Your Ideal Vacuum Freeze Dryer Supplier

- Wide Range Of Applications

- Independent Probe&Auto Defrosting

- High Refrigeration Efficiency

AIPAK Vacuum Freeze Dryer

AIPAK vacuum freeze dryer can be widely used for the research and industrial production of various heat-sensitive biological products such as medicines,biological products,vegetable,fruit,nutrition products,etc.With the development of the pharmaceutical,biological,chemical,cosmetic,food,feed.The vacuum freeze dryer is a necessary equipment in these industries.It is an advanced method for the material de-watering. It has been very famous for its good results and special capturing water alternatively.It freezes the moisture material in the low temperature and makes the water inside sublimate directly in the vacuum condition. Then it collects the sublimated vapor by means of the condensing way so as to de-water and dry the material.Compared with the common drying method,vacuum freeze dryer maintains 97% of the nutritional value of the food,use this technology,the foods have better looking color,better flavor and test.

The Buyer's Guide

Vacuum Freeze Dryer: The Complete FAQ Guide 2024

Today, the product manufacturing trends are dynamically changing that results in building high customer demand to obtain fresh and preserved product with 100% right quality. Yes, vacuum freeze dryer has attributed an innovative property to various processing industries.

A vacuum freeze dryer is proven to be a better alternative than conventional drying. In this review article we will discuss important aspects and characteristics of vacuum freeze dryer. If you are new to the subject, this guide will benefit you in more than one way.

1.What Is A Vacuum Freeze Dryer?

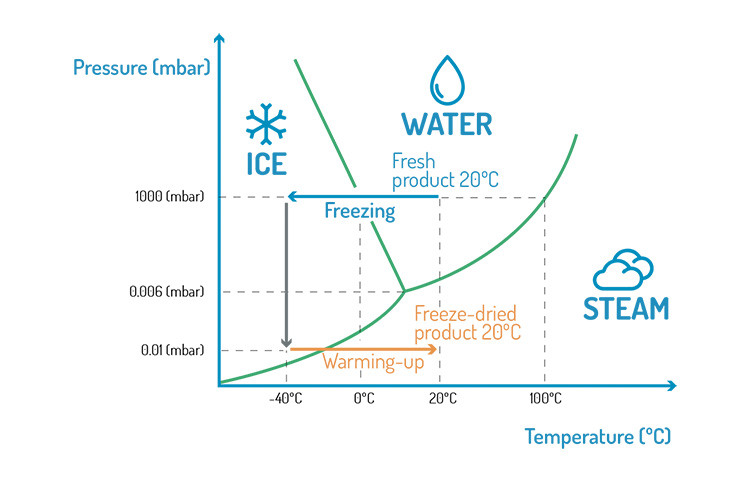

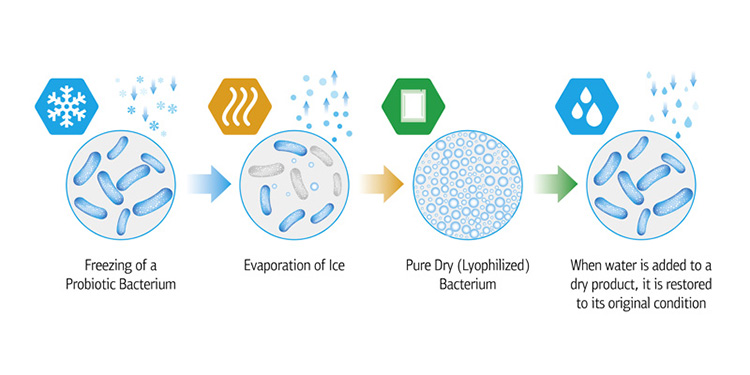

A vacuum freeze dryer is a tool used to dehydrate the raw product. This machine is also termed a lyophilizer or freeze dryer. It helps in product dehydration by freezing ingredients which are then transferred to the drying unit. It works by lowering the pressure and allows solid ice sublimate to be removed from the product. Here, you must keep in mind that water removal is based on sublimation which is the conversion of solid to vapor form. The equipment is required to dry the solution or suspension at or below the freezing point of the following product.

In simpler words, the drying process takes place at a very low temperature. It is mostly recommended for thermolabile products (which are destroyed by heat). The machine ensures the preservation of material for a longer time and makes it convenient to transport. So, the process takes place via freezing the ingredient and reducing its pressure and simultaneous heating where frozen water is transformed to vapor. This is called sublimation which is ideal for sensitive products as it offers high integrity to the biological chemical structures.

2.What Are Industrial Applications Of Vacuum Freeze Dryer?

As compared to other dryers, vacuum freeze dryers are more popular in today’s industrial world due to their unparallel benefits. This machine is extensively used in various manufacturing sectors like biological, chemicals, food, pharmaceutical and others. Moreover, its usages are expanding rapidly as it bound to the most significant technology in 21st century.

Biological Research Sectors

This field of science is basically relying on intricate samples that must be very pure and accurate in order to get desirable outcomes. For example: TB vaccines, BCG vaccines, streptococcus, polio etc.,

biological freezer dryer is used to eliminate water content from intricate biological product without harming their structure and preserve them for longer time. You can use the sample once reconstitute with solvent or water.

Pharmaceutical Industry

In this sector, vacuum freezer dryer is of great value for storing and preserving sensitive medicines. For example, antibiotics, Active pharmaceutical ingredients, hormones, proteins, electrolytes and others.

Traditional Herbal/Chinese Medicines

This machine is of great value when it comes to dealing traditional medicines. For that this process is required once you get an extraction and filtrated product. Passing through vacuum freezer dryer you can be assured about 100% safety of product.

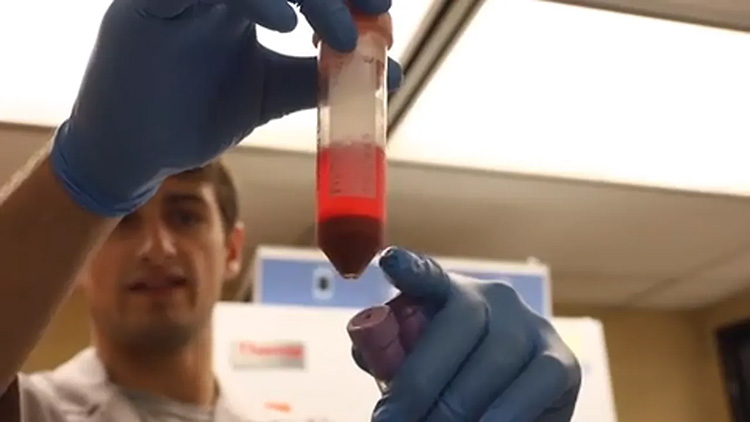

Medical and Criminology Sector

Vacuum freeze dryer machine is useful machine for long term preservation of blood, arteries, skin tissues and other sample. You must know that a lyophilized cell can be stored in room or refrigerator for a longer time up to two years.

Food Sector

This is a major sector where vacuum freeze dryer is used to deal products like meat, vegetables, plants, protein powders, coffee, beverages and much more. Vacuum freeze dryer can reduce the moisture content present in food product and make it suitable for you to use without any harm or preservatives.

Chemical Industry

No one can ignore vacuum freeze dryer when considering aspects of chemical industry. Moreover, the efficiency of chemical products can be increased 5 to 20 times more when lyophilized. Therefore, vacuum freeze dryer is used for dehydrating sensitive chemical products safely.

Technological Industry

In bio-separation, vacuum freeze dryer is used in final stage for purification and removal of solvents from final product to make them more easier to dissolve and stable product. Moreover, this is also required for substances with low molecular weights where filtration and air drying is impossible.

3.What Are The Advantages Of Vacuum Freeze Dryers?

A vacuum freeze dryer is of great value as it offers the following benefits.

Whole Food Nutrition

A vacuum freeze dryer is a preferable option for those manufacturers who consider their consumers’ value and want to provide them with high quality food with real labels. This is because you can get truly real products with little to no artificial substances and free from synthetic ingredients or highly processed ones. A vacuum freeze dryer can give real natural products whether it is a leafy vegetable, drug, or biological sample.

True Color of Product

A vacuum freeze dryer helps in retaining the nutritional value of the product and preserves the actual color and dimension of the product, so ultimately reassuring consumers they get what they deserve for health and wellness.

Bespoke Finished Product

Another great benefit of vacuum freeze dryers is ensuring consumers to their unique demands about project goals/aims. For example, there are many dried ingredients in various shapes and sizes, from whole fruit/vegetable to powder form. It has the ability to produce results that can blend into your formulation or stand out in the real authentic form.

Fast, Efficient, Time-Saving Method

Vacuum freeze dryers offer great advantages for preserving material in a fast and modern way. A conventional method of preserving material was quite laborious and hectic. But vacuum freeze dryer has solved this problem via quick processing.

Long Shelf Life

A vacuum freeze dryer takes product and gives you effective results by removing moisture content from it. The removal of moisture content saves your product from potential bacterial growth and leaves it safe to use. It leaves an average 3% moisture content that assures good product shelf life and quality.

4.What Is The Working Principle Of A Vacuum Freeze Dryer?

The main working principle of a vacuum freeze dryer is based on ‘lyophilization or sublimation and vacuum’. This means machines help you in transferring a solid state into direct vapor form without transitioning to a liquid state. Water content is eliminated from frozen material and subjected directly to gaseous form via high vacuum to heat, mean by using conduction or radiation or both.

The sublime liquid directly leaves the unit, and you can only get the dried product. It has unique working and is beneficial as a sample is kept at the lowest temperature and remains frozen for a longer period. A vacuum freeze dryer is an accepted way of drying heat-sensitive products that are being stored at temperatures above their freezing.

5.What Are The Stages Of Vacuum Freeze Dryer?

The following stages below are involved with the working of a vacuum freeze dryer.

Preparation And Pre-Treatment

↓

Pre-Freezing For Solidifying Water

↓

Primary Drying

↓

Secondary Drying

↓

Packing

Preparation And Pre-Treatment

As the name implies, it includes a method of preparation before the primary stage of vacuum freeze drying. This involved concentration of products, such as the addition of a substance in order to provide stability, revising formulation, decreasing high vapor pressure, and expanding surface area.

While pretreatment involved freezing concentration, and formulation to preserve the physical properties of the product.

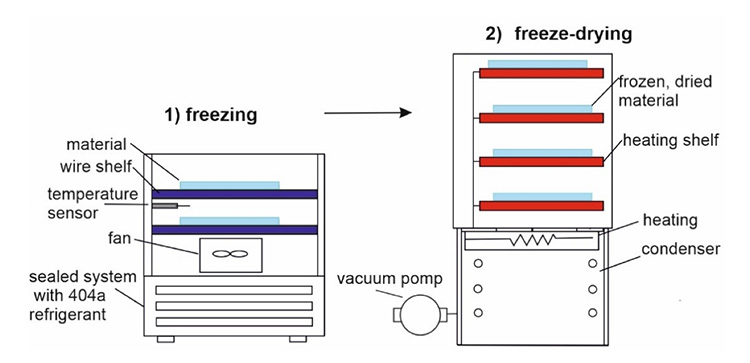

Pre-Freezing for Solidifying Water

This is one of the most important stages of vacuum freeze dryer procedures. In this phase, the sample is cooled down approximately to the temperature of its melting point. Thus, it simply assures you once the material is frozen it can easily undergo sublimation. This stages commonly cool down the sample to -40 to -60 °C till you get a pure crystalline ice form, side by side remaining sample is freeze concentrated to glassy state where a greater viscosity ensures further crystallization.

In case, the material is not properly frozen it can result in evaporation and the sample itself won’t be able to achieve the required preservation that should be occurred with sublimation.

The rate of freezing the sample will directly link to the size of the ice crystal. Moreover, it can impact the integrity, rate of reconstitution, speed of freeze-drying process, and stability of the entire process if not done effectively.

Additionally, a bigger ice crystal ensures rapid and effective lyophilization as water molecules easily move out from the sample during sublimation.

Primary Drying – Sublimation Phase

This stage starts with freeze drying and vacuum process. By keeping the low-pressure environment, the process takes place. Here, the formed freezing ice is eliminated by sublimation under highly low temperature and vacuum. This leaves a high porous structure in amorphous state with generally 10% moisture content. This stage is carried out with pressure of 104 to 109 atm and with temperature of -45 to -20 °C. The sublimation is the outcome of primary drying that takes place with the help of coupled heat and mass transfer procedures.

By the end of procedure approximately 93% of moisture content from the sample is sublimated. To preserve the sample for the longer term, secondary drying is proceeded.

Secondary Drying- Adsorption Phase

This is the final step where most of the moisture content is desorbed from crystal by gradual increase in the temperature up to 10 – 15 °C under static low pressure.

The ultimate product looks like a dry cake with expanded surface area and reduced moisture content such as <3% w/w, that is very easy to be reconstituted. The secondary drying is generally used for samples that are intended for longer preservation.

By replacing the vacuum in the vials or bottles, a dried sample is poured that is enclosed tightly for storage.

6.How Does Vacuum Freeze Dryer Work?

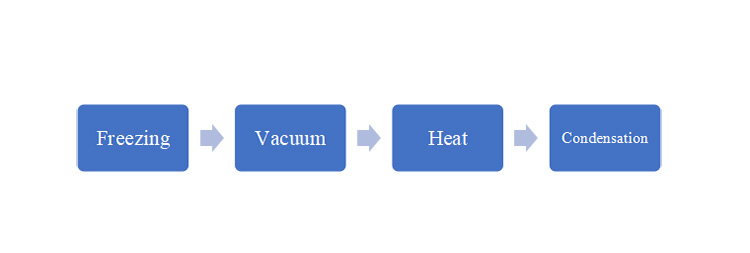

The fundamental steps of vacuum freeze dryer are as followed:

| Freezing

|

First it freezes the product via providing necessary environment for sustaining low temperature drying. |

| Vacuum

|

Secondly, it provides high vacuum where frozen product vaporized without transitioning to the liquid state (sublime). |

| Heat | Heating is provided to speed up the rate of sublimation. |

| Condensation | A low temperature condenser helps in the elimination of vaporized liquid from vacuum via converting them to solid state. This is known as separation. |

7.What Are Parts Of Vacuum Freeze Dryer?

Touch Panel: The unit helps in feeding input, e.g., run time, speed, temperature, etc.,

Power Switch: The unit helps in switch on and off the system.

Acrylic Door: The acrylic door ensures maximum visibility of material in the chamber.

Rotate Handle: A rotatable handle allows maximum possible turning to open or close the door firmly.

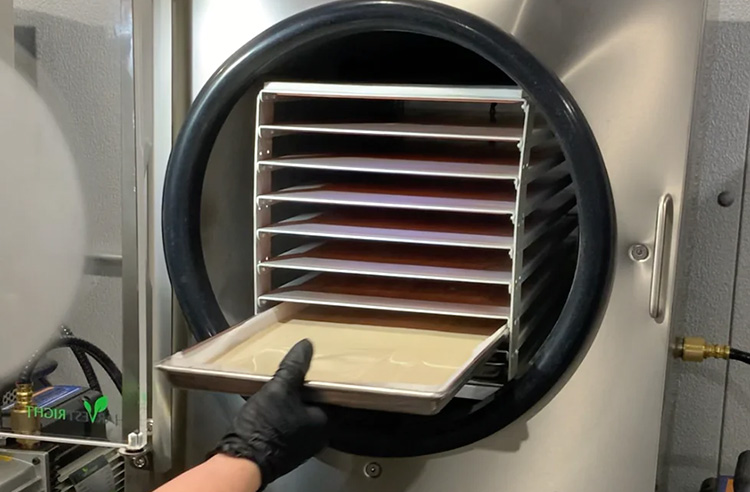

Material Tray: Durable and stainless-steel trays allow material to be placed perfectly for vacuum freeze drying process.

The Cooling Mouth: It is heart of the machine that takes in, compresses, and transformed refrigerant vapors.

But what’s insight the machine? Let’s check!

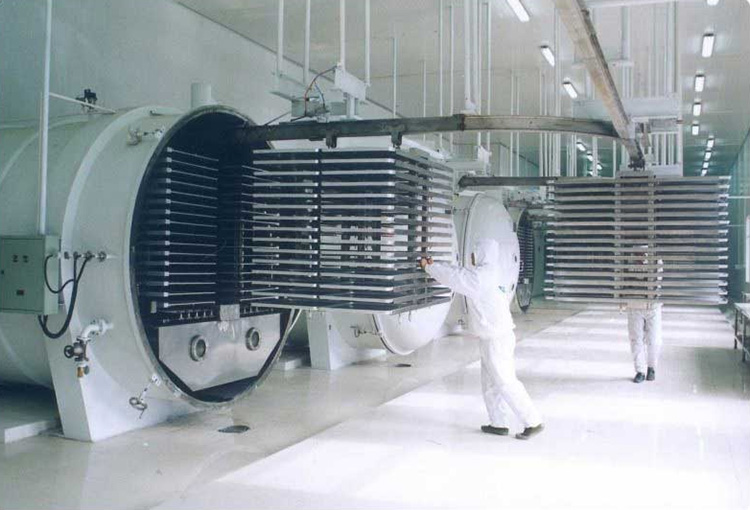

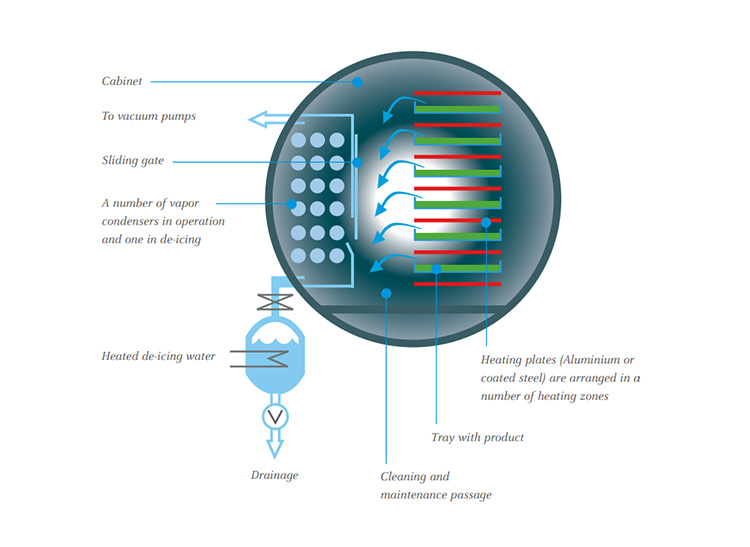

Cabinet:a cabinet is composed of set of units such as vacuum pump, trays etc.,

Vacuum Pump:inside the machine a vacuum pump is present that ensures degassing air and unwanted molecules.

Sliding gate: that helps in enclosing the unit firmly.

Heated Plates: these are designed to emit heat to sublimate the solid to gas.

Trays: they are designed to allow the product on trays for freeze drying process.

Drainage Passage: the entire system is designed in a way that cleans de-icing water from the unit.

8.What Are Basic Types of Vacuum Freeze Dryer?

Vacuum freeze dryer has different types. Each has its own unique characteristics. Let us take a look at these types below.

Rotary Vacuum Freeze Dryer

This type consists of a pump and a motor which is connected by flexible coupling. The rotator rotates the two vanes which is placed in rotor plane groove. Due to this, the inhaled gas inside becomes compressed as it circulates in through exhaust valve and exists through it. The temperature is kept between -50° and -80°C.

This type is also provided with oil anti-suckback system to protect the vacuum system from any emergency. Working at a speed of 60 m3/h and at a pressure of 5 x 10-4 torr, this type is perfect to use for drying pellets, cubes and other liquids since rotary vacuum freeze dryers possess large reservoirs to freeze these products.

Tray Style Vacuum Freeze Dryer

This type is provided with trays which are used to lyophilize medium to large-sized products. It consists of a HP HCFC/CFC-free refrigeration system which cools at a temperature of -50° C which is ideal for freezing aqueous solutions.

Tray style vacuum freezer is ideal for use in pharmaceutical and cosmetic industries since it can be used to lyophilize vials and serum bottles at the power of 2 HP. It has a large rectangular reservoir to cater for the freezing process.

Manifold Vacuum Freeze Dryer

This type of vacuum freezer is perfect to use for research purposes and for freezing large number of small individual samples. The containers in this type are usually in the shape of flasks in which the product is placed and freeze at a temperature ranging between -48C to -80C and vapor pressure ranging from 37.8 mT to 0.15 mT.

The two-stage rotary vane oil vacuum sealed pump helps in removing non-condensable compounds such nitrogen, carbon dioxide and oxygen gas after which the remaining product undergoes sublimation, thus carrying out the vacuum freezing process.

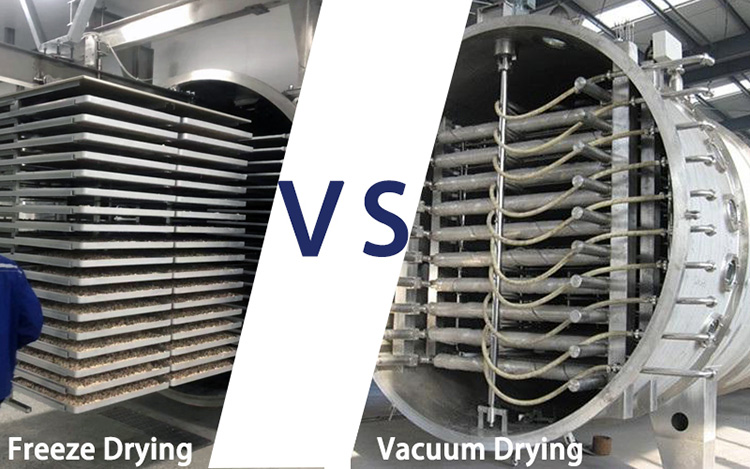

9.What Is Difference Between Vacuum Dryer And Freeze Dryer?

Vacuum freeze dryer is also known as lyophilizer or freeze dryer whereas a vacuum dryer is the only drying procedure by lowering environmental pressure.

In vacuum freeze dryer dehydration from raw product takes place by freezing the substance where drying chamber reduces the pressure inside the cabinet and allow the ice to sublimate directly to vapors/gaseous state. Whereas vacuum drying process is without freezing stage i.e., as per physical laws that govern this universe the boiling point of water can be reduced by reducing the atmospheric pressure such that the water is evaporated under vacuum much earlier and at lower temperatures than in normal conditions.

In vacuum freeze dryer solid directly transformed to vapor state. Solid phase transitioned to vapor phase known as sublimation or freeze drying. On other hand, liquid state goes through transition and convert to vapor known as vacuum drying.

The drying cost of vacuum freeze dryer methodology is much more greater than vacuum dryer.

Vacuum freeze drying and vacuum drying have different physical parameters. Such as

| Vacuum Freeze Drying | Vacuum Drying | |

| Working Pressure | 1~100Pa | 0.1~0.5Mpa |

| Drying Temp. | -35 ~ -5C | +80 ~ +40C |

| Dried Product Structure | No Change | Slightly Change |

| Heat sensitive product | Yes | No |

| Cost | High | Middle |

10.What Vacuum Do You Require For Vacuum Freeze Drying?

In vacuum freeze dryer a strong, accurate and robust vacuum unit is assembled that is composed of set of vacuum pumps used for evacuating air, gas. The vacuum itself has assigned parameter that allows concentration of vacuum reduction.

For vacuum freeze dryer, the required degree of vacuum is generally between 0.3 and 0.03 torr. If you’re wondering about torr, then let us tell you that the unit torr and mm Hg can be used interchangeably. The above values are highlighting the partial pressure of air and water vapor inside the chamber which is commutatively equal to total pressure.

11.What Kind Of Food Can You Vacuum Freeze Dry?

Fruits

Vacuum freeze dryer leaves fruit dissipated via evaporating moisture content in them.

Vegetables

This is a novel solution for making vegetable durable via taking away water concentration from products ultimately diversify portfolio of raw eatables.

Food

Spices, coffee, tea, sugar, milk powder, etc. requires vacuum freeze dryers to extend the shelf life for many years.

Meat

You can’t ignore vacuum freeze dryer significance when it comes to meat industry. The machine efficiently eliminates unwanted moisture content leaving meat safe and preserves to consumers.

Ice cream

Vacuum freeze dryer lowers the air pressure and placed ice cream in a system become crystalline form.

Flowers

For longevity and durability of flower’s petals, vacuum freeze dryers is useful.

Herbs

For research studies and herbals industries, vacuum freeze dryers is of great value as it keeps herbs freshen for longer time.

Pet Food

For pet food, vitamins, minerals, and protein are preserved via treating it with vacuum freeze dryer.

Others

There are unlimited products list that need to be treated with vacuum freeze dryers like eggs, seafoods, dairy, nutraceuticals etc.,

12.How Do You Know If Your Product Is Dry?

This is very simple as your vacuum freeze dryer senses the presence of water content in your product and stops the cycle when it senses all the moisture has vanished off from the product.

A good practice and efficient machine can perfectly run the process.

For good practice, we suggest keeping place equal product so if any moisture is left in the product, it will be recognized if there is any moisture left in the product. Else, machines have the option ‘more to dry’ where you can extend the run time of the dryness.

13.How Does Vacuum Freeze Drying Prevent Food Spoilage?

The process of vacuum freeze drying is not that complex. It uses a process known as sublimation. In this the food product which is solid is directly converted into gas without undergoing liquid phase. If the oxygen or moisture comes into contact with the food item, it can oxidize it, changing the chemical properties of it. As a result the food would lose its flavor, texture and nutrients. To prevent this the food is kept in an air-tight and moisture free containers after freeze drying them which are then stored for long period of time.

Due to this, when the product is rehydrated, the physical and chemical properties of the food are retained including its taste, color and nutrients.

Moreover, this process makes the microorganisms present in food dormant. Though the process does not kill these microorganisms including bacteria, they make them inactive. So they would be unable to spoil the food, increasing their shelf life.

14.What Are Common Mistakes When You Are New To Vacuum Freeze Dryers?

When using vacuum freeze dryers for the first time, one should keep in mind that there’s a certain way the machine works and should avoid these following common mistakes.

Mixing Different Raw Materials in The Dryer

One of the most common mistakes people often make is that they put different raw materials together for freeze drying. Because of this, there is a high chance of cross contamination of bacteria which could result in bad odors and chemical degradation of the products. Moreover, the raw materials would dry at different times since each of them have their own chemical composition.

Freeze Drying High Sugar Content Products

Vacuum freeze drying process is selective, that is, it is only suitable for certain food items. Products containing high sugar content like honey, syrups and chocolate would be difficult to freeze dry since it would be sticky. Moreover, high fat foods would be difficult to freeze dry since they would not easily undergo sublimation process.

Using Thick, Large Sized Products to Freeze

Using large pieces of meat, chicken, or whole sized fruits such as apples or pears to freeze dry would not only take a lot of time to freeze but it would also be very inconvenient to carry out the process. Thus, they should be cut in small pieces of uniform thickness to make the process easy and quick.

Not Using A Liner In The Trays

It is extremely important to use a liner as base when placing the desired products in the trays. One common mistake people do is not placing these liners. As a result it becomes difficult to take out the product from the trays due to its stickiness and would start reacting with the air and moisture in the environment. Moreover, the product can interact with the base of the tray and may change its color and composition.

Overloading The Trays

Some people make the mistake of overloading the trays with the product so that more quantities of product can be frozen dry in a short period of time. This would only end in disaster since the item would be unevenly dried, spoiling the whole process.

15.How Long Does Vacuum Freeze Dried Food Last?

You would be shocked to know that using vacuum freeze drying process for your food items can preserve it for up to 25 to 30 years! This process closes all doors of interaction of the food with dust, moisture, sunlight or air. Since these environmental factors are the ones due to which the food items spoil, keeping them away from your food will protect it from physical and chemical degradation.

Thus they retain their color, taste, nutrition and texture even after 25 years given that they are properly freeze dried at an appropriate temperature and pressure. They also need to be kept in proper air-tight and moisture-free containers so that they can be kept in storage facilities for years. After rehydrating the food product, you want to use, you can use it within a month of rehydrating it.

16.What Are the Limitations Of Vacuum Freeze Dryer?

Even though, vacuum freeze dryers offer multiple benefits, it has certain limitations and restrictions which are:

Only Certain Food Items Can Be Vacuum Freeze.

Not every single food item can be undergo vacuum freeze drying process because there are certain food products which cannot withstand the process. Thus you have to make sure if the food items you deal with would be able to undergo vacuum freezing process.

Storage problem

Using vacuum freeze dryer for preserving food products requires air-tight containers and substantial space to store. Moreover, they also must be kept away from moisture to prevent oxidation. If these conditions are not met, the food item will spoil, making it inedible.

Production Cost

Vacuum freeze dryers are high cost machines since the freezing process which require extremely low temperatures to change the solid directly to vapor requires a lot of energy. Thus, it could be unaffordable for small businesses since only large scale factories would be able to afford it.

Dry Styrofoam Texture

Even though vacuum freeze drying process preserves the food from chemical degradation and protects it losing its color, it gives the food a dry, Styrofoam like texture which a lot of customers are not a fan of. Thus, it could be unpleasant for a lot of people who like to have fresh taste.

Time Consuming Process

Freeze drying process takes patience and a considerable amount of time. The process usually takes 20 to 40 hours. High sugar and dense foods take even more time.

The Machine Cannot Be Placed on The Floor

Vacuum freeze dryers need to be placed at an elevated position since the ice melting needs to be drained below it. Also, the vacuum pumps and their switches need to be accessible to monitor the process.

Conclusion

From this guide ‘Vacuum Freezer Dryer- Complete Buying Guide In 2023’, we assume you’re well acknowledged of crucial properties, features, benefits, types, and running principles of the machine. It is now up to your mind and the production line how to implement the machine in order to carry excellent productivity and increase profitability. This is the right time to choose the best machine for your business. Our team is always available to guide you whether about purchase or troubleshooting! Just click and send us a short message to get connect us.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951