High-Speed Delivery vs. Regulatory Compliance Can You Get a GMP-Ready Capsule Filler in 15 Days

For pharmaceutical procurement managers, the "Emergency Order" is a high-pressure scenario. Whether it’s a sudden production spike or a critical machine failure, the need for a replacement often clashes with the non-negotiable requirements of GMP compliance and regulatory audits.

While a high-quality NJP-1200D capsule filler typically requires a 30- to 45-day lead time, our recent delivery to a European client proves that a 15-day turnaround is possible without compromising safety or quality.

1.The Engineering Strategy Behind a 15-Day Lead Time

Speed in the pharmaceutical industry is not about cutting corners; it’s about strategic modularity.

Pre-Configured Power Systems: We maintain a dedicated inventory of motors and electrical components configured for international standards, such as the 380V/50HZ/3PH systems used in Europe.

Ready-to-Ship Tooling: By keeping common sizes like 00# capsule molds in stock, we eliminate the 14-day fabrication window usually required for custom tooling.

Agile Logistics: For this specific European project, we recommended rail freight over sea freight, cutting transit time to just 20 days while offering better stability for sensitive machinery than standard sea routes.

2.Ensuring "Express" Doesn't Mean "Non-Compliant"

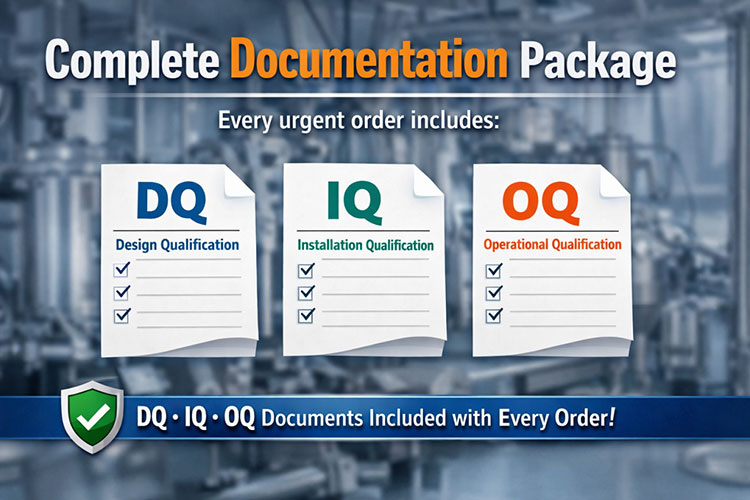

A fast machine is a liability if it fails a Quality Assurance (QA) audit. Our 15-day protocol includes a full verification suite:

Complete Documentation Package: Every urgent order includes a full set of DQ (Design Qualification), IQ (Installation Qualification), and OQ (Operational Qualification) documents.

Virtual FAT Protocols: We utilize high-definition video for Factory Acceptance Testing (FAT). This allows the client to verify filling accuracy (within ±1%) and safety interlock functionality in real-time before the machine is crated.

Site-Specific Engineering: We provide detailed dimension drawings to verify the client’s workshop ceiling height and door widths. This ensures the machine integrates into the production environment without Day 1 installation delays.

3.Technical FAQ: Addressing Procurement Risks

To help our clients navigate the complexities of urgent procurement, we’ve compiled the most critical technical questions we received during this European project:

Q: How do you guarantee spare part accuracy for an urgent build?

Spare parts of NJP-1200D

A: Every NJP-1200D is logged under a unique Serial Number. Every filter, dosing disk, and seal is indexed in our database, ensuring 100% matching replacements for the lifetime of the machine, regardless of how fast the initial build was.

Q: Does the 15-day timeline include the trial run with actual materials?

A: Yes. We perform a full trial run—documented via video—using the client's specific capsule size (e.g., 00#) to ensure the weight variation and separation rates meet GMP standards before shipping.

Q: What if the machine requires on-site installation help?

A: While we provide clear manuals and remote video support, we also maintain a team of engineers ready for on-site installation and staff training should the client require it.

4.Overcoming the "Overseas Supplier" Trust Gap

The biggest barrier to urgent procurement is a lack of transparency. Our client’s previous trauma—receiving incorrect parts and experiencing poor communication—is a common industry pain point.

We bridge this gap through Peer Reference and Lifecycle Support:

Existing User Network: For European or Middle Eastern clients, we can provide contact details for our users in Spain or Turkey who have operated our NJP series machines for over a year.

Lifetime Technical Service: Our commitment doesn't end at delivery. We provide free lifetime consultation via email and video conference to ensure the machine remains compliant and efficient.

Conclusion

Urgency does not have to be an enemy of quality. By choosing a partner who understands both the mechanical urgency and the regulatory necessity of the pharmaceutical industry, you can secure your production line in record time without risking your compliance status.

Don't forget to share this post!

15-Day Fast Delivery for GMP Capsule Fillers

Capsule Filling Machine Related Posts

Capsule Filling Machine Related Products

Capsule Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine