Vial Filling And Sealing Machine: The Complete Buying Guide In 2025

Are you looking for a sterile and accurately filled pharmaceutical devices? In today’s fast evolving pharmaceutical devices, and the evolving of various liquid products packaging the selection of machine can create confusion. The investment on right machine in 2025, is not just a decision, it’s a precision.

Are you planning to invest in the vial filling and sealing machine, but confuse about the features and working steps of this machine? Well, this buying guide will walk you through everything that worth knowing it, that will meet your operational needs and ensure the safety and integrity of the product.

This buying guide of AIPAK will tell you everything about this machine, so keep reading!

1.What is vial filling and sealing machine?

AIPAK vial filling and sealing machine

The pharmaceutical packaging machine that is widely used in pharmaceutical industry for the filling of liquid, powder and lyophilized substances into the small bottles, also known as vials which can then be sealed with a rubber stopper or aluminum caps to ensure the safety of products during storage and transportation. The products are filled and sealed in contamination-free environment and increase the productivity of the vials.

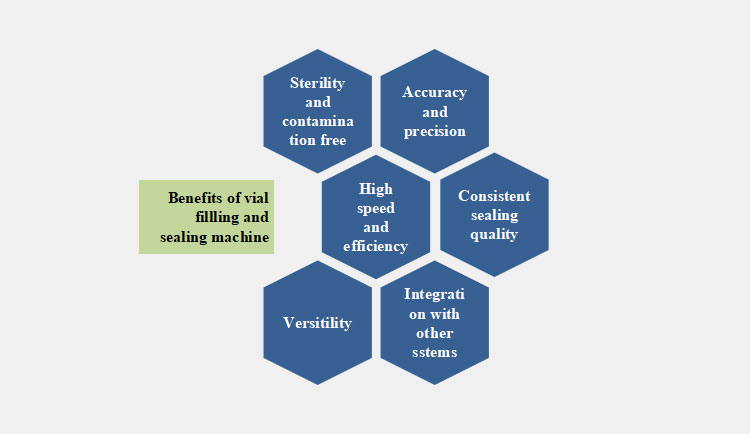

2.What advantages you can get by using vial filling and sealing machine?

Accuracy and precision of the dosage:

Accurate dosage in each vial

The accurate dosage in every vial is very important. For this purpose, the vial filling and sealing machine is used to fill the product in each vial. By using this machine, you can reduce the wastage of the products during filling in the vials and ensures you the constant product quality.

Sterility and contamination free:

The machine functions and operates in sterile and controlled environment. So, the exposure with the environment is less and hence, reduce the chances of contamination.

High speed and efficiency:

The vial filling and sealing machine has the capacity to fill and seal the vials with high speed without losing the quality and integrity of the products. You can get hundreds to thousands of vials can fill and cap the vials in an hour so, this feature can help you to use this machine for large scale production of the products.

Consistent sealing quality:

Consistent sealing

You can use this machine for the sealing of vials. The sealing is usually done by using rubber stopper or aluminum caps to reduce the exposure of contaminants with the product. The airtight caps ensures the product safety, reduce the risk of contamination, exposure to chemical changes and remains intact the molecular structure of the chemicals.

Versatility:

This machine is doing amazing job by handling various vial sizes and materials like powders, liquids and lyophilized drugs. Due to this versatility, you can fill and seal different products in different sized vials.

Integration with other systems:

If you want a complete production line, then you can integrate this machine with others’ like labelling, inspection and packaging machines for the complete production line. In this way, you can easily print the essential elements of the products, inspect and package them.

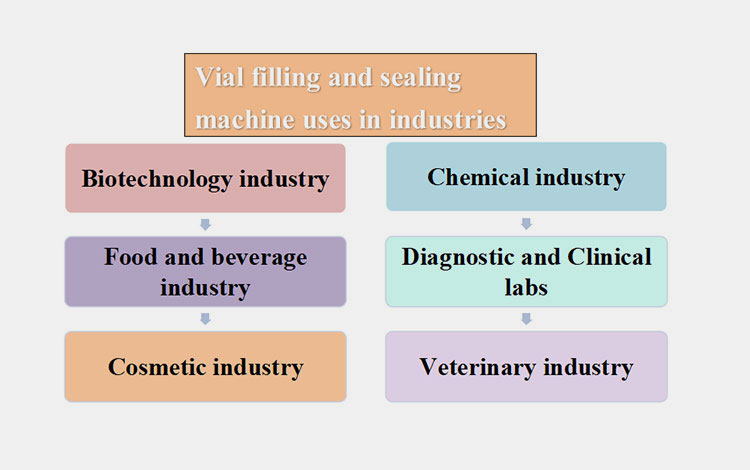

3.Besides pharmaceutical industry, enlist the industries in which can use the vial filling and sealing machine?

The diversity of vial filling and sealing machine is very vast. You can used this machine in various industries besides pharmaceutical industry. These are as follows:

Industries in which vial filling and sealing machine can be use

Biotechnology industry:

DNA solution in vials in biotechnology industry

Biotech products are sensitive and often require sterile and airtight containers. These products require sterile storage condition for its effectiveness. The vial filling and sealing machine fill and seal the products that you needs for research, clinical trials and laboratory testing. The DNA/RNA solutions and enzymes are stored in sterile vials for effective and accurate results.

Food and beverage industry:

Vials in food and beverage industry-Picture courtesy: rodellekitchen.com

The filling of food and beverage products and edible substances are filled with flavored substances, aroma extracts and vitamin shots in small vials and ampoules. The small doses of functional drinks are filled and sealed in a small vials. The health focused substances that can boost your immunity and other energy booster like caffeine energy shots and immunity boosters in 10 mL vials are the application of food and beverage industry.

Cosmetic industry:

Serum in vial in cosmetic industry-Picture courtesy: zenaofficial.eu

The cosmetics and skincare products need airtight, light and contamination free vials for storage of sensitive products. The serum, essential oil and anti-aging serums and vitamin C ampules are filled and sealed in glass vials for enhancing the luxury skincare brands.

Chemical industry:

Vials in chemical industry-Picture courtesy: akciza.net

In chemical industry, the indicator solutions and titration reagents are fill and seal in essential vials. The vials prevent the leakage, contamination and exposure with an environment. The vials are essential to provide safety storage and transportation of the substance.

Diagnostic and clinical labs:

Covid-19 vaccine vial in diagnostic and clinical labs

The accurate dosage and stability of buffers and other sample preservatives are essential for use in lab kits and automated testing system. This ensures the stability and accurate test results. Blood test kits and COVID-19 PCR test kits are stored in small vials.

Veterinary industry:

Vials used in veterinary industry

The veterinary and animal care industry fill and seal injectable deworming solutions and vaccines of pets and animals in a small and sterile vials. This ensures the individual pet treatment or mass livestock treatment programs. Vials are filled with bovine antibiotics, and other antivirus vaccines.

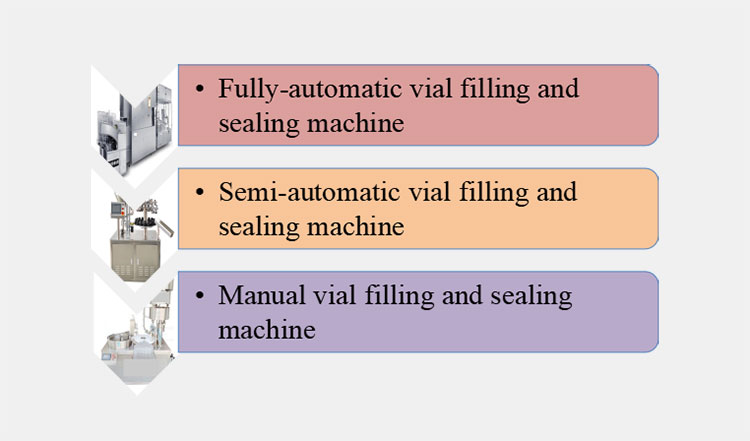

4.What are the types of vial filling and sealing machine available in the market?

In the market, you will noticed various types of vial filling and sealing machine available. Each one has its own advantages. They are as follows:

Based on automation level:

Division of vial filling and sealing machine based on automation

Fully automatic vial filling and sealing machine

Fully automatic vial filling and sealing machine

The fully automatic vial filling and sealing machine can carry all the processes like feeding of vials, filling, sealing and crimping etc. all in one machine. You can also integrate this machine with isolators for aseptic filling of products into the vials. This machine can handle all of the processes in one machine so, its speed of production is also high.

This machine is ideal for your business if you want a high production of vials.

Semi-automatic vial filling and sealing machine:

Semi-automatic vial filling and sealing machine

In semi-automatic vial filling and sealing machine, in some steps the operator intervention is needed. The machine can automatically fill the vials with a solution but the stoppering and sealing needs the help of operators. This machine is low in cost and produce less products as compared to fully-automatic vial filling and sealing machine.

If you wants pilot-scale production or small batches of vials, then you should invest in this machine.

Manual vial filling and sealing machine:

Manual vial filling and sealing machine

This machine is the simplest machine in which you have to feed, fill, and seal the vials. This machine is easy to operate and needs no professional training. But this machine needs labor which cost you more. Also, the production in this machine is low because the human hands process is time taking as compared to machine.

If you wants R & D production or use in labs, then you should invest in this machine.

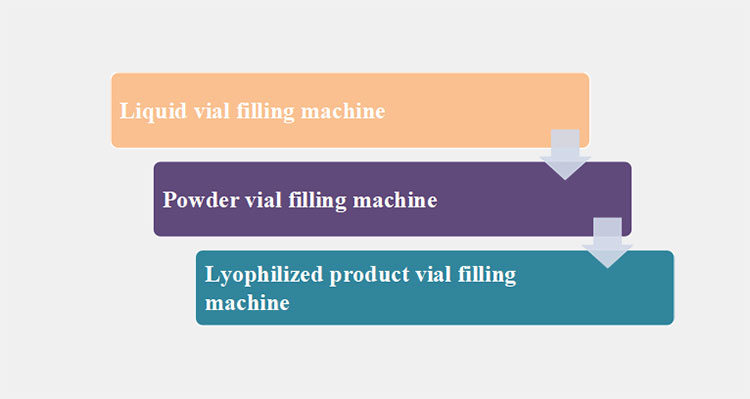

Based on filling product type:

On the bases of filling in the vials or product type, they are divided into following types.

Division based on type of products to be filled into the vials

Liquid vial filling machine:

Liquid vial filling machine

The liquid vial filling machine is a specialized machine which is used to fill the liquid products into the sterile vials. The liquid products can be oil, aqueous solution or viscous liquids. The specialized filling system in this machine is peristaltic pumps, piston pumps, or time-pressure systems which is used for the filling of these liquid filling materials into the vial.

Vaccines, injectables and drugs are filled into the vials by using this machine.

Powder vial filling machine:

Powder vial filling machine

The powder vial filling machine is used to fill the powdered substances into the sterile vials. The specialized systems for filling that is integrated in this machine is auger filler or vacuum dosing system. This machine is often integrated with lyophilizers.

Lyophilized product vial filling machine:

Lyophilized product vial filling machine

This machine is used to fill the vials with liquid drugs which is later cover with a partial stopper to allow the evaporation of moisture during lyophilization. This machine is ideal for handling moisture sensitive and heat sensitive drugs which is then later change into freeze-dried products and finally sealed them.

The filling system that is used in this machine is peristaltic or piston pump which is used to pre-filled the vials with liquid filler and then is followed by the freezing drying.

The prolong shelf-life of the products, also the sterility and stability of the products is the major benefits of the freeze-dried or lyophilized products.

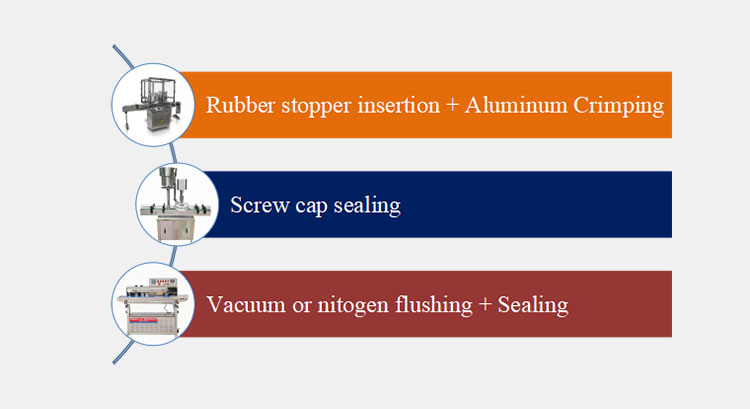

Based on sealing type:

Division of vial filling and sealing machine based on sealing type

Rubber stopper insertion + Aluminum crimping

Rubber stopper insertion and aluminum crimping machine

The rubber stopper insertion and aluminum crimp seal can be done by rotary vial machine. The inert gas like nitrogen gas is flushed before and after the filling. It has a circular, rotating station that moves the vials through each station for filling, stoppering and sealing in a synchronized way.

Capping and sealing

The aluminum caps are placed over the rubber stopper through a cap chute. The rotating crimping head presses the aluminum cap for sealing. The quality consistency throughout the batch production is ensure.

Application of this machine

This machine is suitable in pharma for the filling and sealing of vaccines and insulin’s etc.

Screw cap sealing

Screw cap sealing machine-Picture courtesy: mahalaxmimachine

The screw cap sealing can be done by linear vial filling and sealing machine. The vials in straight line along a conveyor for carrying out different procedures in a stations.

Capping and sealing

The caps are placed onto the neck of the vials and then screw capping is done. This machine is cleanable and you can easily look after the machine. This machine has an amazing feature as it allows changeover for different sized and material of the vials.

Application of this machine

This machine is widely used for both sterile and non-sterile use and used for the cosmetic and some diagnostic applications.

Vacuum or nitrogen flushing + sealing

Vacuum or nitrogen flushing + sealing machine

The vial filling and sealing machine like monoblock machine has a compact unit in which filling and sealing occurs in one machine. It is designed in which the reduction of oxygen occur by flushing nitrogen gas into the vials and displace the oxygen from the headspace.

Vacuum assisted stoppering

Through vacuum chamber, the oxygen content is pulled out of the vial head and then rubber stopper is inserted. This process can reduced the residual oxygen level and enhance the shelf life. This machine enhances the coordination, and reduce the risk of contamination.

Applications

This machine is fully-automatic and ideal for aseptic environment. It is suitable for use in pharmaceutical, biotech and high-value sterile products.

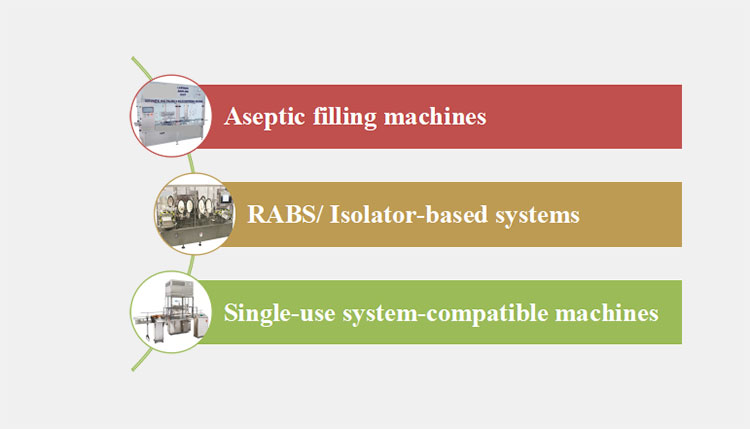

Specialty systems:

Specialty systems

Aseptic filling machines:

Aseptic filling machine

The aseptic filling machines are used to fill the sterilized liquid products into the sterilized vials. The tool used for filling of these liquid materials are peristaltic pumps, rotary piston pumps and time-pressure system. This ensure the accurate dosage filling of materials into the vials.

Integration

These machines are often integrated with robotics for obtaining automated system and high speed production. It also operate under laminar airflow or in isolators to maintain sterility.

RABS/ Isolator-based systems:

RABS/Isolator based system

The modern filling machines are integrated with RABS (Restricted Access Barrier System) or isolator. In RABS, there is barrier between the cleaned room in which the aseptic filling procedure occur and the operator.

In isolators, fully closed systems for aseptic processes occur and operator use separate glove ports. This provides high contaminant environment. As the process is carried out in separate chamber and without the interaction with external environment so, highest sterility assurance is ensured.

Single-use system-compatible machines:

Single-use system-compatible machine

In single-use technologies, the disposable components like filling needles and bags etc. are used once and are discarded. These machines are ideal for small-batch sized production. The benefit you can get by using this machine is reduced cleaning and validation.

There is high product safety because the components are pre-sterilized and you can discard them after use so, lower the risk of cross contamination.

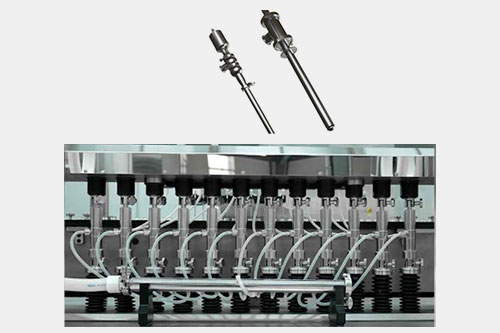

5.Do you know the components of vial filing and sealing machine?

The vial filling and sealing machine consists of different parts which works in integrity to fill and seal the vials. The main components of vial filling and sealing machines are:

| Components | Function |

| Infeed conveyor

Infeed conveyor |

This station receives the empty vials and properly align them and properly spaced the vials before feeding them into the vial filling station. |

| Vial transfer system | Do you know which component is responsible for the transferring of vials between different stations? It’s the vial transfer system which can prevent misalignment and breakage of the vials during transferring them for filling, stoppering and sealing procedure. |

| Filling station

Filling of vials-Picture courtesy: idealpase.com |

There is a system require to fill the accurate amount and dosage of liquid or powder into the vials. It’s the dosing system in the filling station that controls the correct dosage and through the filling nozzles, the filling materials are filled into the vials. |

| Stoppering station

Placing the stoppers in vials |

Have you ever wondered what’s the purpose of the stoppers that can be seen in most vials? It ensures the airtight seal before capping to avoid any contamination. The stoppering station automatically placed a stoppers into the neck of your already filled vials. |

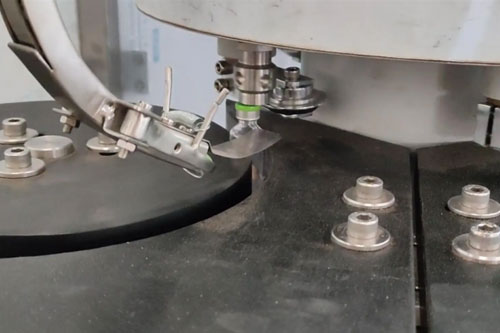

| Capping or sealing station

Capping station-Picture courtesy: harikrushna.com |

The aluminum caps are then placed over the stoppers and crimp it either through rotary crimping procedure or through single head crimping. The purpose of crimping is to provide the tight and secure tamper-proof seal. |

| Inspection system | In some machines, the process is completely visible to the operators to detect the accurate placing, filling, stoppering and capping method. |

| Outfeed conveyor

Outfeed conveyor |

The vials are then transferred to labelling out of the machine. This maintains the smooth production flow and reduce the operator handling. |

| Control panel

Control panel |

It functions as the brain in the machine which monitor and control the machine functions. The operator allows to select the vial format, set fill volume and manage recipes. |

6.What are the working steps of vial filling and sealing machine?

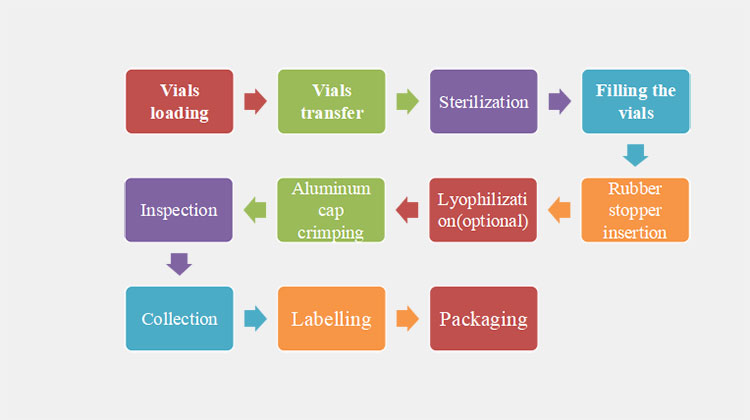

You must have an idea of the steps in which the vial filling and sealing occurs. The working steps are as follows:

Flowchart of vial filling and sealing process

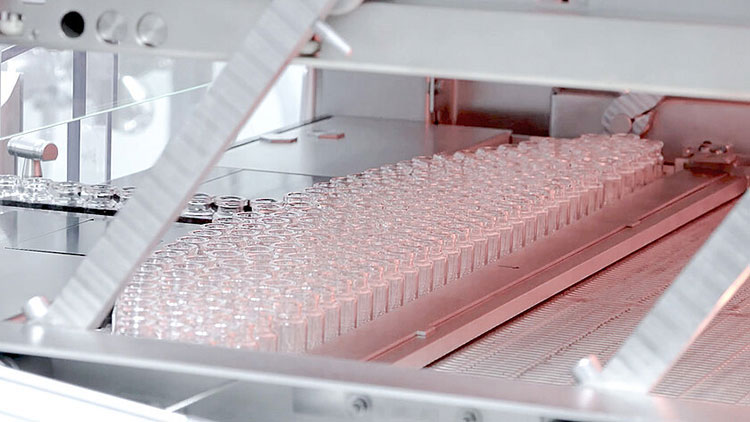

Vials loading:

Loading of vials

The voyage of the vials filling and sealing has been started here. In the first step, you have to feed the empty vials into the infeed conveyor. The machine automatically placed and properly spaced the empty vials and to prevent misalignment of the vials. The purpose of properly alignment of vials are to transfer them into the next station for the properly filling of the vials.

Vials transfer:

Now, the empty vials move to the next station. The vials move smoothly and synchronized. The vials are transferred one by one or in groups using indexing conveyor or star wheel. It is also ensured that each vial reached to the exact place where it is needed. This station ensures the safety and avoid any damage.

Sterilization :

Sterilization of vials

The vials are sent to the depyrogenation tunnel where the vials are subjected to the high temperature to ensure the vials are free from germs and contamination. The sterile vials are then cooled before transferring to the filling station.

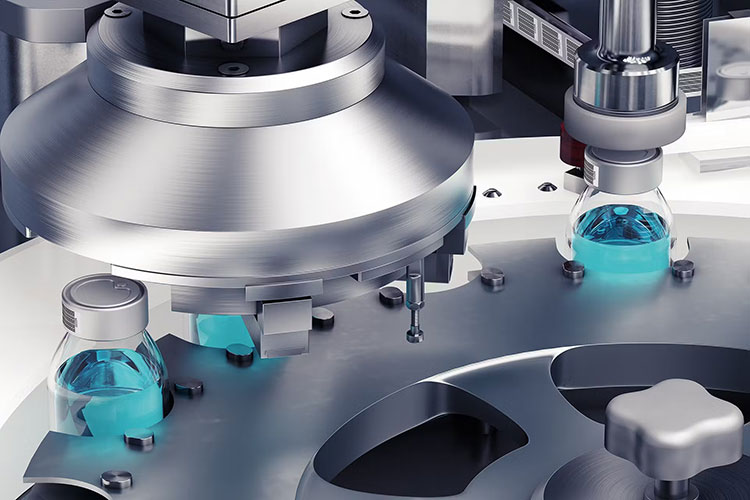

Filling the vials:

Vials filling with liquid material

This is the heart of the process in which the filling nozzle moves into the place and fill the vials with liquid or powder, which is desired to be filled. There is no lost or wastage of the filling materials occur and you can get a precisely measured quantity of the product into the vials.

Rubber stopper insertion :

Addition of stoppers to the vials-Picture courtesy: manufacturingchemist.com

Do you want a firm but not tight sealing? The little rubber stoppers are placed in the neck of the vials to stop the content exposure with the environment. The stopper seal can stop the contamination and ensure the integrity of the product.

Lyophilization( optional):

Lyophilization of products

Some of the vials in stopper addition step are equipped with partially inserted stoppers and that vials are transferred to lyophilizer if you want a product that is rid of water. The products are then dried there by removing water and after that, the stoppers are fully pushed inside the vial.

This step is mostly occur in vials having powdered material is filled because those materials are sensitive to moisture but this step ensures the safety of these products.

Aluminum cap crimping:

Vial sealing with an aluminum cap

After adding the stopper, the aluminum cap is placed over the stopper. Is just placing the cap over the stopper completely seal the vial? For the completely and securely seal, you should crimp it with a crimping tool that tight the aluminum cap and obtain a tamper-proof vials.

Inspection:

Automatic inspection of vials-Picture courtesy: vitronic.com

In this step, the automatic or manual inspection of the vials occur. If the machine or operator observed any damaged vials, improper stoppers, products clarity and cap replacement then those vials are rejected. This ensures the quality and accuracy of the vials.

Collection of vials:

Collection of finished vials-Picture courtesy: mga-tech.com

Finally, the finished vials are discharge and collected through the exit area. You can see the clear, undamaged and aesthetic vials. Their voyage through the machine has been completed.

Labelling :

The finished vials are then transferred to the printing machine where the batch number, QR code, ingredients, dosage and other essential information regarding the vials are printed on the vial. This ensures the satisfaction of the consumers.

Packaging :

vial packed in box

The packaging of the vials are crucial because it ensures the safety of the vials. You can deliver undamaged vials to the market if you package them in a sturdy boxes.

7.Is the vial filling and sealing machine harmonize with other systems to optimize production workflows?

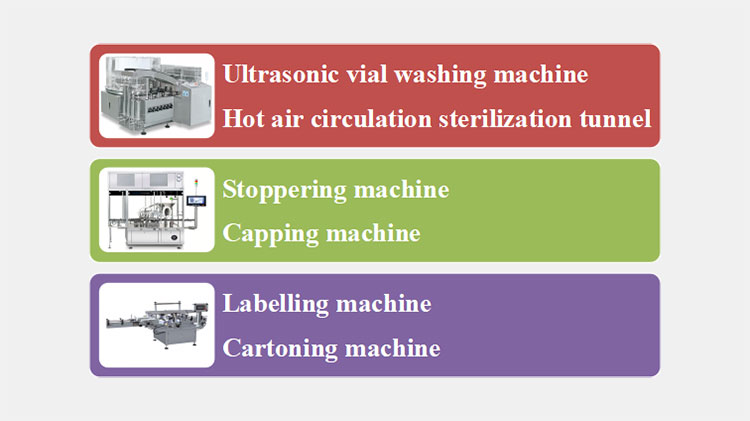

Machines that can be harmonized with vial filling and sealing machine

To harmonize the vial filling and sealing machine with other systems or machines means the machine works in coordination and performs it function in sync. You can get biggest advantages in modern industries.

Ultrasonic vial washing machine

AIPAK ultrasonic vial washing machine

If the vial washing machine is integrated with vial washing machine then it wash the empty vials before they are filled with a filling materials. This can prevent the vials from contamination. The benefits of harmonizing this system with a vial filling and sealing machine is to get the sterilized and clean vials before filling.

Hot air circulation sterilization tunnel

AIPAK Hot air circulation sterilization tunnel

If you integrate sterilization tunnel with vial filling and sealing machine then the sterilized vials are directly fed into the vial filling machine for the filling mechanism. The sterilized vials are transferred through sterile transfer mechanism. In this machine, the vials are sterilized with hot dry air that are heated at 300-350 °C and in this way, sterilized vials are obtained.

The laminar hot airflow occurs through the vials and the sterilized vials are transferred for filling. In this way, synchronized workflow occur.

Stoppering machine

Stoppering machine-Picture courtesy: turbofil.com

The stoppering machine is often integrated with vial filling and sealing machine to insert stoppers immediately after filling. This machine ensures the sterilized stoppers insertion into the vial neck to protect the materials inside the vials from the germs.

Capping machine

Capping machine-Picture courtesy: medicalexpo.com

If you harmonize this capping machine with a vial filling and sealing machine, then this machine synchronized capping head with the incoming flow. It places the aluminum caps over the rubber stopper and seal them by crimping. The capping procedure is the final sterile step in vials processes.

Labelling machine

AIPAK labelling machine

The harmonizing of the labelling machine with a vial filling and sealing machine is the finished vials are directly and smoothly passed for the labelling of batch number, dose and expiry date on the vials. This ensures the smooth workflow and you can get a perfect vials.

Cartoning machine

AIPAK cartoning machine

The integration of this machine ensures the final step and in one-go you can get finally packs of cartons. The cartons of vials can be stored and then ready for transportation to the market and pharmacies. The automatic cartoning machine can reduce the labor cost and you can get bundles of vial cartons in a very less time.

8.Can vial filling and sealing machine handle different vial sizes?

You must be wondering is the vial filling and sealing machine is compatible with your vial sizes? Yes, you can get benefit from vial filling and sealing machine as it can handle different vial sizes. The detail is given below:

Handling different vial sizes:

2 mL to 30mL different vial sizes-Picture courtesy: daspacking

The vial filling and sealing machine are flexible in handling and accommodating the different vial sizes. The capability of holding the vial sizes are from 2mL to 30mL. Vial holders are adjustable for various sized vials and filling nozzles are adjusted for the liquid filling in the vials.

Automatic size detection:

In high-end system, the servo motor or preset programme in the machine are automatic adjusted according to the vial sizes.

9.What are the common challenges you faced while operating a vial filling and sealing machine?

Challenges while operating vial filling and sealing machine

When you are running a machine, at first glance, you will be thinking that just turning on the button of the machine will create a magic for you. But, while operating the vial filling and sealing machine, every drop needs a precision and sterility, and you can face the various challenges. These are as follows:

| Challenges | Explanation |

| Stoppage of machine | Even though the machine is automatic but you can face the overcrowd of the stoppers in the feeder, filling needle may clog and accurate dosage in each vial might affect or the sensors get misalignment then the machine suddenly stops. |

| Vial breakage

|

If one vial breaks during the vial transferring or capping then it completely impact your schedule. You have to stop the machine as soon as possible, clean it and then will restart. This is time taking and can delay the production. |

| Fill volume inconsistencies

|

If the calibration has not set properly or the viscosity of liquid changed during process then if one vial is underfilled then it can be rejected during inspection. |

| Neglecting sterility

|

Sometimes the operator in the room does not wear gloves, gown, mask and more. Due to this, the chances of contamination are rise. Every touching with something during vial filling and sealing require sanitization. So, always wear gloves, gown and mask. |

| Changeovers are seamless and efficient | Sometimes, the changeovers between vial size and require is not as quick as it seems. It requires cleaning and recalibrating the functions of the machine. so, if you will be in rush then it can impact the overall production. |

10.What should you consider while buying a vial filling and sealing machine?

Once you are in the market, you’ll realize that investing in vial filling and sealing machine means you are choosing a business partner. This will increase the efficiency, speed and product quality. The following points should be considered while buying a vial filling and sealing machine.

What will you be filling?

Is the vial desired to be filled with powder or liquid? Picture courtesy: manufacturingchemist.com

First of all you should know your product to be filled in the vials. Do you want to fill liquid, powder or suspension? Are your products sensitive to light and temperature? You must have in mind the products to be filled in the vial because it’s like buying a sport car and you drive it in a farm.

What is your required fill volume and accuracy?

Different sizes vial for filling-Picture courtesy: daspacking

Is the fill volume in the vial is 0.5ml or 30ml? Choose a correct machine for filling the required fill volume in the vials without compromising the precision.

What vial sizes and formats do you use?

Is your machine can handle various sizes and formats of vials? Or is your machine can handle just one vial size? You should invest in flexible machine so that your production demands change.

Automation level

You should ask yourself do you want high production or low production. Or do you want the human effort in the production process? Then you should invest in semi-automatic or fully-automatic vial filling and sealing machine.

Cleanability and sterility

If your machine is cleanable and can easily be cleaned then your products will be free from contamination.

Compliance and certification

Compliance and certification

Compliance is the foundation for trust in pharma. Your machine meets the GMP, FDA, EU, and WHO requirements.

Integration with other equipment

Choose a machine that can integrate with other equipment’s like washing machine, labelling machine and cartoning machine. This can grow your production line and smooth workflow occur.

Conclusion:

After reading this buying guide, now you’ll able to know about the benefits and usage of vial filling and sealing machine in pharmaceutical industry. You must be astonished and surprised that you can also use it in other sectors as well. Whether you are filling the vials with liquid, powder or lyophilized formulation, the right machine will ensure you the guarantee of high speed of production, sterility, and less wastage of materials. You can also integrate this machine with other machines and can create complete production line. In 2025, various vial filling and sealing machines are available, but AIPAK can guarantee you high quality machines. If you still have any query, feel free to contact us!

Don't forget to share this post!

Vial Filling Machine Related Posts

Vial Filling Machine Related Products

Vial Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine