff and other industries

Working Principle:

Paddle dryer is equipped with a hollow shaft which has paddles on it, and inside them there is a heat carrier. When the machine starts to work, the paddles start to stir, driving the material to move, then the material is constantly in contact with the heat carrier and the hot surface to make a heat exchange. That’s the working principle of paddle dryer.

Benefits:

- Due to the use of paddle drying elements and continuous stirring, paddle dryer is able to dry high-viscous and high-humidity materials.

- Paddle dryer has a large heat transfer area, it can dry material quickly and uniformly.

- The rotating speed of the paddles is slow, therefore, paddle dryer is not easy to be worn, in other words, it has long service life.

Ⅸ.Drum Dryer

Drum Dryer-Photo Credit:PotatoPro

Drum dryer is an internal heating conduction dryer, it is widely used in pharmaceutical, chemical, food and other industries. This machine is similar to rotary dryer, they both have a cylinder. Drum dryer is suitable for drying granules, powders and flakes, can dry material quickly and remain the original flavor of it.

Working Principle:

Drum dryer also uses hot air to dry material, at the beginning, material is fed into the drum, and then the hot air which is heated by hot stove also enters the machine, at this time, the drum begins to rotate, let the material totally mix with the hot air so that it is dried.

Benefits:

- Drum dryer has high thermal efficiency because the most of heat which is created by the machine is used for drying.

- Drum dryer has high operation flexibility and a wide range of application, thus it is popular among industries.

- The machine adopts fully automatic control and has strong overload resistance.

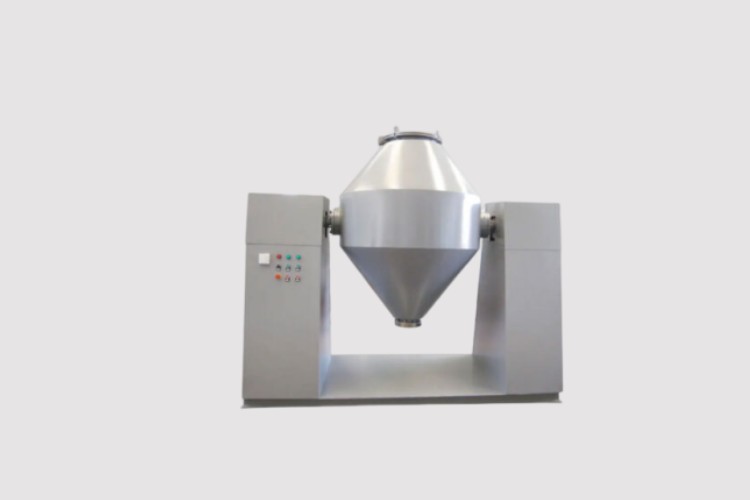

Ⅹ.Rotary Vacuum Dryer

Rotary vacuum dryer is different from rotary dryer and vacuum dryer, it likes a combination of these two types of dryers. As the picture shows, this kind of machine is generally cylindrical or conical. This is a type of batch operation dryer, the drying process is under a vacuum condition. Rotary vacuum dryer is commonly applied in pharmaceutical, food processing, chemical, biological industries, etc.

Working Principle:

The drying process of rotary vacuum dryer is achieved by combination process of vacuum, stirring and consistent heating. The material vessel will be rotated during the working process, and the inner agitator continuously mixes the material so that it is in contact with the heated surface. And then, the moisture content of the material evaporates under a vacuum.

Benefits:

- Rotary vacuum dryer adopts total contained process, as s result, there will not be too much dust during the working process of this machine.

- The rotary vacuum dryer can easily process crystalline or amorphous powders which are prone for lumps.

- Rotary vacuum dryer is a advanced type of drying equipment, it largely shorten the drying time, and it is easy to clean.

Conclusion

In summary, the top 10 best dryers in pharmaceutical industries all have excellent performance and short drying time, they will provide you perfect drying effect. After learn the relevant knowledge of these dryers, do you have a deeper realization of them? Which type of dryer do you think is the best suitable for your business? If you still have queries about these dryers, you can contact us, it is glad to help you solve problems.

Don't forget to share this post!

Dryers Related Posts

Dryer Related Products

Dryer Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine