Key Considerations About Empty Capsules

The capsule is the most frequently used solid dosage form after tablets. In pharmaceuticals, the capsule dosage form is preferred for phase I and phase II due to various factors. Similarly, many herbalists, small entrepreneurs, and hobbyists prepare customized formulations and dispense them in empty pill capsules. In both scenarios, the goal is to develop a stable exploratory formulation for the intended treatment. ‘Key Considerations About Empty Capsules’ is all about variables that you must keep in mind when performing the job.

1.Selecting- Where Can I Buy Empty Pill Capsules?

Before starting the filling job, you need to assemble all the major requirements for the procedure. Make sure you’re getting what you need. For this, you need to evaluate the following parameters

Assess Your Application:

Before selecting an empty pill capsule, examine the type applications. Such as

| Herbs |  |

| Food |  |

| Powders |  |

| Nutraceuticals |  |

| Liquids(oils, serums) |  |

Estimate Budget

Estimating the budget can be done by calculating production capacity (per day, week, month). It will help you to reach the target goal.

Are you looking for Customized Blends?

Different individuals prefer particular customized blends for their brand. You will find many vendors who offer customized pill capsules empty for filling purposes. The prevalence of using empty capsules is increasing as it helps in giving a brand’s identity and power boost to your production line.

Buying

Where to buy pill capsules empty? This is no more a hectic job now. You just need to jot down your requirement and consult a vendor. If you are requiring guidance, many manufacturers offer this job free of cost. Moreover, you can get help from ‘Online’ searching and by reading reviews of customers before purchasing the product.Similarly, you can scrutinize ‘empty pill capsules near me’; where you can find many capsules empty suppliers near to you. Just visit them or make an online order to find the product at your doorstep.

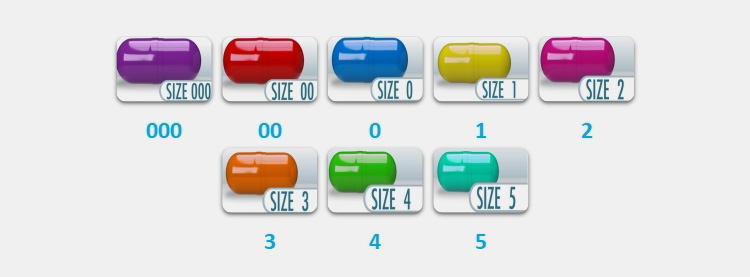

2.Empty Capsules Sizes

Whether the empty capsule is gelatin or vegetarian both are available in various sizes. The standard capsule sizes are denoted by integers. The empty capsules sizes are 000, 00, 0, 1,2,3,4, and 5. ‘000’ is the largest sized capsule while ‘5’ is the smallest sized capsule.

000 sized empty capsule packs the largest volume of drugs while 5-sized capsules are appropriate for smaller dosages.

| 000 | 00 | 0 | 1 | 2 | 3 | 4 | 5 | |

| Length (mm) | 26.1 | 23.4 | 21.6 | 19.4 | 17.6 | 15.7 | 0.2 | 11.1 |

| Volume (ml) | 1.37 | 0.9 | 0.68 | 0.48 | 0.36 | 0.27 | 14.3 | 0.13 |

| Diameter of Cap (mm) | 9.91 | 8.56 | 7.64 | 6.96 | 6.39 | 5.85 | 5.33 | 4.91 |

| Number of capsules in a teaspoon | 3 | 5 | 7 | 9 | 11 | 15 | 20 | 35 |

| Number of capsules in Box | 50,000 | 75,000 | 100,000 | 125,000 | 175,000 | 200,000 | 250,000 | 300,000 |

3.Lead Suppliers

The global empty capsule market is driving a high force which is projected to reach approximately 3.7 billion $ in 2021. The overall growth is majorly driven by a few leading market players who adopted to facilitate Pharma, R&D, and clinical studies. The prime objective of empty capsule manufacturers is to yield low-cost and significant quality capsules.

Some of the lead suppliers of empty capsules are operating Capsugel (USA), CapsCanada (Canada), Aipak Pharmaceutical (China), Suheung (Korea), Bright Pharma Caps (USA), and others.

4.What is the Best Option for Empty Vitamin Capsule: Gelatin or Empty Vege Capsules?

Gelatin is used for several decades for manufacturing empty vitamin capsules. With health awareness more and more people are opting for empty vege capsules for consuming their vitamin supplements.

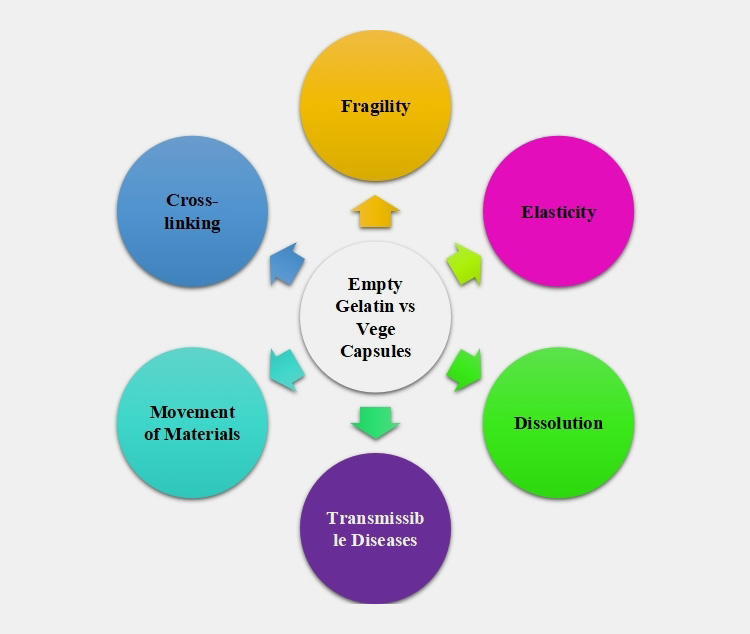

There are some issues that make gelatin an unfit option for empty vitamin capsules, for instance

Fragility

The shell of gelatin capsules contains 12%–16% moisture content. Decreased moisture content in the shell causes its brittleness and breakage.

High humid conditions lead to deformity and stickiness in gelatin capsules. Vegetarian capsules do not face these problems due to lower moisture content in their shells.

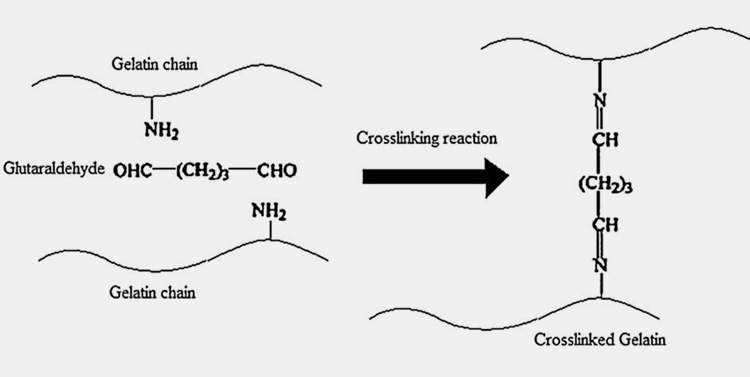

Cross-linking

Gelatin becomes cross-linked on exposures to stress conditions which lower its dissolution in stomach. Excipients, masking agents, and anti-oxidants are added in gelatin capsules to lower their rate of aging.

Movement of Materials

Small molecular weight compounds like PEGs can move in gelatin coating causing its plasticity. Moreover, the contents of fill materials are relatively unstable and may crystallize. This limit the use of gelatin capsules.

Transmissible Diseases

Bovine-derived gelatin materials in empty vitamin capsules can cause transmissible spongiform encephalopathies (TSEs) in consumers. This also make gelatin capsule unsuitable for storing dietary supplements.

There are also problems involved in using vegetarian capsules as dietary supplements for instance,

Dissolution

Gelling agents in vege capsules lower its dissolution in gastrointestinal tract. In addition to this, gelling agents interact with calcium and potassium further affecting the disintegration time of HPMC capsules.

Elasticity

Non gelatin vege capsules lack the elasticity and fusibility present in empty gelatin capsules making them inapt for storing vitamins.

5.Increasing Profitability- Empty Gelatin Capsule or Veggie Capsule?

Profit is an important concern when venturing into the manufacturing of empty capsules. This question is always on the mind of a manufacturer which product will bring more money whether an empty gelatin capsule or an empty veggie capsule.

When it comes to revenue generation, an empty gelatin capsule is more profitable due to a number of factors like:

- Gelatin is naturally obtained by the hydrolysis of collagen whereas polymers for vegetarian capsules are synthetically made costing money.

- Raw materials for making vegetarian capsules are less available and are quite expensive to purchase. Whereas the starting materials of gelatin capsules are easily purchased at a fairly low cost.

- The technology for formulating shell parts of veggie capsules is patented thus adding to cost of manufacturing.

- Consumers prefer to buy gelatin capsules as they are less pricey and also because of their known safety profile.

6.Filling Techniques- Manual, Semi-Automatic & Automatic

In old days, capsules are filled manually by hand. This used to consume much time and energy of filling personnel but with the advancement in technology, now a day; capsules are filled by the machines.

There are three kinds of capsule filling machines.

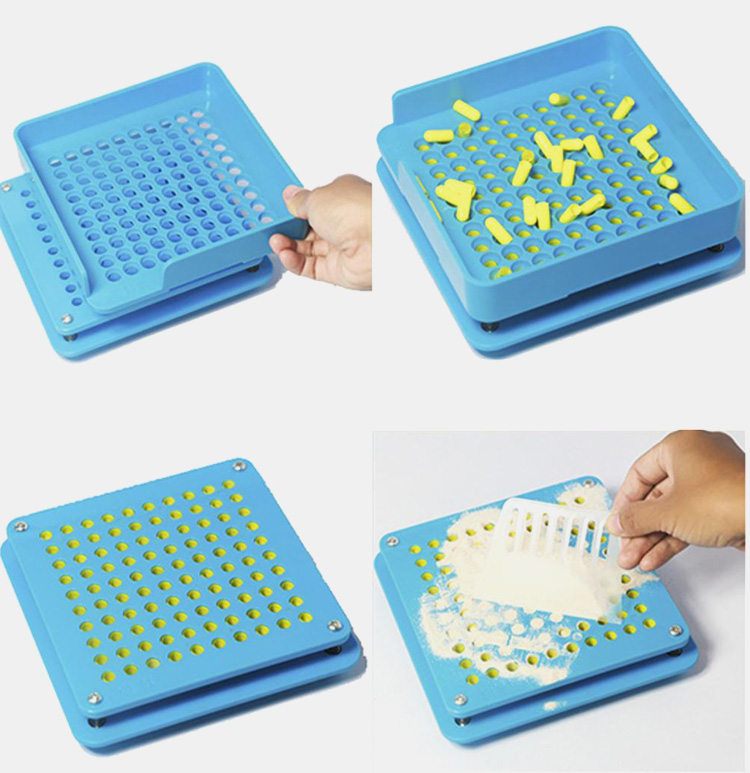

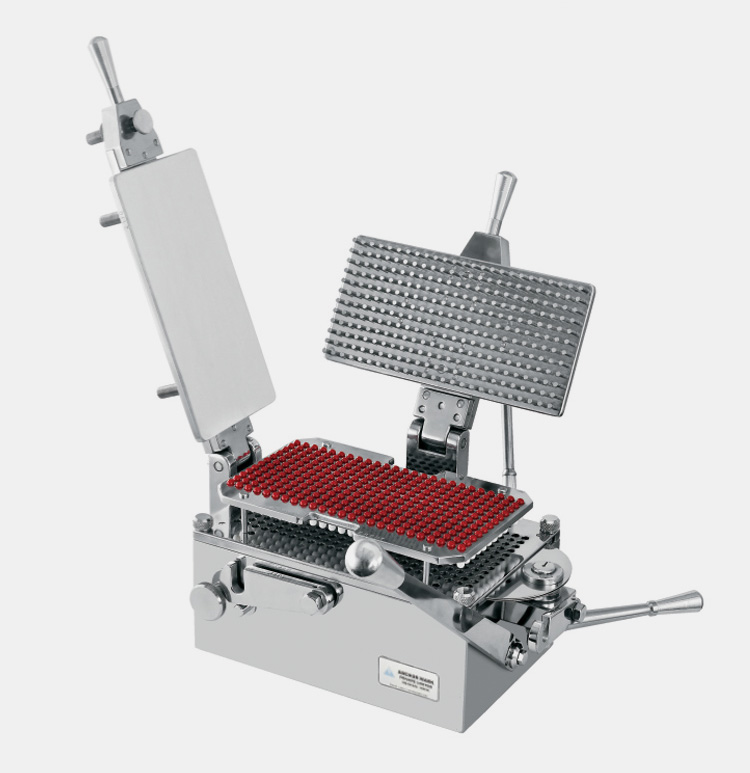

Desktop Capsule Fillers

In this kind of machine, powder is filled by hand inside using scrappers when capsules are placed on loading tray. The cam handler separates the caps of empty capsules.

After filling pin plate is pushed down that presses the powder. The tray containing caps is put back on loading tray and lever locks caps on body. This machine can fill up to 2000-3000 capsules per hour. Usually these handheld equipments are used in small pharmacies and clinics.

Semi-automatic Capsule Fillers

These machines perform filling functions both manually and automatically hence the name. Capsules are manually loaded on the machine and by using a vacuum, cap and body are separated. The fill material hopper is placed on body and by auger filling, fill material is loaded in body.

Pressure is applied for locking cap and body together after filling. The filling output of these instruments is 35,000-40,000 capsules per hour. These are best for small scale capsule filling businesses.

Automatic Capsule Fillers

These types of equipment are the latest innovation in capsule filling technology and are used for filling all kinds and sizes of capsules. Automatic capsule filling machines have versatility in processing various kinds of fill materials such as pellets, mini-tablets, powders, liquids, etc.

Functions such as loading of empty capsules, separation of cap and body, filling of materials, and sealing the capsules are carried out by equipment itself.

These instruments are equipment with safety sensors and empty capsule detection systems that improves the yield of filling process.

The production capacity of these machines is up to 150,000 capsules per hour. These are excellent for large productions.

7.Common Capsule Defects and Causes

Everyday production faces a bit of trouble and sometimes you get defective and damaged capsules. But there is a solution to every problem.

Some common defects of capsules, their causes and remedies are discussed in the table below:

| Defects of Capsules | Causes | Solution |

| Missing Cap

|

High vacuum setting

Cap and body bush are not properly aligned |

Decrease the vacuum by turning the throttle value

Properly align cap and body bush by using an alignment gauge. |

| Damaged edge

|

Blunt knife while cutting damages the exterior or joint | Increase the sharpness of cutting knives. |

| Short Cap or body

|

Wet shell or issues in collet results in inadequate access of body or cap in a collet. | Ensure proper drying conditions

Check for failure in a collet. |

| Star capsule

|

There is the unequal spreading of gelatin on dip pins

On the ends of pin, gelatin is present in large amount |

Ensure accurate consistency and distribution of gelatin solution on dip pins. |

| Splitting

|

Non-uniform drying

Thickness of film is not precise at the location of split |

Give proper condition and time for drying

Ensure the thickness of film during dipping |

| Double Cap

|

Loose caps on the body of capsule on which already loose cap is fitted | Check the position of caps and body in joining block |

| Dot on Exterior

|

Tiny pieces of shell produced during trimming process can enter in dipping area | Properly ventilate trimming area. |

| Misprinting

|

No uniformity in ink flow

Inadequate ink viscosity Partial drying of ink |

Check the uniformity in ink flow.

Use ink of right viscosity Give proper time for drying |

| Bubbles

|

Inaccurate vacuum during extraction process | Maintain proper vacuum during extraction process |

| Holes

|

Stripper jaws pierce the capsule shell when these move to strip capsules from the mold pin | Properly set and install the capsule manufacturing machine |

8.Common Defects in Filling Process

Defects in capsules can also occur during the filling process. Fortunately, these can be easily solved by going through some guidelines.

Here are some hacks for rectifying the common defects in filling process.

| Defects | Causes | Solution |

| Cracks

|

Inaccurate environmental conditions during storage result in travel of moisture from shell to inner fill material

Misconfiguration of cap and body due to incorrect installation of hold-down pin |

Properly maintain the environmental conditions during storage

Accurately install hold-down pin in joining the unit. |

| Unclosed Capsules

|

Dust accumulates in lock area

Overfilling Inaccurate pin size Inaccurate setting of closing length |

Wipe cap-body lock area surface with clean cloth.

Properly encapsulate the capsule with fill material Use suitable sized pin Adjust the setting for closing length |

| Empty Capsules

|

Components of capsule filling machine such as load cells, sensors, pressure gage are damaged or worn out resulting in transport of empty or under-fill capsules to discharge chute | Ensure proper working of an empty capsule detection system. |

| Telescoped

|

Mispositioning of different parts of encapsulation machine

Rubber sheet of closing pin is worn out The positioning of the closing pin is not in the middle of bush |

Check the configuration of parts of the encapsulation machine

Replace the worn out rubber sheet with new one. Use gauge pin to check bending the closing pin. Replace the bent pin |

| Damaged Band

|

The height of wheel, its speed, temperature, band thickness is not right during banding process. | Check and correct all the banding parameters like wheel height, wheel speed, temperature and band thickness |

| Dusty

|

Filling is dusty | Polish surface of capsule with a polisher. |

| Dented Capsules

|

Large closing length setting

High lock length Increased closing pressure Capsules are overly filled Incorrect configurations of pin |

Decreased closing length

Lower the lock length Reduce closing pressure Accurately fill capsule Use pins of right shape and size |

CONCLUSION

Today, consumers are even more concerned about the origin of empty capsules than ever before. The global empty capsule market is looking for plant-based sources with no preservatives and minimum synthetic sources. ‘Key Considerations About Empty Capsules’ is specially designed to make you learn basic performance parameters. With the emergence of empty capsules, we offer a special advanced product range of gelatin and vegetarian sources. Hurry Up to avail of our Free Consultation Program and Product Quotation Right Now.

Don't forget to share this post!

Capsule Filling Machine Related Posts

Capsule Filling Machine Related Products

Capsule Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine