Sterile Vial Filling Machine: The Complete Buying Guide In 2025

Are you looking for a machine that accurately fills your vials? Well, for this there is equipment, a sterile vial filling machine. This machine ensures compliance with hygienic standards and precisely fills vials. The demand for sterile vial filling machines cannot be undergone across industries-pharmaceutical, cosmetics, biotech, and others- where product sterility and integrity are necessary.

Behind patient safety and contamination-free product storage is the sterile vial filling machine as every drop dropping in a vial demands flawlessness. If you work with liquid and powder form products, then this is the best choice as it can fill both of them.

However, this equipment is available in other models. Now, how do you choose the right vial filling machine for your operation? Don’t worry- this buying guide will provide you with information that will help you while buying. Let’s get started.

1.What do you know about vials?

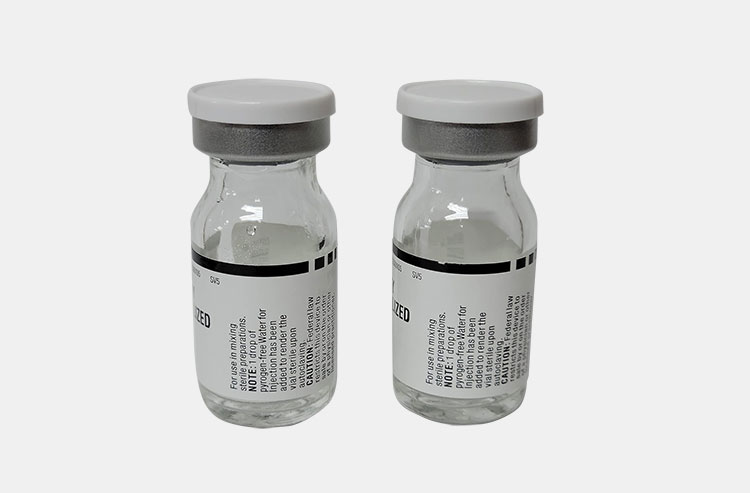

Vials

Vials are small bottles used to store medicine, hormones, vaccines, and dry products. They are either made from glass or plastic. Vials comes in various size from small to large, with caps or stoppers that protect the inner product from reaction with environmental gases. To fill syringe from vial, it is pierced through the stopper. They have flat bottom, capable of storing standing in a shelf. Vials are designed to protect the holding contents to ensure safety of the patients who will use them.

2.What is sterile vial filling machine?

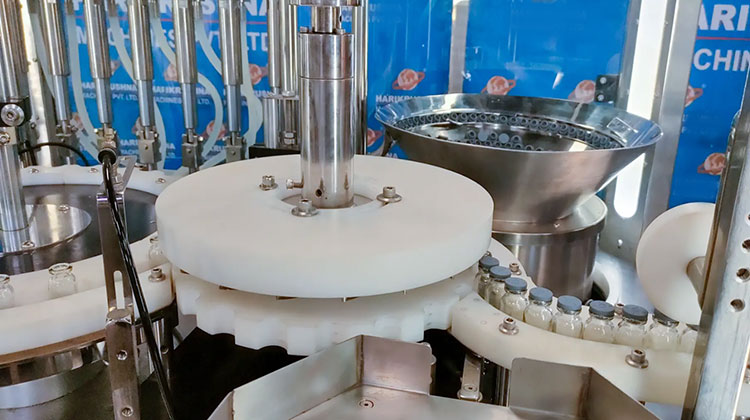

Sterile vial filling machine

Sterile vial filling machine is an equipment designed to aseptically fill vials. Filling is done with high accuracy and under the sterile, controllable solution. Vials are filled from either liquid or powder. With an automated system, it ensures no product wastage, accurate volume, and operates within sterile isolator to prevent no microbial contamination throughout process. Moreover, it operates at high speed so it is ideal for large-scale operations.

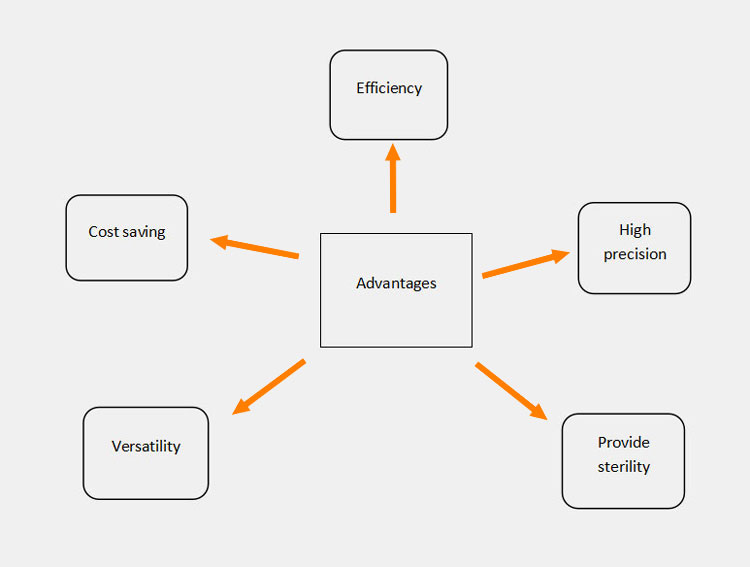

3.Enlist the advantages of using a sterile vial filling machine?

A sterile vial filling machine provides you with numerous advantages. These advantages are given below. Read it and equip yourself with its advantages which will help you in making decision.

High precision

High precision-Picture courtesy: apsf.org.com

This type of machine precisely and accurately fills vials, equal in volume and weight by using piston pump. Due to this, the product wastage is minimum because there is no human intervention where wasting chances are relatively high.

Efficiency

Efficiency

Due to automated system, sterile vial filling machine operates at high speed that fills hundreds of vials in a minute, ensuring efficiency. This fulfills the demands of customer in a very less time, compared to when done manually.

Provides sterility

Provides sterility-Picture courtesy: premiumvials.com

Another important advantage is that it provides sterility of the vials. These are filled under sterile environment by operation the whole process in isolators that prevents microbial contamination. Moreover, the liquid and powdered injectables are used by patients so, even a small number of microbes can lead to a big health problem.

Versatility

Versatility

Modern sterile vial filling machines are designed to handle different vial sizes, materials to be filled, and vial shapes. Some machines have reconfigurable setup for the different production line and requirement. Hence, it is the ideal choice for operations that overseas various products.

Cost saving

Another advantage that it showers you with is it saves you from any extra expenses. It fills vials without underfilling or overfilling from the injectable liquids or powders that reduce the spills, leading to cost-savings. Its energy consumption is slightly lower- cut down the operational costs.

4.What industries use a sterile vial filling machine?

Followings are the industries that uses sterile vial filling machine.

Pharmaceutical industry

Pharmaceutical industry

This industry widely uses a sterile vial filling machine to fill vials from antibiotic, vaccines, insulin, hormones etc. These are filled with under cautious conditions. As these injectable medications go in bloodstream. Therefore, small drops of germs can be a big deal for health.

Veterinary industry

Veterinary industry-Picture courtesy: caloforniapetpharmacy.com

Animals and pets’ medicines also need controlled and microbe’s free environment for their stability and prevention from contamination. These injectable medicines are filled in sterile vials. Clean and sterile is necessary as one diseased animal can leads a widespread disease in herd or flock.

Cosmeceutical industry

Cosmeceutical industry

Have you ever thought that how the cosmeceutical products are stored? The cosmeceutical industry uses vials to fill skin products such as antiaging serum, a botox serum, microneedling serum etc. All of these are injected on sensitive areas. Ingredients in them are sensitive to air, temperature and other environmental factors, so, these vials provide protection to the above serums.

Biotechnology industry

Biotechnology industry-Picture courtesy: thermofisherscientific.com

The cells therapies, RNA/DNA based drugs etc. are sensitive. These are stored in sterile environment to protect from degradation and maintain the product sterility. So, biotech industries use these sterile vial filling machine to handle sensitive products.

Chemical industry

As you came to know the importance of sterile vial filling machine in pharmaceutical and other industries; its importance can’t be overlooked and is importance equally in chemical industries. Some of the chemicals and reagents are sensitive. Slight concentration variations or changes in them cause ineffective and flop experiment. Sterile vial filling machine provides accurate dosing.

5.Describe the components of sterile vial filling machine?

Different parts of machine work together to ensure precise filling and automation. Followings are the components of sterile vial filling machine.

|

Components |

Explanation |

| Stopper feeder

Stopper feeder |

Stopper feeder is aligning with sensor to detect whether the stopper is present or not. Stopper feeder ensures the guaranteed supply of stopper by maintaining sterility. It actually includes hopper to hold vials. |

| Cover feeder

Cover feeder |

There are components names the cover feeder that supply caps of different sizes to the machine for sealing vials. It has the mechanism to feed and orient caps to the machine. |

| Plunger pump

Plunger pump |

Vials are feeded into machine. But, what next? After this, vials are filled by using plunger pump. It ensures a precise and accurate filling of vials, prevent product wastage by underfilling or overfilling. It handles products of various viscosities. |

| Vial rotary plate

Vial rotary plate |

As from its name, you can assume its function that it holds and rotate vials during their filling. It has a rotating table that ensures correct position of vials for filling, stoppering and capping. |

| Vial feeding plate

Vial feeding plate |

Vial feeding plate is designed to feed vials to machine. It ensures sterile and microbes free supply |

| Rotary capping plate

Rotary capping plate |

It applies caps to the filled vials. To tightened caps, torque system is used. This ensures air tight and temper proof sealing. |

| B-knife centrifugal plate | When product is getting in excess amount, this plate is used to remove excess products, removes debris. It maintains the overall cleanliness of machine. |

| Finish vial plate

Finished vial plate |

It collects the fully processed vials. It may has an inspection mechanism through which they are inspected that either all vials are properly processed or not. This prepares vials for the packaging. |

| Main frame

Main frame |

Main frame is the body of machine, made up of stainless steel. It provides structure and durability to the machine. |

| Control panel

control panel |

It has sensors, displays, or touch screen features. It allows users to monitor and control machine, ensures efficient operations. |

6.What is the step involved in sterile vial filling machine?

Followings are the steps involved in a sterile vial filling machine to ensure aseptic liquid and powder filling. Here are the following steps.

Vial feeding

Vials feeding- Picture courtesy: comecer.com

The first step in a sterile vial filling process is the vial feeding. Vials are loaded in rotary infeed table. Here, vials are carefully arranged and make sure no vial breakage. One thing must be kept in mind that is the sterile conditions or environment. This is because vials should be clean and microbes free as the sensitive drugs or medicine are to be filled in.

Sterilization

Sterilization-Picture courtesy: Groninger.com

Another important step is passing vials to depyrogenation tunnel in order to sterilize from microbes or germs. The process of sterilization begins with passing of vials to depyrogenation tunnel where a gentle heat is provided to minimize the thermal shocks.

Afterward, a high temperature is given and expose vials to dry heat of 250 centigrade. As added to your information, a high temperature kills microorganisms, therefore, it is much needed for vials cleanliness.

Before moved to aseptic filling, vials are cooled and, then, transferred.

Aseptic filling

Aseptic filling

This step requires nothing but a perfection in filling. Here, the sterilize vial are filled with drug solution. Aseptic filling is done automatically as manual modes have human intervention that can leads errors and germs addition. A minor error ca risk the patient’s safety.

The whole process is done under a cleanroom or an isolator. The goal is accurate filling, stable product quality ad sterility.

Stoppering

Stoppering

The aseptic filling of vials reaches its final shape or the nectar of fruit is here, and stoppering is considered the nectar of fruit. After aseptically fill vials, they are moved for sealing. Stopper is used to seal the vials.

Stoppers are also pre-sterilized. For liquid vial fillings, stoppers are places immediately after filling. While, for the lyophilized products, stoppers are partially inserted. This process is completed within moments-just like the snap of fingers- since environmental exposure can be a big deal.

Lyophilization

Have you ever wondered why some of the drugs are in powdered form? Because some of the products cannot remain stable and sensitive to moisture and heat in liquid form. For this. Lyophilization is done after vial filling and partial stoppering.

Here, the products are solidified and then by sublimation, it is changed into freeze-dry. At the end of lyophilization, partially inserted stopper is fully sealed to ensure germs-free and long-term storage.

Capping

Capping -Picture courtesy: packaging strategies

When vials are filled, stopper, and sometimes lyophilized, the vials are moved for the capping. This is done to ensures the tightly and temper proof sealing of the vials. Aluminum made caps are actually used that are pre-formed.

These caps are placed over the neck of the vials and crimped. How it will know that caps are poorly capped? There are sensors that detect the misaligned and defective capping and rejects them. To protect the question mark on the company reputation, this is done with great attention as the poor sealing can spoil the batch size and compromise years of research.

Packaging

Packaging

One of the important steps is packaging. Vials are made ready for the delivery. Vials are checked either by automated system or manually. Defected vials are removed and non-defected vials are moved forward for further process.

Product information, batch number, expiry date and other information are labeled on the vials. Now, they are ready for the secondary packaging.

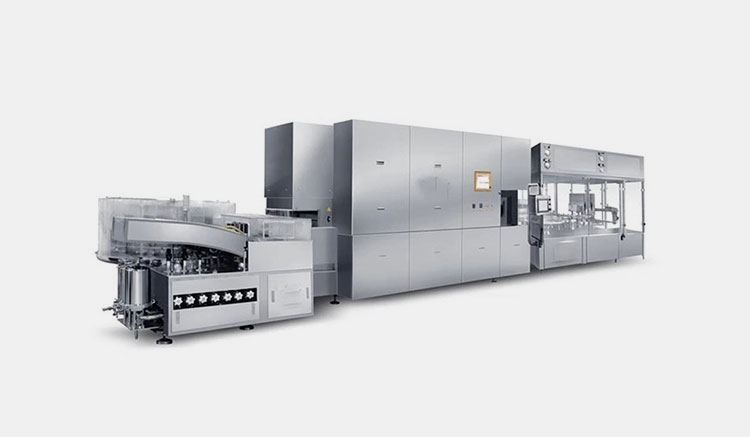

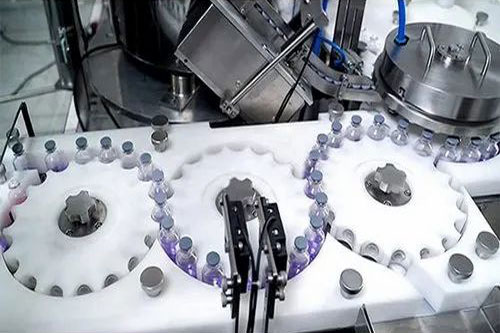

7.What is the production line of a sterile vial filling machine?

In a sterile vial filling line, there are numerous machines used to ensure the efficient and safe vial filling. Are you excited to know? Let’s ready to explore them.

Vial unscrambler machine

The proper organization process starts with unscrambler machine. What it’s job? It is designed to orient vials for feeding.

When the unorganized vials are come, this machine organized them evenly and line up automatically for washing and further process.

Production line

AIPAK sterile vial filling machine production line

Sterile vial filling machine is composed of

- Ultrasonic bottle washing machine

- Dryer sterilizer

- High speed filling

- stoppering machine

- Cap rolling machine

You can use these machines separately or in line. Here are the above machines in detail.

Ultrasonic bottle washing machine

This machine is designed to wash vials by using high frequency waves. Cleaning is done for the effective filling of vials without contamination. Here, tank is filled with vials that is rinsed with purified water and ultrasonic waves are passed that creates bubble which are burst produces shockwave and removes dust and other particles from inside out.

Dryer sterilizer

After washing, hot air tunnel dryer is used to dry and sterilize vials. It uses hot air and dry heat to ensure no contamination, microorganisms, and moisture are left on the vials.

It works by heating vials on low temperature in sterilization, then, the temperature rises to about 3000 centigrade. High temperature is efficient to kill any bacteria, viruses, or any microbes. Vials are cooled down to further pass for filling.

High speed filling machine

Next important step is filling vials from drugs or medicines. This is done by using filling machine. High speed filling machine is used to fill hundreds or thousands of vials in no more time accurately and accurately by using filling nozzles or peristaltic pump. Sensors are used to detect the vials volume.

Stoppering machine

Sealing vials is done by using stoppering machine. This type of machine is designed to stopper vials by using rubber stopper on the neck of vial delicately as too much pressure can damage both stopper and vial and low pressure can result in poor sealing. This ensures air tight and temper-proof sealing and securing the products in vial.

Cap rolling machine

This machine is designed to cap the stoppered vials. Why need a cap when did a stoppering? This is because stopper does not completely seal the vials. It needs a protective cap for complete sealing. This ensures product integrity and protection.

Pharmaceutical autoclave

AIPAK AQS series steam vial pharmaceutical autoclave

Pharmaceutical autoclave plays an important role in the sterilization of parts involved in sterile vial filling process. These are vials, rubber stoppers or aluminum caps. Sterilization for the elimination of bacteria, spores, and other microbes.

It works by using the principle of high temperature and pressure, and uses saturated steam for sterilization. The sterilization is not limited to vials but also the machine parts could be sterilized before entering into the aseptic environment.

It can be integrated into the sterile vial filling line as an important piece of equipment to ensure the safety and effectiveness of the product.

8.Write types of products that can be filled via a sterile vial filling machine?

A sterile vial filling machine is used to fill different products in sterile vials under aseptic condition. Here are the following products.

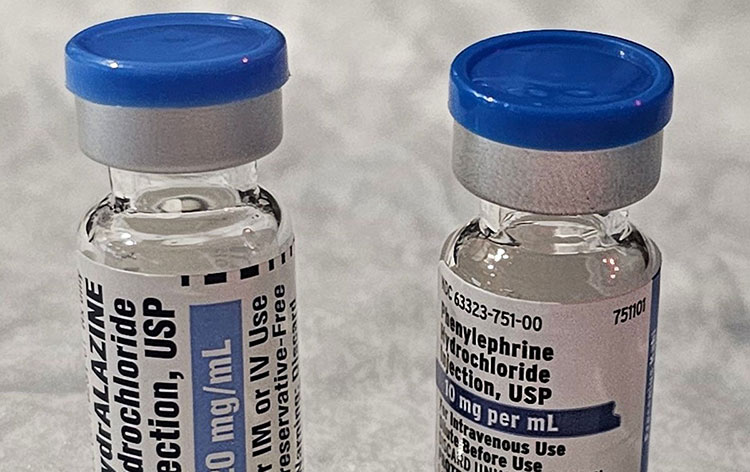

Injectable drugs

Injectable drugs-Picture courtesy: verywellhealth

You might have seen antibiotics in vials that are used in every corner of world. Its demand and packaging is in vials because of their filling in safe and under aseptic conditions.

Most of the injectable drugs such as antibiotic, anti-inflammatory, and other medications are stable in liquid forms. These are accurately filled.

Vaccines

Vaccines

Vaccines are also handled by sterile vial filling machine. Vaccines are highly sensitive to air, temperature, and to other environmental factors because it contains inactivated or active biological materials.

Vaccines require sterility and high sstandard handling to keep their contents stable in a vials.

Chemotherpeutic agents

Chemptherpeutic drugs-Picture courtesy: usf.edu.com

Chemotherpeutic drugs are potent that is used in treating cancer, kills and retard cancer cells. These are filled and sealed by sterile vial filling machine with extreme care as wrong dosing can be life threatning. For this contaminated features is used.

Lyophilized products

Lyophilized products

Some of the drugs are in powdered form which is reconstituted with water for use. But why these are passed through the long process of lyophilization? The answer to this is that some drugs can’t retain its stability in liquid form even when you store in refrigerator.

A sterile vial filling machine first fills the vials, passed for lyophilization, then, sealed. You can now store them for years without any fear of its degradation.

Biotec products

Biotec products-Picture courtesy: dermax.com

Biotec products are also filled via sterile vial filling machine. These products include enzymes, gene therapies, or cell cultures. They need extra care to protect them from contamination as they are expensive. These are sensitive to slight change in PH and temperature therefore, vial filling process for this involves a single-use system to prevent cross-contamination.

9.How does a sterile vial filling machine maintain product free from contamination?

Drugs or medicines being filled in vials need care as they are intended to enter the human body. Therefore, a kind of machine is required- one that can meet high standard of care. Here, a sterile filling machine excels as it is equipped with safety features.

Sterilization of all components

Sterilization of all components

The components in which product will come in contact must be sterilized. Without sterilization, the components have microorganisms that do contaminate the products. Components are pre-sterilized through depyrogenation and autoclaving.

Aseptic environment

The entire process is done in clean room. The isolators or clean rooms maintain temperature, humidity, and other factors to prevent microbes and their spreading by using positive air pressure and HEPA filters to remove the airborne particles such as dust. The risk of entering germs through air can be reduced y filtering the air.

Sterile barriers

Sterile barriers-Picture courtesy: Germfree.com

Sterile vial filling machine maintains product free from contamination by being equipped with sterile barriers that don’t let any foreign disease-causing agents to enter in filling chamber. the sterile barriers are in form of depyrogenation tunnel, laminar flow hood, or as an isolator.

Closed and automated system

Closed system is like the bubble in which your product is entirely closed. When you with your great care pour liquid in vial, there must be the contamination going in vials. But this machine has a filling nozzles and robotic arm to carry on this work. There is fewer human intervention as the fewer hands mean fewer contamination.

The closed and automated system keeps the products protected from the dust, air and even from people.

Sterile filtration

Before drugs or medicines fill in vials, they are filtered through micron-filter. This acts as a strainer that catches bacteria or other small microbes. Even the micron-filter is also tested during its usage to make sure it’s doing its work properly.

10.How to maintain a sterile vial filling machine?

The purpose of having a sterile vial filling machine is not about filling vials no matter how. It is about the protection of vials because medicines being filled in them, go in your body. Therefore, its maintenance is important. Here are the following steps.

Sterilization and cleaning

Sterilization and cleaning-Picture courtesy: syntegon.com

Cleaning is very important in everything. But, as sterile vial filling machine deals with filling of vials, its sterility and cleaning are foremost. A daily cleaning of components is necessary- after and before the batch.

But relying on cleaning is not enough. With cleaning, you can not be sure are there any microbes left? Yes, there are probability of having them. With sterilization by using UV rays or steam, components are being sterilized.

Lubrication

Lubrication- Picture courtesy: advancedtechnology.com

To lubricate the machine part’s is required for the proper and smooth function of machine. Lubrication is necessary to prevent friction because most of the breakdown of machines occur due to friction effect.

Preventive maintenance

You may have seen that with every appliance, there is a detail notebook in which preventive maintenance schedule is also provided. It is based on the manufacturer recommendation. Same, with sterile vial filling machine, preventive maintenance schedule is provided. You can reduce the risks of machine malfunctions by follow them.

Software updates

Software updates

The updates give you the features that make your system a healthier- smooth function. Wouldn’t you like to pick the features that can enhance your productivity? Yes, why would you not.

Keep your sterile vial filling machine software updated that can enhance the performance and safety.

Routine inspection

Routine inspection- Picture courtesy: mashvisor.com

Inspection on daily basis is important. Check whether the machine is working properly or not. Identify any wear and tear in machine parts, filling nozzles, seal and gaskets. The important thing that must not be overlooked for maintenance is to test the sensors for responsive functions. Routine inspection should be well-documented to reduce the downtime.

11.What are the factors to consider when buying a sterile vial filling machine?

Followings are the factors to consider when buying a sterile vial filling machine because it is a life time decision. Initial research is better than later regret.

Compatibility

Compatibility=Picture courtesy: Pacific vials

While buying a sterile vial filling machine, it is necessary to look for vials and caps material you are handling. Different products require different vial sizes, so it needs a machine that can handle all of them efficiently.

Some of the machines handle one specific format. If you are planning to handle different formats, select the machine that is of multiformat.

Automation features

Sterile vial filling machine comes in various models. First, choose the machine that matches your budget. Secondly, go for a machine if you want an updated features such as automated sterile vial filling machine. Why automation? Because there is fewer chances of errors as there is almost no human intervention.

Regulatory compliance

Regulatory compliaance-Picture courtesy: logowik.com

To make sure that drugs or medicines are filled in a safe and clean environment, select a machine that is FDA, GMP etc. verified. As a sterile vial filling is all about the patient’s safety. However, its regulation is necessary.

Production rate

Production rate

Different machines model has different production capacity. But choose the machine that comply with your demands. How much vials do you need to fill per day, hours or per batch? According to your production need, select the machine.

Conclusion

To conclude this extensive and productive buying guide, you must conclude that before buying sterile vial filling machine, some points that need to be considered. As vial filling needs an aseptic environment, therefore you need to create space that is on germs-free environment. However, if you are looking for a machine to buy, you are most welcome to our website, AIPACK, where you can select any of an efficient machine that fits your budget.

Don't forget to share this post!

Vial Filling Machine Related Posts

Vial Filling Machine Related Products

Vial Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine