High-Speed Tablet Pressing Machine: The Complete Buying Guide In 2025

We live in a world driven by efficiency and output, so all the advance and modern technology we see around is more of a necessity than a luxury. High speed tablet pressing machine is a very important component of the modern pharmaceutical as well as nutraceutical manufacturing as speed, precision and compliance is an integral part of the manufacturing.

High speed tablet pressing machines are also known as rotary tablet presses. They can produce large batches of high quality tablets with consistency and uniformity in their size and shape. The ability of high speed tablet pressing machine to compress thousands of tablet per minute, make them integral part of large scale production to meet the growing needs of both prescription and over the counter medications.

In the FAQ guide below, we’ll cover all the possible questions in your mind about this high speed tablet pressing machine, and by the end of this guide you are going to have all the insight about the high speed tablet pressing machine. So let’s dive into the most pressing questions!

1.What is a high speed tablet pressing machine?

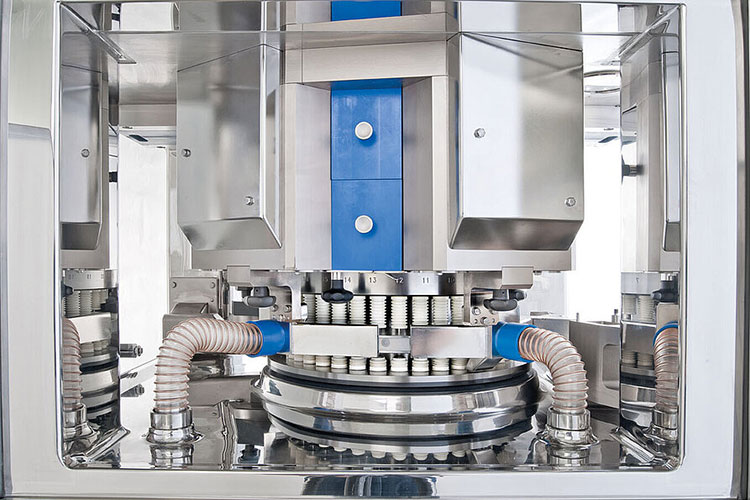

AIPAK high speed tablet pressing machine

A high speed tablet pressing machine is a rotary machine, designed for continuous and large volume production of tablets of various shapes and sizes. It is called double rotary press because it has two set of rotating turrets, which comprises of two rotary plates or punches and two separate set of dies, for the compressing of powder into large number of tablets simultaneously.

It is equipped with multiple tooling systems on a rotating turret, which is a central rotating platform that holds multiple punches and dies stations in a circular manner. The two punches and a die form a cavity in which the powder is forced to enter. The punches are then pressed together with a great force to fuse the material together. In this way the tablets being produced are of uniform size, weight and shape.

Its versatile nature and ability to produce large batch of tablet in much lesser time and decrease chances of human error due to manual fatigue make it best choice for large scale production.

2.What are different types of high speed tablet pressing machine?

A high speed rotary tablet pressing machine-picture courtesy: Romanco

They are classified into different types depending upon their design, station count and type of tablet they produce. Here are the following types:

Depending upon the design:

On the basis of its design, they are differentiated on the basis of different types of tooling, different number of stations, or by production capacity.

Different type of tooling:

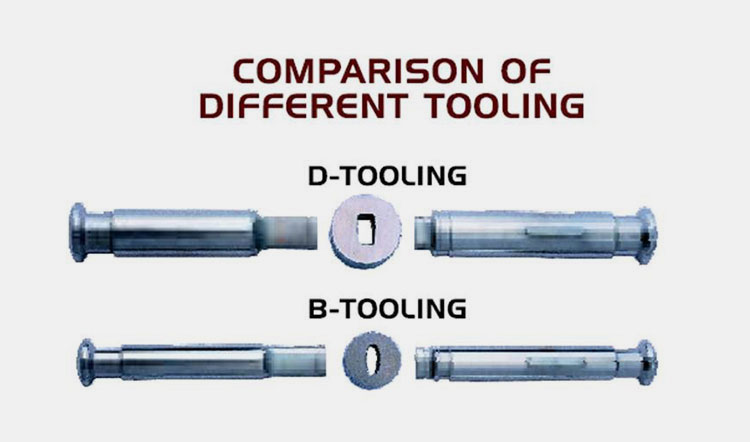

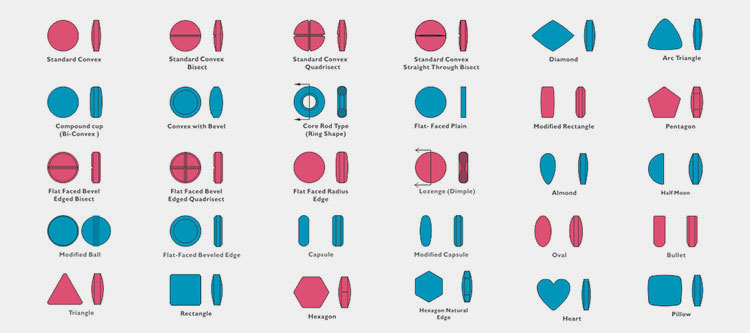

Types of tooling –Picture courtesy: pharmachine india

Different type of tooling is used for different types of tablet shapes, size and compression requirement.

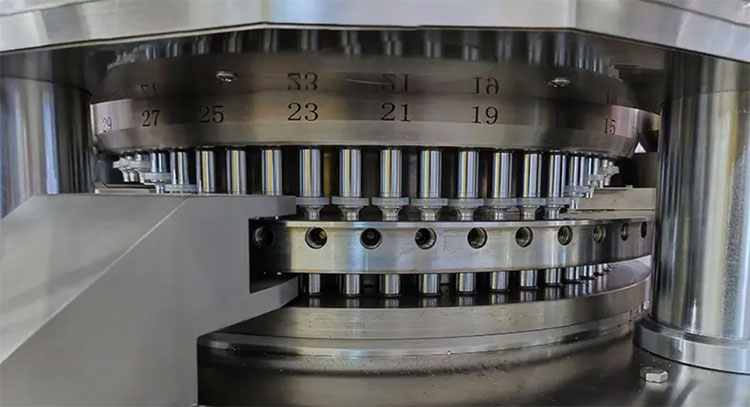

Different number of stations on the rotating turret:

Punch stations on a rotating turret-picture courtesy: united pharmatek

The number of stations here means the number of sets of punch and dies, that are tablet making parts of the machine, on the turret. In a high speed tablet making machine they are usually high in numbers, ranging from 26 up to 75.

3.How does a high-speed tablet press differ from a standard tablet press?

Yes the high speed tablet press and standard tablet press are totally different from each other; the following points elaborate their basic differences:

High speed rotary tablet press:

Compressed tablets coming out of a high speed rotary press-picture courtesy: u.s validation services

High speed tablet pressing machine and a standard tablet press differ mainly in the production speed and the quantity they are producing. The production rate of a high speed tablet press is usually exceeding 100,000 tablets per hour, which is indeed a great number, making them a perfect choice for large batch production.

They are more complex and unlike standard tablet press, they have multiple set of dies and punches which are arranged in a circular manner, for continuous formation of tablets.

Standard tablet press:

Manual tablet pressing machine AIPAK

A standard manual tablet press on the other hand is the simplest form of tablet pressing machine, and they use a single punch and die set. A single tablet press is cost effective and very easy to use, without any specific operator training. They are ideal for research samples in R&D or in the laboratories. They can make tablets of different size and shape by changing the punch type.

But the manual tablet press has some limitations, mainly they have very low production rate, they require more labor increasing the cost of labor and still the end results are much lesser than a high speed tablet pressing machine.

4.What is the principal of the high speed tablet pressing machine?

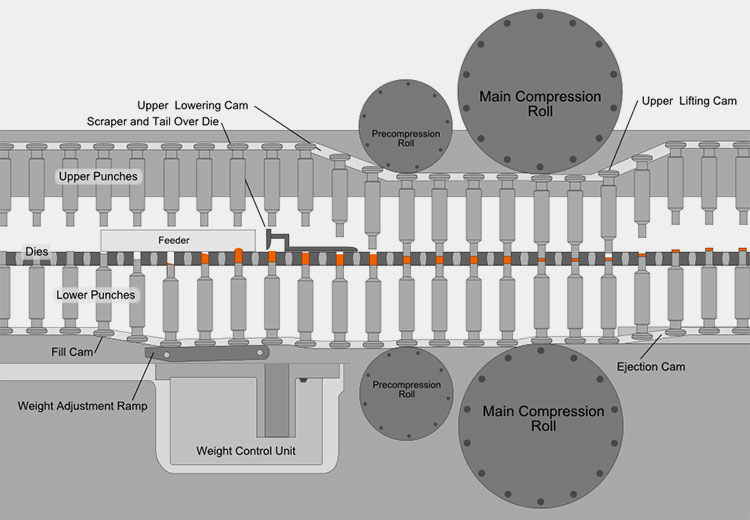

Working mechanism of high speed tablet pressing machine-Picture courtesy: wikipedia

The high speed tablet pressing machine works on the principal of compaction or compression. According to which, the powder or granules to be compressed are filled in a die, and after that a specific weight adjustment pressure is applied by compression rollers, and this roller pressure is ultimately transferred to the powder or granules to compact them in a firm tablet.

Basically, we can say the working principal of high speed tablet pressing machine comprises of powder filling, compression and lastly tablet discharge. This is a brief explanation of the steps involved:

Powder filling:

The first step in tablet compression starts with a hopper which feeds the powders or granules on to the die cavity, this filling of powder is properly monitored by a process called metering, which control the amount of powder being entered into the die. That’s how consistency in tablet weight and volume is controlled effectively.

Compression:

In high speed tablet pressing machines, there is a rotating turret on which upper and lower punched are arranges, which apply pressure to the powder within the die, with a significant force. Hence, the conversion of powder into tablet takes place through due to this pressure.

Ejection:

After compression, the lower punch rises and ejects the tablet from the die cavity.

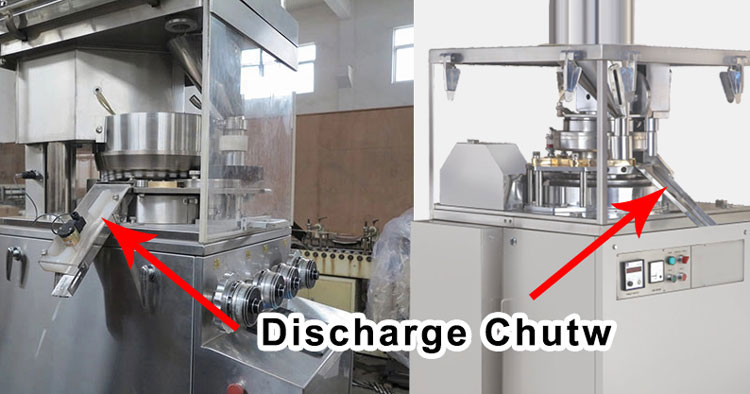

Discharge:

The compressed tablet ejected, is guided through a discharge chute to the collection bin.

5.What are the main parts and functioning of high speed tablet pressing machine?

Let’s briefly learn about the main parts of high speed tablet pressing machine:

Hopper:

Image showing hoppers in the high speed tablet pressing machine-Picture courtesy: pharma education

Hopper is a very significant part of the tablet pressing machine and it is the first part of the machines that comes in direct contact with the powder or granules to be compressed. Hopper is the first part of compression machine which is loaded with powder or granules. It is made up of stainless steel as it comes in direct contact with the product.

In advance high speed tablet pressing machines, the uniform flow of the particles through the hopper is made sure by a vibratory mechanism, while in the conventional types the powder flow through hoppers under the influence of gravity.

Feeder:

An individual feeder –Picture courtesy: tablet compression machine parts

After the hopper, the powder flow to the feeders. As the name suggests, the purpose of the feeders is to feed powder to the die bore cavity. A feeder has various housings, and the powder from the hopper pas through these housings, into the die cavities.

In advance tablet pressing machines, feeders have rotating fins to ensure the uniform filling of the die cavities.

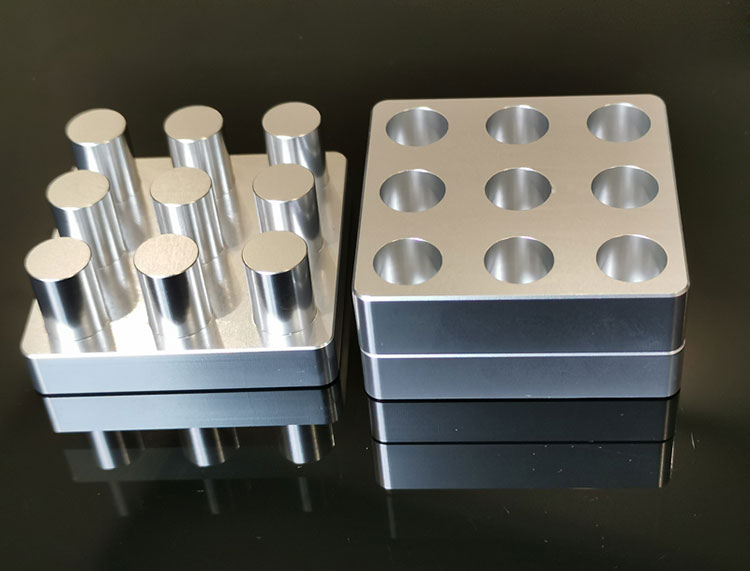

Punches and dies:

A set of punch and dies press molds-Picture courtesy: shopee

Punches act like a mold and are used to compress the powder into tablets. The size, shape and dimensions of the tablet depend upon the size and shape of the punches and dies. Punches are of two types, upper punch and lower punch. The pressure is transferred from the rollers through these punches to the powder in the die cavity and the powder is compressed into tablet in between the upper and lower punch.

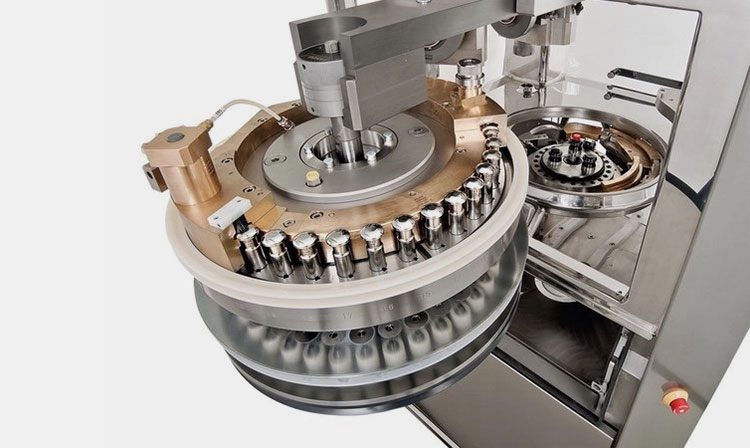

Turret:

Turret with set of punches and dies – Picture courtesy: finalwe pharma

The process of the tablet compression starts with rotating of the turrets, therefore turret is said to be the heart of the tablet pressing machines. It is a rotating platform with sets of die and punches. These dies and punch stations are arranged over the turret in a circular manner. The number of these stations determines the main capacity of the tablet pressing machines; this relation is directly proportional to each other.

The manufacturing industry is achieving higher output by increasing the compression speed of turret, increasing the number of dies and punch stations and increasing the points of compression.

The turret is provided with a motor and gear system, which enables the rotation of the turret and ensures a precise rotation. It has heavy duty ball bearings, which provide friction less movement.

Pressure rollers:

Pressure rollers over the punches- picture courtesy: pharma approach

During the entire compression process, the vertical movement of the upper and lower punches is controlled by a well devised system of pressure rollers and cams.

Different types of cams and rollers are responsible for different stages of the process:

Pre pressure roller: provides pre compression force for uniform density and good powder flow.

Main pressure roller: applies the final compression force to shape the tablet.

Swipe of blade/drive system:

Finely compressed tablets-picture courtesy: EPR

When the compressed tablets are ejected out of the die cavity, swipe of blade deflects or guide the tablet toward the discharging chute. The tablets are then collected from the discharge chute.

Tablet discharge from discharge chute:

Image showing discharge chute of tablet pressing machine-picture courtesy: pharma education

When the tablet is compressed, the lower punch pushes the compressed tablet put of the die cavity and the upper punches make the top punches come back to their original position. As a result of all these events, the scrapper removes the compressed tablet from the compression machine to the discharge tube.

6.What is tooling and how to choose the right tooling type for high speed tablet pressing machine?

Tablet punches and dies and dies with different tooling-Picture courtesy: bhagwati pharma

Tooling refers to integral part of the tablet pressing machine, which is required to press the tablet. The three main parts of the machine which are termed as tooling are upper punch, lower punch and dies. The size, shape, weight and quality of the tablet depend upon these three parts, i.e., tooling of the tablet pressing machine.

There are four types of tooling available:

- B type tooling

- D type tooling

- BB type tooling

- DB type tooling

The punch length remains the same in all types of tooling. The die height also remains the same except for the D type tooling, in which die height is 23.82mm instead of 22.22mm.

The main difference lies in the punch barrel diameter and outer diameter of the die.

The table below shows the difference in dimension among the tooling types.

| Type | Barrel diameter -mm | Die Diameter -mm | Die Height -mm |

| B | 19.0 | 30.15 | 22.22 |

| D | 25.4 | 38.10 | 23.82 |

| BB | 19.0 | 24.0 | 22.22 |

| DB | 25.4 | 30.15 | 22.22 |

The main differences between the tooling types and which is the right tooling for the desired tablet product is as below:

Different sizes of tablets achieved through different types of tooling- Picture courtesy: research gate

B type tooling:

The b type tooling configuration is normal, and is used for small to medium sized tablets, and is suitable when high output capacity is required, keeping a normal size of the tablets.

BBtype tooling:

It is another type of B type tooling; it is smaller than the B type of tooling, having a die diameter of 24mm. It is best suited for smaller size tablets, ranging from 9mm diameter to a maximum size of 11mm diameter.

It gives a moderate output capacity.

D type tooling:

D type tooling is specially used for large size tablets, having a larger die diameter. It has the capacity to exert larger pressure on the powder. It offers a medium output capacity as compared to the B type tooling.

DB type tooling:

DB type tolling offers high output capacity, with smaller to medium sized tablets.

Application of tooling in shape and embossing of the tablet:

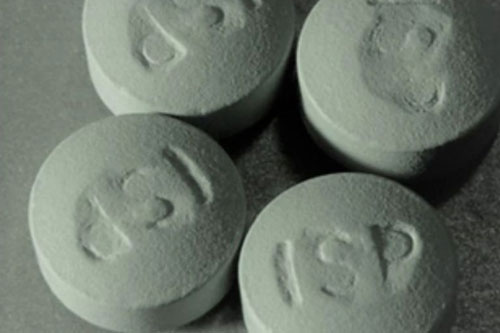

Various shapes of tablets-Picture courtesy: cadmach

Apart from the volume and quantity of the tablet production, tooling can be customized to produce tablets of various size, shapes including round, oval, geometric, and as well as embossing of specific symbol or alphabets on the tablet.

7.What is the impact of machine speed on tablet hardness in high speed tablet pressing machine?

Finely compressed bi layer tablets-Picture courtesy: outsourced pharma

The most critical thing while compressing a tablet is the tablet hardness. The optimal rotating speed of the compression rollers not only affect the tablet hardness, but other attributes related to it, like disintegration, friability and dissolution. These features further impact the transportation and coating of the tablet.

The ultimate goal during compression of tablet is to maintain the required tablet hardness along with the content uniformity.

Dwell time:

The amount of time powder comes in contact with the punch head is the dwell time. Also, the amount of time for which the punch head and pressure rollers remain in contact with each other is the dwell time.

Relation of dwell time and hardness:

The production rate increases with the increase in the speed of the machine, but an optimum speed level is important to be maintained, as high speed can also decrease the dwell time of the powder under compression, resulting in decreased tablet hardness.

Similarly, reduced speed increase the dwell time leading to better bonding of the powder particles and increased hardness.

There is a technical relationship between the dwell time and the tablet hardness. Hence, the balance in the speed of the machine is necessary to obtain a tablet of desired hardness and characteristics.

8.What is the typical output and rpm of the high speed tablet pressing machine?

A high speed double punch rotary press turret with multiple stations-Picture courtesy: Elizabeth companies

The output of the machine depends upon the number of punch and dies station on the turrets and the number of rotation per minute. The rpm of the high speed double rotary press machine ranges from 70-150rpm, with an output of 70,000 to 300,000 per hour. The double rotary press has usually 27, 35,39,45,49,51,55,63 or 75 stations.

In a single rotary press we can easily calculate the output of the machine, by multiplying the number of stations on a turret with the rotating speed in a given period of time. The single rotary press has usually a 10-50 rpm. The number of station in a single rotary press usually ranges from 9 to 28 stations.

9.What type of tablets can be produced in the high speed tablet pressing machine?

High speed tablet pressing machine can produce a variety of tablets, other than the obvious pharmaceutical tablets. These high speed tablet pressing machines are well suited for any kind of large scale production. These include:

Pharmaceuticals:

Various forms of pharmaceutical tablets-picture courtesy: chemintel360

The most extensively produced tablets are the pharmaceutical tablets, which are manufactured in a large quantity by high speed tablet pressing machines. It includes over the counter and prescription tablets.

Nutraceuticals and veterinary:

A blister of multivitamin tablets

The multivitamins and nutraceutical tablets are also made in high speed tablet pressing machines. The increase in the demand of these tablets requires the manufacturer to increase the output by using advance high speed machines.

Bolus tablets:

Large size veterinary tablets

The veterinary tablets are usually larger in size than the regular human tablets. They are called bolus or slugs. They are also produced in high speed tablet pressing machines.

Non- pharmaceutical applications:

Fertilizer for the plants –Picture courtesy: Sabosib

Now days the chemical industries use the high speed tablet pressing machines to compress the chemical powder or fertilizers into tablet form. Other than those camphor balls, detergent block tablets and pesticide tablets are also made.

Camphor tablets –Picture courtesy: BBC

Confectioneries:

Artificial sweetener tablets –Picture courtesy: fit day

The confectionary industry also uses the high speed tablet press to produce processed sugar tablets, candies and such other edibles.

Cosmetics:

Compressed collagen tablets-picture courtesy: gotimoy

With so much advance and modernization in every filed, there are new methods being developed in the cosmetic industry as well. The cosmetic companies use high speed tablet pressing machines for producing pressed powder tablet and pressed masks.

10.What are the common defects of tablet compression in high speed tablet pressing machine?

The tablet compression defects are most commonly faced in all pharmaceutical industries during the production of tablets. Some of these defects are formulation related or sometimes they are machine related, which may be due to defects in the tooling of the machines or may be due to negligence of the operator.

Some of the very common defects include:

| Capping:

Due to inadequate granulation, excessive compression force or improper tooling. |

Picture courtesy: pharma sciences |

| Lamination:

Due to inadequate dies wall lubrication, over compression or improper powder mix. |

Picture courtesy: pharma sciences |

| Weight variation:

Due to uneven powder flow, incorrect metering or worn out feeders. |

Picture courtesy: pharma guddu |

| Sticking:

Due to insufficient lubrication, poor quality granulation. |

Picture courtesy: journal of engineering and technology

|

| Double impression:

Due to incorrect punch alignment, worn out punches or dies or excessive powder compression. |

Picture courtesy: pharma specialist |

11.What are the precautions to prevent compression machine accidents?

Compressed tablet flowing out the machine-picture courtesy: freepik

The high speed tablet pressing machines should be handled by proper trained and vigilant operators to avoid any kind of miss handling of the apparatus which may lead to accidents like damage of the tooling, machinery and any kind of operator accident.

Precautions are explained below to avoid the following machine accidents:

Improper dies installation:

Ensure proper cleaning of the die housing before installation of the die. The operator should check the level of the dies after installation, it should be smooth and edges should not be out of the die table. Run the speed at jog speed to ensure proper installation.

Loose die bolts:

Die bolts are the screws that are used to tighten the die in the die house. It is recommended to use proper die bolts and if the machine is taking heavy load it is recommended to tighten the bolts after regular interval of time.

Improper lubrication:

Timely lubrication of the punches is very important for the smooth running of the compression machine, to avoid any kind of friction. Do not run a machine without proper lubrication.

Punch head and tip damage:

If low quality material is used for the construction of punch, it may result in the broken punch head or tip, leading to defects in the final product tablet. Always use high quality material parts for the machine.

Over loading:

It is the increased pressure on compression machines and punches; it can be due to increase weight of the tablet or hardness of tablet. It is advised to operate the machine at slow speed to adjust the parameters; sudden weight increase at high speed can cause damage to the machine.

Moisture in the product:

High moisture content in the powder can cause the sticking of product inside the dies, which can cause over loading resulting in tooling damage. Always check for the optimum level of moisture in the product.

12.What are the features to consider when selecting a high speed tablet pressing machine for a specific formulation?

a highly calibrated double punch rotary press-picture courtesy: Romaco

Following are a list of guidelines to consider while looking for a high speed tablet pressing machine:

- Keep in mind the production capacity and speed required as per the size of batch.

- Ensure that the machine is compatible with the type of tablet intended to be produce, the size shape and quality of the tablet.

- The material of machine construction is a very critical thing to be monitored; stainless steel is resistant to corrosion.

- The material should be compatible with the machines, keeping in mind the factors like stickiness and flow ability.

- It is better to choose a machine that is easy to operate and require less operator training.

- Machines with higher level of automation can increase the efficiency and reduce labor cost.

Conclusion:

The choice of right type of high speed tablet pressing machine is very important to meet the production needs for all types of pharmaceutical and non-pharmaceutical production of tablets on large scale. The automation of smart controls and compliance doesn’t only offer speed but they provide precision and reliability. The production is optimized by the right tooling, output capacity, ease of maintenance and regulatory standards. While choosing the high speed tablet pressing machine, keep in mind your production plans and needs, which will align with the equipment you, are choosing. For more information feel free to contact AIPAK team now.

Don't forget to share this post!

Tablet Press Machine Related Posts

Tablet Press Machine Related Products

Tablet Press Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine