From Startup to Pharma Partner: A Comprehensive Guide to Scaling with the NJP-1200D

In the highly regulated world of pharmaceutical manufacturing, the leap from a small-scale laboratory to a high-volume production facility is the most dangerous phase for any business. Many startups fail during this transition due to equipment mismatch or lack of technical expertise.

Recently, we had the privilege of supporting a client in Slovenia through this exact journey. This case study details how they evolved from a startup using entry-level manual processes to becoming a trusted OEM partner for a local pharmaceutical giant using our NJP-1200D fully automatic capsule filling machine. Beyond just hardware, this is a story of how technical partnership overcomes mechanical barriers.

Phase 1: The Startup Reality – Why We Started with Semi-Automatic

In early 2023, the Slovenian market was seeing a surge in demand for organic dietary supplements. Our client, a newcomer with a bold vision but a lean team, reached out seeking their first machine.

The Initial Consultation: After a detailed discovery call, we learned two critical things:

They were processing specialized, expensive botanical powders.

They had no full-time mechanical engineers on staff.

While many suppliers would have pushed for a high-cost automatic machine immediately, we recommended a Semi-Automatic Capsule Filler.

For a startup, the semi-auto model offers a lower capital expenditure (CAPEX) and allows the team to learn the "feel" of capsule filling—understanding powder flow, capsule orientation, and locking pressures without the complexity of a fully automated synchronized system.

Zoom meeting with this Slovenia customer

The Support Ecosystem: For 18 months, we acted as their remote engineering department. Through Zoom-based technical training, we taught their operators how to calibrate the feeding hopper and maintain the vacuum segments.

At the same time, we also shipped some required parts to the customer.

Shipping tracking number for parts

This phase was crucial; it built the client’s confidence and ensured that when the big order finally came, they were ready for the next level.

Phase 2: The Industrial Leap – Entering the "Big Pharma" League

By mid-2025, the client’s commitment to quality paid off. They secured a contract with a pharmaceutical giant that required production volumes exceeding 500,000 capsules per week. Their manual processes were no longer viable.

Choosing the NJP-1200D: We recommended the NJP-1200D specifically for its balance of speed and precision. But transitioning to a fully automatic machine is not just about "pressing a button." It requires a sophisticated understanding of mechanical timing and material science.

Detailed Technical Analysis: NJP-1200D Features for Scale-Up

The Enclosed Rotary Turret: Unlike many entry-level automatic machines, the NJP-1200D features a fully enclosed 10-station rotary turret. This is vital for GMP compliance. It prevents dust from entering the internal mechanical drive, which reduces wear and prevents cross-contamination—a non-negotiable requirement for the Slovenian client’s new pharma partner.

Vacuum Segment Cleaning: High-speed filling creates dust. Our system includes an automatic vacuum cleaning station that clears the segments in every cycle, ensuring the next capsule is seated perfectly.

Advanced PLC Integration: We utilized the Siemens PLC system to pre-program the client's specific formulas. This "recipe management" allowed them to switch between different products in under 60 minutes.

Phase 3: Deep-Dive Problem Solving (Expertise in Action)

Even with the best machinery, real-world variables like humidity and material texture can create challenges. Here is how we solved two advanced technical issues for the Slovenian facility.

Challenge A: Bridging the Gap in Weight Consistency

To meet their massive deadline, the client ran their old semi-auto machine alongside the new NJP-1200D. However, the client noticed a variance: the semi-auto capsules were slightly heavier.

The Technical Breakdown: Semi-auto machines often rely on gravity and light vibration, whereas the NJP-1200D uses a 5-stage tamping system. This system compresses the powder into a "slug" before inserting it into the capsule. Because the NJP-1200D packs the powder more efficiently, the volume required to reach a specific weight changes.

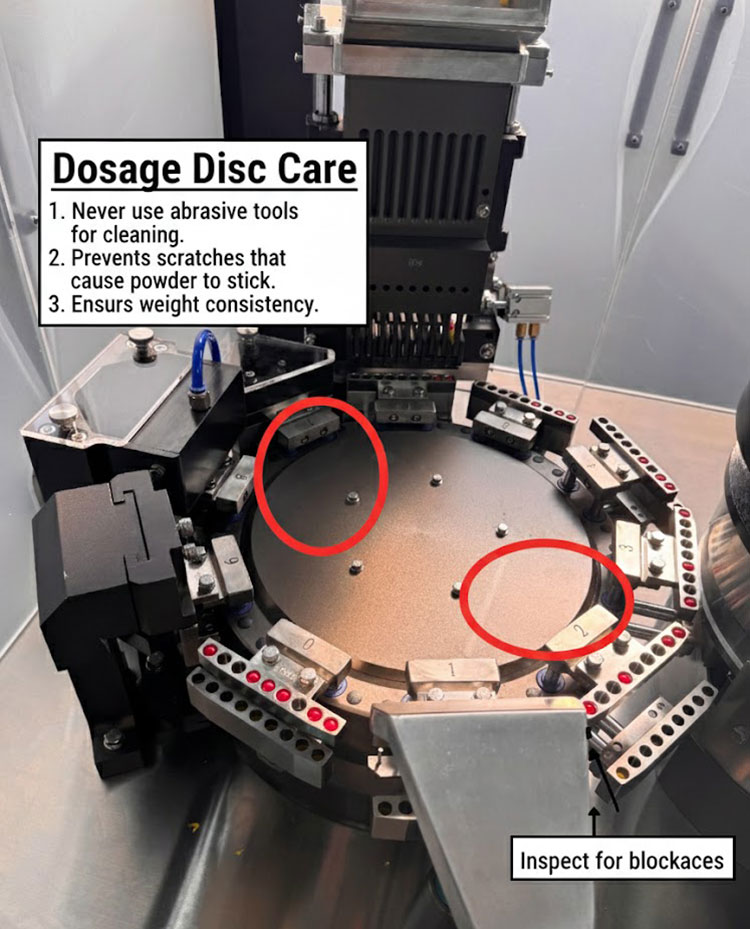

Our Engineering Solution: We didn’t just tell the client to "adjust the settings." Our engineers designed a custom-thickness dosage disc.

New dosage disc

By increasing the depth of the dosing holes by a fraction of a millimeter, we allowed for a larger volume of powder to be tamped, effectively matching the "fluffy" fill of the semi-auto machine. Result: The weight variance dropped to under ±2%, well within the pharmaceutical giant’s strict tolerances.

Challenge B: Material Science – The HPMC "Denting" Issue

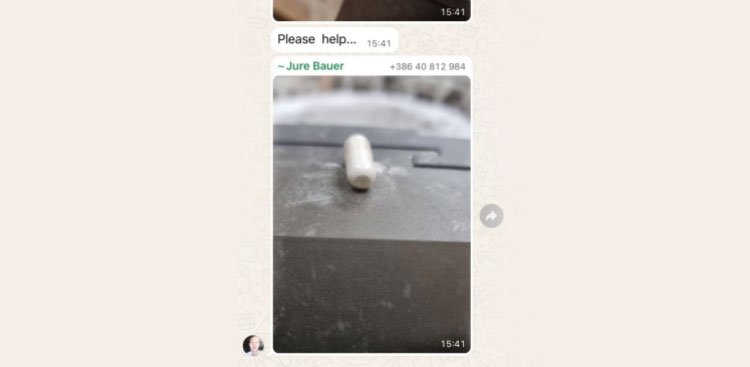

The client switched to HPMC (Vegetable) capsules to meet vegan market demands. Suddenly, they saw "dimples" or dents on the bottom of the capsules after locking.

When using the old capsule-locking device, the bottom of the capsule was severely indented

The new pusher pins received

The Science of HPMC vs. Gelatin:

Gelatin: Contains 13-16% moisture. It is elastic. If you press it, it bounces back.

HPMC: Contains only 4-8% moisture. It is stiff and brittle. When the NJP-1200D's high-speed locking pins (pusher pins) hit the HPMC base, the force was too concentrated.

Our Engineering Solution: We re-engineered the Pusher Pins. Standard pins are narrow to fit all capsule types. We customized a set with a wider, contoured head that perfectly matched the radius of the capsule bottom. This distributed the locking force over a 40% larger surface area. Result: The denting disappeared, and the rejection rate fell from 5% to 0.1%.

Capsules well locked after using the new pusher pins

Phase 4: Comparative ROI – Why Automation Wins

For businesses still on the fence, let’s look at the hard data comparing the two phases of our client's growth:

| Feature | Semi-Automatic (Phase 1) | NJP-1200D (Phase 2) |

| Throughput (per shift) | ~80,000 - 100,000 capsules | Up to 576,000 capsules |

| Labor Requirement | 3 Workers (Loading, Filling, Locking) | 1 Supervisor |

| Material Yield | 95% (Due to dust/spillage) | 99.5% (Enclosed recovery) |

| Consistency | Human dependent | PLC Controlled (Fixed) |

| Compliance | Basic Health Standards | Big Pharma / GMP Ready |

Phase 5: Prevention & Maintenance – Lessons for the Industry

To help other manufacturers, we asked our engineers to list the Top 3 Preventative Measures based on the Slovenia case:

Humidity Control: For HPMC capsules, maintain facility humidity between 35-55%. Too dry, and capsules become brittle; too wet, and they become sticky.

Dosage Disc Care: Never use abrasive tools to clean the dosing disc. Even a microscopic scratch can cause powder to "stick," leading to weight fluctuations.

Vacuum Strength: Regularly check the vacuum pump filters. A weak vacuum is the #1 cause of "non-separated" capsules in automatic machines.

Conclusion: Your Growth is Our Success

The journey of our Slovenian client highlights a vital truth in the pharmaceutical industry: The machine is just the beginning; the engineering support is what guarantees success. From providing a simple semi-auto filler for a startup to customizing high-precision components for a pharma OEM, we stay with our clients at every stage.

Don't forget to share this post!

Scaling Production with the NJP-1200D

Capsule Filling Machine Related Posts

Capsule Filling Machine Related Products

Capsule Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine