Supplement Manufacturing Equipment: The Complete FAQ Guide In 2025

How to raise the standards of supplements? Nowadays, people are looking for ways to improve their health and support their wellness goals, so they’re turning towards supplements. As manufacturing and wellness are evolving, so is the demand for more excellence and quality. Therefore, supplements are crafted with supplement manufacturing equipment, which plays a central role in producing reliable products.

To understand the nutraceutical insight production, go through this article “Supplement Manufacturing Equipment”, where the intricacies of the utilized manufacturing systems are discussed. By gaining a deeper understanding, you can make informed decisions about the expansion of your supplement business. So, let’s put your reading glasses on!

1.What Is Supplement Manufacturing Equipment?

Supplement Manufacturing Equipment

The supplement manufacturing equipment is referred to as advanced devices in the manufacturing of supplements. For example, tablets, pills, capsules, powders, etc. Based on FDA perspectives, supplements are mainly intended to be incorporated into your diet, which is obviously an alternative to traditional foods. Therefore, these equipment are similar to machinery used for the manufacturing of medicine, nutraceuticals, and food products. It is ultimately aimed at preparing supplements from raw materials till their final packaging in a comprehensive integration.

The key significances of using supplement manufacturing equipment are:

Novel Precise Technology

These equipment are essential that help the customers in supplement manufacturing with fast and accurate measuring of the raw materials and formulation. The technology ensures novel handling of the equipment hooked in a series to provide high capacity and rapid workflow.

Unparalleled Work Versatility

Every company prefers a machine that can provide handling of multiple ingredients. For example, solid dosage formulation, powder, etc. The supplement manufacturing equipment is specialized, and a versatile solution can manage different dosage states.

Compact and Excellent Productivity

The advanced and modern one-stop solution that increases productivity and ensures companies are meeting with greater demand with no downtime.

Compliance

The supplement manufacturing equipment is modern technology compliant with quality standards designed by regulatory bodies such as cGMP, FDA, etc.

2.Main Types of Supplement Manufacturing Equipment

The main types of supplement manufacturing equipment are described below:

Capsule Filling Machine

AIPAK Encapsulation Machines for Capsules

The capsule filling machine which is responsible for filling different types of materials, like powders, pellets, and granules, into a two-piece hard gel capsule. These systems can perform various steps, such as capsule loading, rectification, separation, filling, sealing, rejection, and ejection. The machine is capable of running small, moderate, and large production batches that vary from hundreds to hundreds of capsules per hour. The degree of automation of the capsule filling machine varies from manual to semi-automatic to automatic; therefore, fast and error-free operation is possible for small to large production capacities.

Tablet Press Machine

AIPAK Tablet Press Machine

The tablet press machine is essential when you want to compress supplement powders into tablets. With the help of single or multiple toolings (punches and dies), these machines can form single or hundreds of tablets per cycle. They are available as single and rotary punch tablet machines based on their application and the level of complexity.

The single-punch tablet press machine is mostly referred to for limited or small production of supplement manufacturing. On the other hand, the rotary punch tablet press machine is designed with multiple punches in a row, which offers high-speed tablet production in a continuous process of supplement manufacturing.

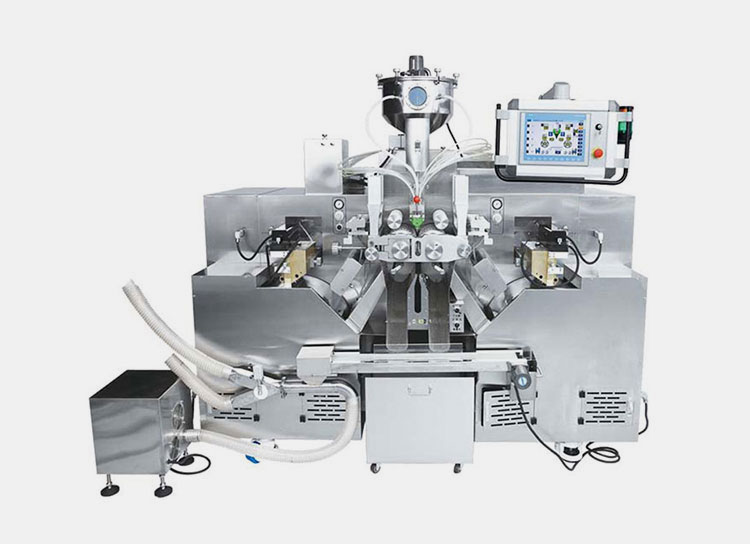

Softgel Encapsulation Machine

AIPAK Softgel Encapsulation Machine

A softgel encapsulation machine is ideal to hold formulation in delicate layers of gelatin ribbons. The greater demand for this machine is observed for supplements such as CBD and unsaturated oils (omega-3) and serums. The machine is featured with a stainless steel roller designed with small cavities for molding gelatin ribbons with a thickness of typically 0.032–0.040 inches. In each cavity, a pre-determined liquid formulation is injected with the help of a wedge.

With the help of high heat and pressure, a simultaneous hermetically sealing of the softgel capsules takes place. A trimming die ensures smooth and sharp cutting of the softgel capsule to produce a final product.

The market size of softgel encapsulation machines is growing due to a greater spike in the requirement for liquid supplements across the globe. The reason for this is easy consumption and improved bioavailability than tablets. Moreover, the key trends proposed in machine learning are the implementation of advancements such as AI and IoT also boosted its market size in the manufacturing world.

High Shear Mixer Granulator

AIPAK Granulator

With the help of high shear mixer granulators, you can create high-quality and free-flowing granules from powder with fluidity and compressibility in a short time. Wet granulators are vital when you’re mixing powders with liquid binders with a high-energy procedure like a chopper and an impeller, with minimum chances of wall caking and residues without operator intervention. Whereas moisture-sensitive ingredients are granulated using dry granulators. In results, identical and consistent batches of granules are formed, which is ideal for tablet and capsule supplement manufacturing, and are safe to transfer to a fluid bed dryer.

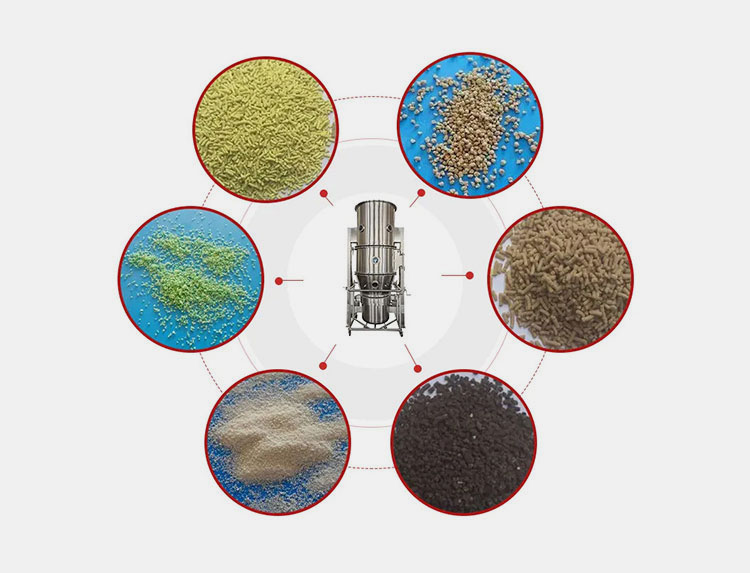

Fluid Bed Dryer

Fluid Bed Dryer

In the world of supplement manufacturing, the fluid bed dryer has emerged as a significant player for efficient and optimized drying of solid particles. The working principle mainly relies on the fluidization mechanism, allowing suspension of particles in hot air for adequate drying in a floating state, like a fluid. In this way, rapid evaporation of moisture is achieved, thus favoring rapid and safe drying of ingredients used in the production of supplements.

Powder Filling Machine

AIPAK Powder Filling Machine

In the powder filling machine, various common types, such as augers, vibratory, premeasured cups, or net weigh fillers, are used to dose various types of supplements in powder, granule, or pellet form in a safe manner. This is available with extensive automation, including automatic, semi-automatic, and manual powder filling machines. The machine is ideal for dispensing in bottles, jars, containers, etc, with real-time monitoring and stringent regulatory requirements. This supplement manufacturing equipment is mainly used for the precise filling of protein powders, minerals, vitamins, and trace elements that support basic physiology.

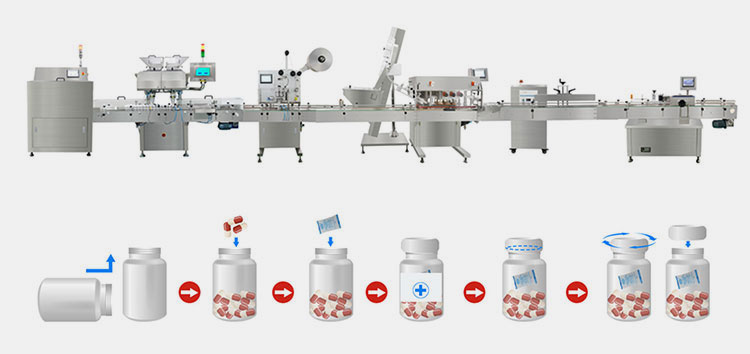

Tablet Counting Line

Tablet Counting Line Supplement Manufacturing Equipment

A tablet counting line is crucial for supplement, nutraceutical, and pharmaceutical for modern and advanced work lines. It is a one-stop solution line when conforming to the market demands of supplements as it boosts high speed, accuracy, and reduced manual intervention. It is mainly comprised of a bottle unscrambler, a high sensor tablet counting unit, a desiccant inserter, a capper, an induction sealing machine for tamper-evident packaging, and a labeling machine; thus, reducing your production cost and offering industrial-grade operational solutions.

Blister Packaging Machine

AIPAK Blister Packing Machine

Typically, a blister packaging machine involves the formation of blister cavities with the help of heat. The formed blisters are filled with the pills, tablets, capsules, or gummy supplements inside, followed by sealing with foils (most often aluminium foil) on the back side with increased pressure. The machine is safeguarding the supplements from physical hazards, improving aesthetics and visibility with improved stability. There are common types of blister packaging machines, including ALU-ALU, ALU-PVC, and others, offering adaptable production needs.

Gummy Making Machine

AIPAK Gummy Manufacturing Equipment

For manufacturing gummy supplements, diverse gummy-making equipment is used. This production line is exclusive to only gummy form and includes mixing or melting tanks, depositors, molding devices, and, cooling tunnel that melts and heats gelatin, pours gummy mixture into molds, shapes gummies, and dries them, respectively.

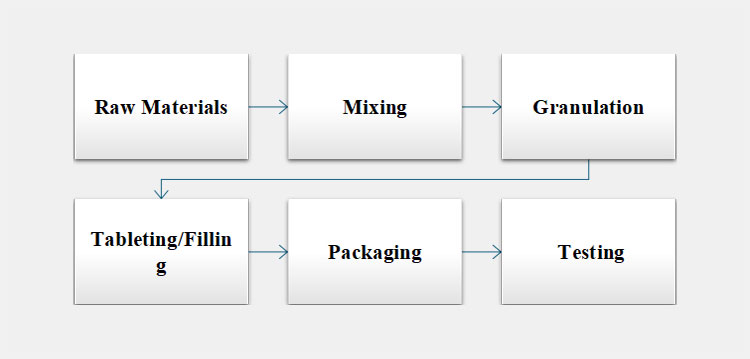

3.How Does Supplement Manufacturing Equipment Work?

Scheme chart of supplement manufacturing equipment working

You see diverse supplements manufacturing with long development steps. Let’s have an insight into the key stages of supplement manufacturing equipment working.

Raw Materials

Sourcing Ingredients -Picture Courtesy: Ultra Nature

Upon completion of supplement manufacturing formulation design, the important step is the resourcing of top-tier raw materials in order to craft high-quality supplement products. For this, the significant step which guarantees the potent supplement product therefore choosing wisely the selected ingredients, as their quality hinges on these promising elements.

Mixing

Mixing- Picture Courtesy: Stable Diffusion Online

The specialized supplement manufacturing mixers precede tremendous mixing or blending of the materials. It ensures all components are evenly distributed, so each tablet, capsule, or gummy contains the same amount of active ingredient. There are a number of units that help in this matter, including ribbon blender, V mixer, planetary mixer, etc, hence providing identical and correct nutrient distribution in the whole batch.

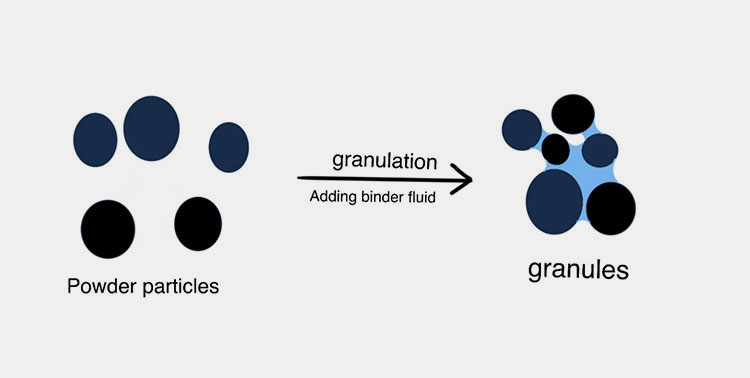

Granulation

Granulation- Picture Courtesy: Pharma tech-RX

For supplements manufacturing, where you need a better flow of ingredients with improved compaction, the process of granulation is carried out. There are two basic types of granulations known as wet and dry granulation, which mainly depend on the formulation need. The small particles are transformed into smooth and compacted granules with improved textures once passed through the granulation method.

Tableting /Filling

Tableting/Filling- Picture Courtesy: Pharma Specialists

In this step, the mixed or blended material is incorporated into their transformed supplement dosage formulation. For tablets, the raw material in powder form goes straight to the tableting machine, where it is compressed into tablets. In the case of capsules, the encapsulation machine fills the powders into hard gel capsules. Gummies are prepared with specialized gummy supplement manufacturing equipment that involves various steps, ranging from melting of material to final soft and chewy gummies, which are ready to use.

Packaging

Packaging- Picture Courtesy: Faberlic

After checking the in-process quality of supplement forms, they’re packed into blister packs, sachets, stick packs, strip packs, jars, etc. Then desired labels are put on the primary packaging to inform users about the packed supplements. Now, labeled packaging is placed into cartons, shrink wraps, etc.

Testing

Testing Final Product

Before distributing supplements for retailing, they’re once again passed through the final steps of strict quality checks to assess identity, potency, microbial and heavy metal amounts, as well as stability tests to determine product shelf-life. After finishing these tests, the supplement manufacturer issues a Certificate of Analysis (COA) to assure consumers that the product is safe for consumption.

4.Key Factors to Consider When Buying Supplement Manufacturing Equipment

Factors to Consider for Supplement Manufacturing Equipment- Picture Courtesy: Willings

The significant key factors prior to selecting and purchasing the supplement manufacturing equipment are discussed below:

Capacity requirements

Since acquiring supplement manufacturing equipment is a long-term investment, keep in mind that equipment throughput must match your working goals. Also, it should be designed to create a variety of supplement types. For beginners or small-scale supplement manufacturing, equipment with small designs is economical and easier to carry for production goals. Whereas, for large-scale capacities and constant production, advanced machines are ideal for improving business growth.

GMP certification & FDA compliance

Always ensure that supplement manufacturing equipment and materials adhere to regulatory standards for safety, hygiene, and product uniformity. GMP certification of machines endorses the precision and high quality of production and the outcome. Similarly, compliance of equipment with local regulatory bodies like the FDA in the USA is also necessary. Therefore, don’t be swayed for advanced machinery at first sight, but ensure that it has regulatory adherence and future possible outcomes.

Automated Vs. Semi-Automated

Before going to buy supplement manufacturing equipment, always estimate the production capacity and the kind of equipment you need. If the manufacturing size is limited and low cost, then you must opt for semi-automated machine that offers high automation with some involvement of the operator. On the other hand, if your production demands are higher, then your choice should be automatic supplement manufacturing equipment that proposes additional innovative features with little to no human intervention for a fast and accurate workflow.

Energy consumption and maintenance costs

When planning for investing in supplement manufacturing equipment it is significant to assess energy consumption and its maintenance costs for long-term planning. The machines mostly require drainage with high utilization of energy and of course, maintenance costs. Therefore, selecting energy efficient machines featuring sustainable operation always helps. Moreover, low maintenance and durable equipment can limit downtime, consequently, save time and production output.

5.Top Trends in Supplement Manufacturing Equipment for 2025

Understanding top trends in supplement manufacturing equipment is always essential and critical for manufacturers to bring innovations in the supplement industry. The significant new technologies in their designs are mentioned below:

AI Monitoring & Automation

AI Monitoring & Automation - Picture Courtesy: Congnex

There is no doubt that AI Monitoring & Automation are everywhere in supplement manufacturing equipment. Moreover, collaborative robotics assists operators in handling monotonous tasks. Manual inspection is prone to human mistakes and errors; consequently, currently, you currently have automated systems in production. They integrated AI and advanced imaging processes to examine tablets, capsules, and aid in identifying hard-to-detect anomalies, for example, minute cracks, resolution, debris, and undesired sealing.

Internet of Things (IoT) Remote Monitoring

Internet of Things (IoT) Remote Monitoring- Picture Courtesy: AMCORE

Nowadays, digital transformation is everywhere, and it has even altered supplement manufacturing equipment. With the help of IoT tech and sensors, manufacturers monitor real-time changes in humidity and temperature. Similarly, machine learning algorithms help in forecasting product demand, thus brand owners can quickly optimize their production plan.

Eco-friendly and Energy-Saving Design

Eco-Friendly & Energy-Saving Design-Picture Courtesy: Isowall Group

In recent times, manufacturers have strived to adapt eco-friendly and energy-saving designs for supplement manufacturing equipment. You can see the use of stainless steel machines and an accurate dosing system, which promotes process efficiency and lowers the waste production. For packaging, numerous eco-friendly packaging containers are introduced, like biodegradable capsules, pouches and blister packs. Therefore, machines are crafted with low-energy-consumption motors and smart automation that encourage energy-saving design.

6.Cost Analysis of Supplement Manufacturing Equipment

When you talk about the cost analysis of supplement manufacturing equipment, it narrates all the expenses related to installing, operating, and maintaining the equipment required to make supplements.

Equipment Price Range

The cost analysis of supplement manufacturing equipment may be based on Three Factors’, production scale, type of supplement, and regulatory compliance. For limited budgets, installing semi-automated equipment ranges between USD 5,000 – 15,000, covering fundamental needs for manufacturing supplements. As far as a large plant solution is concerned, it requires an automated and complete range of specialized equipment. For large-scale setups, you need USD 50,000 – 200,000 or more for essential machines used for making and packaging supplements.

Maintenance & Training Costs

Investing in a maintenance planner and training the operators can reduce the future costs related to machine downtime. Commonly, it characterizes 2-5 % of the total annual asset value of total maintenance (preventive, spare tools, and general consumables). This can reduce the cost of reactive maintenance to fix the problem. You can bring more privileges to your cost strategy by planning a predictive maintenance program. This program is supported by sensor data, analytics, etc., which results in reduced maintenance costs and increased machine uptime.

ROI analysis

An ROI (return on investment) analysis manifests in how profitable your investment is in comparison to your total cost of manufacturing. You can carry out this analysis by following a few steps, such as evaluating the cost of investment and counting the gain from investment that contributes to boosting your gain and lowering the cost. To determine the return on investment (ROI) % with the formula below, which helps you to get the amount of net profit.

Net profit = Gain of investment – Cost of investment

After calculating the net profit, you will compute the percentage of return on investment using by given formula:

ROI (%) = Net profit x 100

Cost of investment

7.FAQs About Supplement Manufacturing Equipment

What is the average lead time for supplement equipment?

The timeframe for completing the supplement manufacturing process depends on the product to be created and the amount of customization required. On average, though, it typically takes 12 to 16 weeks from the date a purchase order (P.O.) is received. If we break the sections, the testing of batches usually takes one to two weeks, exclusively for stability testing.

Is custom equipment available for unique formulations?

Yes, custom equipment with particular or unique supplement formulations is available in the market that provides bespoke properties for tailored and specified ingredients. This is included with functional properties of the machine, handling of particular substances such as granules, types of powders, colorants, developing new flavors, etc., and specialized filling or packaging. Therefore, manufacturers can now flexibly create different formulation designs, safe filling, and effective packaging under your customized plan and budget.

Do I need GMP certification for my equipment?

Yes, supplement manufacturing equipment is required to comply with GMP certification, particularly for therapeutics, nutritional, food, and health-related applications. The prime object is to provide a safe and hygienic product and involves regular maintenance and proper calibration of machines. Also, not just supplement manufacturing equipment, but the whole working facility must adhere to GMP certification, which is suggested for reliable and reproducible procedures.

Conclusion

In ever-growing trends of supplements and health-related products, it is essential to align the industrial workflow with comprehensive cGMP-compliant supplement manufacturing equipment. With unlimited access to a variety of pharmaceutical preparations, equipment inclusive of clinical, non-clinical products, foods, and nutraceuticals, AIPAK offers an excellent solution to pharmaceutical, food, veterinary, and various other sectors. We are the central supplier of supplement manufacturing equipment in both domestic and international production markets. “Looking for GMP-compliant supplement manufacturing equipment? Contact us for a customized solution today!”

Don't forget to share this post!

Capsule Filling Machine Related Posts

Capsule Filling Machine Related Products

Capsule Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 156 0710 8630

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine