What Are The Key Influencing Factors of Capsule Filling?

Capsules have special requirements for filling. When the formulation is delivered in capsule form, the formulation mixture needs to have appropriate characteristics to ensure precise filling into the quantified capsule body.

The key influencing factors of capsule filling mainly involve the properties of the contents, the quality of the capsule shell, process parameters, and environmental conditions, which directly affect the accuracy of filling, the stability of the capsule, and the quality of the product.

1.How Do the Properties of the Contents Affect Capsule Filling?

What is the property of the content? This refers to the material used for capsule filling, which is one of the major factors affecting capsule filling.

Fluidity

Fluidity - Sourced: Making.com

Powder with poor fluidity (such as strong moisture absorption and high friction between particles) is prone to clogging equipment during the filling process, resulting in uneven filling or filling failure.

Due to its high hygroscopicity, traditional Chinese medicine extract powder may clump in the hopper of the filling machine if no lubricant (such as magnesium stearate) is added.

Bulk density

Fluctuations in bulk density can lead to significant differences in the weight of contents of the same volume, affecting the accuracy of filling dosage. Adapt to different bulk densities by adjusting the metering parameters of the filling machine, such as screw speed and plunger stroke.

Particle size distribution

Particle Size Distribution - Sourced: BulkInside

Fine particles can easily generate dust, resulting in weight loss or equipment pollution during filling; If the particles are too coarse, they may block the filling channel or cause layering during filling (separation of coarse and fine particles).

If aspirin powder does not pass the 80 mesh sieve, uneven particle size may cause fluctuations in the filling amount of hard capsules.

Moisture absorption and viscosity

Moisture Absorption and Viscosity - Sourced: Biolin Scientific

Drugs with strong hygroscopicity are prone to clumping due to moisture (such as glucose), and materials with high viscosity (such as traditional Chinese medicine containing polysaccharides) will adhere to the inner wall of the filling equipment, affecting the filling efficiency.

Material characteristics

The properties, particle size, and flowability of the drug have a significant impact on the filling rate. For example, drugs with uniform particle size and good flowability are easier to quickly fill into capsules.

2.How Does the Quality of Capsule Shell Affect Capsule Filling?

Capsule shell is one of the essential items in capsule production, and its quality also affects capsule filling.

Capsule shells can be classified into several types, as follows:

| Gelatin capsule shell | HPMC capsule shell | |

| Type | Animal derived capsule shell | Plant derived capsule shell |

| Gelatin (derived from animal bones and skin) | Hydroxypropyl methylcellulose (derived from cotton wool and wood pulp)+Water | |

| Production process

|

Animal tissue is subjected to a series of processes such as degreasing and demineralization under appropriate conditions to obtain gelatin. Gelatin or HPMC is dissolved in water at appropriate temperature to form a solution, and a specially made mold is immersed in a hot solution. When the solution is cold, gel will form a film, and then it will be dried and polished. | |

| Moisture content | 12.5~17.5% | 4%~7% |

| Solubility | Rising in cold water at 25 ℃, insoluble | Dissolve gradually in cold water at 25 ℃ |

| Friability | No | Less than 5 out of 50 grains |

| Safety | Safe and reliable, included in pharmacopoeias of multiple countries. | There is a risk of excessive preservatives and mad cow disease. |

Moisture content

Moisture Content - Sourced: Sensum

The moisture content of the hard capsule shell usually needs to be controlled between 12% and 15%. Too low a moisture content makes the capsule shell brittle (such as when it is below 8%, it may break when locked); If it is too high, it is easy to adhere (such as when it is higher than 18%, the capsule shell softens and cannot be sorted properly).

Dimensional accuracy

Dimensional Accuracy - Sourced: Manufacturing Chemist

The inner diameter, length, and wall thickness errors of the capsule shell must comply with the pharmacopoeia standards (such as the inner diameter error of No. 0 hard capsule being ≤± 0.1mm). Inconsistent sizes can lead to inaccurate positioning of the capsules in the filling machine, resulting in powder leakage or loose locking.

Shell material characteristics

Gelatin Capsule Shells - Sourced: Empty Hard Gelatin Capsules

Gelatin capsule shells need to pay attention to freezing strength and transparency, while plant capsules (such as HPMC) need to pay attention to film-forming and temperature resistance. If the freezing force of the gelatin capsule shell is insufficient (such as below 150 Bloom), it may deform due to pressure during filling.

3.How Does Process Parameter Control Affect Capsule Filling?

Capsule filling is influenced by process parameters, including speed, pressure, and other parameters involved in the filling process.

Filling speed

Filling Speed - Sourced: Flaticon

Excessive speed can lead to uneven distribution of contents in the filling chamber (such as powder stratification), especially for materials with poor fluidity. Adjust the filling machine speed according to the characteristics of the content (such as when filling powder into hard capsules, the speed is usually controlled at 20-40 revolutions per minute).

When the filling speed is fast, if the drug powder or particles are not fully filled in the shell, the filling amount will be low. If the filling speed is slow, the air content in the shell will be low, and the filling amount will be high.

Filling pressure and locking force

Hard capsules: Insufficient locking pressure can cause the capsule cap to not close tightly, resulting in powder leakage; Excessive pressure may crush the capsule shell.

Soft capsules: In the compression method, the molding pressure needs to be uniform, otherwise it may cause uneven wall thickness and rupture of the capsule.

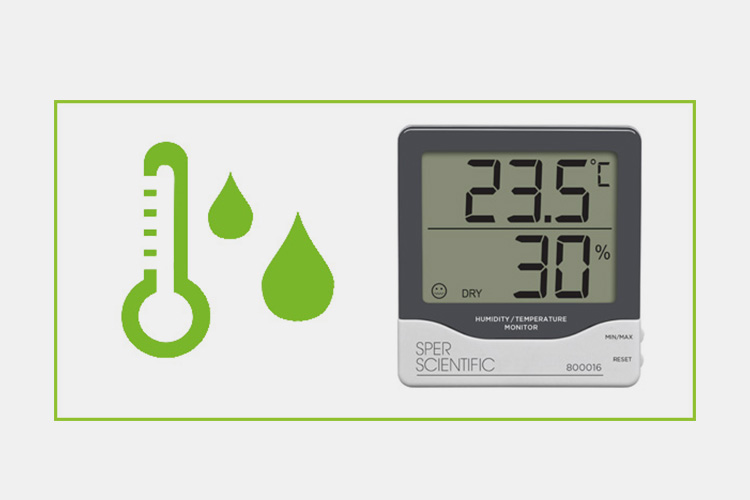

Temperature and humidity

Temperature and Humidity - Sourced: The Healing Canna

The hard capsule filling workshop usually requires temperature control of 18 - 26 ℃ and humidity control of 45% - 65%. When the humidity is high, hygroscopic contents are prone to deliquescence (such as penicillin drugs); Excessive temperature can cause softening of the contents of soft capsules (such as oily drugs).

Different filling densities

The density of powder or particles during filling can also affect the filling volume. If the filling density is high, the filling amount will be higher, and if the filling density is low, the filling amount will be lower.

Transport

Transport - Sourced: ESSPL

During transportation, if the hollow capsule is impacted and deformed, it will block the capsule filling machine during production, affecting production efficiency and product quality.

4.How Does Equipment Performance And Maintenance Affect Capsule Filling?

Machines can also affect capsule filling. The better the efficiency and maintenance of the capsule filling machine, the higher the filling accuracy.

Accuracy of measuring devices

Screw metering is suitable for uniform powder, plunger metering is suitable for particles, and multi station metering discs are suitable for high-precision requirements. Wear of measuring devices (such as screw thread wear) can cause deviation in filling amount, and regular calibration is required (such as weekly calibration with standard weights).

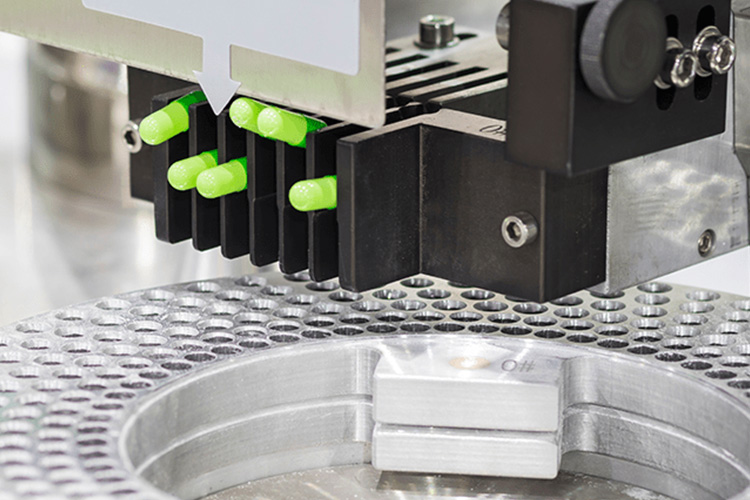

Capsule sorting and positioning accuracy

Capsule Sorting And Positioning Accuracy - Sourced: Fve. International

If there are foreign objects or wear on the capsule sorting track of the filling machine, it will cause the capsules to tilt or get stuck, making it impossible to fill accurately. The directional device of the hard capsule filling machine is malfunctioning, which may cause the capsule cap to face upwards and prevent the contents from being filled into the capsule body.

Wear and tear of filling pump

In the daily production process, if non-metallic materials are not selected for sterilization equipment, the pump rod will come into contact with the metal material during sterilization, and the metal material will stick to the pump rod, which can easily cause wear of the pump rod, poor airtightness, and bubbles during the filling process.

Equipment model

As you know, capsule filling machines of different models have different production rates. Generally speaking, large equipment has a relatively high speed due to its more complex structure and more complete functions.

5.How Do Excipients And Formula Design Affect Capsule Filling?

Due to the different ingredients and formulas of capsules with different functions. Therefore, when selecting ingredients and formulas, it will affect the efficiency of capsule filling.

Accessory selection

Adding diluents (such as lactose) can improve the bulk density of the contents, lubricants (such as talcum powder) can enhance fluidity, and anti sticking agents (such as silica) can reduce clumping. When filling traditional Chinese medicine extract powder, adding 1% to 3% micro silica gel can prevent moisture absorption and clumping.

Formula compatibility

Formula Compatibility - Sourced: SMP Nutra

The reaction between the contents and the capsule shell material (such as cross-linking between aldehyde containing drugs and gelatin capsule shell) may lead to the brittleness of the capsule shell or drug degradation.

6.How Do Environmental And Operational Standards Affect Capsule Filling?

Environment and operating standards are also factors that affect capsule filling, and damp and unclean workshops can affect the quality of capsule filling.

Cleanliness requirements

D-level Clean Area - Sourced: Cleanroomshop

The filling of pharmaceutical capsules should be done in a D-level clean area (with dust particles ≤ 3520000/m ³) to avoid microbial contamination. Particles in the air may clog the filling equipment or cause excessive microbial content in the capsule.

Operator skills

Operator Skills - Sourced: OwlGuru.com

The adjustment of filling machine parameters (such as measuring disc depth) and troubleshooting of equipment (such as checking the locking pressure when powder leaks) should be carried out by skilled personnel to avoid human errors.

Proficiency in operation

The proficiency of operators is also an important factor affecting speed. Skilled operators can adjust equipment parameters faster, handle abnormal situations, and thus improve production efficiency.

7.Why Choosing AIPAK Capsule Filling Machine?

AIPAK produces semi-automatic and fully automatic capsule filling machines, which have many advantages and can provide you with convenient choices to help you produce high-quality and efficient capsules.

AIPAK Capsule Filling Machine

New powder hopper

By using a new powder hopper, the AIPAK capsule filling machine can evenly feed, even powders with poor flowability can proceed smoothly without powder jamming. Compared with ordinary hoppers, this type of hopper takes less time to disassemble and maintain, only 8 minutes.

Capsule feeder rail

Through the stainless steel linear guide transmission system, it can effectively prevent dust from entering and reducing pollution. In addition, it can accurately transport capsules and achieve precise transportation. Automated systems can precisely control the filling process, ensuring that each container is filled in the same way, thereby improving product consistency and quality.

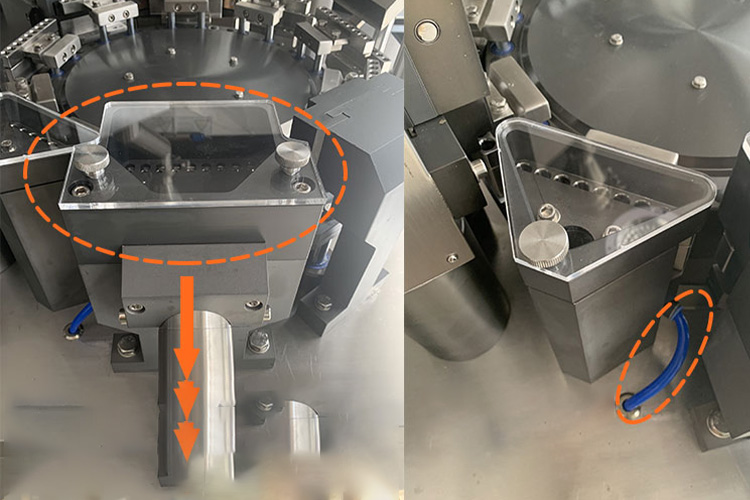

Anti-powder leakage device

During the filling process of ordinary capsule filling machines, there may be powder leakage, which can affect the hygiene of the machine and thus affect the accuracy of filling. AIPAK capsule filling machine is equipped with a powder recovery device, greatly improving the hygiene of the machine filling station.

New modular design unit

The entire device adopts a modular system, and the upper and lower modules can be moved separately, which can be quickly adjusted to achieve automatic filling, greatly improving work efficiency.

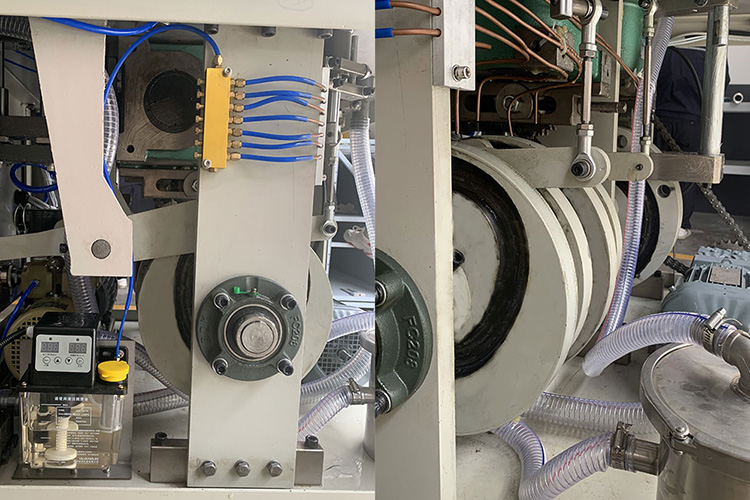

Automatic lubricating system

Automatic Lubricating System

If the machine is not lubricated, it may experience jamming or rusting. This capsule filling machine adopts an automated lubrication system, which can provide timed oil supply and extend the service life of the equipment.

New transmission system

In order to enhance the power of the machine, the AIPAK capsule filling machine adopts double chain and internal groove cam. The design of these transmission systems further enhances the stability of machine operation. This flexibility enables manufacturers to quickly switch to different product lines or container specifications to meet changing market demands.

Dry vacuum pump

Due to the use of screw rotation to generate vacuum, the noise and vibration of the dry vacuum pump of the capsule filling machine are relatively low, which does not affect the environment in the workshop and the operation of the staff. In addition, dry vacuum pumps have high pumping efficiency, low power consumption, and energy savings.

New discharge mechanism

New Discharge Mechanism

The new discharge device is equipped with a glass cover, which is in a sealed state and can reduce the entry of dust. The final capsule product will not be contaminated by external factors, further improving the quality of the product.

Conclusion

There are many factors that affect capsule filling, and if there are problems with your capsule filling process, you can consider these aspects. The capsule filling machine is particularly important, so it is necessary to choose a suitable capsule filling machine. Have you gained a deeper understanding of capsule filling after reading this article? If you have any further questions, please feel free to contact AIPAK at any time.

Don't forget to share this post!

Capsule Filling Machine Related Posts

Capsule Filling Machine Related Products

Capsule Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine