Blue White Capsule: The Complete FAQ Guide In 2025

If you have ever noticed a blue and white capsule in your medicine cabinet, and wondered about its color and composition than you are not alone. You can find this blue white capsule almost in every other medicine box. They could be used for regular OTC medicines and for prescription anti-depressants. They are recognizable and prominent but they can be confused sometimes.

Person taking a blue white capsule orally

The blue and white in these capsules is just not a mere color combination for the sake of marketing but in fact they can contain a wide variety of medications. So whether you are a patient or you just randomly came across blue and white capsule, you need to identify these medications for the appropriate usage.

As curiosity is the first step to understanding something bigger. So here you go, in this article you will get answers to all your questions about the composition and need of these blue white capsules.

1.What is a blue white capsule?

Photo showing two parts of blue white capsule

A blue white capsule is an oral medication enclosed in a hard gelatin shell or sometimes soft gelatin shell, which is half blue and half white in color. The capsule has two parts, a lower blue body and its white cap or vice versa. The cap has a slightly bigger diameter than the body to get it fixed over the body.

The blue white capsule can contain powder, granules, pellets or even liquid dosage forms. The blue white color itself is not for the representation of a medicine but it is imprinted further with codes that determine the drug. The different pharmaceutical companies manufacture different drugs with different dosage in blue white capsule which are identified through the imprinted coding and packaging.

2.Why do capsules come in different color like blue and white?

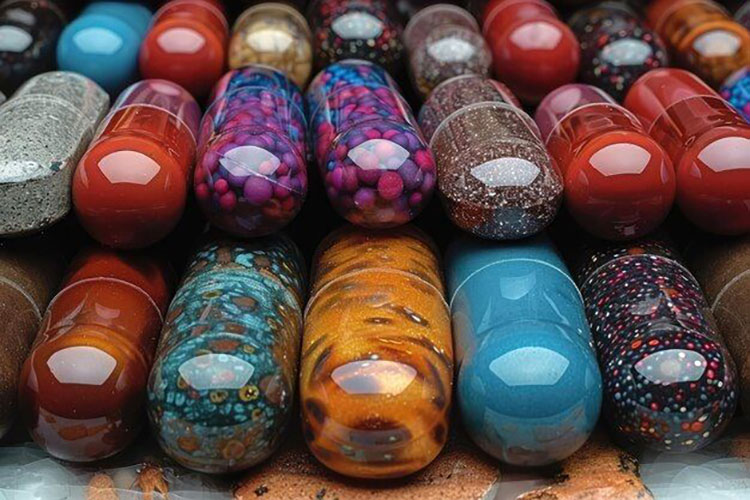

A variety of capsules with different color and different contents

There are many different reasons for which the capsules are given different colors. They different colors of the capsule give them separate identification, brand differentiation, to discriminate the dosage of a same drug and also patient compliance. There are studies that shows blue color is for calming affect while white color gives a soothing affect.

Similarly red color conveys strength of a medication. This difference in colors of the medical capsules can impact the perception of the consumer and decrease the error of medication to a great extent.

Some common reasons for different colors are given below:

Identification:

The color of capsule has a great effect on the identification of a medicine. Especially when the patient has to take multiple dosage at a time and the capsules are similar in size and shape, difference in color make it easier for the patient to identify.

Branding and marketing:

The pharmaceutical brands produce capsules with different colors like blue white to make brand recognition. The colors of capsule are very important in the nutraceuticals industry, where it is usually according to the color of supplement. Now a day’s aesthetics plays a major role in the purchasing decision. The vibrant colors and colors soothing to eyes make the product appealing and how people perceive about the medication.

Dosage differentiation:

There are dosage forms prepared which have same active ingredient but they only differ in their dosage strength or formulation, which is represented by different in their capsule color. For example a dosage form has a blue white capsule of 10mg and a red white capsule of 20mg.

Patient compliance:

The bright and two toned capsules like blue and white help the patient to remember the medicine in a better way. The color makes a memory in the patient’s conscience, especially in case of geriatrics, which have usually difficulty in keeping a track of their medication. The colorful medications help them avoiding mistakes in the medication.

Regulatory compliance:

The different medications with different strengths and combinations need to be clearly distinguished from each other. The international regulatory bodies like FDA have made this factor a major requirement while manufacturing of the medication. The capsules with different colors help in achieving that.

3.What are the benefits of blue white capsule?

The key benefits of blue white capsule are given below:

Easy identification:

Capsules of different colors arranged in a pill box

There are people who are taking multiple medications at different time of a day. The confusion about the medicines is very common is such case of medication, irrespective of the age group. The color contrasting of the capsules make it easy for the patients on poly pharmacy to remember the medicine and keep track of the dosage.

Better patient compliance and visual appeal:

Geriatric patients are often confused with medication-picture courtesy: Getty images

The chances of wrong medication are greatly reduced through distinct colors. The geriatric patients can keep track of their medicine without the need of any guardian. It is also easy to administer a visually appealing medicine to the children. This causes a positive effect on the medication adherence.

Contents masking:

Photo showing different possible contents of a capsule

These gelatin shell capsules can contain powder, granules, pellets or liquids. These contents of the capsule are usually not very appealing and sometime have a very strong odor which makes it difficult for the patient to take it. The capsule shells help in masking the strong odor and also the colorful and vibrant capsules make the medication pleasant for the patient.

Color combination as per the combination of active ingredients:

Different color combination for capsules with different potencies

There are drugs with same formulation which only differ in the potencies or combination of the active ingredients. The specific color combination for a particular potency or formulation makes it easy for the patient to differentiate among the medicine. This increases the drug safety and makes it easy for patients as well as health care practitioners to identify the right medicine.

Opaque protection:

Opaque dual color capsules

The blue white kind of capsules can be opaque or transparent. Sometimes the contents of the capsules are light sensitive, e.g. fish oil or probiotics capsule. The opaque capsules provide a shield to the light sensitive contents.

The shell of the capsule also protects the contents from humidity and moisture.

Gender specific marketing:

Blue capsule for men and red for women-picture courtesy: shutterstock

The color combination for capsules can have a major impact on the marketing. It is very common in the nutraceuticals to have different formulations for men and women. There are supplement capsules for men who are usually blue in color and capsules with women supplements are red in color. This color specificity according to gender is not only limited to nutraceuticals but common in other medications as well.

4.What kind of medication comes in blue white capsule?

The blue white kind of capsules is usually available in hard gelatin capsule shells. As we know there are different types of dosage forms available. It’s the contents inside the capsule that determine what kind of dosage form the capsule offers. It could be extended release, immediate release or delayed release.

The pharmaceutical manufacturers can attribute a specific color combination to a specific dosage form or dose strength but color itself does not describe any dosage form.

The following table explains the different dosage forms and medication in a blue white capsule:

| DOSAGE FORM | DESCRIPTION |

| BASED ON METHOD DRUG RELEASE | |

| Extended release (ER/XR)

|

The ER or sustained release capsules are made to release the medication slowly over a longer period of time. The blue white form of capsules is a best choice for ER dosage forms. |

| Immediate release (IR)

|

The IR capsules are made to release the medication immediately upon administration.

These blue white capsules are versatile enough to offer different modified release dosage forms. |

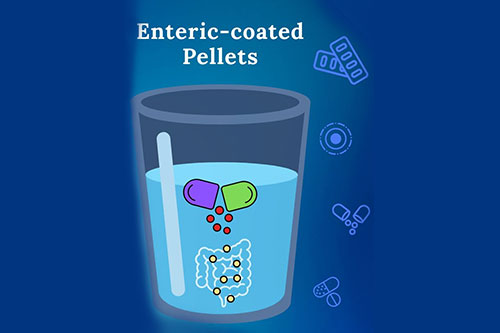

| Delayed release (DR/EC)

|

Delayed released drugs are made to pass through the stomach and release into intestine. The coating is made to protect the drug from stomach acid.

The DR capsules are also called enteric coated (EC) capsules because they are coated with material which is resistant to stomach acid. |

| BASED ON TYPE OF CONTENT IN THE CAPSULE | |

| Pellet filled capsules

|

There are pellets or coated beads of medication enclosed in the capsule.

They are usually made for modified release dosage forms. |

| Powder filled capsules

|

This is the simplest and most common form. The capsule is filled with medicine in the form of fine powder. |

| Granules filled capsules

|

It is somewhat similar to the pellet filled capsules. The capsules are filled with granules which could have different rate for release or dissolution. |

5.What is the composition of blue white capsule?

The composition of the blue white form of capsules can be divided into three parts, outer shell, inner components and excipients.

Basic composition of a Capsule

Outer Shell:

The outer hard shell of the capsule that is colored and divided into two halves has all the components inside it. It is usually made of the following:

| Components | Function |

| Gelatin:

Gelatin sheets-picture courtesy: dreamstime |

It forms the basic structure of the capsule shell. It could be derived from animals.

In case of vegetative capsule, gelatin is plant based. |

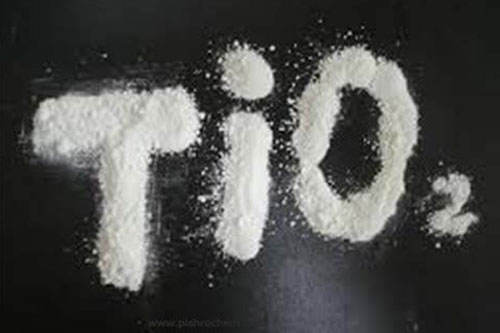

| Opacifier:

Titanium dioxide-Picture courtesy: pishro chem |

The Opacifier is added in the capsule shell to make it opaque.The most commonly used is Titanium dioxide to make the capsule shell opaque. |

| Preservative:

Preservative chemicals-picture courtesy: aussie soap supplies |

Preservatives are added to inhibit any kind of microbial growth in the gelatin capsules. |

| Colorants:

|

They dyes or colors that are used to give color to the capsule shell are FDA approved. |

| Plasticizer:

Picture courtesy :twin rivers technology |

Plasticizers like glycerin or sorbitol are added to enhance the flexibility of the capsule shell. |

Excipients:

Picture courtesy: depositphotos

The excipients also called additives are added to the capsule to provide stability to the dosage form. The commonly added excipients and their purpose are given below:

| Components | Function |

| Binder | As the name suggest, it hold the powder together in powder filled capsules. |

| Disintegrants | They are added to help in disintegration of the capsule, once it reaches it specified site for absorption. |

| Lubricant | Lubricant or glidants are added to ensure that there is a smooth filling process for capsules. |

| Buffers or pH modifiers | The buffers or pH adjusters are very essential help the drug release from the capsule and ensure the stability of the capsule and its components. |

Inner Components:

The inner components of a capsule comprises of main active ingredient. The active pharmaceutical ingredient (API) of a capsule varies from drug to drug. The inner component could be in powder form, liquids, pellets or granules, as explained earlier.

6.What are the machines used for the production of blue white capsules?

Picture courtesy: satrap

The machines involve in the production of hard shell gelatin capsules, from filling of shells to final sealing and packaging are given below:

CAPSULE FILLING MACHINES

| Machine | Features |

| Manual capsule filling machine

Manually capsule filling machine-picture courtesy: SS pharma |

These machines are ideal for small scale batches in the labs or compounding pharmacies. These machines require manpower to carry out the capsule filling operation.

The capsule separation, filling and rejoining and all other procedures are carried out manually in these machines. They are used for production of a few hundreds capsules in a small scale production setup. |

| Semi-automatic capsule filling machine

AIPAK semi-automatic capsule filling machine |

These machines combine the features of manual and automatic capsule filling machines. The process of capsule loading into the machine is manual.

The machine fills the capsule automatically but the separation of capsule head from the body and monitoring of filling level in the capsule requires manual assistance. These machines are suitable in medium sized production units or when there is a restricted budget. |

| Automatic capsule filling machine

AIPAK fully automatic capsule filling machine |

These are fully automatic high speed capsule filling machines. They are able to fill 30,000 capsules, ranging up to 200,000 capsules per hour.

All the operations of capsule loading, alignment, filling, sealing and ejection are automatic. These machines have even inline inspection of the capsules. They are best suited in high speed production lines and large production units. |

CAPSULE PACKAGING MACHINES:

| Machines | Features |

| Counting and bottling machine

AIPAK high speed capsule counting and bottling machine |

These machines are advance and automatic. These machines offer an automatic presetting of the number of capsules and dispense them into the bottles automatically.

These machines have optical sensors and vibratory trays for the counting of capsules. The bottle feeding, capping and labeling machines are integrated in these machines for a high speed automatic production line. |

| Blister packaging machine

AIPAK blister capsule packaging machine |

These machines are used for encapsulation into a blister. They can be alu-alu blistering machines or PVC-alu blistering machines. The capsule is encased between the layers of PVC/PVDC blisters, with a backing of aluminum foil.

These blister packaging machines can be integrated in high speed production lines with labeling and cartoning. These machines could be thermoforming or clod forming blister packaging, depending upon the requirement of the manufacturer. |

7.What is the filling mechanism for blue white capsule by the manufacturers?

The filling mechanism comprises of different steps to ensure an accurately filled capsule. The basic filling mechanism is same for all the hard gelatin blue white form of capsules, irrespective of their contents, i.e., powder, pellets, granules or mini tablets.

The main steps include:

Capsule orientation and separation:

The empty hard gelatin shell capsules are oriented downward in the machine. The body and cap is intact at this stage, with the body being at down position. The automatic capsule filling machine has vacuum suction system, which separates the cap from the body. The machine moves the body to filling station while the cap is stationed right there.

Capsule dosing:

The dosing or filling of the capsule depends upon the type of the content to be filled in the capsule shell. In case of powder filled capsules, powder is filled through a tamping pin system, which compresses the powder into tiny slugs, which are then fed into the body of capsule.

In case of pellets or granules, they are fed through a gravity hopper provided with a metering system. A calculated volume of granules or pellets is fed into the capsule body through rotary or piston based fillers.

Capsule closing:

When the capsule body is filled, the machine automatically realigns the cap and body of the capsule. There are mechanical or pneumatic pressure system through which machine presses the cap down onto the capsule body.

There is already a predefined locking ring engraved in the capsule shell which enables the locking of the cap on the body of capsule. This locking ensures the safety of the capsule contents by preventing the capsule from opening during handling and packaging.

Weight check and inspection of capsules:

The advance and automatic capsule filling machines have optical sensors and in line weigh checker. The weight checkers ensure the proper and right weight fill of the capsule.

The optical sensors visually detect any kind of defects in the color or closing of the capsule shell. The defected capsules are rejected by the machine before they reach the ejection unit.

Ejection of capsule:

This is the final stage in capsule filling where the filled capsules move out of the machine. The automatic machines have sensors which reject the loose or defective capsules. The filled and properly closed capsules are ejected through ejecting pin or by the use of air pressure.

The capsules are ejected in a collecting unit or on a conveyor belt to move to the next packaging unit in production line. If the machines have polishing unit then the filled capsules are moved to the capsule polishing machine.

8.What is the procedure for imprinting of different codes on blue white capsule and what does it identifies?

Imprinted capsule-picture courtesy: PR newswire

The imprinting on the capsule shell is important to avoid medication errors. The imprinting on the capsule shell creates a recognizable product which decreases the chances of any counterfeit drug. The imprinting on the capsules shells are very unique, with each dosage form capsule having its own specific imprinting as per authorized by FDA.

The imprinting can include:

| Company logo:

It represents the brand or manufacturer of the capsule. |

Leaf is the company logo on this capsule |

| Alphanumeric code:

It is a specific code, unique to every dosage form capsule. It identifies the name of drug, strength of the drug and manufacturer of the drug. |

Alphanumeric code on capsule |

| National drug code (NDC) :

It is a specific code, which is used to match the drug capsule with its official data of drug registration. |

687 is the NDC code on these capsules |

The printing on the filled capsules shells is done by feeding the capsules in the printing units using a hopper and guide track. The advanced automatic machines have integrated printing systems in them. There are two printing methods for the capsules:

Rotary offset printing:

Rotary printing -picture courtesy: Ackley machine

It is the most common method of printing hard gelatin capsules. It has a silicon printing roller that picks up the printing ink from engraved plate. This inked pattern is transferred from the roller to the capsules. The capsules are rotating gently to ensure a uniform printing when passing through the rollers.

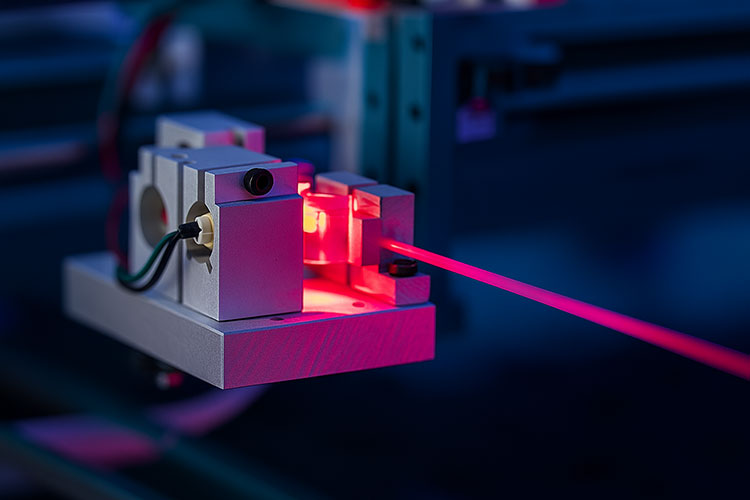

Laser printing:

Laser printing

This is used in sensitive or high value drugs. Laser printing is temper and smudge proof. Printing is done through precise laser beam which etches a mark on the capsule shell surface.

9.Is there any effect on the shelf life and stability of the product due to color of the blue white capsule?

Photo showing capsule colors through natural pigments-Picture courtesy: K-CAPS

The color pigment used in the hard gelatin shell capsule shell has no direct effects on the stability or shelf life of the product. But it does play a part in the protection and identification of the drug product in some ways indirectly. Following are the few factors:

The drug products are usually light sensitive and dark color capsules provide protection from light due to their dark shades as compared to colorless or light colored capsules. The colorants used in the capsule shells are pharmaceutical grade and FDA approved, thus the safety and stability of the product is ensured.

Color of the capsules although have no effect on heat or heat protection but there are capsule shells with stabilized pigments, they can offer UV resistance to the drug product in the capsule. Capsules have not effect on humidity or moisture.

Hence, we can say that while color pigment of capsule does not have any effect on chemical properties or stability of the product but they can provide light protection to light sensitive drugs.

10.What area the safety and regulatory requirements in the manufacturing of blue white capsule?

Capsules in the filling machine-picture courtesy: SP automation & robotics

The manufacturing units for the blue white form of capsules are required to follow the GMP guidelines. The pharmaceutical grade capsule filling and production lines are required to maintain the hygienic conditions, process validation and trained personnel as per GMP guidelines. The colorants used in the shell color should be FDA approved and non-toxic, stable and safe.

All the raw material used, gelatin, excipients, colorants, preservatives, must complies with the USP, EP or other official pharmacopeias and international guidelines. It is required to maintain a control environment to avoid any kind of cross contamination between the colorants and drug products.

Before the filling process, all the drug products and products used for manufacturing of capsule shell must go through purity testing and microbial load tests. It is essential for the product to follow ICH guidelines of stability testing to verify the shelf life and stability of the capsule and drug product in normal and accelerated conditions of temperature and humidity.

The capsules imprinting is required to be according to the FDA, with a unique code to maintain the traceability. All the process that takes place, from the empty capsule shell to the filling, sealing and packaging is required to be documented and made available to any audits and inspections.

Conclusion:

If you have reached this far in the article than its safe to say you have got answers to all the FAQs in your mind regarding the blue white form of capsules. These gelatin hard shell capsules have a vital role in pharmaceutical and nutraceuticals manufacturing due to their versatile nature. The colorful shells with temper evident features make the medication safe and effective. These capsules have made the oral administration of powders, granules easier. They are best suited for modified release dosage forms. The technological advancement in the manufacturing and filling of these capsules provide us with flexibility in capsule design. These advance filling machines ensure that the consumers receive safe and effective blue white form of capsules. For more information visit our AIPAK website.

Don't forget to share this post!

Capsule Filling Machine Related Posts

Capsule Filling Machine Related Products

Capsule Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine