Capsule Dosage Forms- The Surprising Facts You Should Know

Capsules are everywhere! Globally, more than 18% of therapeutic drugs are delivered in the form of capsules which makes them the most recognized and trusted form. According to a survey from Natural Marketing Institute, 42% of supplement users in the US prefer to choose capsule dosage form, while this preference is even higher in heavy users, which is up to 56%. Today, capsules are available in various colors, designs, textures, shapes, and sizes in your drugstore. In this article, we’d like to share surprising facts about capsule dosage forms that you will definitely find interesting.

1.History of Capsules

As with other western pharmacies, the roots of capsules are also traced back to Ancient Egypt. A papyrus from 1500 B.C. has mentioned about 811 compounds and their mode of delivery like pills, powders, injections, capsules, potions, etc.

After that, the second report of capsule was in 1730 that mentioned Viennese pharmacist de Paul who used an oval-shaped capsule made of starch for gout treatment.

2.Revolution in Capsule Making- From Iron Wire to Automatic Machine

In 1868, F. A. Hubel discovered the Iron wire method for capsule production. He made iron molds that are fixed on wooden slabs and were covered with gelatin. He used pins varying in sizes for forming the body and caps parts of capsules and these parts were interlocked together.

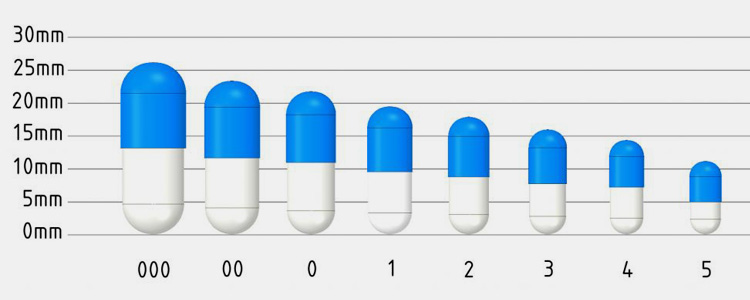

Hubel started to manufacture empty capsules on large scale in 1874. He also launched a number system for measuring sizes of capsules ranging from 0 to 5

By 1900, better materials than iron were introduced for producing capsules. Ultimately in 1930 stainless steel replace iron molds for capsule manufacturing.

Automatic Machines Drive the Innovation

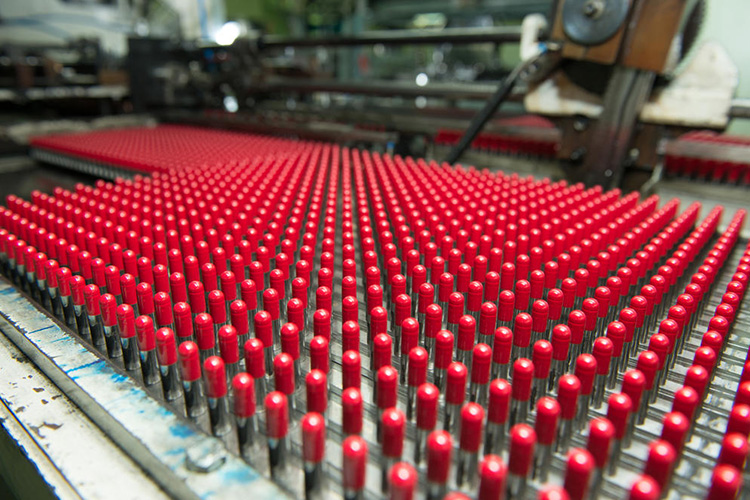

In 1968, with the emergence of automatic machines demands quickly followed for various designs. For instance, empty gelatin capsules, a two-piece design, groove, and a tapered rim for proper locking. This feature was particularly offered on high-speed encapsulation machines.

Today, capsule manufacturing machine enjoys the full demand in pharmaceuticals, foods, nutraceuticals, and large production firms. Surprisingly, today’s capsule-making, and filling machine may produce approximately 200,000 capsules/hour (brand to brand). Thanks to better advancement and better operating efficiency.

3.The First Patent Capsule

The first ever capsule patent was issued to a French student Franciosi Achille Mothes and Joseph Gérard Dublanc. They named their creation “gelatin bladders”. Their formulation is comprised of mercury filled leather bag that was coated with gelatin. When this gelatin dried, it was removed from bag and encapsulated with various liquid-based ingredients

4.Types of Capsules

There are two basic forms of capsules:

Hard Gelatin Capsule

The pioneer of hard two-piece capsules was Mothe’s patent. Parisian pharmacist J.C. Lehuby invented a cylindered-shaped, two compartment medicinal covering or capsule in 1846.

Hard gelatin capsules are the most common form of capsules and are made of two parts (cap and body) that are fitted together. The formulation encapsulated inside is typically made of drug powders that readily dissolve in the stomach.

These are filled with pellets and powders. Some hardgel are packing liquid materials inside them and are called liquid filled hardgel capsules (LFHCs).

With using LFHCs, a single capsule can deliver multiple drugs, so these are best for double-action or delayed-released drugs.

Soft Gelatin Capsules

The invention of softgel capsules was attributed to F. A. B. Mothes in 1833.

Soft gelatin capsules are one-piece capsules, most suitable for encapsulating oily ingredients such as fish oil, vitamin D, E. The development of these capsules made it possible to encapsulated poorly dissolving substances.

People prefer consuming chewable or malleable softgel as they have attractive color and fruity flavors. These capsules as lipophilic vehicle have superior dosage accuracy and enhance the bioavailability of ingredients by increasing their solubility and absorption in gastric track.

5.Innovative Designs-Common Capsule Sizes and Shapes

Hard Gelatin Capsules

These are rigid and cylindrical in shape. But these oral dosage form (OSD) are present in different sizes.

| Size | Covering Length (mm) | Picture |

| 000 | 25.4 |  |

| 00 | 22.2-23.2 |  |

| 0 | 20.7-21.7 |  |

| 1 | 18.5-19.5 |  |

| 2 | 17.0-17.5 |  |

| 3 | 15.0-15.5 |  |

| 4 | 15 |  |

| 5 | 11 |  |

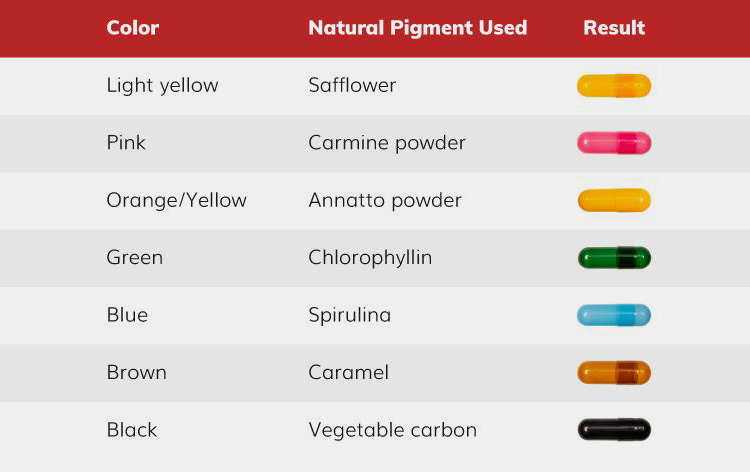

Capsules have evolved throughout the times and now companies are formulating these OSD in various colors using natural plant colors.

Soft Gelatin Capsule

Softgel capsules come in various shapes and sizes. Examples of these shapes are given below:

| Shape | Size | Picture |

| Oblong | 3-26 |  |

| Tube | 5-120 |  |

| Suppository | 6-80 |  |

| Oval | 1-80 |  |

| Round | 1-90 |  |

| Fish | 5-20 |  |

| Special Shape | Vary in size |  |

6.What Size Capsule Is Required To Hold Your Formulation?

Capsule filling capacity is determined both by volume and mass (weight). Usually, people think that size of the capsule is depended upon the amount of semi-solid or liquid material filled in it but this is not the case.

The weight of ingredients also plays a significant role in the selection of right-sized capsule. The weight is impacted by formulation density which differs for every substance.

For determining the accurate size of capsules that will encapsulate your formulation, you should first familiarize yourself with two characteristics of fill material.

- Weight

- Formulation Density

For calculation of mass or weight, you should know about the amount of formulation in milligrams present in each prescribed dosage.

While formulation density is assessed by formula

Density = Mass (g) /Volume (ml)

The mass is estimated from dosage while volume is amount of space taken by dosage in a measuring spoon.

EMPTY CAPSULE SIZE

| Capsule Size | 000 | 00E | 00 | 0E | 0 | 1 | 2 | 3 | 4 | 5 |

EMPTY CAPSULE WEIGHT (mg)

| Average Weight (mg) | 158 | 143 | 123 | 107 | 99 | 78 | 61 | 48 | 38 | 28 |

| Tolerance | ±10 | ±10 | ±7 | ±7 | ±6 | ±5 | ±4 | ±3 | ±3 | ±2 |

EMPTY CAPSULE VOLUME CAPACITY (ml)

| Capacity | 1.37 | 1 | 0.9 | 0.78 | 0.68 | 0.48 | 0.36 | 0.27 | 0.2 | 0.13 |

FORMULATION DENSITY (g/ml)

| Formulation Density | ||||||||||

| 0.6g/ml | 822 | 600 | 540 | 468 | 408 | 288 | 216 | 162 | 120 | 78 |

| 0.8g/ml | 1096 | 800 | 720 | 624 | 544 | 384 | 288 | 216 | 160 | 104 |

| 1.0g/ml | 1370 | 1000 | 900 | 780 | 680 | 480 | 360 | 270 | 200 | 130 |

| 1.2g/ml | 1644 | 1200 | 1080 | 936 | 816 | 576 | 432 | 324 | 240 | 156 |

First look for formulation density which is closer in value to your actual density, let say your density is 0.6g/ml. then look for a weight that is more similar to the weight of your fill materials e-g 520mg.

So based on this information you should go for size 00 capsule.

7.The Benefits of Capsule

Capsules are the preferred choice of millions of people all across the globe. Moreover, these are a reliable option as compared to tablets. Do you why? Well, the reasons are:

- Capsules are easier to encapsulate than tablet manufacture. This feature augments the manufacturing process thus resulting in delivery of more of these products in short time.

- These are filled with liquid or semi-solid ingredients with no trouble which is not achievable with tablets.

- Furthermore, capsules are imperative in patient compliance. The capsules are much smaller in size than tablets which improve their swallowability. They also appeal to patients by hiding bitter or pungent taste of compounds. This unpleasant taste is more noticeable in syrups and pills.

- These products are present in various color, sizes, and shapes for their recognition. This offers customers the choice to buy their preferred choice of capsules.

8.Proper Storage Requirement for Capsule

Capsules can withstand harsh manufacturing conditions, but they still deteriorate if not stored at proper settings. You should be aware of the fact that rigorous surrounding has a major effect on the moisture of empty capsules. The humid environment damages the shell of capsules. Gelatin capsules lose their water content more quickly than HPMC capsules when faced with severe ambient conditions.

So, environmental elements should be monitored at every stage of manufacturing, storage, and delivery of these products as the capsules either dried up or become too flaccid in high temperature or humid surroundings.

Temperature and humidity should be in the range of:

| Type of Capsule | Humidity | Temperature in Centigrade |

| Gelatin capsules | 35% to 65% | 15° to 25° |

| HPMC capsules | 35% to 70% | 15° to 30° |

Following precautions should be taken while storing capsules:

- These should be placed away from heated water, hot water or steam pipes and radiators

- Do not store them in direct sunlight and in high-altitude places.

- These should be kept away from light ceilings and vents.

9.Is There A Magic Formula For Adding Flavor To Children’s Capsules?

Yes, children’s capsules are manufactured with a special magical formula known as natural sweeteners. Flavored capsules are high in demand because of consuming difficulties of elderly and pediatric patients.

Palatability is the main focus of pediatric drug whether they are used for treating chronic illness or are developed against bacterial infections.

Kids have highly sensitive sense of smell and taste and they are more likely to reject bitter and pungent smelling drugs. However, most drug ingredients are bitter in taste and aggravate mouth and throat. Sugars or artificial sweeteners can be added to drugs for their acceptance by pediatric patients.

Palatable capsules are the exceedingly preferred choice among children. Different flavors such as grapes, bubblegum, apple, cherry, and bananas are added to capsules for making them tastier. Grapes are favored by 28% of young kids while bubblegum is preferred by 26% of children.

10.Acid Resistant Capsule- What makes them Acid Resistant?

Acid-resistant capsules are a widely popular choice of therapy as these prevent formulations of being released in the stomach. These are enteric-coated with the sole purpose of releasing active substances in the duodenum where they are instantly absorbed by the small intestine. They are layered with alkaline and acidic compounds that act as shields or protection against stomach acidic pH.

Uses of Acid Resistant Capsule

- These capsules are delivered dosage to intestine that otherwise released in stomach and causes the irritation of stomach lining and patient discomfort.

- The drugs encapsulated in these OSD are often used for treatment of intestinal diseases.

Some examples of these dosage forms are:

- Antibiotics

- Enzymes

- Proton pump inhibitors

11.Why Capsule Is the Most Trending Pharmaceutical Formulation?

Both capsules and tablets are highly manufactured types of dosage due to patient-friendly mode of administration. But compared to tablets, the market of capsules is expanding every day as many pharmaceutical firms have a preference for manufacturing capsules.

There are various rationales behind this approach, for instance:

Patient Compliance

Capsules are popular dosage form among customers as these do not dissolve in mouth. Also, these medication forms are not formulated with a binder that causes gastric track tenderness. These OSD are gentler on the inner lining of stomach. Thus, patient acceptance in turn causes higher selling of products meaning more profits.

Ease In Manufacturing

Capsule manufacturing is much faster resulting in rapid delivery to market. Tablet preparation is lengthy and time consuming process needing many materials and specialized equipment. Tablets have to achieve desired hardness, compactness, and thickness. This is not the case with capsules.

Production Steps

Material preparation of tablets like blending, milling, and compaction is quite elaborate and prone to error. Furthermore, tablets have to be coated before packaging. In comparison to this, capsule formation is fairly simple and has a low error rate.

Fill materials

Capsules are extremely versatile products where fill materials are concerned. These can enclose pellets, powders, liquids, semi-solids and mini-tablets. These vehicles can pack potent, water-liable, hygroscopic substances as well as temperature-sensitive ingredients. This task is not doable with tablets.

Release of APIs

The shells of capsules can be modified according to disintegration timing. Some capsules are immediately break up and release their inside material while others dissolve slowly over passage of time releasing their ingredients in a controlled manner. Tablets disintegrate rapidly when coming in contact with acidic gastric environment.

Branding

The capsule can be customized according to branding style. Various aspects such as color, size, taste, printing, finish of these OSD can be modified for unique identification. This also helps the patients in distinguishing their medications.

12.Capsules or Tablets: Which Form of Supplement is Better?

Patients prefer supplement capsules than tablets because of several reasons:

- These dosage form as smooth, slick, and swallowed without any difficulty especially by children and elderly patients. Tablets are hard that render them tricky to consume.

- Drugs are packed inside shell in capsules which decreases the probability of proximity between drug and oral lining. In tablets, drugs are in direct contact with oral cavity which can lead to irritation of said part.

- Pediatric and geriatric patients, who face trouble in taking medications, can easily open up capsules and scatter inner drug on food like honey etc.

- Most of the capsules are tasteless while tablets usually have bitter taste. This feature of capsules makes them favored choice of many valetudinarians.

- They are available in appealing colors having glossy, sleek and elegant form. Tablets typically have white color which does not attract patient particularly children.

The Bottom line

Capsules are high demanded form of medication and are preferred equally by adults and children due to their ease of swallowability. There have been many innovations in capsules over the years like the invention of flavored capsules. These are trending medication form in the pharmaceutical industry due to patient compliance, bioavailability, and simplicity of manufacturing. Want to know more? Contact our High- Tech staff to answer your queries and technical consultation 24/7/365.

Don't forget to share this post!

Capsule Filling Machine Related Posts

Capsule Filling Machine Related Products

Capsule Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget,we'll reply you ASAP within 24 hours