Creatine Capsules: The Complete FAQ Guide in 2025

Are you aware that creatine capsules are the most frequently used supplements by fitness enthusiasts? In 2025, creatine capsules continue to dominate the fitness industry market due to their user-friendly format and proven effects on strength and recovery. Gym-goers and athletes rely on creatine capsules to enhance their muscle strength, improved physical health, and speedy recovery.

This comprehensive guide outlines in-depth knowledge about creatine capsules, from their importance to their manufacturing process. Whether you are an athlete, fitness enthusiast, or a manufacturer, you will find this guide very helpful to gain insights about creatine capsules. Let’s dive right in.

1.What are creatine capsules?

Creatine capsules- Picture Courtesy: Earth Nutri

Creatine capsules are comprised of creatine monohydrate powder. It is best known for its energy boosting properties and mainly present in the cells of your muscles. These capsules are crafted to improve energy, muscle strength, and athletic performance. You can easily use them as some people dislike the taste of its powder formulation even though it is odorless and tasteless. However, the enclosed formulation ensure a flexible administration via oral intake.

2.When did creatine capsules become popular?

Creatine capsules formulations- Picture Courtesy: Eat This, Not That

The growth in popularity of creatine capsules began in the late 1990s and early 2000s, when creatine monohydrate became well-known for its impact on the health and fitness industry globally.

Research indicated creatine’s efficiency in improving muscle health and athletic performance. Soon after that, supplement companies started offering creatine in different formulations, the most popular one being capsule, as they are easy to consume.

3.In what ways are the creatine capsules beneficial?

Creatine capsule intake- Picture Courtesy: Extreme Nutrition

Creatine capsules have a number of benefits, some of which are mentioned below.

| Significant | Description |

| Improves Muscle Strength

Creatine capsule intake with water |

Creatine capsules help the body generate more energy during intense workout sessions.

Creatine increases ATP (adenosine triphosphate) in the body, which is the main source of energy. |

| Boost Recovery

Muscle soreness- Picture Courtesy: NASM Blog |

After intense workout sessions, your muscles experience inflammation and soreness. Creatine capsules help by reducing inflammation and restoring energy levels rapidly. |

| Ease of Use

Creatine capsule jar- Picture Courtesy: Women’s Best |

Creatine capsules are hassle-free to consume. Just take them with water, no powder mixing or measuring scoops required, ideal for busy individuals.

This ease of use helps you stay consistent with your supplement routine. |

| Improved Physical Activity

Weightlifting- Picture Courtesy: Your Health |

Creatine capsules support high-intensity workouts like heavy weight lifting and HIIT sessions.

They boost energy level during intense physical activity, resulting in more working out sessions without making you tired soon. |

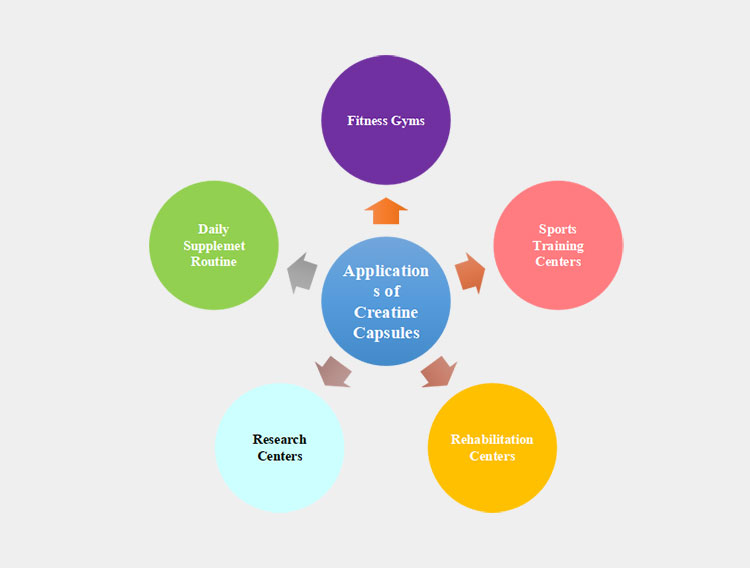

4.What are the typical applications of creatine capsules?

Creatine capsules have various applications and some of them are described below:

Creatine Capsule Applications: Graphical Representation

Fitness Gym

Muscle Support - Picture Courtesy: musclesblaze

If you go to gym, it is commonly used there. Because of intense body workout, the level of creatine keep releasing to replenish your body with energy. Even in the case of muscle spasm or fatigue, creatine capsules help in speeding up recovery.

Sports Training Centers

Powered by creatine-Picture Courtesy: NutraIngredients.com

Creatine capsules are widely used by athletes as part of their training and practice routines. These capsules are specifically important in sports that require a lot of energy, like football, weightlifting, track running and more, to improve performance.

Rehabilitation Centers

Rehabilitation center exercises- Picture Courtesy: Northwell Health

Creatine capsules are often used in rehabilitation centers and physical therapy centers as part of a recovery plan, especially in cases of muscle injury or surgical operation recovery. These capsules help in overall functioning by enhancing energy levels within muscle cells. Under professional supervision and care, creatine capsules accelerate recovery and boost the rehabilitation process.

Research Centers

Research team- Picture Courtesy: Virginia Tech

Creatine capsules are commonly studied in research centers and clinical trials to explore their possible treatment benefits beyond sports and fitness. Researchers study its impact on muscle-related issues such as muscle dystrophy, age-related muscle loss and recovery from specific muscle injuries. These research studies are conducted under strict operation protocols to evaluate creatine capsule safety and therapeutic benefits.

Daily Supplement Routine

Creatine Capsule

Many individuals add creatine capsules to their daily supplement routine at the ease of their own homes. The capsule formulation is preferred by many consumers as it doesn’t involve the hassle of measuring scoops and mixing powder to form a solution, since all of these are time-consuming practices. This formulation saves time and offers a convenient, pre-measured solution that can easily be added daily in a supplement routine.

5.What are the common types of creatine capsules that are used?

Creatine capsules are available in different types; some of them are mentioned below.

Creatine Monohydrate Capsules

Creatine Monohydrate Formula- Picture Courtesy: Horbaach

Creatine monohydrate capsule are the most common type, also used the most in research studies. They are popular among athletes because of their ability to improve muscle strength, physical strength and overall health. Along with its effective properties, it is the most affordable formulation available on the market, that is why most consumers prefer it.

Creatine Hydrochloric Capsules

Creatine Hydrochloric Capsules - Picture Courtesy: Faithful To Nature

Another type of creatine capsule is creatine hydrochloric capsules; this type is more soluble in water, making it easier to mix and absorb. It is also said to have a gentle effect on the stomach, so people with bloating and water retention issues prefer this type.

Buffered Creatine Capsules

Buffered Creatine Kre-Alkalyn Capsules- Picture Courtesy: Now Foods

Buffered creatine capsules for e.g. Kre-Alkalyn are designed with higher PH level, this PH level makes the creatine more stable and prevents the creatine from breaking down into creatinine. This type of creatine is also mild on the stomach and less likely to cause side effects. It is popular among people who want a mild choice that will be well-tolerated by their system.

Ethyl Ester Creatine Capsules

Creatine Ethyl Ester Capsules- Picture Courtesy: Matrix Nutrition

Creatine ethyl ester capsule was designed to be more lipophilic. For e.g., it was made more fat-soluble to help pass is through cell membrane easily. However, after some passage of time, research showed that ethyl ester creatine breaks down into creatinine way faster than expected making it ineffective. For this reason, ethyl ester creatine capsule is not the most common type used.

Micronized Creatine Capsules

Micronized Creatine Capsules Container- Picture Courtesy: Ultimate Sup

Micronized creatine capsules consist of creatine monohydrate in finely ground form, as it helps the creatine dissolve properly in water. This fine grounding process is called micronizing. This micronized creatine capsule form is said to be milder than creatine monohydrate since it easily dissolves in water, preventing bloating and stomach issues.

6.What is the composition of creatine capsules?

Creatin Capsules- Picture courtesy: EarthBorn

Creatine capsules are nutritional supplements designed for muscle strength and recovery. They consist of a number of ingredients and components. Here’s a list of the composition of creatine capsules.

| Components | Description |

| Active Ingredients | The most common active ingredient used in creatine, while other active ingredients include creatine hydrochloride, buffered creatine and creatine ethyl ester. |

| Fillers

|

Fillers are binders that are used to bind and fill the powder. Some common fillers in creatine capsules are microcrystalline cellulose, dicalcium phosphate, and more. |

| Flow Agents | Flow agents are anti-cracking components that prevent the capsule from cracking and breaking to ensure safe manufacturing. Common flow agents include magnesium stearate and silicon dioxide. |

| Preservatives & Stabilizers | Preservatives and stabilizers are added to creatine capsules to add shelf life to the capsules and improve their stability and safety. |

| Capsule Shell | The capsule shell in creatine capsules is either made from gelatin or is plant-based; it is the outer covering of creatine capsules. |

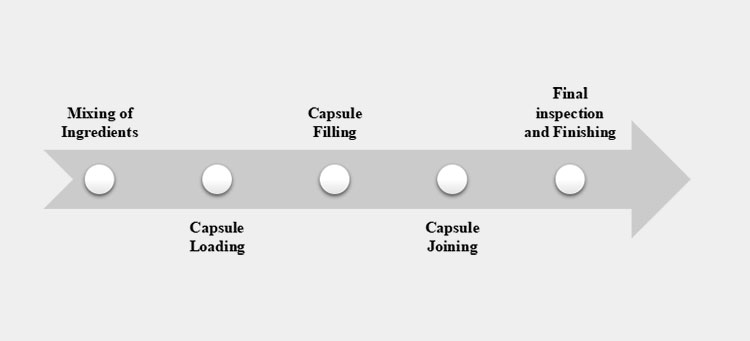

7.How do you manufacture creatine capsules?

Manufacturing of creatine capsules is a precise process involving several crucial steps. From capsule formation to packaging. Each step is carried out with great care to ensure the capsules are stable, safe, and effective. Here’s a detailed explanation

Creatine Capsule Manufacturing Process Flow Diagram

| Steps | Description |

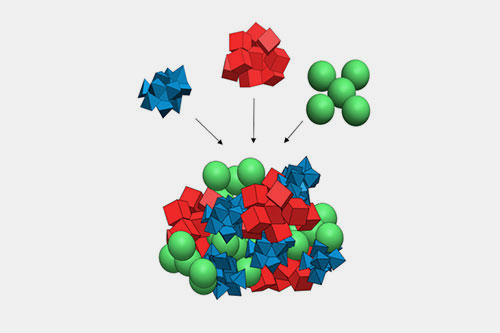

| Step 1: Mixing of Ingredients

Mixing- Picture Courtesy:CinChem |

The first step of manufacturing creatine capsule involves mixing of creatine powder with other excipients. The precise mixing process ensures capsule’s stability and flow.

This is the most important step in order to achieve uniform distribution of ingredients in every capsule. |

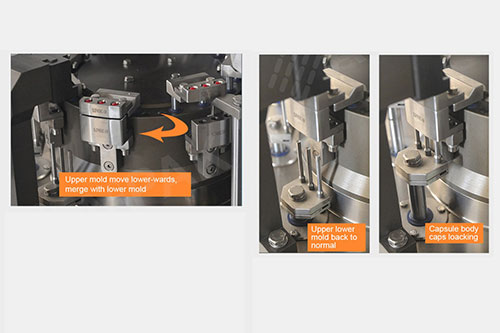

| Step 2: Material Loading

Material Loading |

After mixing of ingredients, filling material and the empty capsules are loaded into the capsule filling machine.

The machine works by separating the capsule shell into two parts i.e. cap and body. |

| Step 3: Capsule Filling

Capsule Filling |

In this process, automated filling machines are used. The process starts with loading of capsules in the orientation station, where they are separated into caps and bodies and aligned properly. The caps are then lifted while the bodies remain in place.

Using either the dosator or tamping method, the creatine powder is filled and the cap is placed back. |

| Step 4: Capsule Joining

Joining Station |

After the capsule filling process, the capsule shell caps and bodies are joined together and locked. This process is performed by gentle pressure through a machine. This step ensures tight sealing to avoid wastage and leakage of creatine. |

| Step 5: Final inspection and Finishing

Final Inspection And Finishing |

Following capsule joining, each batch goes through testing process in order to check capsule weight, ensure proper filling and locking and to check for any defects.

To prevent the product from contamination, it goes through metal detectors. After testing and approval the capsules are packed into bottles and desiccants are added to prevent moisture. The products are labeled and stored in controlled environments for shipment and distribution. |

8.What types of machines are used in the manufacturing process of creatine capsules?

There are different types of machines available depending on the manufacturing requirements.

Here’s a list of all machines used in the manufacturing process of creatine capsules.

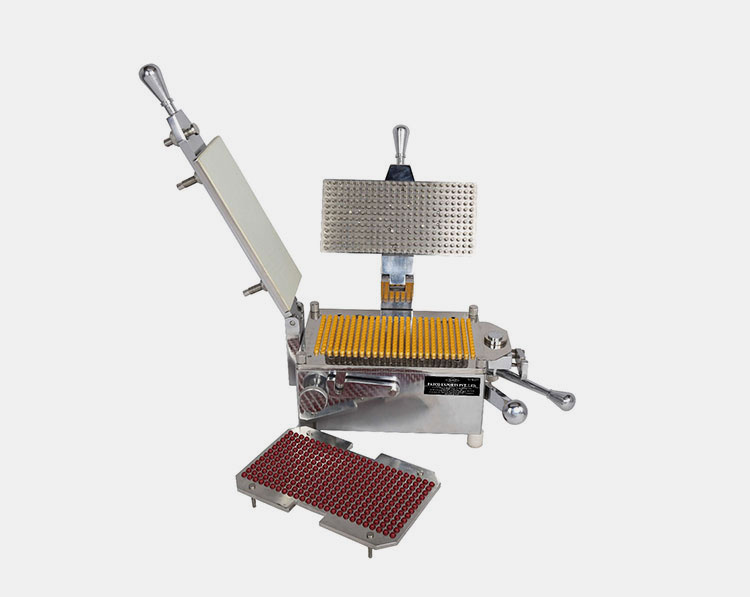

Manual Creatine Capsules Machine

Manual Creatine Capsule Machine- Picture Courtesy: Patco Pharma

Manual machines are operated by hand, typically required for small-scale production. These machines are completely dependent on operators and handlers and cannot do any function on their own. These machines are inexpensive but require labor and time and there is often a chance of error and inconsistency.

Semi-Automatic Creatine Capsules Machine

Aipak Semi-Automatic Creatine Capsules Machine

Semi-automatic machines have manual and automatic functions. These machine save time by offering some automated mechanisms but they still require human and operator intervention. Semi-automatic machines are ideal for medium-scale production.

Automatic Creatine Capsules Machine

Aipak automatic Creatine Capsules machine

Fully automatic creatine capsules machines are designed to handle the entire manufacturing process by themselves. From loading, filling to packing, the entire process is carried out by the machine itself with zero human intervention. These kinds of machines are ideal for large-scale production as they offer high accuracy and precision.

9.What auxiliary machines are used in the production of creatine capsules?

The production process of creatine capsules is a complex procedure, relying on a number of specially equipped machines. These machines are specialized with automated systems to ensure precise manufacturing of creatine capsules. Some of the machines are listed below.

Capsule Polishing Machine

Aipak Automatic Capsule Polishing Machine

The purpose of capsule polishing machine is to prevent dust and residue contamination on the surface of filled capsules. It ensures that the capsules are clean and safe before packaging. It works by rotating filled capsules with the help of soft brushes or cloth rollers, which remove any dust from their surface.

Capsule Dust Collector/Vacuum Cleaner

Capsule dust collector- Picture Courtesy: Hanningfield

In creatine capsule manufacturing, powder molecules are often extracted and can be wasted. The dust collector helps in collecting excessive powder around the machinery surfaces. By this machine removal of powdery particles also prevents the risk of contamination.

Vacuum Capsule Loader

Vacuum Capsule Loader- Picture Courtesy: PTK

A vacuum capsule loader automatically loads empty capsules into the filling machine. The machine uses vacuum suction to lift and feed capsules without causing any harm or disruption. This process supports less labor force while speeding up the production process.

Blister Packaging Machine

AIPAK Blister Packaging Machine

The advanced programmable control blister packaging machine works using touch screen to proceed fast packaging of creatin capsules in blisters or cavities for secure packing. The machine is fully programmed to offer sensitive deviations, detection of faults, no cross-contamination, and do not requires your valuable time. Thus it ensures that work is carried out very smoothly and yielding large packaging capacities.

Creatine Capsule Production Machine

AIPAK Creatine Capsule Production Line

Following the process of creatine capsule production line, the packaging stage starts with bottle unscrambler, counting machine, desiccant insertion machine, capping machine, induction sealing, and a labeling machine to provide easy and fast working. This process ensures smooth and continuous movement of creatine capsules filling without errors.

10.What types of packaging are used in creatine capsules?

To maintain capsule integrity and safety, it is important to ensure proper packaging of creatine capsules. Depending on the brand and storage requirements of capsules, different types of packaging are available. Following is the breakdown of common packaging options available for creatine capsules.

Jars

Jars

Plastic bottle packaging is most commonly used in creatine capsules. This kind of packaging helps protect the capsules from light and moisture. In order to prevent clumping, small moisture absorbing packet called a desiccant is also added.

Blister Packs

Supplements in blister packaging- Picture Courtesy: No whey

Blister packaging is also used for creatine capsules. In blister packs, each capsule is locked in its own compartment. This kind of packaging is ideal for individual dosing and protection from humidity and contamination.

Glass Bottles

Capsules in a glass bottle- Picture Courtesy: Creative Fabrica

Glass bottle packaging is not frequently used in creatine capsules, but it is used for premium creatine capsule products. This kind of packaging offers great moisture and chemical resistance and they are usually more expensive.

11.Are you aware of the potential side effects of taking creatine capsules?

Creatine capsules are mostly safe when taken as prescribed, but some consumers may experience mild side effects. The effectiveness of creatine capsules relies on consistency and proper use. Some of the potential side effects that may occur are mentioned below.

| Potential Side Effects | Description |

| Excessive water retention

Water retention- Picture Courtesy: IAFSTORE Blog |

One of the most common side effects of creatine capsules is water retention, which is mostly temporary.

Water retention occurs when water is drawn into muscle cells by creatine to help the muscle with hydration. This can lead to bloating or a temporary increase in body weight. Proper water intake and a balanced diet can minimize any possible bloating. |

| Stomach issues

Stomach cramps- Picture Courtesy: Sydney Gut Clinic |

While creatine capsules are tolerated fine by consumers, some of them may experience stomach discomfort.

Some of the potential stomach issues that may occur are nausea, diarrhea and stomach cramps. These happen if the creatine capsule is consumed on an empty stomach. To minimize these effects, creatine capsules should be taken after a meal ideally. |

| Muscle Fatigue

Muscle cramps- Picture Courtesy: ASPC Manipulation Therapy |

Muscle cramp is a common side effects of creatine capsules, as the capsule affects the electrolyte levels in the body if proper hydration is not maintained.

Staying hydrated can prevent this side effect, especially during an intense workout or physical activity. |

| Dehydration

|

Creatine can cause dehydration in the body as the capsule draws water into your muscles, which can alter water balance throughout the body.

Proper water intake can prevent this side effect. Symptoms like dry mouth, fatigue, or dizziness can warn that you need more water in your body. |

| Kidney stress effect

Kidney stress- Picture Courtesy: TheHealthSite |

This side effect may occur in those individuals with pre-existing kidney conditions.

Due to pre-existing kidney issues, your kidneys may struggle to filter out waste because of the workload due to higher creatine levels. Moderate use of creatine capsules and consumption as directed by a professional can minimize these side effects. |

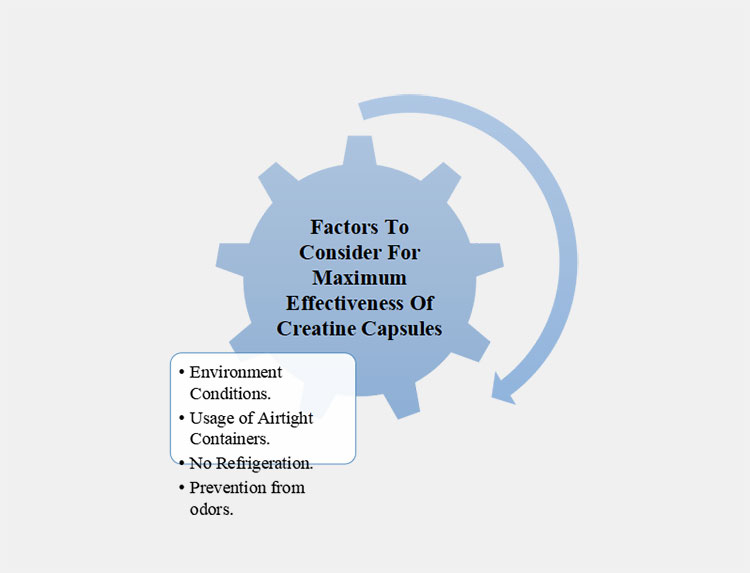

12.How do you store creatine capsules for maximum effectiveness?

Factors affecting the efficacy of creatine capsules SmartArt

To ensure the potency and stability of creatine capsules, proper storage conditions are a must. Here’s a detailed breakdown of things to keep in mind to get the maximum effectiveness of creatine capsules

Environment Conditions

Temperature sensitive creatine capsules- Picture Courtesy: WSVN

Creatine is a sensitive compound; it can lose its efficacy if exposed to elevated temperatures. Keeping that in mind, creatine capsules should be stored at a temperature below 25 °C and humidity under 50%. Do not keep the capsules in the bathroom, near the kitchen or inside vehicles, as these places contain steam and heat.

Usage of Airtight Containers

Air-tight containers and HDPE bottles- Picture Courtesy: Regent Plast

To get maximum effectiveness of creatine capsules, always keep them in air-tight, sealed containers. If not, creatine capsules can be exposed to air or light, which can lead to hydrolysis, making them less effective. The preferred packaging options for creatine capsules are HDPE bottles, blister packs, and glass jars with tight lids.

Don’t Refrigerate

Refrigeration of capsules- Picture Courtesy: Mitsubishi KYW

Refrigeration and freezing of creatine capsules is not recommended. These places have higher humidity levels, which can result in condensation inside the capsule bottle. The higher humidity level can contaminate the capsules by promoting microbial growth.

13.What precautions should be taken during the production of creatine capsules?

To ensure the safety and effectiveness of creatine capsules, there are certain precautions that should be taken during their production. Some of the precautions are listed below.

Raw Material Check

Creatine Capsules - Picture Courtesy: NIFDO

The first step of creatine capsule production is gathering raw material. Ensure the raw materials are untainted and pure to meet the pharmaceutical standards. To avoid clumping or capsule degradation, moisture content should be controlled. Lastly, test the materials for any microbes or other contaminants.

Environmental Precaution

Environmental effect on creatine capsules- Picture Courtesy: Capsuline

If the environment is not controlled, the risk of creatine capsule degradation increases significantly. To avoid these kinds of environmental issues, maintain a controlled environment and prevent excess moisture content and degradation. Ensure the production takes place in GMP-compliant cleanrooms.

Proper Filling Techniques

AIPAK Creatine Capsule Filling Machine

Avoid overflowing the dosage amount in order to prevent the risk of inaccurate dosing, which can lead to capsule breakage or leakage. Regular calibration of filling machines and equipment for precise dosing can prevent formula overflow.

Capsule Integrity

Capsule intake- Picture Courtesy: Livestrong.com

Use appropriate material and select gelatin or HPMC (hydroxypropyl Methylcellulose) capsule shells, these shells are moisture-resistant and are compatible with creatine. Ensure the capsule is sealed properly to avoid any leakage risk.

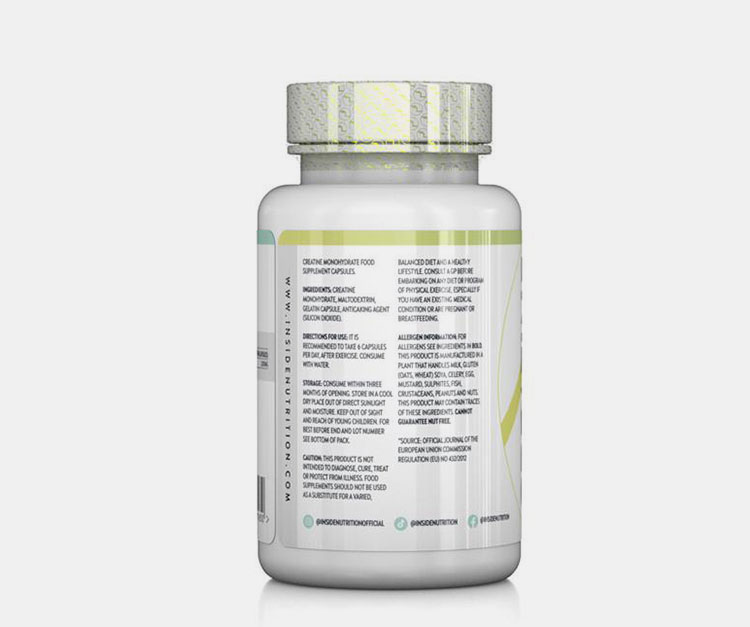

Storage Precautions

Ingredients and storage precautions- Picture Courtesy: Inside Nutrition

Creatine is sensitive towards air and UV light. Exposing them to these conditions can result in capsule degradation. To prevent these issues from happening, creatine capsules should be stored in a controlled environment to avoid prolonged exposure to air and light.

14.What are the common problems and their solutions during the production of creatine capsules?

Creatine Capsules- Picture Courtesy: Women’s Best

Creatine capsule production is a complex process, which requires precision and care. There are a number of issues that can arise during the production of creatine capsules. Some of them are listed below

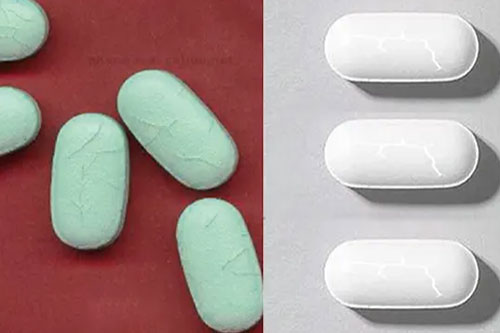

| Problems | Description | Solution |

| Capsule Brittleness

Capsule cracking- Picture Courtesy: pharmaeducation.net |

During the production process, creatine capsules may become weak and fragile leading to cracking or degradation of drug. | To prevent these kinds of issues from happening, it is important to enhance the moisture content of granules and properly adjust the compression pressure. |

| Improper Powder Flow

Improper powder flow- Picture Courtesy: Research Gate |

Inconsistent mixing and powder flow can lead to uneven dispersion of creatine during the process of capsule filling. This leads to weight difference and inconsistency as some capsules may contain more or less ingredients. | In order to avoid uneven dispersion, ensure stable and even blending of components.

Choosing powder formula with adequate flow properties can significantly ensure uniform dosing. |

| Visual Flaws

Creatine capsules and powder jar- Picture Courtesy: Levels Protein

|

Due to inadequate mixing of colorants, creatine capsules can often show visible flaws.

Improper drying conditions and exposure to elevated temperatures also lead to discoloration or brittleness. |

To prevent this issue, it is important to ensure proper mixing of colorants during the production of creatine capsules. |

| Improper Capping

Creatine capsules and powder form- Picture Courtesy: Adobe Stock |

Partially closed caps or improper capping can occur during the production of creatine capsules.

This is a common issue that arises due to improper alignment of encapsulation equipment or usage of an incorrect disc size. |

To prevent this issue from happening, proper alignment of encapsulating equipment is important. |

| Humidity Issues

Capsule defects- Picture Courtesy: Sensum |

Improper humidity levels can cause excess moisture, which leads to capsules being sticky or clumping together. These kind of issues arise due to improper temperature control during the production of creatine capsules. | To prevent capsule degradation, it is crucial to maintain a controlled environment that is suitable for storing creatine capsules. |

Conclusion

Creatine capsules have upgraded the game of supplements in fitness and health field. Appraised for it’s ease of use, effectivity and proven results, creatine capsules are a top choice of athlete and gym-goers for muscle gain and strength. This comprehensive guide has covered all the important features of creatine capsule, from benefits to manufacturing. Whether you are a consumer or manufacturer, this guide will provide you all the key insights you need to understand about creatine capsules thoroughly. Ready to expand your knowledge of creatine capsule production? Visit AIPAK website to explore series of capsule manufacturing solutions.

Don't forget to share this post!

Capsule Filling Machine Related Posts

Capsule Filling Machine Related Products

Capsule Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine