Coffee Powder Filling Machine:The Complete FAQ Guide In 2025

Coffee powder, as the name suggests, is a powdery substance made by grinding coffee beans. For convenience, more and more people are carrying their own small bags of coffee powder and can brew it anytime, anywhere. Coffee brewed with coffee powder usually has a high caffeine content, which has a significant refreshing effect on the mind.

Due to the various forms of packaging for coffee powder, there are also different types of coffee powder filling machines involved. Do you know how a coffee powder filling machine can not only fill coffee powder, but also other products? Do you know the operating process of this machine?

Well, let’s learn the complete FAQ guide of coffee powder filling machine.

1.What Is the Definition of Coffee Powder Filling Machine?

Coffee Powder Filling Machine

Coffee powder can be brewed at any time and is also convenient to carry around, which has been favored by many people. The coffee powder filling machine is used to fill coffee powder into bottles, small bags, and other containers. By this machine, transporting coffee powder into the hopper and filling it quantitatively into the container through a measuring tool and PLC system control. However, due to differences in packaging types, the specific coffee powder canning machines vary.

2.How Does A Coffee Powder Filling Machine Benefit Your Business?

With the improvement of mechanization, coffee powder filling machines have replaced manual filling, bringing a series of benefits.

Flexible container size

Humanized operation display screen, automatically matched with various actions through PLC control system, with high precision and easy adjustment of bag length and other dimensions.

Improvingwork efficiency

Improving Work Efficiency - Sourced: The Edge From the National Association

Using screw measurement, the coffee powder filling machine has high measurement accuracy and does not damage materials. The screw is customized according to the user’s packaging quantity and material characteristics to achieve packaging speed and improve work efficiency.

Meetingthe production needs of various industries

In addition to coffee powder, the coffee powder filling machine can also be used for other powders such as seasoning powder, flour, milk powder, etc. Therefore, it can meet the production needs of various industries.

Easy to operate

Easy to Operate - Sourced: Flaticon

The coffee powder filling machine adopts a PLC control system, so you can adjust parameters only through a touch screen. Simply setting the filling weight and speed, clicking start button, and the machine can automatically operate.

3.Can Coffee Powder Filling Machines Be Used For Other Products?

You must be wondering if coffee powder filling machines can be applied to other industries? Can other products be filled in? The answer is affirmative. Next, let’s see if there are any products that you like.

(1)Food industry

Milk Powder - Sourced: Revala

In daily life, there are many powders in our diet. To ensure consistent grams per bag or can of food, the coffee powder filling machine is used to filling them into containers. The specific products are as follows:

- Milk powder

- Flour

- Condiment

(2)Pharmaceutical industry

Chinese Herbal Powder - Sourced: Transformational Herbal Pharmacy

Some supplements and medicines are also in powder form, in order to facilitate patient absorption. The coffee powder filling machine can strictly control and ensure the compliance of the powder. The specific products are as follows:

- Talc

- Chinese herbal powder (ginseng powder, etc.)

- Composite powder

(3)Cosmetics industry

Cosmetic - Sourced: Bellapierre Cosmetics

Some cosmetics are in powder form, and a coffee powder filling machine can accurately fill powdered cosmetics into containers. The specific products are as follows:

- Loose powder

- Prickly-heat powder

4.What Are the Regular Packaging Formats of Coffee Powder?

There are various types of packaging for coffee powder, which ones have you seen? Some are small bags for easy carrying when going out, while others are bottled. Let’s take a look together.

Stick pack

Stick Pack - Sourced: BowePack

The stick packaging contains a certain amount of coffee powder, enough to brew a cup of coffee. The stick pack is easy to carry, whether in a bag or elsewhere. This packaging form is very convenient, saving the trouble of measurement and storage, especially suitable for fast-paced lifestyles.

Sachet

Sachet - Sourced: DMart Ready

Sachets of coffee powder are usually made of materials with good sealing properties, which can effectively prevent moisture, oxidation, and maintain the freshness and taste of coffee.

Stand-up pouch/doypack

Stand-Up Pouche - Sourced: Amazon

The stand-up pouch/doypack combines many advantages of glass and plastic bottles, and coffee powder is also packaged in a doypack, which can effectively prevent moisture from entering and keep the packaged items dry.

Jar/bottle

Bottle - Sourced: Amazon

Bottle packaging is one of the most common forms of packaging for coffee powder. This type of packaging usually uses metal or plastic cans, which have excellent sealing performance and durability. Bottle packaging can effectively protect coffee powder from moisture, sunlight, and oxygen, extending the shelf life of coffee powder.

Premade pouch

Premade Pouch - Sourced: Superfoods Company

What other packaging have you seen? In fact, coffee powder can also be packaged in premade pouch, which come in various types and can be specially customized according to different contents, product requirements, storage conditions, and other factors.

5.What Are Common Types of Coffee Powder Filling Machine Available?

According to different packaging types, it can be divided into several types of coffee powder filling machines.

Coffee powder filling machine

Coffee powder filling machine

The coffee powder filling machine, a most common known filling machine, is used to systematically and uniformly fill loose powder products, such as coffee powder, into containers without dust or leakage during the process, and can also achieve precise coffee powder filling.

Main parts

The coffee powder filling machine is mainly made of hopper, motor, conveyor belt, filling head, electrical cabinet, and PLC touch screen, etc.

Working principle:

| Step 1: Loading powder into hopper | Placing the coffee powder into the hopper. Hoppers are typically made of stainless steel and have certain bending and control devices to ensure smooth material flow and control filling speed. |

| Step 2: Setting parameters | Adjust according to the required product specifications, such as speed, and weight etc. |

| Step 3: filling | Powder materials are filled into containers according to the set capacity through a weighing system. |

| Step 5: output | After filling, the coffee powder product will be output through a conveyor belt. |

Stick packing machine

Stick Packing Machine

The stick packing machine can automatically complete functions such as automatic measurement, automatic filling, automatic bag making, sealing, and cutting of coffee powder in multiple lines. It can complete 4-12 lines of packaging at the same time, with a single machine capacity of up to 120 packages per minute, greatly improving production efficiency.

Main parts

The components of the stick packaging machine are different from those of a regular powder filling machine, it involves forming and sealing devices. It is composed of hopper, forming system, vertical seal, PLC, cutting device and servo pouch pulling.

Working principle:

| Step 1: loading material | Put the packaging material into the material roller and put the required materials, such as coffee powder into the hopper. |

| Step 2: adjusting parameters | Adjust according to the required product specifications, such as length and width of stick pack. |

| Step 3: forming | The packaging material enters the forming tube through a film roll, ultimately forming stick packs. |

| Step 4: filling | Powder materials are filled into stick pack according to the set capacity through a weighing system. |

| Step 5: sealing | Once the powder filling is completed, the packaging is sealed using methods such as heat sealing and cold sealing. |

| Step 6: cutting and output | The formed stick packaging is still in a row and needs to be cut using a cutting device to form a single packaging. |

Sachet machine

Sachet Machine

The sachet machine is mainly used to achieve fully automated production of packaging processes such as material filling and packaging, automatic bag making, measuring and filling, and sealing. This machine is capable of accurately canning coffee powder into each small bag. After long-term testing, the feeding and weighing accuracy is accurate to plus or minus 50g, meeting customer requirements.

Main parts

The main parts of this machine is similar with stick packing machine, which include roll film, hopper, filling device, PLC, bag former, and heat sealing.

Working principle:

| Step 1: loading material | Put the bag packaging material into the roll film and put the required materials into the feeder. |

| Step 2: adjusting parameters | Adjust according to the required product specifications, such as length and width of sachet. |

| Step 3: film unwinding and sachet forming | By using devices such as roller conveyors, the packaging film is unrolled and formed into small bags. |

| Step 4: filling | Fill coffee powder and other powders into small bags through the feeding device. |

| Step 5: sealing | The top of the small bag is sealed by heat sealing or cold sealing. |

| Step 5: cutting and output | The formed sachet needs to be cut using a cutting device to form a single package. |

Doypack machine

Doypack Machine

The doypack machine adopts a microcomputer PLC controller, a touch screen operation panel, and real-time visible working status, which can achieve all automated packaging functions such as automatic feeding, metering, bag making, filling, sealing, and output. The packaging material can be selected from heat sealable film materials, with diverse bag styles, adjustable quantity and speed, and high filling accuracy.

Main parts

The main parts of this machine include: hopper, unwinder, sealing jaw, cutter, sensor, PLC control system and motor, etc.

Working principle:

| Step 1: loading material | Put the bag packaging material into the roll flm and put the required materials into the feeder. |

| Step 2: doypack forming | The bag maker makes packaging bags according to the preset size and shape. |

| Step 4: filling | After the bag is secured, the vertical packaging machine begins to inject materials into the bag. |

| Step 5: sealing | After the bag is filled with materials, the vertical packaging machine will perform a sealing operation to ensure that the contents of the bag will not leak or be contaminated. The sealing method can be heat sealing, pressure sealing, ultrasonic sealing, etc |

| Step 5: output | The bags that have been packaged are taken out of the packaging machine and usually collected and arranged through devices such as conveyor belts or robotic arms. |

Can/Bottle filling machine

Can/Bottle Filling Machine

The can/bottle filling machine adopts a stainless steel material box, which prevents dust leakage. The filling accessories are equipped with a dust removal system to protect the workshop environment. The device transfers bottles or cans to the filling head through a conveyor belt, and accurately fills the powder into the container through sensors.

Main parts

As this machine is mainly suitable for bottle or jar, a conveyor belt device will be required. The main parts of this machine include: hopper, PLC, filling head, sensor, conveyor belt and HMI control system.

Working principle:

| Step 1: loading material | Load the powder material to the hopper for storage. |

| Step 2: adjusting parameters | Adjust according to the required product specifications, such as filling capacity and speed. |

| Step 3: filling | Powder materials are filled into bottles according to the set capacity through a weighing system. |

| Step 4: capping | To further seal the product, it is necessary to screw the cap and seal the bottle with the cap. |

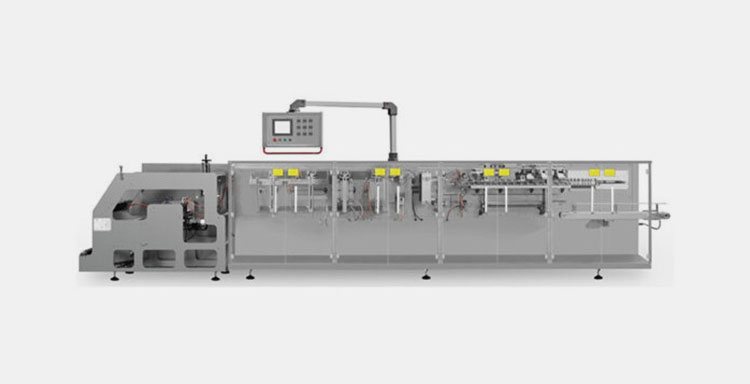

Premade pouch filling machine

Premade Pouch Filling Machine

The premade pouch filling machine can achieve functions such as automatic molding, filling, and sealing. This machine is suitable for various packaging materials such as PET, PE, etc. It can fill coffee powder into premade pouch to ensure the cleanliness and hygiene of the final product.

Main parts

Due to the fact that this machine is used for filling premade pouches, it has some unique components. Specifically, this machine is mainly made of hopper, pouch opener, inflation device, filling equipment, sealer, PLC touch screen, etc.

Working principle:

| Step 1: loading material | The staff load the powder material to the hopper. |

| Step 2: putting pouch | Placing the premade pouch in the bagged section of the machine and then pass it through. |

| Step 3: filling | By using vacuum suction cups and other devices, the bag is first opened, and the detector detects whether the bag is open before filling the material. |

| Step 4: sealing | After filling, the premade pouch is heat sealed with sealing jaws and then cold sealed. |

6.How to Ensure Accurate Weight of Coffee Powder Filling?

During the filling process, there may be inconsistent filling of coffee powder. How to ensure that the weight of each bag or bottle of coffee powder is consistent?

Adopting high-precision weighing system

In order to ensure consistent weight of coffee powder filling machine, advanced weighing systems must be used. Through sensitive sensors, accurate weighing can be achieved, and the weight of all packaged coffee grounds is consistent, with an error maintained within a few milligrams.

Accurately controlling the loading speed

You cannot increase the production speed of coffee powder just to improve production efficiency. It should be controlled within a reasonable range, as excessive speed can easily lead to problems. While maintaining efficiency, it is necessary to set the speed of the filling machine reasonably, so as to avoid the problem of inconsistent weight of coffee powder filling.

Ensuring sealing

Ensuring Sealing - Sourced: Jochamp

If there is a problem with the packaging seal of powder filling machine, some air will enter, causing the coffee powder to become damp and the weight to increase, resulting in inconsistent filling volume. If you face this situation, you can ask the staff to adjust the sealing ring.

7.What Are the Common Problems and Solutions of Coffee Powder Filling Machine?

Problems and Solutions of Coffee Powder Filling Machine - Sourced: Trio MDM

Due to the quality and service life of the coffee powder filling machine, there may be some problems during use, as detailed below.

| Problem | Solution |

| Poor sealing | The reason for poor sealing of coffee powder filling machine may be due to the influence of temperature or humidity. If it is too humid, it may affect the packaging and make it difficult to seal; It could also be a problem with the sealing device. Therefore, staff need to repair or replace the sealing device in a timely manner, place the machine in a reasonable position, and avoid placing it in a damp environment. |

| Container blockage | If the coffee powder filling machine gets stuck during operation, it may be due to the material filling speed being adjusted too quickly or a problem with the conveyor system. Therefore, you can try adjusting the speed of material filling or repairing the conveyor system. |

| Component damage | Long term use of the coffee powder filling machine may result in some malfunctions, such as engine failure, conveyor belt breakage, filling head damage, etc. If these components are damaged, they can be repaired or replaced in a timely manner. |

8.How To Maintain and Clean Coffee Powder Filling Machine?

The maintenance of machines can extend their service life, therefore, long-term maintenance and cleaning of coffee powder filling machines are necessary to ensure their efficient operation.

Regular cleaning

Regular Cleaning - Sourced: Anchor World Services

You should regularly clean the outer shell, internal parts, and pipes of the coffee powder filling machine equipment to prevent dust, dirt, and other impurities from damaging the equipment. After the machine runs, the measuring sensor and bag clamping mechanism should be cleaned in a timely manner.

Checking fasteners

Checking Fasteners - Sourced: LinkedIn

You should regularly check whether the fasteners of the filling machine equipment are loose, such as screws, nuts, etc. If there is any looseness, it should be tightened in a timely manner to prevent vibration or detachment of the equipment during operation.

Lubricating the parts

Lubricating the Parts - Sourced: Machinery Lubrication

As you know, if the machine runs for a long time, it does not run smoothly. You should regularly lubricate and maintain the bearings, chains, and other moving parts of the coffee powder filling machine equipment to reduce wear and friction, and improve the service life of the equipment. When you add lubricating oil to the main parts, please be careful not to drip oil onto the drive belt to prevent slipping.

9.What Quality Certifications And Standards Should Be Paid Attention To When Purchasing a Coffee Powder Filling Machine?

Good quality is the first element in purchasing products, and powder filling machines also require strict quality control and professional certification.

CE certification

CE Certification - Sourced: Novelty Steel

CE certification is the standard for the circulation of products in the European Union. Powder filling machines are mechanical equipment that requires CE certification to ensure that the products meet the safety, hygiene, and environmental protection requirements of the European Union.

ISO9001 certification

ISO9001 Certification - Sourced: Precision Cut Industries

This standard specifies the requirements of the quality management system that enterprises should comply with, including design, production, installation, commissioning, and other aspects. The ISO9001 certification represents that the quality of the coffee powder filling machine meets international standards.

RoHS certification

RoHS Certification - Sourced: Intelligent Building Controls Ltd.

With the increasing awareness of environmental protection, environmental directives such as RoHS certification require products to be free of harmful substances, which can ensure that the electronic and electrical components of powder filling machines, such as control systems and sensors, meet environmental requirements.

10.How To Choose a Suitable Coffee Powder Filling Machine Based on Production Scale?

Coffee Powder Filling Machine Based on Production Scale

The production scale and capacity demand of enterprises are also important factors to consider when choosing filling equipment. Determine the production capacity of the filling machine based on the enterprise’s production plan and market demand.

For small or newly established enterprises:

Small or newly established enterprises may produce hundreds to thousands of bottles (bags) per day, and can choose semi-automatic or fully automatic coffee powder filling machines with lower output;

For large enterprises:

Large enterprises need to choose high-capacity fully automatic powder filling machines to meet the needs of large-scale production, such as equipment that can fill thousands or even more bottles per hour.

11.What Service And Technical Support Should Be Considered When Choosing a Supplier of Coffee Powder Filling Machines?

For customers who purchase coffee powder filling machines, choosing a reliable manufacturer is very important. So, how to choose a reliable filling equipment manufacturer?

Pre-sales service

Before purchasing a coffee powder filling machine, customers need to understand their needs in terms of equipment usage scenarios, filling volume, production efficiency, and other aspects.

Filling equipment manufacturers should provide professional pre-sales services, including providing customers with detailed product information, answering their technical questions, and offering professional solution design. When choosing a filling equipment manufacturer, customers need to pay attention to whether the manufacturer can provide pre-sales services that meet their needs.

After-sale service

After-sale Service - Sourced: CRIMS

During the use of the coffee powder filling machine, there may be some malfunctions or problems, and after-sales service becomes particularly important. A good filling equipment manufacturer should provide timely after-sales service, including fault diagnosis, parts supply, maintenance, and other aspects. If the after-sales service is poor, customers may delay production due to a small issue, resulting in significant economic losses.

Technical support

Technical Support - Sourced: Vecteezy

The filling equipment has a high technical content and requires professional technical support. In the process of purchasing and using a coffee powder filling machine, customers need to understand the working principle, operating methods, maintenance skills, and other aspects of the equipment.

Filling equipment manufacturers should provide comprehensive technical support, including operating manuals, technical training, on-site guidance, etc. for customers. The quality of technical support is directly related to the customer’s user experience and production efficiency.

Conclusion

Coffee powder is a necessity in our daily life, and the coffee powder filling machine greatly improves work efficiency. As a filling equipment, besides coffee powder, it can also focus on filling other materials. This article takes you to understand various types of coffee powder filling machines and their workflow. If you have more to learn, feel free to consult AIPAK at any time.

Don't forget to share this post!

Powder Filling Machine Related Products

Powder Filling Machine Related Posts

Powder Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine