Your Best Mesh Belt Dryer Manufacturer

- Continuous Drying Equipment

- All Kinds Of Drying Applications

- Wide Temperature Range

AIPAK Mesh Belt Dryer

AIPAK Mesh belt dryer is a continuous drying equipment for batch production, used for drying flakes, strips and granular materials with good air permeability, especially suitable for materials with high moisture content and high temperature not allowed for dehydrated vegetables, catalysts, Chinese medicine tablets, etc.; the series mesh belt dryer has the advantages of fast drying speed, high evaporation intensity and good product quality, and for paste materials in the form of dehydrated filter cake. It needs to be granulated or made into strips before drying.All AIPAK mesh belt dryers combine closed type heat pump dehumidification drying technology with belt transmission drying mode; Circulation hot air through, stratified air drying and fast drying speed to meet the requirements of material drying process better.

AIPAK Mesh Belt Dryer Application

AIPAK Mesh Belt Dryer Working Principle

The Buyer's Guide

Mesh Belt Dryer: The Complete Buying Guide in 2024

Did you what equipment can allow seamless and efficient drying without harming your product? The mesh belt dryer is the correct solution for this question.

Today, industry manufacturing departments opt for this machine as it offers drying of materials in a large capacity. This is ideal for a variety of products from grains to nuts, vegetables to fruits, drugs to metals, and so on.

Whether you are from the food industry or pharmaceutical, a mesh belt dryer is an excellent machine to invest in! How? To answer, we recommend going through the article which is collectively described by pharmaceutical experts.

1.What Is A Mesh Belt Dryer?

A mesh belt dryer is an important drying machinery that is used for extracting out moisture from various flat products, strip, granular, flake-like fibrous materials.

This equipment is utilized for drying applications in food, pharmaceutical, chemical, agricultural, and other industries. Mesh belt dryer holds a unique place in the industry due to its extraordinary features which will help you reducing reduce the cost hence it is economical for a variety of industries.

A mesh belt dryer uses continuous hot air drying and cooling system that circulates around the belt where the material to be dried is placed. Due to its efficient drying speed,

low energy consumption, and continuous working it makes an ideal choice as a drying equipment for many industries.

There is a useful part in the mesh belt dryer system, which is highly beneficial during transportation because it is used for eliminating water.

Either you are a small business owner or a big industry. if you want to save money in the long run, go for a mesh belt dryer that possesses a high capacity and many other advanced features.

2.Why Do You Need Mesh Belt Dryer?

As we discussed above a mesh belt drying equipment finds its purpose amongst many industries. The purpose of a belt dryer is for persistent evaporation, cooling and heat loss from granular materials, wood chips, pellets, paste like substances, moulded compounds by using air or inert gas.

Whether you want to develop small spherical balls out of wooden pieces, or manufacture pellets of biomass, make feeding material for poultry, protein powder or pelletized fuel, efficiently drying medicinal agents like ginseng or Chinese herbs, or transforming food substances like drying of fruits and vegetables to preserve their freshness, mesh belt dryer works suitably.

3.What are the Benefits of a Mesh Belt Dryer?

The mesh-belt dryer is an important component of the processing and production line. This equipment offers many benefits, some of which are listed below:

Vitality and High Safety

The mesh-belt dryers can be used continuously for a long period of time. Unaffected by the weather or other environmental issues it can run for 24 hours continuously.

Hence, it can dry up a large amount of material in each time. Additionally, mesh belt dryer is more often operated by a single operator.

Moreover, due to semi- enclosed housing, machine itself is highly safe for operator. The presence of sight holes ensure protection of machine and operators.

Simple Installation

The machine is no doubt requires large space and giant in structure, but it is convenient to install. A mesh belt dryer is easy to transport and transfer and easy to assemble and disassemble.

Automation

The high degree of automation of a mesh-belt dryer makes it an integral part of the production lines. The mesh belt dryer can adjust the air volume, heating temperature, material residence time, and feeding speed to achieve a drying effect automatically.

The mesh belt dryer can adjust the air volume, heating temperature, material residence time, and feeding speed to achieve a drying effect.

Easy Operation And Maintenance

These machines are easy and simple to operate. The mesh belt cleaning requires no cleaning chemicals and is easily cleaned using water only making it highly environmentally friendly and a great solution for dry environments.

Versatility and Broad Applications

The machine highly significant in every field across the globe due to its wide application. It can be used for the drying of a large range of products: from fruits, vegetables, and grains to charcoal briquettes and chemical products as well.

Its versatility for a large range of products makes it more efficient and cost-effective. Moreover, the heat sources it uses for drying are versatile as well. The heat source can be steam, heat conduction oil, hot air stove, or gas stove.

Energy Saving & Environment Protection Machine

The machine gives maximum output with no noise and no pollution. Furthermore, the hot air produced in the dryer is effectively used because of the good circulation system making it energy-efficient equipment.

You can highly minimize the utilization of energy with the use of a mesh belt dryer since it is designed as a low temperature drying equipment.

Due to unique construction and electric control unit, the machine is able to work at very low power. Side by side, machine is designed with good energy conservation and environment protector.

4.What Are the Industrial Uses Of Mesh Belt Dryer?

Mesh belt dryer exclusively finds their uses in many fields of applications. They are the pharmaceutical industry, food industry, chemical industry, agricultural industry, and some miscellaneous items.

Let’s see them one by one.

Pharmaceutical Industry

A mesh belt dryer can be used to dry granular particles, medicinal products, chinese medical herbs, pellets, and pastes. It is employed for drying wet materials from bulk solids and powders.

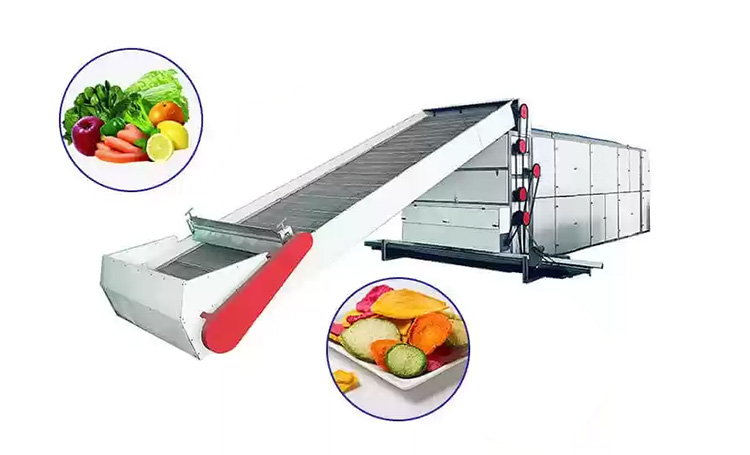

Food & Agricultural Industry

Mesh belt dryer is employed by food and agricultural industries for the purpose of drying and removing moisture from food substances to preserve them like vegetables, fruits, dry fruits, meat products, eatable fungi, and seafood.

It can be also used to produce pastes from different types of food products and in baking processes.

Chemical Industry

The chemical industry utilizes mesh belt dryer to achieve stability of solid materials by removal of moisture, removal of toxic substances from polymers, facilitating convenient handling of powderous materials, and making pellets and granules by solid drying.

Construction Industry

A mesh belt dryer is absolute solution for fine distribution of material to be dried for construction procedure as material is spread on heated channels. This is preferable in construction industries as drying speed requirement is low and drying time is longer.

Metallurgy & Electronic Industry

A mesh belt dryer ensures continuous evaporation of moisture content by uniform circulation of hot air on the material present in unit. The dryer is significantly utilized for drying of metal powders mixtures used in the pellet production line in steel work.

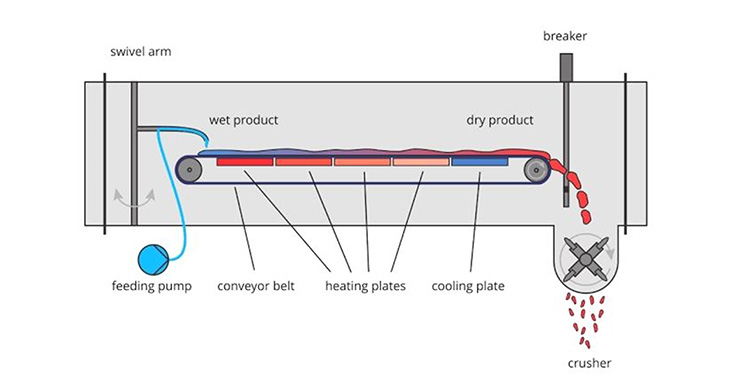

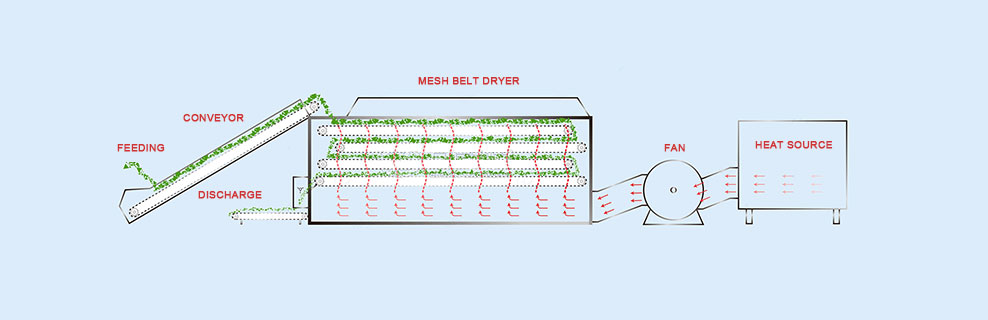

5.What Is the Working Principle Of A Mesh Belt Dryer?

The working principle of a belt dryer undergoes the following steps.

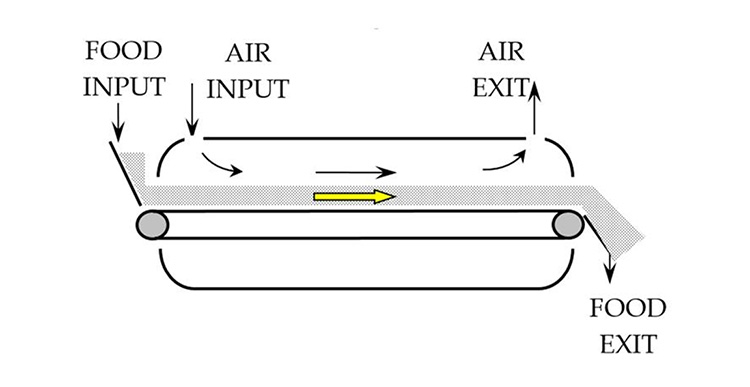

Spreading Of Material On Mesh Belt

The material supposed to be dried is applied on the mesh belts consistently with the help of a feeding system. The conveyance system drags these belts which are about 12-60 steel mesh belts to transfer into the hot air drying system.

Transfer To Hot Air System For Drying

Hot air elimination from this system circulates around the drying units with the help of dehumidifier fan. It provides 80-120°C of heat which is distributed onto the mesh belt covered with material supposed to be dried, applying the heating methods such as power driven heating, hot air heating and steam heating.

Application of heating method results in the material being pasted on the bottom mesh layer that is turned upside down over the top layer. This ensures smooth and consistent drying of the material on mesh belt without any destruction.

Discharge Of The Dried Products

After the exhaustion of air with cooled temperature and increased humidity completes the drying process efficiently, the mesh belt moves the dried products continuously into the receiver.

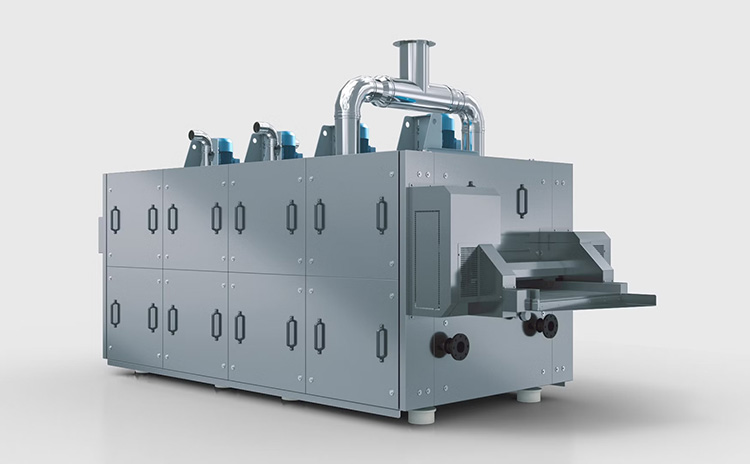

6.What Are Different Parts of A Mesh Belt Dryer?

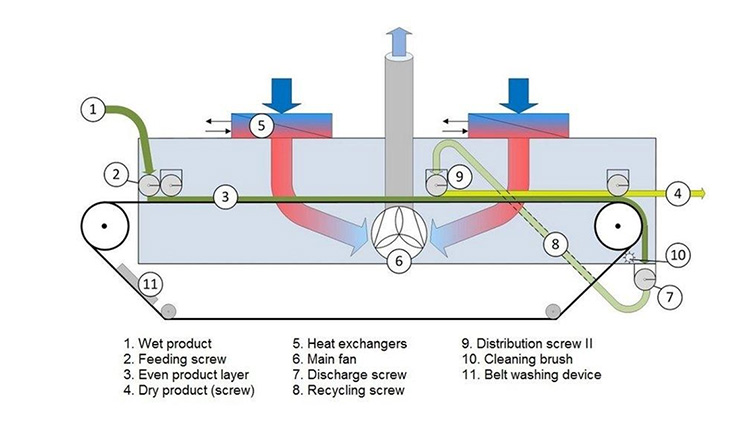

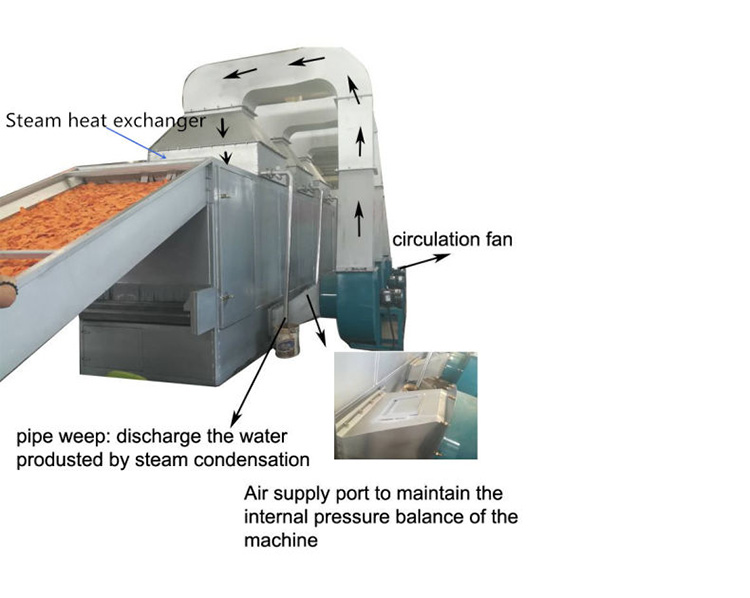

To assist the working of a mesh belt dryer machine, different parts work together in collaboration to achieve this drying process. We will first see what this equipment looks like and then we will present you its labeled diagrammatic representation.

It consists of various component parts, which are as follows:

| Wet Product: A mass of wet products enters through the inlet of the machine. |

| Feeding Screw: A screw feeder is a type of conveying device which transfers solid or liquid material and controls the quantity and rate of its flow into the system. |

| Even Product Layer: An even layer of product is spread over a sheet of stainless steel plates |

| Dry Product: A section ensuring discharging of dry product. |

| Heat Exchangers: They are installed above the belt dryer and used to replace hot residual air and exchange it for fresh drawn air. Heat Exchangers are responsible for providing heating methods through their hot air systems. |

| Main Fan: It controls the inlet and outlet of air coupled with the functioning of the heat exchanging system throughout the whole equipment. It also dries and removes any excess moisture ensuring dehumidification of the raw material. |

| Discharge Screw: Discharge screw is located at the end point of belt dryer and works similarly to a screw feeding conveyor. They discharge the dried product towards further processing. This is the point where dried product is reached. |

| Recycling Screw: The raw material fed into the belt dryer once again after reaching the recycling screw is cleared for any waste and dust removal, and then sent to the distribution screw. |

| Distribution Screw: This part sends the dried and recycled raw material to the receiving discharge screw. |

| Cleaning Brush: For belt drying machines, this component serves as a cleaning brush to scrape and remove away any chunks of wet raw material that may be stuck on the belt. |

| Belt Washing Device: It is utilized for washing the belts and has a similar cleaning purpose to the cleaning brush to remove waste particles. |

7.How to Classify Mesh Belt Dryer?

The classification of mesh belt dryer is described as followed:

Single Mesh Belt Dryer

A single belt continuous mesh belt dryer is equipped with continuous flow drying tools.

The material is fed onto the conveyor evenly and uniformly for drying procedure. It is applicable in a variety of industries for a variety of products for instance drying flake, strip, and granular materials with the finest air permeability.

A single mesh belt dryer is designed with advanced features due to its fast-paced working with high evaporation rate.

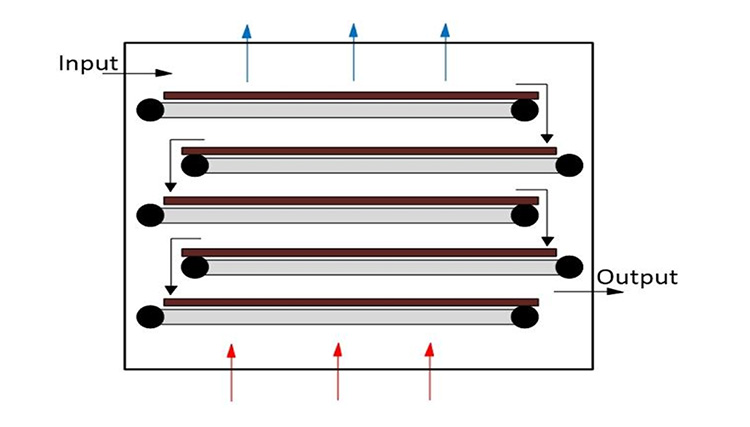

Multilayer Mesh Belt Dryer

Multilayer mesh belt dryer is an innovated featured with multi-layered drying belts for drying sheet, strips, and other granular commodities. This machine suitable for those materials that cannot be dried with high temperature since these are high moisture content, hence these materials can be suitably dried with multilayer mesh belt dryer.

Due to repeated charging and discharging material, this is not suitable for materials that are prone to damaged or stickiness onto conveyor.

8.What are the Important Factors Governing the Drying Time of Mesh Belt Dryer?

Many factors govern the drying time of the mesh belt dryer which include:

Type Of Material

If the material has high amounts of moisture it tends to consume more time till it is dried to the desired percentage.

The Thickness of the Material

Materials that are thick and bigger in size tend to take more time in the drying processes. However, the powders and other delicate materials get dried up in lesser time and in greater quantity.

The Humidity of The Air Circulating Through The Dryer

Higher drying rates are attained when the circulating air is less humid so that it has more capacity to withhold water vapors.

The Speed Of The Belt

The speed of the belt needs to be monitored and set up according to the requirement. If the objects are smaller and have less moisture the belt moves faster resulting in quicker outputs while objects that have more moisture content or are bigger in size take more time and hence the belt is set to slower speeds. Setting up the belt at higher speeds can result in improper drying outcomes.

9.What is the Capacity of a Mesh Belt Dryer?

The capacity of a mesh belt dryer depends upon the dimensions such as the machine’s size, shape, and features such as automatic or manual types of equipment.

The unit used for measuring the capacity of the mesh belt dryer is the amount of material it operates per unit of time such as 500 kg/1hr or 100 tons/1hr etc. A mesh belt dryer can possess a high range of capacities from a small scale to a larger industrial scale.

- Some of the factors that determine the capacity of a mesh belt dryer include.

- The concentration of moisture in the material that is going to be dried with the mesh belt dryer.

- The final level of moisture i.e., the target level of moisture.

- Rate of airflow.

- The design of the mesh belt dryer.

- The configuration of the mesh belt dryer.

Moreover, detailed information about the capacity of the mesh belt dryer can be determined by consulting with the manufacturer or supplier of the machine.

10.What Is Drying Time of Mesh Belt Dryer?

Drying time indicates for how long the raw material will be exposed to hot air and moisture being evaporated. This ensures that any product’s low moisture content will preserve it.

The usual drying time duration taken by a mesh belt dryer for the drying of various substances is from 0.5 to 5 hours.

Depending on the type and amount of the material and the parameters applied, the time taken for drying is strictly considered to avoid melting or destruction of product. The drying time also depends upon different types of products to be dried; some takes less time to dry and some require more.

11.What Is The Difference Between Mesh Belt Dryer And Vacuum Dryer?

Mesh-Belt Dryers and Vacuum dryers are both effective and essential equipment of the processing industry and are used for taking out the excessive moisture from the products. Both these equipment work on different principles.

Mesh belt dryer works continuously by circulating hot air for the drying process. On the other hand, vacuum drying uses airtight vessels in which pressure and humidity is reduced using vacuum pumps. The process is conducted in batches.

Mesh-belt dryers are more commonly and effectively used for materials that are non- hygroscopic and requires gentle thermal heat treatment. Whereas a vacuum drying is more effective for heat-sensitive ingredients.

Mesh belt dryer is commonly used to dry wet products by ventilating fans and hot air such as bulk pastes, creams, slurries. Whereas vacuum dryer is used applications like drying of enzymes, extracts, protein powders etc.

Mesh belt dryer gives direct hot air circulation to the environment, the prime structure based on heat exchangers works under controlled air and temperatures whereas vacuum dryers give static temperature under reduced pressure continuously with different ranges steam or water heated elements ranging from single vacuum dryer to ten belt vacuum dryers.

12.Is Mesh-Belt Dryer Suitable For Small Businesses?

The mesh-belt dryers are now available in a multilayered compact form that is feasible for smaller businesses. These multi-layered dryers are typically 6 to 30m in length.

However, the single layer mesh-belt gives more efficient output with a large amount of material. Moreover, many companies have developed mash-belt dryers that are specific for certain materials like the fruit dryer, vegetable dehydrator, spice dryer and much more.

However, the mesh-belt dryers are more feasible for bigger setups as it is an expensive equipment and has a large size despite the multi-layering. This equipment has proven to be cost-effective and energy efficient only when used for drying in massive quantities.

13.Does Large Installation Space Necessary for Mesh Belt Dryer?

A mesh belt dryer machine is a large equipment mainly used for large production scales equipping greater installation space in the term of flooring as well as ventilation.

Moreover, the machine is composed of large sections such as heat exchangers, distributing plates (12-60 steel mesh belt), dehumidifier, hot air, etc., generally have larger installation space. Nevertheless, to save spacing, machine is made up of multi-layer types.

Furthermore, machine works by integrating with other important operational accessories to bring an efficient result. So, it would be impossible to bring bulk operational services under compact or small working surface.

Collectively, these parameters claiming larger installation surface area to bring smooth production running.

14.How To Clean and Maintain The Mesh Belt Dryer?

Our experts recommend to clean and maintain mesh belt dryer from flammable and explosive ingredients that compile with time and hazardous for environment.

The following mentioned guidelines must be followed to increase lifespan of the machine.

| Conveyor Belt | This unit must be washed by hands using soft bristle brush and safe cleaning agents that are non-corrosive and safe for food. This cleaning must be routinely done. |

| Drying Chamber | You can vacuum residual from the surface of drying chamber on regular basis. |

| Dehumidification Fan and

Ducts |

This is an important component that must be cleaned from opening and duct’s region at least once in a month to assure dehumidifier is cleaned and free from unwanted obstruction. |

| HMI/ Electrical Cabinet | Inspecting HMI and electrical cabinet every shift assuring cabinet is safe to operate. |

15.What are the Technical Problems and Solutions of Mesh Belt Dryer?

Every machine often meet some problems but it is the responsibility of the operator to find an immediate solution to maintain the safety and productivity of the production house. We have enlisted some common problems and its immediate solution for you:

Problem: Failure of Hot Air Circulation

This is common problem occurs using mesh belt dryer when system fails to release hot air for material drying.

Solution

Technician must be aware to check whether supplying unit of circulating air working via observing micro-circuits. Secondly, you must check the power supply of 110V and 480V normal, thirdly check if dehumidifying fan is blocked or eccentric or over heated.

Problem: Failure of Dehumidifier Fan

The unit fails to control proper dehumidification.

Solution

You must check power supplies voltages. Release thermal overload relay and Reset button of thermal overload.

Problem: Failure in Material Discharge

Dried material output is improperly attained.

Solution

The supply system motor blockade can cause the problem due to over current, overload, or over-heating. Make sure micro-circuits are well-controlled.

Conclusion

A mesh belt dryer is continuous operating machine release hot air in various direction such as unidirectional or multi-direction ensuring drying of product that is mostly subjected in a bulk amount. This is why this machine is considered as the ideal solution for larger production sectors. If you’re willing to invest on mesh belt dryer, we would suggest contacting us for more information and current deals about the equipment. We’re here to guide you with 100% customer satisfaction. Just Hit Us Back Now!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951