Industry Leading Soft Gel Capsule Making Machine

- China Best Softgel Machine Manufacturer&Supplier

- High-speed Soft Gel Machine

- Various Sizes&Shapes Softgel Making

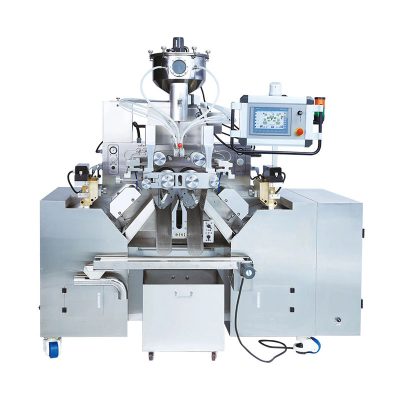

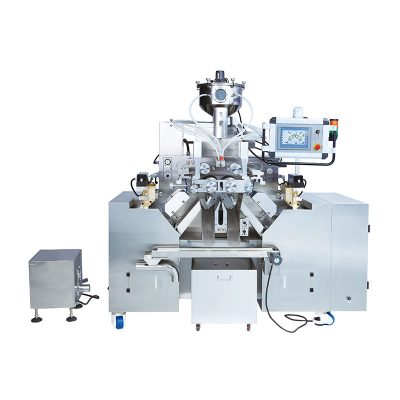

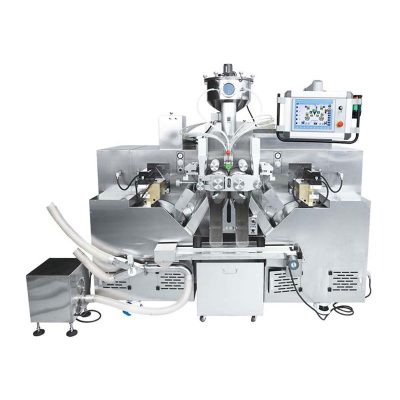

AIPAK Soft Gel Capsule Making Machine

AIPAK Soft gel capsule making machine is mainly used for the encapsulation of liquid drugs, and can also encapsulate the suspension, emulsion or paste formed by the dissolution and dispersion of solid drugs. There are also some specific products that can also be made with the soft gel capsule making machine, such as paintballs, laundry coagulants, beauty essence and etc. All AIPAK soft gel capsule making machines have compact structure, easy operation, simple maintenance, stable performance, high production and low consumption. They are suitable for food, pharmaceutical, cosmetics, etc industries.Softgel is generally suitable for drugs with high oil content, or easy to decompose and deteriorate after moisture, heat, and pressure. These drugs are not suitable for tablets, softgel is a very suitable choice, such as cod liver oil, royal jelly, vitamin E, coenzyme Q10 and so on.

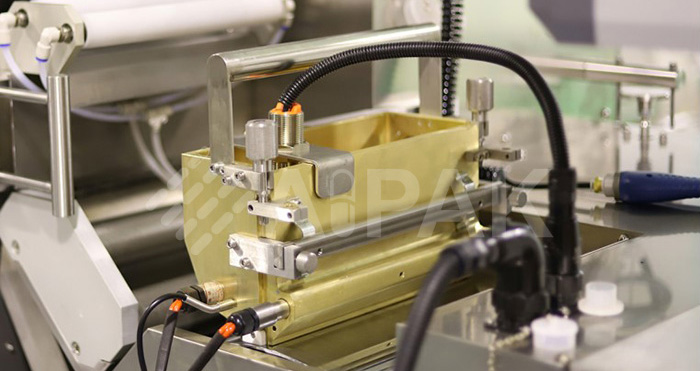

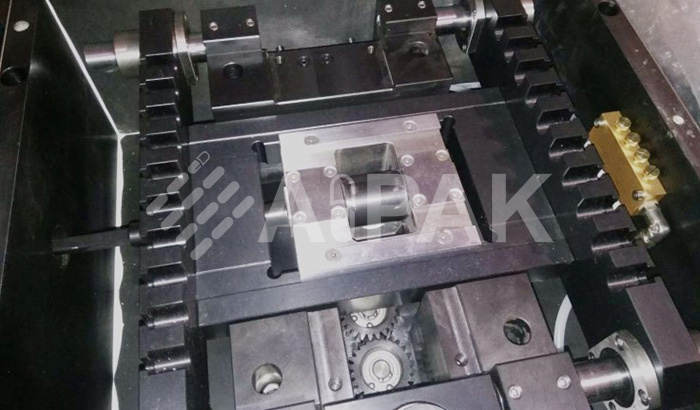

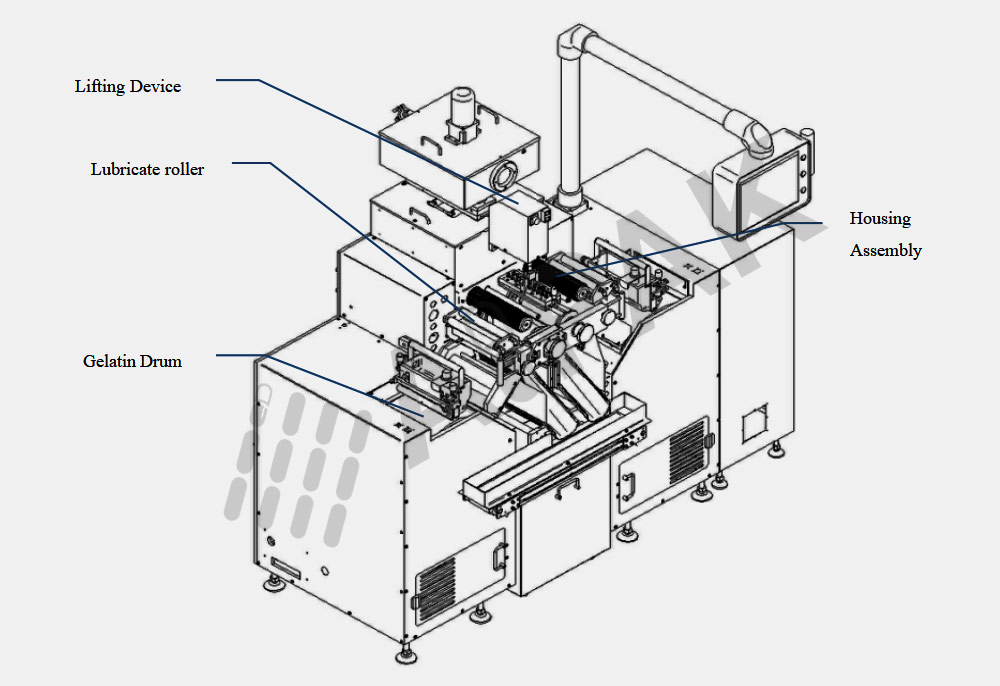

Soft Gel Capsule Making Machine Details

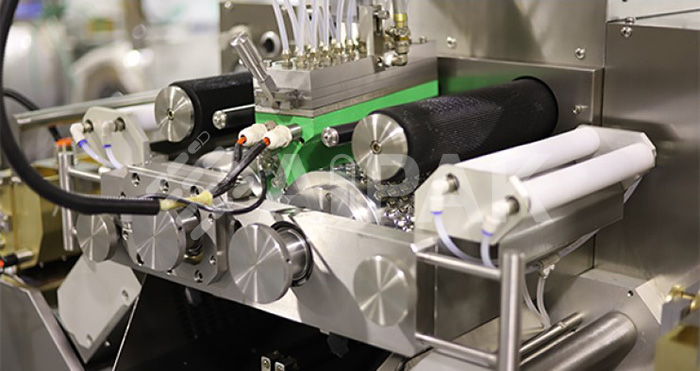

Patented die roll shaft support base structure with higher precision and longer MTBF.

Gelatin liquid level in the gelatin box is controlled by capacitive proximity switch, non-contact, stable and reliable.

The patented symmetrical loading structure of feed pump ensures the stability of dosage and the adaptability of materials.

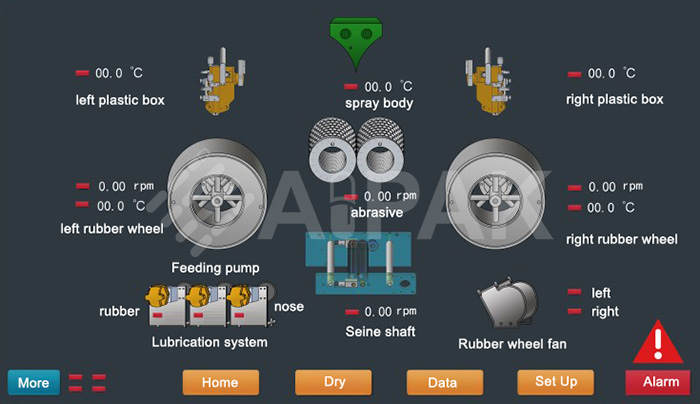

Operation interface design is more humanized, simple and intuitive, easy to learn and understand.

Patented wedge lifting mechanism, mechanical position limit structure, to prevent accidents.

Patented cold air technology of die roll can improve production efficiency and yield when encapsulating special materials (optional).

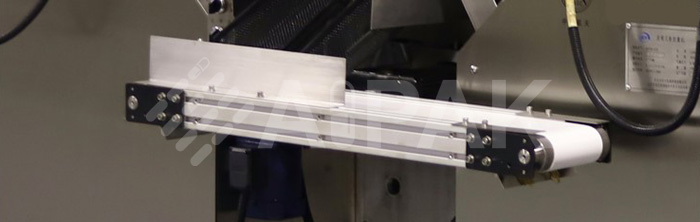

Light conveyor, small volume, light weight, convenient disassembly and cleaning.

Soft Gel Capsule Making Machine Part Details

Soft Gel Capsule Making Machine Production Line Accessories

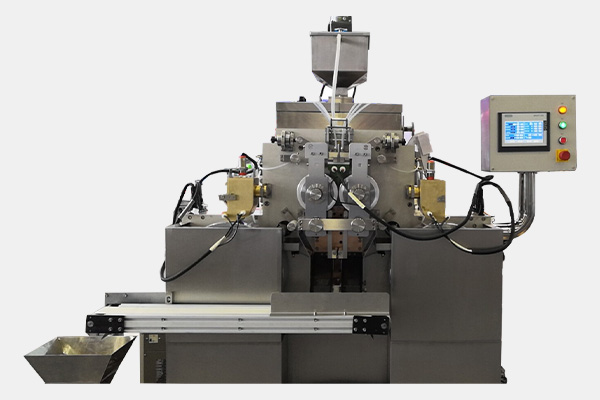

Main Machine

Prepare Tank

Gelatine Melting Tank

Colloid Mill

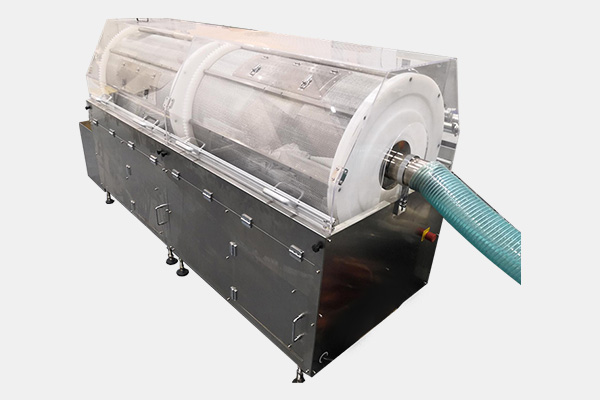

Tumble Dryer

Vacuum Pump

PVC Tray

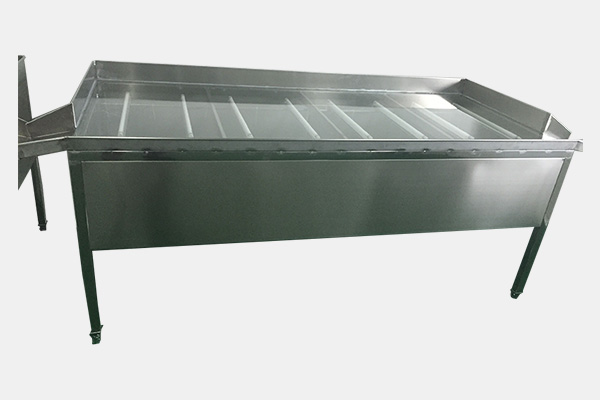

Light Inspection Table

Drying Car

Soft Gel Capsule Making Machine Working Process

Samples Manufactured By AIPAK Soft Gel Capsule Making Machine

The Buyer's Guide

Soft Gel Capsule Making Machine: The Complete Buying Guide In 2025

How well do you know about soft gel capsule making machine? With the development and improvement of capsule manufacturing technology, the market demand for new capsule packaging is increasing, especially soft gel capsule making technology and equipment.

Due to the market demand for large-scale filling and packaging technology of soft gel capsule making machines, more and more customers are gradually increasing their demand for soft gel capsules. The soft gel capsule making machine guide will focus on explaining the equipment and technology of soft gel capsule technologies. Roll in right now!

1.What Is Soft Gel Capsule And Common Types?

Soft Gel Capsule-sourced: pharmaceutical-technology

Softgel is a soft-shell oral capsule made of gelatin. It can be used to contain oily or liquid products. The soft gel capsule shell is usually made of animal or plant gelatin. It is specially used for packaging and sealing semi-solid substances such as oily liquids, suspensions, emulsions, etc. in various industries. The soft gel capsule is an ideal choice for oil and fat-soluble formulations. Ingredients are wrapped in a soft shell and can be taken orally or applied externally.

Common types of soft gel capsules are:

- Solid-liquid suspension soft gel capsules

Solid suspension soft gel capsules are mainly a kind of soft capsules that encapsulate insoluble particles, liquids and oily liquids. This soft capsule contains both liquid and solid substances.

- Content of water-soluble soft gel capsules

Content of water-soluble soft gel capsules-sourced: capsuline

This soft gel capsule is generally composed of vegetable oil and water. When dissolved in water, the substances will immediately release the active ingredients and be quickly absorbed by the human body.

- Enteric-coated soft gel capsules

Enteric-coated soft gel capsules-sourced: robinsonpharma

In order to prevent the soft gel capsule from dissolving and being diluted in the stomach, the shell of this soft gel capsule is packaged so that it disintegrates and releases in the intestinal fluid and forms a protective effect on the stomach.

- Instant soft gel capsules

Instant soft gel capsules-sourced: lifevisionhealthcare

Instant soft gel capsule is specially designed to be quickly disintegrated and released in the mouth or throat. It can quickly release the active ingredients in the drug.

- Emulsified soft gel capsules

Emulsified soft gel capsules-sourced: contractpharma

After being dissolved and absorbed by the human body, the substances in this soft gel capsule will exist in the form of micro-emulsions such as oil-in-water and be quickly absorbed by the intestines. The design principle is to improve the bioavailability of the product.

2.What Are Soft Gel Capsule Made Of?

The composition of soft gel capsule is very simple. It is mainly composed of capsule shell and active ingredients in the capsule. These include:

Gelatin

Gelatin-sourced: prb

Gelatin is the most important component of soft capsule shell. It can provide flexible and soft properties, and is mainly divided into animal gelatin and plant gelatin.

Plasticizer

Plasticizer-sourced: totalconnection

Plasticizers in capsule shell mainly include substances such as glycerol and sorbitol. It can provide certain flexibility and elasticity to the capsule shell.

Water

Water-sourced: laballey

Water is an important component of the capsule shell. It gives soft gel capsule shell elasticity and flexibility.

Other additives

Other additives-sourced: foodrevolution

If you want to increase the color of the capsule shell, you can add colorants and sunscreens. To extend the shelf life of capsule shell, choose preservatives appropriately. To improve the taste of the capsule shell, you can add certain flavors or sweeteners.

3.What Is Soft Gel Capsule Making Machine?

AIPAK Soft Gel Capsule Making Machine

Soft gel capsule making machine, also called softgel encapsulation machine, can encapsulate various oils, mixed suspensions, and pastes into soft gel capsules of various sizes, shapes, and colors by weighing and filling.

Soft gel capsules made by this equipment have a fast disintegration speed, are convenient for users to take orally, not easily oxidized, and are easy to store and transport. It is not only used in the food industry, but also widely used in various pharmaceutical, health care, and cosmetic industries.

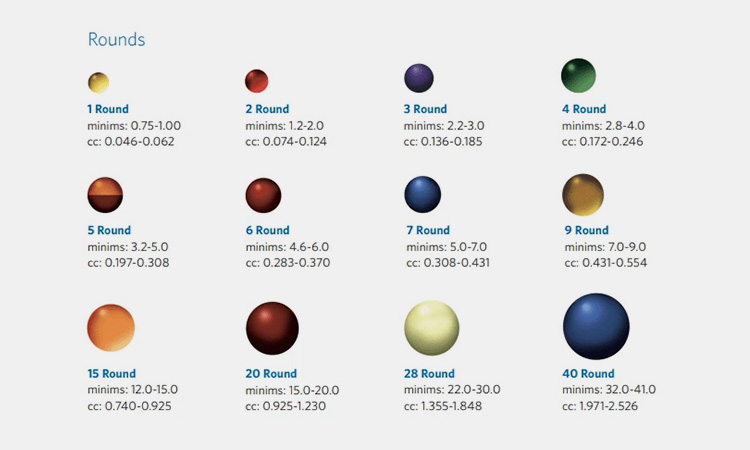

4.What Are The Common Shapes Of Soft Gel Capsules?

Common shapes of soft capsules are:

Round

Round softgels-sourced: capsulcn

Round soft gel capsules are usually perfectly round. The active ingredient is usually contained in the center. This shape is suitable for delivering small doses of drugs. When the size of round capsules increases, it becomes difficult to swallow.

Oval

Oval softgels-sourced: capsulcn

Oval soft gel capsules are slightly flat on both sides, which appropriately increases the potential capacity and is suitable for swallowing. Oval is the most common soft gel capsule shape on the market.

Rectangular or oblong

Rectangular or oblong softgels-sourced: capsulcn

Compared to the oval, the four sides of the rectangular are not smooth and similar to a cylinder.

Suppository

Suppository softgels-sourced: capsulcn

Suppository are usually teardrop-shaped. It makes it easy for patients to insert into the anus or the body.

Tube

Tube softgels-sourced: capsulcn

Tube soft gel capsules can usually carry higher doses.

Special shape

Special shape softgels-sourced: capsulcn

Depending on the special uses of different customers, special shapes of soft gel capsules can be designed and developed with special patient drug usage in mind.

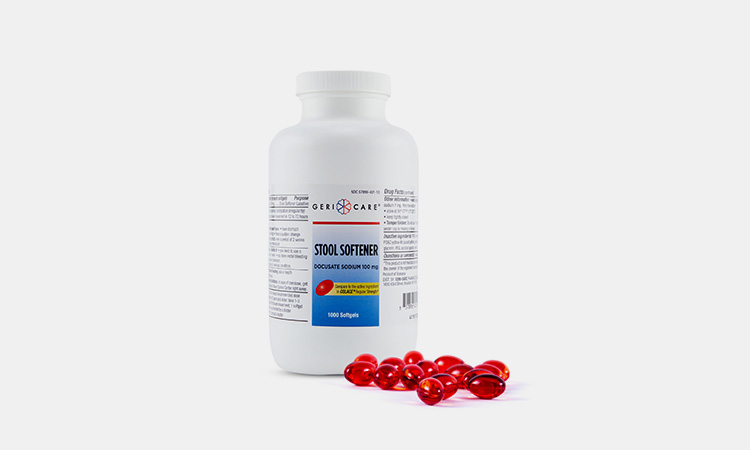

5.What Are The Applications Of Soft Gel Capsule Making Machine?

The soft gel capsule making machine has a wide range of uses. It not only has high production efficiency and accurate filling volume, but also has stable quality and high yield rate. Its uses include:

Pharmaceutical industry

Pharmaceutical industry-sourced: GeriCare

Most soft gel capsule making machines are used in medical production and pharmaceutical fields. It can accurately and high-quality fill liquids, oily liquids, and suspension mixtures of different drug ingredients into soft gel capsules.

Health care products industry

Health care products industry-sourced: sunsetlakecbd

Many health products and supplements are presented to users in the form of soft gel capsules. Whether it is various herbs, vitamin ingredients, minerals and other liquid ingredients, soft gel capsule making machines can be used to achieve perfect filling and encapsulation.

Veterinary industry

Veterinary industry-sourced: whole-dog-journal

Soft gel capsule making machine can also be used to can and seal animal medicines. Not only oral drugs, but also topical drugs can be packaged in soft gel capsules.

Cosmetic industry

Cosmetic industry-sourced: imimg

Various skin care products, cosmetics, essence creams, shower gels or shampoos can be filled in soft gel capsules. Not only is it convenient to store, but it is also convenient to carry and use.

6.What Can Soft Gel Capsule Making Machine Bring You?

It mainly benefits you in:

High efficiency and productivity

High efficiency and productivity-sourced: theuspe

The soft gelatin capsule making machine adopts a fully automatic control system, which can accurately fill different pharmaceutical ingredients into the soft gelatin capsule shell. It not only optimizes the production speed, but also improves productivity and reduces costs.

Versatility

Versatility-sourced: globalso

The equipment can handle different liquid oil bodies, suspensions and formulations. And it can be applied to various industries such as pharmaceuticals, health products, cosmetics, and shrouds with strong compatibility.

Easy to maintain and clean

Easy to maintain and clean-sourced: 51microshop

This equipment can minimize downtime for maintenance and cleaning during operation. It ensures that the parts are complete and not easy to wear. It is reliable for a long time and operates smoothly.

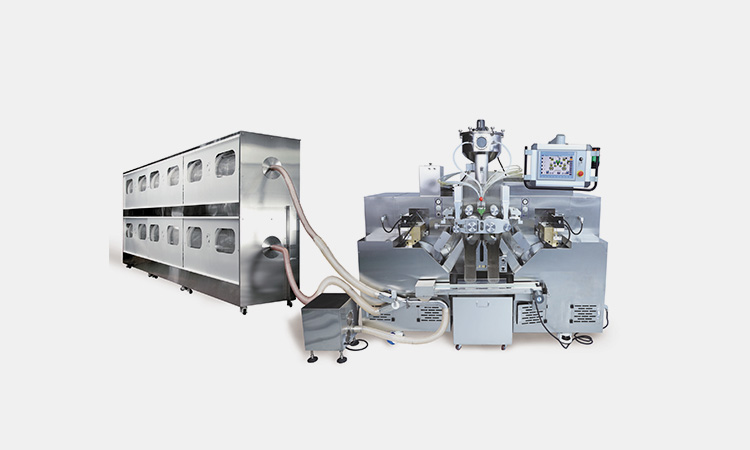

7.What Are The Types Of Soft Gel Capsule Making Machines?

By production scale, the soft gel capsule making machine can be divided into:

Lab-scale soft gel capsule making machine

AIPAK lab-scale soft gel capsule making machine

Lab-scale soft gel capsule making machine can automatically process soft capsules of various sizes, shapes and colors, providing you with different soft gel capsules making and encapsulation, and is easy to maintain and clean. Its production capacity can only meet the needs of small-scale or laboratory-scale soft gel capsule production and filling.

Commercial or industrial scale soft gel capsule making machine

Commercial or industrial scale soft gel capsule making machine-sourced: pagmachinery

Commercial or industrial scale soft gel capsule making machine is suitable for large-scale soft gel capsule production and packaging. It not only includes the main filling and sealing equipment, but also equipped with pressing system, gelatin melting system, raw material batching system, molding and drying system, cleaning system, recycling system, etc.

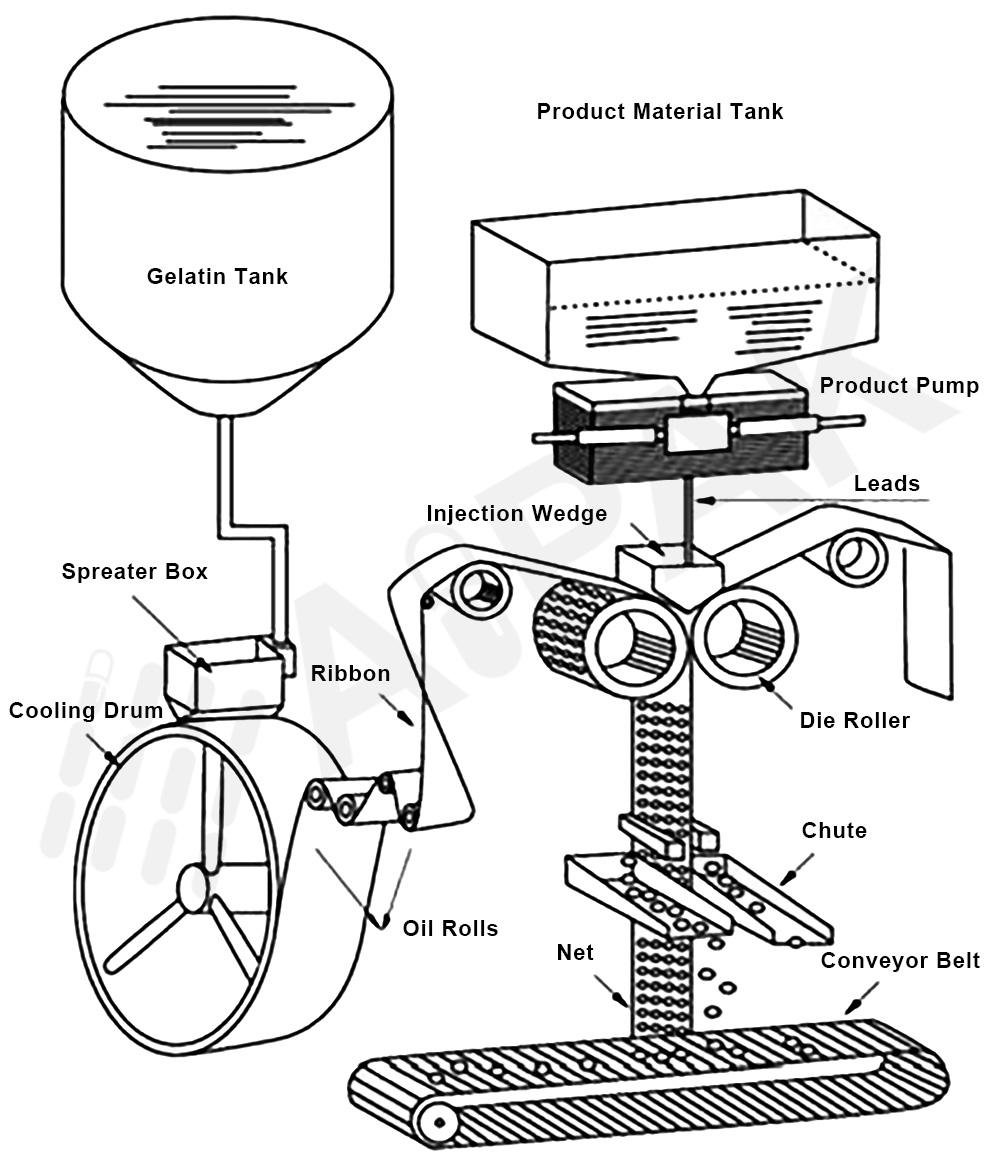

8.How Does Soft Gel Capsule Making Machine Work?

The operation process of the soft gel capsule making machine is as follows:

Gelatin preparation

You need to add gelatin water, glycerin, colorant and other additives and excipients to the boiling pot in the prescribed dosage. Heat the liquid to boiling and set the corresponding temperature and humidity.

Filling material preparation

Pre-treat the materials to be filled through other equipment, such as emulsifier grinders, etc. It is convenient to inject them directly into the soft gel capsule shell later.

Soft capsule shell production

When the gel mixture is prepared, the equipment will directly pump the mixture liquid into the mold. When the capsule shell in the mold is prepared, the pre-prepared filling material will be injected into the empty capsule shell.

Sealing

When the precisely controlled dosage of filling materials is filled into the soft capsule shell in turn, the soft gel capsule belt will be sealed.

Drying

The filled and sealed softgels will be de-molded. The fully de-molded softgels will be directly sent to the drum dryer to remove moisture. It will then be sent to the drying tunnel to fully dry.

Inspection and classification

Fully dried soft gel capsules will be further inspected and tested for quality. Soft capsules with poor quality, incomplete filling, or failed sealing will be eliminated. Soft gel capsules that are complete and well-sealed will be classified to facilitate the next step of packaging and boxing.

9.What Are The Main Components For Soft Gel Capsule Making Machine?

The main components of a softgel gel making machine include:

Main Components For Soft Gel Capsule Making Machine |

|

| Heated material hopper

|

The heated material hopper is ideal for handling heat-sensitive or viscous raw materials. It helps keep the material at optimal temperature and activity before encapsulation. It prevents clogging of the material during the subsequent filling process. |

| Injection wedge

|

The syringe is a metal segment with a metering device. It is specifically used to inject liquids or oils into the softgel shell. Before use, it will be heated to facilitate the pre-treatment of the gelatin strip. |

| Spreader box

|

This component is specifically used to store the prepared gelatin and spread it on the casting drum before the material is filled, thus forming a high-quality gelatin strip. Generally, soft gel capsule making machines are equipped with one on each side. |

| Casting drum

|

The casting drum is generally in the shape of a flat belt. When the prepared raw materials are filled into the gelatin strip, the drum will be cooled during the rotation. The sealed softgel will be sealed. |

| Lubrication rollers

|

It is made of porous material. Before the tape travels, its surface is coated with lubricant to prevent the gel tape from sticking. |

| Die roll

|

It has multiple custom cavities. These cavities can be customized. The shape and style of your finished soft capsule are determined by these cavities. It is equivalent to your soft capsule mold. |

| PLC touch screen

|

The operation screen adopts a fully automatic system. Equipped with a friendly HMI interface, your operation and control are very convenient and intelligent. |

10.What Are The Main Parts For The Soft Gel Capsule Making Line Except Soft Gel Capsule Making Machine?

Generally speaking, a complete soft gel capsule making line needs to be equipped with corresponding gelatin melting tank, prepare tank, colloid mill, tumble dryer, PVC tray, drying car, inspection table, vacuum pump.

Gelatin melting tank

AIPAK gelatin melting tank

It is mainly used for the preparation of gelatin mixtures, and can provide precise temperature and humidity control for your gelatin. Provide you with high-quality capsule shells in the later stage.

Prepare tank

AIPAK prepare tank

Prepare tank mainly used for processing filling materials, like oils, liquids and other substances.

Colloid mill

AIPAK colloid mill

Colloid mill is specially designed for grinding and reducing the size of particles in various suspended liquids. It can provide high-quality ultrafine grinding, emulsification, homogenization, mixing, dispersion and extraction for any mixture.

Tumble dryer

AIPAK tumble dryer

Tumble dryer can efficiently remove excess moisture from soft capsules in a short time. At the same time, it can ensure the integrity of the capsule shell.

PVC tray

AIPAK PVC tray

PVC trays are generally made of environmentally friendly materials. It can store processed soft capsules. The processed soft capsules need to be laid flat and left for a period of time.

Drying car

AIPAK drying car

Drying car is specially used to transport processed and dried softgels.

Inspection table

AIPAK inspection table

After the soft capsules are finished, they need to be inspected and classified manually, and incomplete, worn and incompletely sealed soft capsules are removed.

Vacuum pump

AIPAK vacuum pump

Vacuum pump can maintain the best vacuum state in the equipment and improve higher efficiency.

11.What Is Softgel Production Room Temperature And Humidity?

Softgel Production Room Temperature And Humidity-sourced: squarespace

During the production process of soft gel capsules, the indoor temperature and humidity required at different stages are different.

Soft gel capsule making room

Indoor temperature 18~22℃, relative humidity 35%~45%;

Soft gel capsule drying room

Indoor temperature 20~24℃, relative humidity 20%~25%.

12.How Are Soft GelCapsules Inspected And Sorted?

Quality inspection and control are crucial in the filling and sealing process of soft gel capsules. Therefore, the capsule shell should be classified accordingly to ensure the highest quality of soft gel capsule products. The measures that need to be ensured are:

How Are Soft Gels Inspected And Sorted-sourced: secsoftgel

Manual inspection

The inspector needs to screen and inspect the soft gel capsules on the inspection table to find them with gaps, cracks or wear. They will be removed and recycled.

Using the soft gel capsule inspection system

The equipment can automatically classify, screen and remove the finished soft gel capsules. Classify according to your predetermined standards. Any soft gel capsules that do not meet the standards will be rejected.

13.What Are The Quality Control For Soft Gel Capsule Making Machine?

The quality inspection of soft capsules includes:

Inspection of gelatin tape

Inspection of gelatin tape-sourced: theuspe

- Monitoring the thickness, transparency and elasticity of the gelatin tape;

- Removing any torn or uneven-edged gelatin tape;

Randomly inspecting the soft gel capsule dosage

Randomly inspecting the soft capsule dosage-sourced: theuspe

- Regularly inspecting the soft gel capsule material, filling accuracy and dosage;

- Also inspecting the integrity, strength and uniformity of the capsule sealability;

Appearance inspection

- Evaluating the appearance, color, size and shape of the soft gel capsule shell;

- Evaluating the stability of the soft gel capsule to ensure its long-term efficacy and safety;

- Testing the solubility and disintegration of the soft gel capsule to maintain the best performance;

14.What Are The Major Problems You May Encounter And Solutions During Soft Gel Capsule Making?

Major Problems You May Encounter And Solutions-sourced: owlcation

The most common problems and solutions in using soft gel capsule making machines are:

| Common problems | Solutions | |

| Uneven thickness of gelatin tape | Uneven thickness of gelatin tape will cause unstable or defective sealing of the subsequent capsule shell; | Regularly calibrate the casting cylinder and set the corresponding temperature and speed;

Regularly check the thickness and uniformity of the tape during production; Ensure the normal operation of the cooling fan; |

| Incomplete seams or capsule shell leakage | Poorly sealed capsule shells will cause capsule leakage in the later stage, thus affecting the quality of the product; | Ensure that the mold is aligned and calibrated during production;

Monitor the sealing degree to reach 2% of the tape thickness 0%; Randomly check the thickness of the rubber strip; |

| Filling weight variation | Filling weight variation or inconsistency will damage the efficacy and safety of the product; | Regularly check and accurately adjust the injection pump;

Use servo control pump to complete accurate injection and filling of materials; Regularly check and replace worn parts; |

| Capsule adhesion | Adhesion between capsules or adhesion between capsules and parts not only affects product quality, but also affects equipment operation efficiency; | Appropriate use of lubricants on gelatin tape wedges;

Extend the drying time of soft capsules; Ensure that soft gel capsules maintain optimal temperature and humidity levels during production; |

15.What Are The Quality Standards Of Soft Gel Capsule Making Machine?

Each soft gel capsule making machine should meet the corresponding quality standards, including:

Compliance with cGMP standards

Compliance with cGMP standards-sourced: spectrumchemical

According to relevant management regulations, each soft gel capsule making machine must comply with cGMP standards to ensure that the equipment is safe and efficient during use, easy to clean and maintain, reduce any environmental pollution, and use clean, safe and environmentally friendly materials.

Environmental regulations

Environmental regulations-sourced: smallbizdaily

When purchasing or selecting a soft gel capsule making machine, it is necessary to consider that the equipment complies with all environmental regulations. In this way, the equipment will be economical and efficient and bring the greatest benefits during the production process.

CE standards

CE standards-sourced: sunfiretesting

Comply with CE standards, it can meet the various sizes and shapes of soft gel capsule filling, which is convenient for various manufacturers to purchase and use.

16.How To Maintain The Soft Gel Capsule Making Machine?

Any equipment will wear out or even break down during long-term uninterrupted use. Therefore, you need to perform regular maintenance and cleaning, including the following steps:

How To Maintain The Soft Gel Capsule Making Machine-sourced: fieldinsight

Regular inspection and cleaning

Regular inspection and cleaning of the soft gel capsule making machine can keep the equipment in good condition.

Regular lubrication of parts

Regular lubrication of equipment parts, especially the mold, gelatin belt roller and casting cylinder of the equipment. It not only helps to reduce the wear of friction and anti-paint equipment, but also ensures the smooth operation of the equipment.

Adjustment and calibration

Proper adjustment and calibration of the equipment in the near future can ensure that the equipment can run smoothly and efficiently.

17.What Are The Factors When Choosing A Soft Gel Capsule Making Machine?

Choosing the right soft gel capsule making machine can maximize your production efficiency. You need to consider the following factors during the selection process:

Production capacity

Production capacity-sourced: pharmaceutical

You need to confirm the production capacity requirements of the equipment you need. This includes how many softgels can be produced per hour and whether it can meet the future production volume requirements after expansion.

Softgel size and shape

Softgel size and shape-sourced: encyclopedia

Softgel size and shape determine the mold and technical specifications you need.

Whether to connect

Depending on the scale of your business, you can choose a single-muscle soft gel capsule making machine or a softgel capsule making line.

Conclusion:

The wide application of soft gel capsule making machine makes it possible to make various softgels of oils, medicines, dietary supplements, etc. Whether you are a hobbyist, manufacturer or supplier, you will be amazed by this equipment with advanced technologies. If you have any other needs or questions in the future, welcome to consult AIPAK anytime!

Soft Gel Capsule Making Machine Related Posts

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586