Filling Machine for Powder: The Complete FAQ Guide In 2025

Powders find their significant place when filled perfectly and accurately. For medical fields, pharmaceuticals, food businesses, and others, having a comprehensive and uninterrupted powder filling workflow is always an essentiality. A little or minor disruption in your production process can disturb the operation and may lead to loss in various aspects, such as product, time, energy, and inconsistencies of powder filling batches. This is where a filling machine for powder comes to play!

In this article, you will explore in-depth knowledge on how a filling machine for powder offers an uninterrupted and dust-free dispensing. Whether you’re running a small business or belong to a large-scale operating business, the right powder-filling machine for powder can revolutionize your business. So, in this blog, the described insight discussion will help you to opt for the best machine according to your requirements

1.What is a filling machine for powder?

AIPAK Filling Machine for Powder

The filling machine for powder is a comprehensive solution for dosing of both free-flowing and non-free-flowing materials that are significantly important in medical and non-medical care fields.

To process powders is a difficult task; the fine powders are capable of generating dust easily, so the machine is an absolute solution to dispense challenging and complex materials with consistency. Consequently, the machine guarantees efficient, hygienic powder filling with the use of auger screws, vibration, or vacuum-based filling systems.

2.Why choose a filling machine for powder?

Here’s how investing in a filling machine for powder offers various benefits:

Precision and Uniformity in Every Batch

Precision Throughout Batches

The filling machine for powder features a developed weighing system that regulates high speed and promises accurate weight or volume in each container. Therefore, you will not suffer from unnecessary product wastage, maintain product uniformity, and meet strict dosing standards required in regulated industries.

High-Speed and Spontaneous Action

Fast Speed- Maximum Volume

With advanced automation, these machines support high-volume production lines, minimize downtime, and reduce labor dependency. This helps manufacturers meet growing market demand without sacrificing accuracy.

Hygienic and Controlled Environments

Hygienic and Controlled Environments- Picture Courtesy: Altrimex

Sensitive powders are easily protected, and cleanliness is maintained in controlled environments. Most fillers are designed with robust materials such as stainless steel and feature dust-tight enclosures to avoid puffing of powdery dust in a working environment. Thus, operators and working conditions are safe with the filling machine for powder.

Compatible with a Wide Range of Materials

Wide Range of Materials- Picture Courtesy: Twentronix

Modern filling machine for powders handles free-flowing, semi-sticky, and ultra-fine powders with minimal adjustments. This versatility ensures smoother production across diverse product types, from baby formula to chemical agents.

Cost-Efficient and Low-Waste Operations

Cost-Efficient and Low-Waste Operations- Picture courtesy: Syntegon

The filling machine for powder detects variation in weights in a swift manner. Intelligent sensors and dosing systems reduce overfill, prevent spillage, and ensure optimal use of raw materials. The modular design leads to better operational efficiency and reduced production waste so offering cost savings benefits.

Easy Integration and Maintenance

Easy Integration and Maintenance

Speed and time is significant in every production industry. Most filling machines for powders integrate smoothly into automated packaging lines, making upgrades hassle-free and fast operation. Additionally, modular designs with user-friendly controls allow quick changeovers and simple cleaning.

3.In what industries do you find the filling machine for powder?

It is an important question that may come to your mind if you’re a first-time machine buyer or interested in the powder filling process. As almost every global industry manufactures or processes powder, the filling machine for powder has a central role in every single one of them. Here are a few major sectors in which this system is found:

Food Industry

Food Industry

In the food industry, an auger filling machine for powder is extensively utilized for its consistency and negligible batch-to-batch variation. Due to its quick format change-over, you can easily fill almost any kind of powder, whether ground spices, herbs, flour, salt, seasoning, chili powder, baking mixes, dairy powder, or Jell-O powders, with this machine.

Pharmaceutical Industry

Pharmaceutical Products

When packaging pharmaceutical products, for example, antibiotics, laxatives, antacids, snuff, and analgesic powders, exact dosing is all that matters. Hence, using a filling machine for powder in the pharmaceutical industry allows manufacturers to attain the highest level of accuracy and sterility.

Nutraceutical Industry

Nutraceutical Industry- Picture Courtesy: Nutra-Life

To accommodate the all-time high demand for nutraceutical powder, including protein (whey, casein, collagen), amino acids (glutamine, beta-alanine), vitamins, minerals, antioxidants, probiotics, and other specialized nutraceutical powders, manufacturers add a filling machine for powder to their production to ensure dosing accuracy and minimize wastage.

Chemical Industry

Chemical Industry- Picture Courtesy: CDH Fine

The filling machine for powder is the first choice to handle abrasive, corrosive, cohesive, volatile, or even toxic chemicals. In fact, this system safely handles and fills your challenging powders, like cleaning powders, varnishes, and adhesives safely without exposing operators to these harsh chemicals.

Cosmetic Industry

Cosmetic Products

Often, cosmetic powders such as henna powder, face masks, dusting powder, various glitters, face cleaners, and dry shampoos are considered premium products. Hence, they should be packed precisely in containers because even a minute filling discrepancy can lead to major product loss. To overcome this challenge, a filling machine for powder is a must in the cosmetic industry.

Agriculture Industry

Agriculture Industry- Picture Courtesy: Aptus Plant Tech

In the agriculture production lines, a filling machine for powder is utilized for dispensing powdered fertilizer, herbicides, pesticides, humus, manure, and animal feed in bottles, pouches, or even drums. A major pro of this system is that it can easily pack bulk volumes of agricultural goods efficiently.

4.What types of filling machine for powder are there?

It is quite hard to find a perfect filling machine for powder unless you learn about its types. Indeed, there is a wide array of filling machines for powder that provide you with capacity utilization. So, without delaying, let’s look into each type one by one for better optimization of your production process:

By the Filling Principle

Cup Filling Machine for Powder

Cup Filling Machine for Powders- Picture Courtesy: All-Fill

If you run production in which time is more critical than dosing accuracy, you can rely on the powder cup filling machine. Certainly, you can find this system useful in the food industry, like for packing sugar and grains. This is because these products are retailed by volume, instead of weight. A premeasured cup is a distinctive part of this equipment by which the latter scoops and doses powders.

Vacuum Filling machine for powder

Vacuum filling machine for powder

In this equipment, a vacuum is created that provides the necessary suction force to pull powders through dosing devices and ultimately to your containers. Using this system, you can preserve the quality of goods that are exceedingly fragile, whether flour or instant milk formula. This system is capable of packaging extremely light powder because it can modify its filling speed according to the item's settling rate.

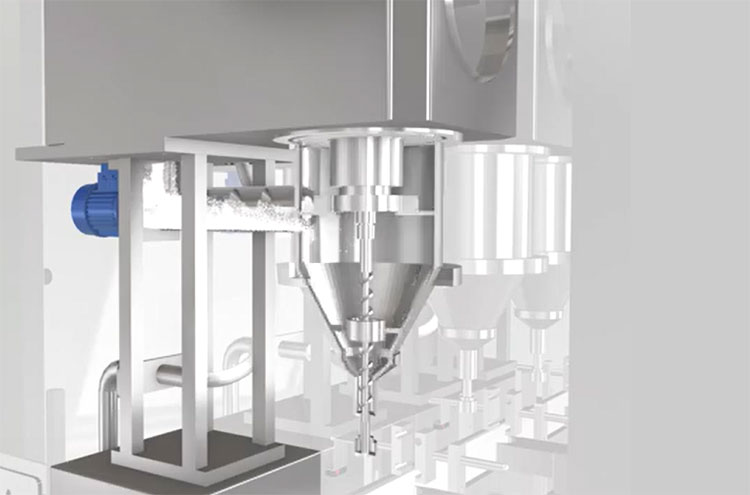

Auger Filling Machine for Powder

Auger Filling Machine

The auger filling machine comes with a revolving auger. This component is the main part involved in powder filling. It can be your go-to choice if you’re dealing with fine powders. Because not only is it more efficient, but it also keeps dust from getting into the product. Moreover, you can design your auger filling system in such a way that there is no entry of air during product loading.

Net Weight Filling Machine for Powder

Net Weight Filling Machine for Powder- Picture Courtesy: ACCUTEK

In this machine, your filling operation typically starts with the machine weighing the quantity of your chosen powder. Its precise weight-filling feature gives it a competitive positioning over other machines. And precision is achieved by decreasing the dribble feed speed as the target weight approaches.

By Automation Level

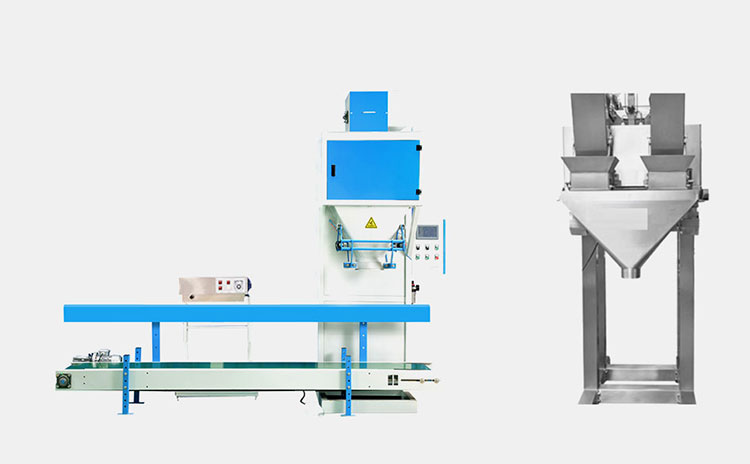

Semi-Automatic Filling Machine for Powder

AIPAK Semi-Automatic Filling Machine for Powder

The semi automatic filling machine for powder combines two modes of working (manual and automatic) in one system and is suitable for medium-sized industries that need more speed and precision in the filling process. Simply put, in this device, operators have to put containers, whether pouches or bottles, on the conveyor, while the machine automatically handles the filling process without any assistance from operators.

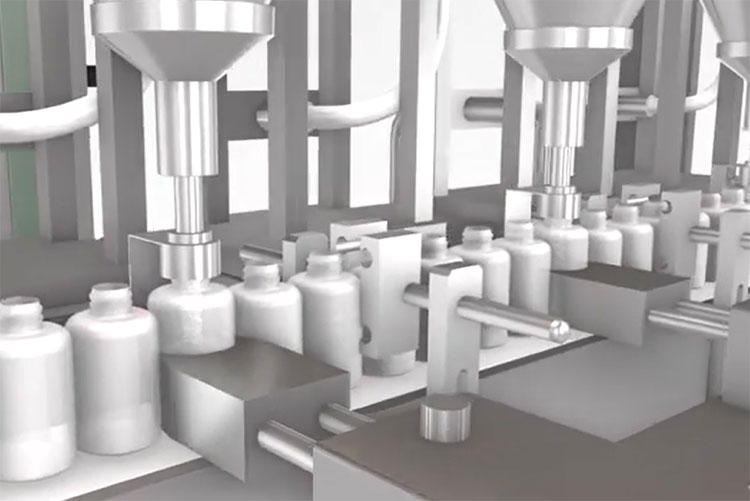

Fully Automatic Filling Machine for Powder

AIPAK Fully Automatic Filling Machine for Powder

A fully automatic filling machine for powder is an advanced unit that carries out the filling operation all by itself with just programming by operators. It is worth mentioning that this device is synonymous with adaptability and can easily process diverse product types. In addition to this, it provides fill weight integrity with an error margin of less than 1%.

By Container Handling

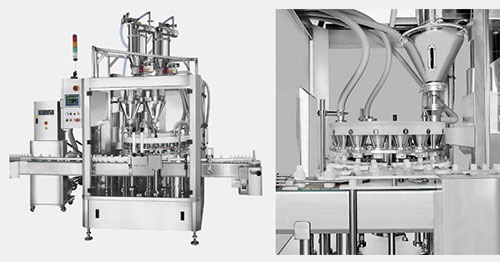

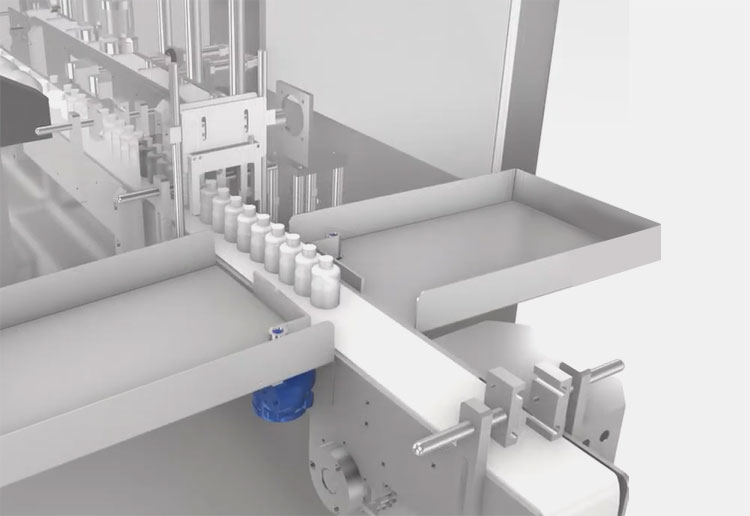

Bottle Filling Machine for Powder

AIPAK Bottle Filling Machine for Powder

Structurally, this equipment is very different from its counterparts and comes with a conveyor on which you’ll position bottles. To prevent tumbling of bottles or jars on conveyors, this equipment comes with grippers or star wheels, while the load cells, agitators, and filling nozzles aid in measuring and filling sequence.

Sachet/Stick Pack Filling Machine for Powder

AIPAK Sachet/Stick Pack Filling Machine for Powder

Usually, you see sachet/stick pack filling machine in the vertical compact configuration. It comes in both single-lane and multi-lane configurations and is used for making long, narrow, and flat rectangular packets called stick packs or sachets, respectively. With the help of a film unwinder, forming tube, vertical and horizontal sealing jaws, it forms sachets and stick packs.

Pouch Filling Machine for Powder

AIPAK Premade Pouch Filling Machine for Powder

With higher demand for flexible packaging, the pouch filling machine is gaining quite a traction in modern industries. It is an efficient system and can make many pouches per minute. Also, it has another form that fills powder in pre-made pouches. Hence, many packaging units prefer this filling machine for powder due to its fast and inexpensive packaging for everyday products.

Capsule Filling Machine for Powder

AIPAK Automatic Capsule Filling Machine for Powder

In the pharmaceutical and nutraceutical industries, the capsule filling machine has a prime place. Depending on their automation, capsule filling machines for powder have various output capacities. Normally, the first capsules are separated into caps and bodies, and then they’re dosed with powders using tamping and dosator methods.

Vial Filling Machine for Powder

AIPAK ENGINEERING Vial Filling Line for Powder

With the help of vial filling machine, you can pack lyophilized powder and non-lyophilized powder into vials. Typically, a star wheel or indexing unit is used for vial positioning, whereas dosing nozzles are integral in powder loading. Finally, you’ve stoppering station in this unit that affixes stoppers or closures in vials once they’re filled to programmed capacity.

5.What are the common designs of a filling machine for powder?

By understanding the structural designs of a filling machine for powder, you can enhance operational efficiency and streamline your packaging workflow. In case you’re wondering, here is a brief overview of various designs of a filling machine for powder:

| Multi-Head Filling Machine for Powder

Multi-Head Filling Machine For Powder |

This system comes with multiple filling stations, and due to the synchronized action of these multi-heads, your filling throughput is increased multi-fold.

Manufacturing units prefer to have a multi-head filling machine for powder if they’re running a mass-scale operation that needs both fill precision and speed. It allows them to pack several containers in quick succession. |

| Rotary Filling Machine for Powder

Rotary filling machine for powder- Picture courtesy: CVC technology |

You can see that this type of design adopts a circular configuration with a star wheel or turntable as a main fixture. Instead of traveling sequentially, the container moves in a circle around the round platform for filling.

The design has a value for you if you need quick packaging, since it mitigates downtimes and loads multiple containers in one cycle. |

| Inline Filling Machine for Powder

Filling machine for powder |

This design is often ideal for moderate operation. Because it only allows one-by-one dosing of containers due to its linear configuration style. With the help of this simple equipment, you can easily fulfill your minimal filling needs. It’s another plus point is its compact structure, due to which you can easily integrate this unit into space-restricted facilities. |

6.What are the working steps of the filling machine for powders?

Many people incorrectly assume that there is only a single step in the operation of a powder-filling machine for powder. Rather, its working consists of several steps that are discussed in the following section:

Container Loading

Container Loading

First of all, empty containers, whether bottles or cans, are loaded on the machine typically by a conveyor belt. In some cases, operators manually position and align containers on the machine.

Powder Infeed

Powder Infeed

Also, before turning on the equipment, the bulk load of powder is fed into the conical hopper, normally present at the top of the filling mechanism. These hoppers are usually equipped with agitators to facilitate smooth powder flow from the hopper to the filling station.

Metering

Metering

Now it's time for the central act in the working of the filling machine for powder. The materials present in hoppers are accurately metered into the filling mechanism using either auger screws, measuring cups, vibration, gravitational pull, or vacuum systems.

Dispensing or Filling

Filling of powder

Afterwards, measured powder is loaded into containers through filling nozzles that are generally controlled by precision-engineered valves. This allows you to control the flowability of powders into the container and prevent over- or under-filling.

In some cases, a vibration or leveling tool may be used after filling to compact powders and achieve a denser, consistent, and even fill.

Container Sealing

Final Sealing

Lastly, containers are sealed or capped by transferring them to sealing units. Depending upon the container, it might be sealed by affixing a stopper on its opening, or capped using screw or snap-on caps. Sometimes, packaging, for instance, bags or pouches are hermetically closed using adhesives, heat, pressure, or ultrasonic rays.

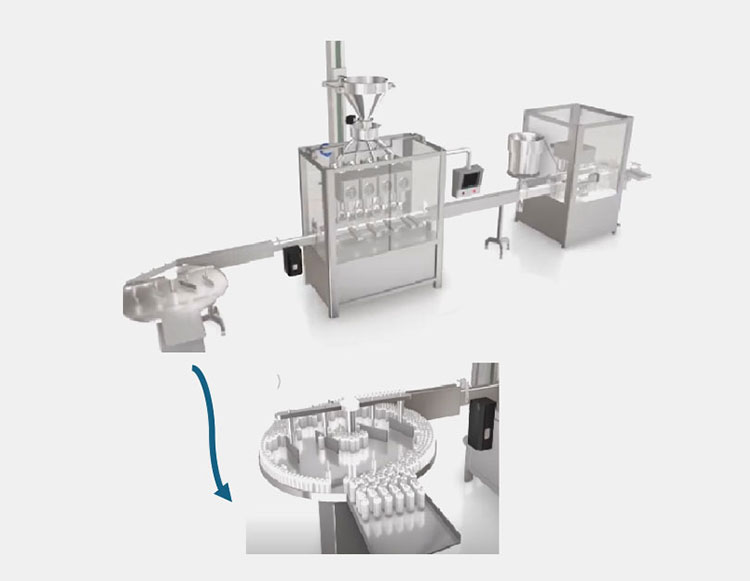

7.What is a complete production line of a filling machine for powder?

AIPAK Production Line of a Filling Machine for Powder

Based on leading production requirements and supporting fast filling activities, the complete production line of a filling machine for powder is designed. This is composed of a certain machine to present a leading production solution, such as a bottle unscrambler machine, that ensures uniformity and aligns the release of filling containers in the procedure of filling.

The capping machine is integrated to allow convenient securing of filled packaging material with automatic sensing and firm screwing of lids. Each individual packaging is sealed when it passes through the aluminium foil sealing machine, which produces tamper-evident protection with induction of electromagnetic radiation. The labeling and coding machine is integrated to offer the final formalities of packaging, including information related to products, codes, and necessary details.

8.What challenges are related to the filling machine for powder?

Filling machine for powders are essential across diverse industries, but they face several challenges depending on different factors. Some of the challenges are.

Inconsistent Powder Flow

Powder flow problems-Picture Courtesy: Pharma Exicpient

Some powders, due to their hygroscopic and cohesive properties, have inconsistent flow behavior. Due to this, the powder may clog, clump together and flow unevenly, resulting in challenges during filling process.

To prevent inconsistent powder flow, it is important to use auger fillers, which are particularly suitable for handling irregular powder flow, in case of clumpiness knockers are used to facilitate bridge breaking.

Dust Emission

Fine particles-Picture Courtesy: GoodRx

Fine powders, especially those with high air content and strong electrostatic retention are prone to airborne dispersion. This dust emission leads to increased risk of cross contamination, product loss and safety concerns for operators.

This challenge can be avoided through enclosed filling systems with dust extraction properties and electrostatic neutralization.

Blockage of Powder

Blockage of Powder

Clumpy and electrostatic powder may cause blockage and clogging during filling process, disrupting the flow area especially filling nozzles and hopper. These challenges can result in defected production cycles, irregular dosing and increased maintenance of machine.

To prevent the issue, it is recommended to apply coating of fluororesin inside the surface of which improves the slipperiness, constant agitation and vibration-assisted hoppers for smooth powder flow.

9.How to choose the right filling machine for powder?

Choosing the right kind of machine for filling powder is the most critical step, depending upon numerous factors. Some of the factors to consider while selecting a filling machine for powder are as follows.

Powder Type

Different types of powders- Picture Courtesy: Evonik and Lyrin

The most important factor to consider before choosing a filling machine is the type of powder. There are typically two types of powders, such as free-flowing powders and non-free flowing powders. Choosing the machine type based on powder categories ensures safe operational efficiency, accurate dosing and enhance product quality.

Packaging Type

Different Types of Packaging

After evaluating the powder type, it is essential to take into consideration the type of packaging that you are going to use. There are several kinds of packaging such as bottles, jars, cans, and containers. Some machines are versatile while some of them are designed for specific formats.

Production Volume

Production Volume-Picture Courtesy: Autopack UK

There are different kinds of filling machine based on the type of production volume. For small-scale to medium-scale production, semi-automatic machines are preferred as they suit the production volume and are also cost-effective. For large-scale production, fully automatic machines are suitable as they offer consistency, advanced system and speed.

Conclusion

Filling of powder requires awareness of principles, behaviours of powders, and knowledge of right equipment. one must know importance of such parameters to bring successful work outcomes. Based on customer’s demands, AIPAK is able to provide well executed plan related to filling machine for powder which is included with dust management, operator safety, and pocket friendly solutions. Today, we are serving pharmaceuticals, foods, chemicals, research and many other fields across the globe with tremendous project reviews. Our focus is customer’s priority; if you’re looking for machine’s technical or procurement help, you’re welcome to message us now.

Don't forget to share this post!

Powder Filling Machine Related Products

Powder Filling Machine Related Posts

Powder Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 156 0710 8630

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine