Uniform heat distribution

Sterility assurance

Wind pressure assurance

Want A Free Consultation

AIPAK AKDH series hot air circulation sterilization tunnel

AIPAK AKDH series hot air circulation sterilization tunnel is mainly used for drying, sterilization and pyrogen removal of small glass bottles such as ampoules, vial bottles and oral liquid bottles in pharmaceutical industry.It can automatically complete the whole production process from bottle feeding, preheating, drying and sterilization, cooling to bottle bottle discharging.

The laminar flow principle and hot air high speed disinfection technology can make the container reach the national cleanliness level 3 standard (American industrial standard level 100) in the sealed tunnel. It is the most popular drying sterilization equipment with the best sterilization effect in the world. Its heat distribution is uniform and the effect of pyrogen removal is good.

The sterilization tunnel can be used not only by single machine, but also by connecting with the bottle washer in front and the filling machine in back.

FEATURE

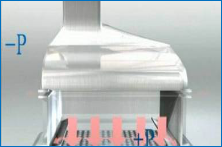

- Adopt a new type of equalization technology,uses a shunt box between the outlet of the fan and the high temperature and high efficiency filter to equalize the flow,to improve the uniformity of air supply.

- Ashunt box is set at the lower part of the filter to equalize the flow so as to improve the uniformity of heat distribution.

- An adjustable return air equalizer is set at the return air channel to ensure the uniformity of heat distribution.

- 1st measure to ensure the effect of pyrogen removal:The high temperature section is equipped with high temperature and high efficiency filters (using the brand of German Camfil), side-mounted independent electric heating system, high temperature fan, dehumidifier fan, refreshing fan mechanism, etc. The bottle is sterilized and pyrogen removed under 100-level laminar flow by using the principle of hot air laminar flow.

|

2nd measures to ensure the effect of pyrogen removal: The high temperature sterilization section adopts the piecewise PID temperature control technology, which divides the high temperature into several sections to control, fully ensuring and adjusting the uniformity of heat distribution, bottle pyrogen removal and sterilization effect. At the beginning and end of production, the control system keeps the bottle at high temperature for 5 minutes to ensure that the bottle is just produced and finished. |

|

|

1st measure to Ensure the Quality of 100-level Laminar Flow:High temperature and high efficiency filter adopts negative pressure sealing structure, without using sealing strip and sealing glue. The sealing problem of the filter has been solved thoroughly, and the quality risk of drug production has been reduced. |

|

|

2nd measure to Ensure the Quality of 100-level Laminar Flow: Eccentric wheel self-compacting drawer structure is adopted in the installation of high temperature and high efficiency filters. It is convenient to install and disassemble and has good sealing effect. It is the most popular way in the world at present. |

|

1st measure to ensure wind pressure: The automatic air pressure balance system can effectively control the air pressure balance between cooling section and filling room, preheating section and washing and drying room. A differential pressure meter is installed between the control sections and a backflow prevention control system is added to the cooling section. When the air pressure fluctuates in the filling room or the washing room, the differential pressure automatic control system starts and adjusts the air pressure through the valve actuator.

|

2nd measure to ensure wind pressure : |

|

3rd measure to ensure wind pressure: The preheating section is equipped with medium-effect and high-effect filters and air supply and dehumidification fans to achieve 100-grade laminar flow. The bottle is preheated by partial hot air in the high temperature section to remove most of the moisture from the bottle. The wind speed difference between the two sections not only keeps the pressure difference between the two sections, but also forms the necessary top bracket for the high temperature section, so that the pressure in the high temperature section does not fluctuate greatly.

4th measure to ensure wind pressure :In the high temperature section, there are ramps at both ends of the box (inlet and outlet), which reduces the windless area and increases the drying and sterilization time by more than 10%. At the same time, it can better maintain the top bracket of the air pressure in the preheating and cooling sections to reduce the fluctuation of the air pressure in the high temperature section.

|

Sterility assurance measures: The equipment control system is equipped with day mode and night mode. When daytime production, start daytime mode, equipment production according to normal mode; when night does not produce, start night mode, equipment electric heating tube does not heat, laminar fan normal operation, to ensure 100-level laminar flow effect in the cavity. It meets the requirements of aseptic production. |

|

|

1st guarantee measures for equipment cleaning: The inner wall of the tunnel is cleaned. There are several slag discharge ports at the bottom of the mesh belt, the bottom of the tunnel and the outlet of the bottle. It is convenient and fast to clean the inner parts of the equipment and reduce the risk of cleaning. |

|

|

2nd guarantee measures for equipment cleaning: Equipped with on-line ultrasonic cleaning mesh belt device. After the net belt has been cleaned by ultrasonic wave, the process of water flushing and air-pumping is carried out. The cleaning is convenient and thorough. It meets the requirements of aseptic production. |

|

|

1st assurance measures for equipment verification:The machine is equipped with PAO interface, wind speed verification interface and dust particle verification interface for the integrity test of high efficiency filters, and is closed by quick change clamp in non-detection state, which is convenient and fast to operate. |

|

|

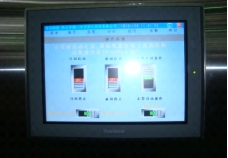

2nd assurance measures for equipment verification:The advanced PLC man-machine interface control system not only monitors the working condition of the machine and ensures the production process requirements, but also implements joint control with other equipment to show the cause of the failure, location, simple elimination methods, etc. At the same time, it can dynamically display the working status of fan and mesh belt motor in each area, etc. |

|

|

3rd assurance measures for equipment verification:To verify the sterilization temperature, two temperature probes are equipped, which are monitoring probe and recording probe respectively. The two sets of data can be compared and analyzed regularly. |

|

|

1st equipment risk control measures: There is a temperature sensing probe in the preheating section. When the temperature in this section is higher than the set temperature upper limit, the tunnel stops heating automatically to protect the high efficiency filter from burning. |

|

|

2nd equipment risk control measures: Risk control device of air supply outlet in high temperature section. When the temperature is higher than the set temperature limit, the tunnel stops heating automatically to protect the filter from burning out. |

|

|

3rd equipment risk control measures: This machine is equipped with power-off protection device, and has intake pipeline in high temperature area. In case of sudden power failure, the control valve is opened manually. Clean compressed air directly enters high temperature area to cool down, so as to prevent burnout of high temperature and high efficiency filter (user-owned gas storage tank and clean compressed air). |

|

|

4th equipment risk control measures: The cooling method of high temperature fan is water-cooling, and a set of circulating water-cooling system is added to the bearing. The cooling effect is greatly improved. It is not only beneficial to prolong the service life of high temperature fan, but also convenient to select high temperature grease. |

|

|

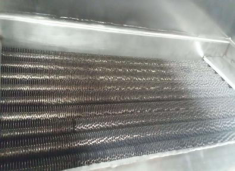

5th equipment risk control measures: The stainless steel heating tube is used for heating, and the arrangement is interlaced and the radiator is arranged in a special way along the direction, which reduces the air resistance, reduces the loss of air pressure and volume, improves the heat exchange efficiency and prolongs the service life of the heating tube. The integral type of heating pipe and connecting wire can prevent the discharge blackening when the connection between heating pipe and wire is not reliable, which is more safe. |

|

6th equipment risk control measures: The control circuit is equipped with interlocking device. When the tunnel temperature is lower than 100℃, the control system can automatically cut off the power supply, but when the tunnel temperature is higher than 100℃, all the fans can not be shut down, thus protecting the high efficiency filter. Each fan is controlled by a frequency converter, and only one fan is controlled by a frequency converter (showing the frequency value instantly), which saves energy consumption and ensures the balance of pressure values in each area. The system is equipped with protective devices. When the dryer does not reach the set temperature, the bottle washer stops working and the mesh belt stops running. When any fan fails, the dryer stops heating, etc.

DATA SHEET

|

Model |

AKDH620/2600 |

|

Dry capacity |

2ml Ampoule 200pcs/min |

|

Voltage |

380V, 50Hz |

|

Power consumption |

60kw |

|

Fresh air |

4000 m3/H |

|

Ampoules outlet temperature |

≤ room temperature +15℃ |

|

Bottle damage rate |

<0.05% |

|

Working temperature difference between each zones |

Empty load ≤±5℃ full load≤±10℃ |

|

Sterilization temperature |

280℃-350℃ adjustable |

|

Mesh belt speed adjustment |

100-400mm/min |

|

Noise |

<70dB |

|

Weight |

4200KG |

|

Transfer table height |

FL+950mm |

|

Dimension |

2600×1820×2245mm |

VIDEO

CONTACT

Get in touch with an expert

Andrew Yang

Engineer Director

Phone: +86 189 7157 0951