Facing Powder Flowability Challenges? How We Won a Client Who Was Using a Leading European Brand

In the pharmaceutical industry, the equipment brand is often seen as a guarantee of quality. But what happens when even a world-class machine—such as a Bosch capsule filler—struggles with a specific material?

Recently, an Austrian pharmaceutical manufacturer approached us with a persistent issue. Their facility was equipped with high-quality Bosch capsule machines, which were in excellent condition. However, they faced a recurring reality: poor powder flow and unstable filling accuracy.

What followed was a 5-month technical journey that proves why technical honesty is more valuable than any brand name.

1.Diagnosis Before Prescription: The 2-Month Technical Deep Dive

Most suppliers rush to offer a "perfect" solution. We took a different path. For the first two months, we focused solely on understanding the root cause.

Identifying the Real Culprit: After multiple email exchanges and data analysis, we confirmed the issue wasn't a structural flaw in the Bosch machine, but rather easily absorbs moisture and forms clumps and poor flowability of the client's specific powder.

Setting Realistic Expectations: Instead of claiming our NJP-2500D was a "magic fix," we provided an honest assessment: this powder would pose a challenge for any machine on the market.

Leveraging Comparative Knowledge: Because we have a deep understanding of the powder handling logic used in Bosch equipment, we provided a targeted optimization plan for our NJP series to minimize the accuracy error.

2.Trust is Built in the "Silent" Period

In B2B procurement, the "silent" phase of consultation is where trust is truly earned.

Respecting the Decision Cycle: We didn't push for a sale; we spent months explaining that while raw material limits exist, engineering adjustments can maximize performance.

AIPAK NJP-2500D on customer site

The Breakthrough: In the fifth month, the client returned with a clear decision. They chose our NJP-2500D because we were the only supplier who respected their production reality and provided a realistic engineering path.

3.Engineering Precision: Matching the "Bosch" Standard

The client’s core requirement was that our powder handling logic must be as close to the Bosch system as possible while addressing the flow issues.

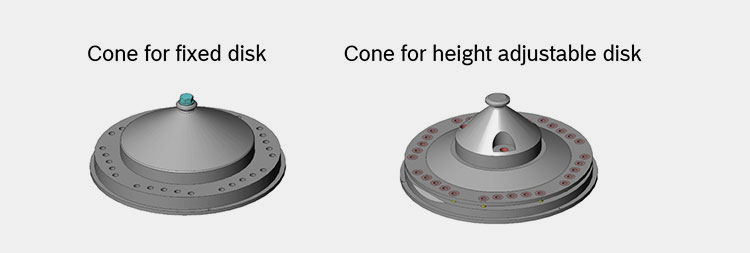

Targeted Mechanical Adjustments: Based on the client's powder characteristics, we provided detailed specifications for our dosing disk, stirring structure, and feeding rhythm.

Transparency in Limitations: We were explicit about which performance aspects could be improved and which were inherently limited by the raw material. This level of technical integrity is essential for GMP-regulated facilities.

4.Why This Matters for Your Procurement Strategy

This case proves that solving a production bottleneck requires more than just a famous brand—it requires a partner who understands your specific material challenges.

Global Reliability: Our NJP series has successfully operated alongside or replaced legacy brands in high-regulation markets like the USA, Spain, and Turkey.

Comprehensive Validation: To ensure a seamless integration, this NJP-2500D was delivered with a complete FAT, IQ, OQ, PQ, and DQ documentation package.

Conclusion

At the end of the day, a capsule filler is a tool for your production. The best tool is the one supported by engineers who prioritize your real-world challenges over a sales pitch.

Don't forget to share this post!

Choosing AIPAK Over European Pharmaceutical Brands

Capsule Filling Machine Related Posts

Capsule Filling Machine Related Products

Capsule Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine