The Hidden Cost of Maintenance A Guide to Lubrication and Filtration for NJP-1200D Capsule Filling Machine

In pharmaceutical manufacturing, purchasing an NJP-1200D Automatic Capsule Filling Machine is only the beginning of your investment. Many production managers overlook the "hidden costs"—the potential for thousands of dollars in lost output every hour due to downtime caused by improper maintenance.

As a specialist supplier with a track record of delivering to the US, Europe, and Turkey, we know that two specific technical details—Lubrication and Filtration—determine whether your machine remains a reliable asset or becomes a costly liability.

1.Why "Off-the-Shelf" Oil Can Ruin Your Certification

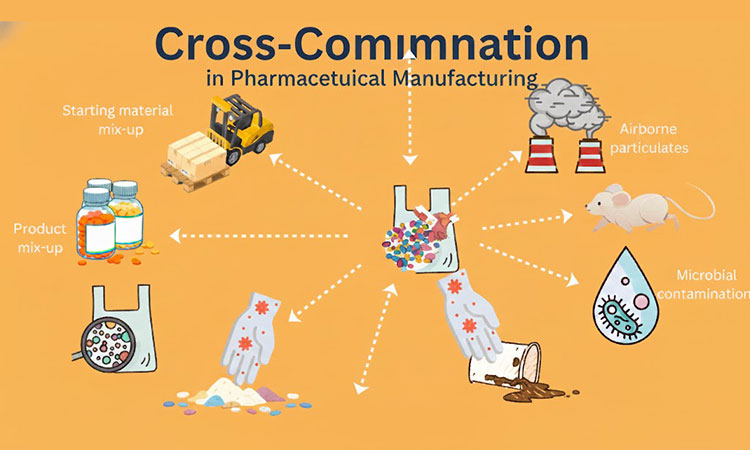

Cross-contamination is a primary concern for pharmaceutical manufacturers. If non-compliant industrial lubricant leaks into the capsules, entire production batches must be scrapped to meet safety standards.

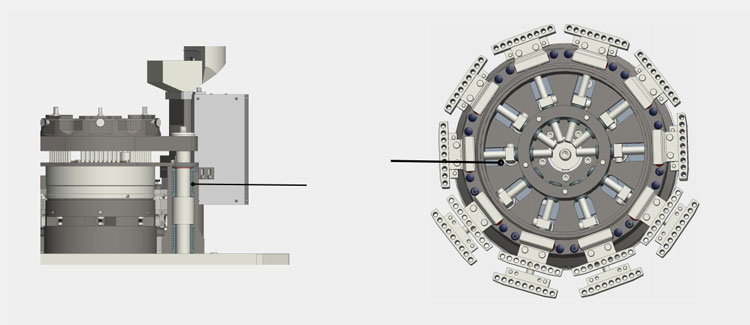

Bearing &Cam Of Capsule Filling Machine

Food-Grade Standards (NSF H1): For components like bearing and cam that may contact the product, it is mandatory to use NSF H1 certified food-grade lubricants.

Precision Lubrication Mapping: We provide a comprehensive Lubrication Chart for every NJP-1200D, specifying exactly where to use long-life grease versus light-duty oil to prevent residue buildup and mechanical jams.

2.Filtration: The "Respiratory System" of Your Production Line

Powder Recycling Bin Filter

Filters are the unsung heroes of continuous, high-efficiency production. If they fail, the machine's precision fails with them.

Dry Vacuum Pump Filter

Dry Vacuum Pump Filters: The NJP-1200D relies on vacuum suction for capsule orientation. A clogged filter drops the separation rate from 99.9% to below 90% almost instantly.

Powder Recovery Systems

Powder Recovery Systems: Our systems use high-efficiency filters to ensure dust doesn't escape into the workshop, maintaining your GMP compliance.

Our Practical Approach: We include an extra set of filter elements with every machine, ensuring your production never halts during peak periods due to a simple consumable part.

3.CASE STUDY: Solving the "Trust Crisis" for a European Client

NJP-1200D Capsule Filling Machine On Customer site

Recently, a European pharmaceutical manufacturer approached us with an urgent requirement and deep-seated concerns regarding overseas procurement. Their experience highlights how technical precision meets logistical excellence:

Meeting the 15-Day Deadline: The client required an urgent 15-day lead time. By maintaining a strategic inventory of 00# capsule molds and standard 380V/50HZ/3PH motors, we completed the build in exactly 15 days.

Logistics & Site Constraints: We recommended rail transport (20-day transit) to meet their tight schedule and provided detailed dimension drawings to verify their workshop ceiling height, ensuring the machine could be installed without any structural modifications.

Validation & Documentation: To bridge the trust gap, we provided a Virtual FAT (Factory Acceptance Testing) video of the actual trial run and delivered a complete documentation package, including FAT, IQ, OQ, PQ, and DQ files.

Guaranteed After-Sales: Addressing their past bad experiences with incorrect spare parts, we demonstrated our Serial Number Tracking System. Every component on their NJP-1200D is indexed by a unique ID, ensuring 100% accurate replacements for the lifetime of the machine.

4.Expert Tips to Lower Your Maintenance Costs

Global Technical Support

Based on our global technical support data, following these steps can extend your machine’s lifespan significantly:

Daily Post-Shift Cleaning: Inspect and clean the powder recovery bin filter daily to prevent material caking.

Lifetime Technical Support: We provide free technical consultation via email, phone, and video conference for the entire lifespan of the equipment, ensuring you never face a communication barrier.

Peer Reference: For clients in Europe or the US, we can provide contact details of existing users—such as our clients in Spain or Turkey—so you can verify our machine performance directly.

Conclusion

Buying pharmaceutical equipment is the start of a long-term partnership. From our 15-day urgent delivery to our precision serial number management, we are committed to solving your production worries before they even happen.

Don't forget to share this post!

Maintenance Guide for NJP-1200D Capsule Filler

Capsule Filling Machine Related Posts

Capsule Filling Machine Related Products

Capsule Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine