Capsule Machine: The Complete FAQ Guide In 2025

Did you ever think about how your tiny capsules are filled? What equipment is versatile enough to load empty capsules with powder, liquids, tablets, etc? Here is news for you, it’s a capsule machine.

Indeed, it is a powerful system by which you can increase the capsule filling speed. And due to the capsule machine, your filling errors will become a thing of the past. It flawlessly executes the encapsulation process with limited output from the workforce.

Whether you’re a green hand in the capsule manufacturing business or a seasoned businessman in the process of upgrading your production, this blog post is your backstage pass to the arena of capsule machines. Here we’ll explain everything from the benefits, working steps, types to components, and more. So, stay tuned and discover hidden secrets.

1.What is a capsule machine?

Capsule machine

In simple terms, you can define a capsule machine as equipment found in pharmaceutical and other healthcare industries and used to load various fill materials in empty capsules.

You may also know this machine by the name of capsule filling machine or capsule encapsulator. It takes empty capsules, loads them with desired materials, and seals them firmly to avoid material leakage.

By using a capsule machine, you and other manufacturers can form a variety of capsules, like HPMC capsules, hardgel capsules, vegan capsules, and many more.

2.How capsule machine benefit your production facilities?

Believe it or not, the capsule machine is a game-changer in the production facilities. It not only provides you with convenience, but it also speeds up your processing without creating tons of errors. To find the benefits of the capsule machine, read the subsequent section:

Boosting Production Rate by 1000 Times

High production

Are you under a time crunch and want to complete your inventory by the end of the day? Then, the capsule machine will help you in this endeavor. Undoubtedly, using automated models of this equipment, you can encapsulate up to 200,000+ capsules per hour. So, it is way faster than simple hand-filling.

No Compromise on Dosage Precision

No Compromise on Dosage Precision

In the world of pharmaceuticals, accurate fill weight means uniformity in dosage. Hence, you won’t get any complaints from customers that they had more or less drug dosage in their capsules. Here is where, capsule machine comes in handy, as it lowers variability in dosing and packs the exact dose every time.

Cleaner and Safer Working

Cleaner and Safer Working

Yes, capsule filling comes with powder clouds and poses a health hazard for workers. But with a capsule machine, you won’t have to worry about dust production. Why? Because this system is equipped with dust control devices, powder contaminant components, and hygienic parts. So, you’ve minimal dust generation and lower contamination possibility, which keeps your workers and facility safe.

Save You from Hiring More Labor

Time and Energy Save

If you acquire a capsule machine for your production, it decreases the need to hire more labor for the capsule filling job. Thus, you and your team can focus their efforts on getting the right quality, perfect packaging, and testing new product ideas instead of tediously packing capsules by hand for hours.

Quality Finishing

Quality Finishing

Certainly, capsules with uniform shapes and sizes go a long way in attracting customers. That’s why you need a capsule machine in your plants. It produces capsules with quality finishing, tight sealing, and minimal anomalies. Consequently, your products look premium in pharmacies and other shopping centers.

3.What key industries do the capsule machine serve?

Many people mistakenly assume that a capsule machine serves only pharmaceutical industries. But they couldn’t be more wrong. Instead, you’ll spy this equipment in a number of industries that require clean and fast capsule encapsulation. Here are the main industries in which the capsule machine does its job:

Pharmaceutical Industry

Pharmaceutical Industry

This is the stomping ground of the capsule machine. Almost every type of pharma business employs a capsule machine to load prescription as well as over-the-counter capsules. By installing this machine in your plants, you can fill the exact drug dose of antibiotics, painkillers, digestive aid, and hypertension controlling agents in capsules.

Dietary Supplement Industry

Dietary supplements- Picture courtesy: Nutraceutical Alliance

Definitely, when you think of the dietary supplement industry, vitamins, minerals, collagen, superfood blend, and other nutraceutical products come to your mind. And capsule machines are essential in this industry to satisfy the growing demand for nutraceuticals by fitness-conscious individuals.

Veterinary Industry

Veterinary Industry

Yes, pets and wild animals also get infected and need supplements for their growth. So, you’ll spot a capsule machine in this industry for making animal-friendly capsules to boost animal health. Subsequently, due to the use of this equipment, capsules are gaining popularity among pet owners and vets as a convenient dosing option.

Research Institutes

Research sectors- Picture courtesy: GEN

Many of the research and development sectors use manual or semi-automatic capsule machines for making small batches of capsules for clinical trials and research purposes. These systems are of prime importance in these sectors because they’re pocket-friendly and easily allow developers to test a limited batch of drug substances.

Beauty Industry

Beauty Industry- Picture courtesy: Love Ryes Australia

The use of the capsule machine is emerging in the cosmetic and aesthetic sectors. Now, women and men alike are conscious about their skin, hair, and overall look. So, with the help of capsule machines, cosmetic brands have developed capsules for nourishing skin and hair, whitening and tightening skin, reducing wrinkles, and more.

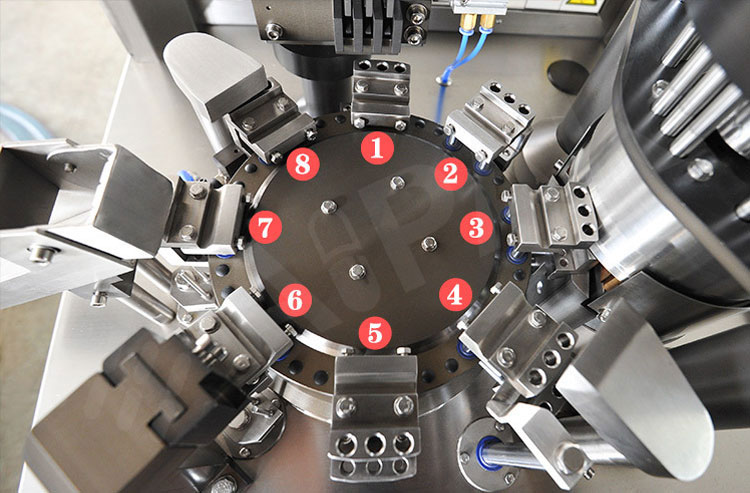

4.What are the operational stages in the working of the capsule machine?

It doesn’t matter what type of capsule machine you’re using; the core stages are almost similar in every kind, only with a little more automation in sophisticated versions. Here is a complete sequence of operational stages in the working of the capsule machine:

Step 1: Loading of Materials

At the start, the bulk volume of empty capsules and fill materials is deposited in the hoppers or reservoir by the operators. After loading, the empty capsules are conveyed to the capsule plate, while active drug materials are moved to the filling station.

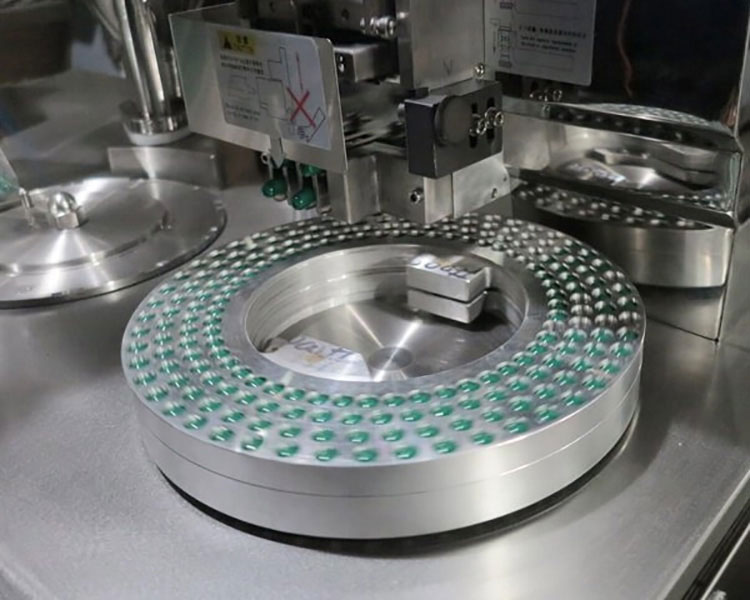

Step 2: Capsule orientation

Since the capsule caps and bodies are attached to each other, they must be separated in order to fill the capsules. For this purpose, sorting devices, channels, and brushes are used to position capsules in the right manner. This means that in this orientation, caps are in the upward direction, while bodies are in the downward configuration.

Step 3: Separation

As soon as capsules are aligned properly, they are transferred to the separation station, where the vacuum system is typically utilized to delicately remove caps from bodies.

Consequently, the bodies are securely contained in the lower plate or dosing tray, whereas suction force lifts caps upward. In this way, the two capsule halves are separated. In some models, mechanical pins force bodies down, which detach caps from bodies.

Step 4: Dosing and Filling

Dosing and Filling

This is the core stage in the working of the capsule machine. Before the initiation of this step, the separated bodies are sorted and transported to the filling station. Then, a pre-defined quantity of drug substance is loaded inside the open capsule bodies. Sometimes, tamping pins or dosing pins are utilized to compact or pulverize the fill substances, respectively, in the capsule bodies.

Step 5: Capsule Rejection

The faulty and unseparated capsules are not catered by the machine and rejected.

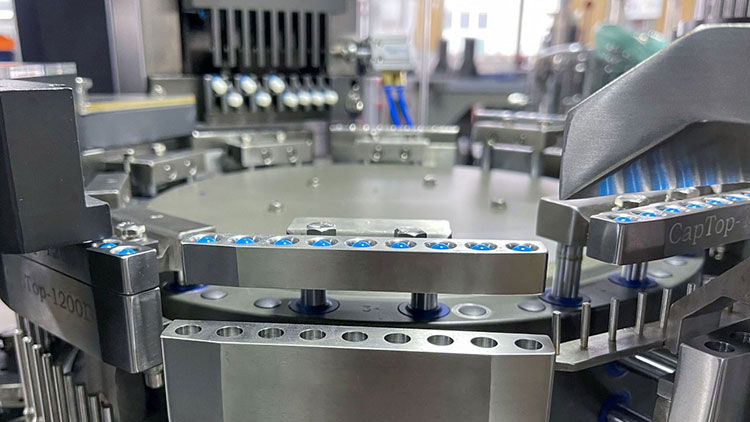

Step 6: Capsule Closing

Closing

Once the filling stage is successfully commenced, now it’s time to rejoin the filled capsule halves. This is done by bringing caps and bodies in contact with each other. For this, at the locking station, the pressure plate or rotary locking system applies an accurate amount of pressure on caps and bodies to lock them together. Just like that, capsule halves are firmly joined.

Step 7: Ejection of Locked Capsules

Immediately after locking, the joined capsules are discharged from their holding trays and are collected in a collection bin. Sometimes, they’re transported to the next processing stage via a chute or conveyor.

5.What are the classes of the capsule machine?

Well, you probably get confused when you see a variety of capsule machines in the market. Rest assured, we’re detailing every single class of capsule machine just for you in the following section:

Automatic Capsule Machine

AIPAK Automatic Capsule Machine

As the name suggests, it’s a highly sophisticated model of capsule machine. In fact, you can consider it the pinnacle of capsule forming technology. Since this system can produce hundreds of thousands of capsules, you’ll spot an automatic capsule machine in mass production facilities.

In this machine, every step from starting capsule loading to final ejection of filled capsule is automated. Hence, it needs minimal or no human assistance. Moreover, it presents you with the highest level of accuracy in capsule filling.

Semi-automatic Capsule Machine

AIPAK Semi-automatic Capsule Machine

You’ve hit the right mark. The semi automatic capsule machine is a major advancement from the manual capsule machine. As a matter of fact, it has both manual and automatic operating capabilities. Principally, with this machine, you can automate tedious and time-consuming capsule filling; however, it still depends on human operators for other tasks.

Instead of operating by hand, you’ve to provide an electric or pneumatic source for its working. It has a more complex construction with a capsule loading unit, filling station, powder hopper, and locking system.

Manual Capsule Machine

Allpack Manual Capsule Machine

Manual capsule machine is the simplest of all capsule machine types. Usually, it constitutes a rectangular board made of plastic or stainless steel. It comes with many parts, such as loading tray, body plate, cap plate, etc., that are aligned over one another to fill capsules. Usually, it is operated with the hand and has a low production power of about 6000-8,000 capsules per hour.

However, it is quite simple to operate, and simply by changing molds, you can produce capsules of diverse sizes.

6.Enumerate various fundamental components of the capsule machine.

In order to correctly operate the capsule machine, you must first learn about its various parts and their function. In this way, you can easily know how and when to troubleshoot the machine in case of error. So, for your knowledge, we’re penning the basic parts of the capsule machine in the next section:

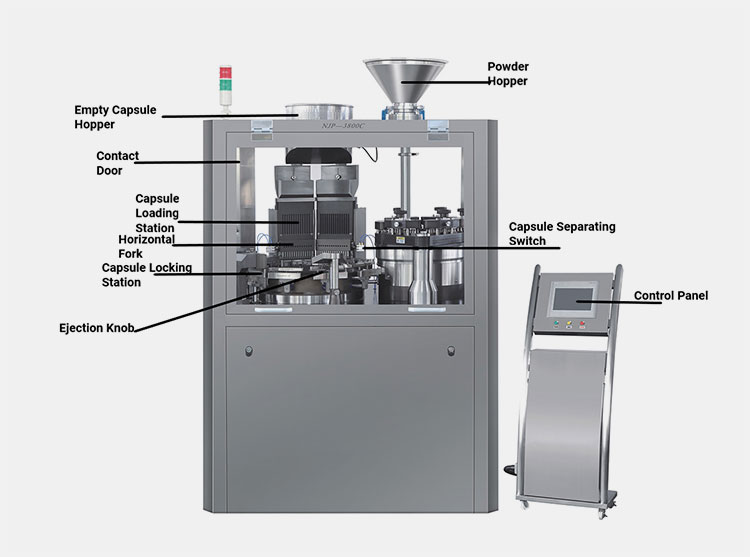

Parts of the AIPAK Capsule Machine

| Empty Capsule Hopper | Typically, one of the first components in the capsule machine. A bulk load of empty capsules is placed in the capsule hopper for smooth operation. |

| Contact Door | A transparent glass enclosure is fitted on the sides of the capsule machine and is known as the contact door. You may think of it as a safety mechanism that separates the processing of the capsule machine from the surrounding working environment and operators. This barrier is vital in preventing contamination risk from outside agents. |

| Capsule Loading Station | Sure, you can also call this component loader assembly. It features diverse parts, for instance, a capsule magazine, a push block, and a finger block. You’ll note the capsule loading unit starts from the main shaft and ends at the separation unit. With the help of the cam loader, capsules travel from the capsule hopper towards the magazine part. Here, a push block is present that ensures the correct orientation of capsules within the loading station. Simultaneously, finger block guides or propel capsules towards the rectification unit for ultimate sorting. |

| Horizontal Fork | This part is placed between the capsule magazine and the separation unit. Horizontal fork consists of two pins with which it gently holds capsules around their centers. In this way, the capsules are oriented on the horizontal axis, and at the same time, the vertical fork positions them along the vertical axis. These two forks work together to execute rectification in the correct way. |

| Capsule Locking Station | After capsule encapsulation, the capsule locking station acts on the separated capsule halves to join them together. For this purpose, the upper and lower segments are brought together. By utilizing cams and a lever in the locking station, capsules are locked. |

| Ejection Knob | Also known as the ejection lever. Structurally, it resembles like lever and it mechanically forces capsules into the capsule outlet. To remove capsule jamming, ejection knob is used. |

| Control Panel | You’ll certainly see an intuitive screen display featured on the capsule machine. It is the part through which you can adjust and set the filling parameters for the operation of the machine. |

| Powder Hopper | Before turning on the capsule machine, your operators generally load a large volume of powder into the cylindrical powder hopper. In some cases, powders are also dispensed inside this part using a pump system. |

| Capsule Separating Switch | As the name suggests, it is the main part responsible for disjoining capsules into two halves (caps and bodies). Basically, through its sensors, it assesses proper capsule rectification and then transmits a signal to the separation station to begin capsule separation. |

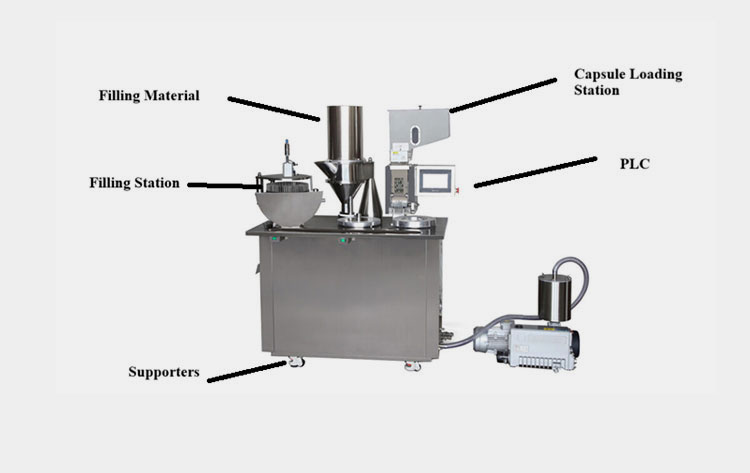

Semi Automatic Capsule Machine

AIPAK Semi Automatic Capsule Machine

The parts of semi automatic capsule machine are described as:

| Filling Material | The material to be filled inside capsule is loaded in this section which is also known as hopper. |

| Capsule Loading Station | The empty capsules are loaded using the loading station, later it is removed manually. |

| Filling Station | The material to fill is done in this section where empty capsules are supplied, filled, and capped again. Once it is filled, it is removed manually. |

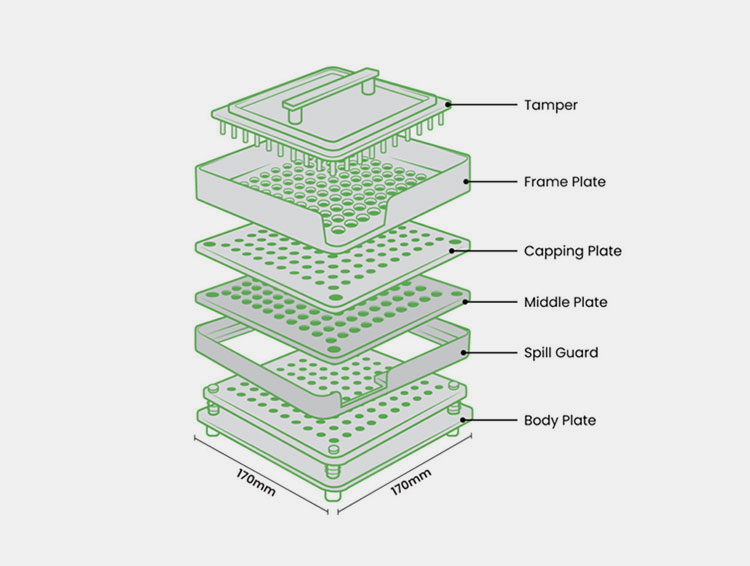

Manual Capsule Machine

Manual Capsule Machine

| Tamper

|

It presses the filled material and minimizes air. |

| Frame Plate | It supports the capsule bed and ensuring alignment. |

| Capping Plate

|

The capsule caps are taken up by this frame till filling of the bottom half capsules. |

| Spill Guard | As its name indicates, this section prevents spilling of the material from capsules during filling. |

| Body Plate | The bottom capsules mainly adjusted here till filling and locking of the whole capsules. |

7.What are auxiliary equipment of capsule machine?

Of course, the capsule machine production line helps to complete the entire supply products in a flawless manner. Let’s read about different auxiliary machines found in capsule production:

Capsule Polishing Machine

AIPAK Capsule Polishing Machine

Yes, capsule polishing machine is primarily used for enhancing the overall look of filled capsules. With the aid of rotating soft brushes and a vacuum system, the capsule polishing machine delicately scrubs the surface of capsules to give them a smooth, clean, and glossy look. You can increase brand reception and customer acceptance using this system.

Capsule Dust Collector / Vacuum Cleaner

Capsule Deduster- Picture Courtesy: OEM Magazine

Normally, capsule deduster is present after the capsule machine. Simply, this system clears loose or residual powders or other fine particles stuck to the capsule surface. Using air blowers, light agitation, or vibration, it dislodges powder-dust present around the edges where the capsule is locked. Vacuum units or air blowers then suck these particles, making capsules clean.

Vacuum Capsule Loader

Vacuum Capsule Loader- Picture Courtesy: Pkt-Gb

Generally, you’ll notice this machine after the capsule deduster in capsule production facilities. Since defective capsules, like deformed, cracked, faded, overfilled, damaged, or empty capsules, are not suitable for shipping and retailing, you use a capsule sorting machine to separate capsules of good quality from faulty ones.

Metal Detector

Capsule metal detector

A high-speed capsule metal detector accurately identifies the presence of metals and helps to meet the safety requirements. The machine is useful for pharmaceutical applications to inspect medications such as pills, capsules, tablets with metal particles and sends to rejected sections.

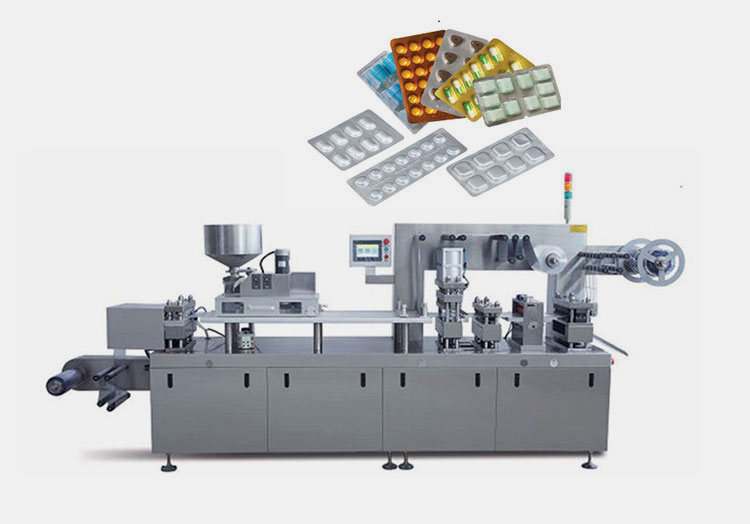

Blister Packing Machine

AIPAK Capsule Blister Packing Machine

Most of the time, capsules are packed in blisters because they’re sturdy, impermeable, and tamper-evident. So, the capsule blister packing machine is pivotal in pharmaceutical industries, as it seals capsules in individual compartments, offering not only dosage control but also the strongest possible protection.

Bottle Filling Line

Capsule Machine Production Line

The bottle filling line is composed of capsule bottle unscrambler which is a multifunctional machine that implies rotational and blowing properties to align the bottles for the filling of capsules. The machine receives bottles in random positions and exists in an orient direction thus known as a time-saving solution.

8.What capsule types are filled by the capsule machine?

Can you believe it capsule machine is very good at processing various capsule types? Certainly, depending on the machine construction and production requirements of manufacturers, it can help create a wide array of capsule types. Here are some examples of these capsules:

Hardgel Capsules

Hard Gelatin Capsules- Picture Courtesy: Pharma Trends

Very prevalent capsule type in the pharmaceutical, nutraceutical, and herbal arena. They’re a subcategory of two-piece capsules, formed by a shorter cap and a longer body. However, there is bad news for vegan or kosher people, these capsules are created from gelatin, bovine, and porcine sourced material.

Vegetarian Capsule

Vegetarian Capsule- Picture Courtesy: SMP Nutra

Contrary to hardgel capsules, these vegan or vegetarian capsules are less common. But they are excellent for people who’ve special dietary needs and restrictions. Also, they’re favored by vegan or vegetarian individuals because these capsules are created from plant sources, typically, Hydroxypropyl Methylcellulose, pullulan, starch, or seaweed.

Not only this, they’re great for encapsulating moisture-sensitive or thermo-labile ingredients.

Enteric-Coated Capsules

Enteric Coated Capsule- Picture Courtesy: EM Pharma

Generally, they’re pre-coated with films to make them resistant to the stomach's acidic environment. So, enteric-coated capsules are designed to release their fill materials inside the small intestine.

In case you’re wondering how the capsule machine fills them? Clearly, they’re filled just like standard capsules, while coating materials are spread over the capsule before or after encapsulation, not during it.

9.Does the capsule machine encapsulate capsules of diverse sizes?

Yes, it does. The capsule machine is capable of handling diverse capsule sizes. But here’s a catch, you’ve to change tooling parts, for instance, the magazine, filling plates, to go from filling one specific size to another. Also, you’ve to change machine input parameters, for example, fill volume, tamping pin height, and pressure level.

Large Capsule Size

| Capsule | Fill Weight (mg) | Volume Capacity (ml) | Capsule Locked Length (mm) | External Diameter (mm) | |||

| Light

(0.45) |

Medium

(0.70) |

Heavy (1) | Cap | Body | |||

|

615 | 960 | 1370 | 1.37 | 26.14 | 9.91 | 9.55 |

000 (triple zero) is considered one of the largest capsules on the market. Due to its largest size, with an overall length of 26.1 mm, it has the highest internal volume, usually of 1.37 ml. Thus, it can accommodate more amount of powder, often around 950 mg to 1370 mg (milligrams).

Medium-Sized Capsules

| Capsule | Fill Weight (mg) | Volume Capacity (ml) | Capsule Locked Length (mm) | External Diameter (mm) | |||

| Light

(0.45) |

Medium

(0.70) |

Heavy (1) | Cap | Body | |||

|

430 | 665 | 950 | 0.95 | 23.3 | 8.53 | 8.18 |

|

305 | 475 | 680 | 0.68 | 21.70 | 7.65 | 7.34 |

|

225 | 350 | 500 | 0.50 | 19.40 | 6.91 | 6.63 |

Sizes 00, 0, and 1 are included in the medium-size capsule category. 00 (double zero) is normally the most favored capsule size in the supplement industry, as it can hold 735-950 mg of powder and is comfortably ingested by individuals.

On the other hand, 0 size is the most suitable for encapsulating pharmaceutical formulation. 1 size is preferred when you want more ease of swallowing and fill lower-dose drug preparations.

Small Capsules

| Capsule | Fill Weight (mg) | Volume Capacity (ml) | Capsule Locked Length (mm) | External Diameter (mm) | |||

| Light

(0.45) |

Medium

(0.70) |

Heavy (1) | Cap | Body | |||

|

165 | 260 | 370 | 0.37 | 18.00 | 6.35 | 6.07 |

|

135 | 210 | 300 | 0.3 | 15.90 | 5.82 | 5.56 |

|

95 | 145 | 210 | 0.21 | 14.30 | 5.31 | 5.05 |

|

60 | 90 | 130 | 0.13 | 11.10 | 4.91 | 4.68 |

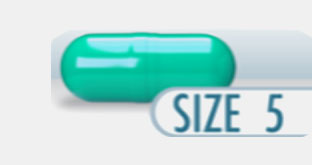

2, 3, and 4 are small-sized capsules, with size 5 being the smallest of them all. Size 2 is used to encapsulate moderate doses of formulation and is generally favored for pediatric or geriatric populations. 3 and 4 sizes are used for specialized therapies and animals.

10.Can you use a capsule machine to fill different fill materials?

Absolutely! By integrating a capsule machine into your production, you can easily encapsulate a wide array of materials differing in their properties. There is no question that this equipment is great for multitasking. Here are some major fill materials that you can fill with a capsule machine:

Powders

Powders- Picture Courtesy: Forbes

No doubt, these are the most frequently filled materials in capsules. Powder kinds may include active ingredients, herbs, supplements, nutraceutical blends, and more. Every capsule machine, from manual to automatic ones, can easily handle powder substances.

Granules

Granules- Picture Courtesy: Globela Pharma

As powder may segregate after filling, leading to inconsistent dosing, granules are used for making sensitive capsule preparations. Some granule types filled in capsules are effervescent granules, coated granules, non-coated granules, and sustained-release granules.

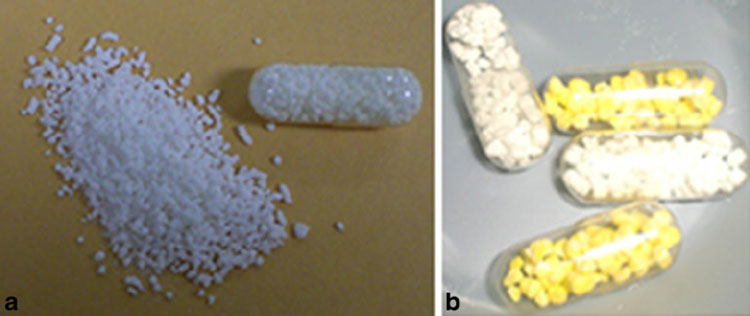

Pellets

Pellets

In contrast to granules, pellets are smoother and look like tiny beads. Often come in a size of 0.2-2 mm. You need pellet-dosing systems in a capsule machine for filling them.

11.What problems can you face during the operation of the capsule machine? How to remedy them?

Despite all the engineering efficiency and control units, problems and issues can still occur in the operation of the capsule machine. But don’t take too much stress because you can resolve these problems easily with the right skill and training. Some of these problems, plus their quick remedies, are discussed in the section below:

Capsule Halves aren’t Separating Correctly

Incomplete Separation

Did you ever observe improper separation of caps and bodies of capsules? It is more common than you think. It can be due to poor-quality or brittle capsules, incorrect input of vacuum pressure, and a mismatch between capsule size and the separation unit.

Remedy

To fix this issue, first of all, you’ve to use high-quality capsules that are stored under the right conditions. Secondly, change your pressure settings and properly align the capsule feeding unit. Lastly, ensure there is correspondence between capsule sizes and separation parts.

Discrepancy in Fill Weights

Discrepancy In Fill Weights- Picture Courtesy: Blog Capscanada

The reason for this issue could be related to a number of things, for instance, poor fluidity of powders, improper configuration of tamping pins or dosators, and, blocked filling compartment.

Remedy

Here is what you can do to resolve it. You should use powder with free-flowing characteristics. Also, you may improve powder flow by adding glidants in the formulation. Adjust the alignment of tamping pins or dosators. Always calibrate and clean the machine, especially the fill unit, between batches.

Improper Capsule Locking

Improper locking of capsules

While capsule filling, do you see fill materials leaking from locked capsules? Improper capsule locking is the reason for content spillage. Why does it happen? Because of damaged or awry locking pins, surplus powder on the capsule locking seam, and overfilling of capsules.

Remedy

To troubleshoot this concerning matter, you must properly align the locking pins. And if they’re damaged, replace them instantly. It is best to thoroughly clean your capsules, especially their rims, before locking. Don’t overfill materials because it will cause bulging of bodies, leading to issues in capsule closing.

Capsules Get Stuck in Machine

Capsules Get Stuck

Sometimes, you might have a problem of capsule jamming in your machine parts. Often, deformed, soggy, or sticky capsules get stuck in the equipment. Also, unclean capsule tracks or bores, as well as high speeds of the system, can be a cause of this issue.

Remedy

Some simple suggestions to overcome this challenge are, properly store your empty capsules at room temperature, and their storage place shouldn’t be too humid or dry. Adhere to a properly maintained cleaning schedule. Always remember to operate the system at a lower speed if you’re dealing with a tricky batch.

Conclusion

Now, you may understand that the capsule machine isn’t just another piece of equipment; it is a powerhouse on which the whole capsule filling line depends. From precise dosing and faster batch processing to saving time and decreasing material wastage, it’s the ultimate solution for you if you’re looking for ways to increase your output and deliver quality products to your customers. Convinced of buying a capsule machine or looking for an upgrade? No worries- we’re here to help. Explore the complete catalogue of machines related to capsule manufacturing, get expert advice, or request a quote by visiting the AIPAK website.

Don't forget to share this post!

Capsule Filling Machine Related Posts

Capsule Filling Machine Related Products

Capsule Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine