How to Choose the Best V Mixer for Your Nutraceutical Supplement Powder Processing?

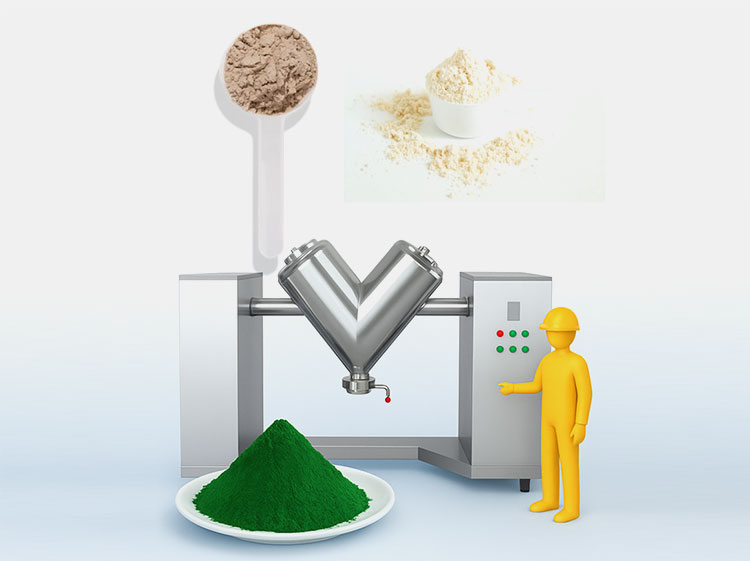

Whether you are planning for a leisurely walk or going to a party, what you eat impacts how you feel. Nutraceutical supplement powder helps in fuelling your body with the right requirements of your body. Getting a good machine is essential to manufacturing a powerful fuelling supplement powder that can do wonders. It’s not just powder, but it depends on how well key nutrients are distributed and properly mixed. The manufacturer is responsible for providing key supplements to maintain the expected nutritional balance. For this, the key unit is the V mixer.

Discover How to Choose the Best V Mixer for Your Nutraceutical Supplement Powder Processing. Learn the basic knowledge to improve the processing of your nutraceutical supplement powder.

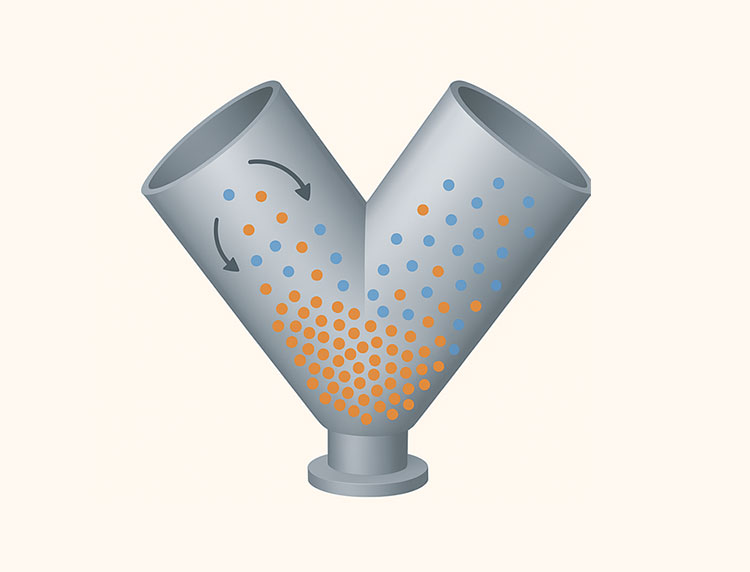

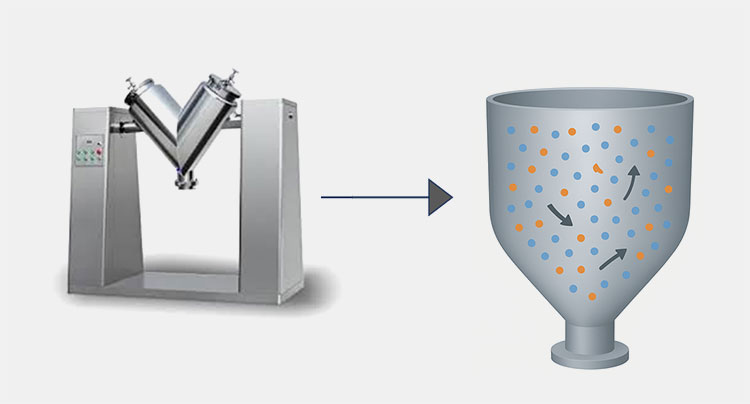

1.What is a V Mixer and why it is essential in nutraceutical powder production?

AIPAK V mixer

A V mixer, which is also known as a V-type cone mixer, twin shell mixer, or V cone mixer, is the type of mixing solution used for homogenization of nutraceutical powders and granules. The machine design looks like a V where two cylinders connect each other at the base. When the machine rotates, continuous tumbling allows a consistent mixing of the materials in a definite pattern.

When it comes to knowing why the V mixer is essential in nutraceutical powder production, then there's science lies offstage. The V mixer allows more active and subtle revolutions than traditional mixing machines. The nutraceutical products are mostly composed of around 30 to 40 health-related essential elements. For mixing, agitators or rigorous mixing are not a solution. Rather V mixer is used for thorough and gentle dispersion of the materials evenly. Nutraceutical powder production requires fine processing and gentle, repeatable mixing. It helps in maintaining superior blending and preserving physical properties.

2.What is the importance of achieving uniform blending for supplement quality and consistency?

The uniform blending for supplement quality and consistency has fundament role in providing effective and potent nutraceutical product. The significant important reasons are described below:

Distribution of Nutraceutical Actives and Excipients

Distribution of Nutraceutical Actives and Excipients

When product is subjected to uniform blending, it means all ingredients of the supplement are uniformly distributed. This is the primary factor that helps in achieving quality and consistency of the supplement response. However, if it is not properly treated inside the mixer, the consequences can be an ineffective supplement response. Therefore, homogeneity matters to avoid segregation and attaining quality response of nutraceutical supplement.

Batch-to-Batch Consistency

Batch-to-Batch Consistency

Apart from therapeutic response, the uniform blending of supplement also helps in the production of quality and consistent batches. In case of variability, the whole batches can be withdrawn. Therefore, consistency in manufacturing products is significantly important for every manufacturer or company. The blending uniformity ensures that formulation is released that is adhered to regulatory compliance and can offer expected therapeutic outcomes.

User Satisfaction and Safety

User Satisfaction and Safety- Picture Courtesy: Australian Sports Nutrition

The success of product is lies in uniform blending of supplements as it delivers exact dose and effectiveness labeled in the packaging. Whether it is taste, texture, ingredients or overall looks, the quality and consistency ultimately improves patients or user confidence while dozing the supplements. It is therefore important to strengthen the company’s credibility in the global market.

3.How the right V mixer improves efficiency and product integrity?

Manufacturers cautiously select a suitable V mixer for nutraceutical supplement powder processing to improve both production efficiency and product integrity. This machine offers homogenous mixing while reducing product loss. Here is how the right V mixer helps manufacturers attain suitable outcomes:

Gentle Treatment of Powders & Energy Efficiency

Gentle Treatment of Powders & Energy Efficiency

The V mixer working relies on slow and gentle movement of the V shell. This is suitable for sensitive and delicate nutraceutical substances as no friction, no heat, or excessive mixing takes place. Side by side, the structure of machine is constructed in a way that requires low energy for mixing of the powders. Combinedly, the machine is ideal for managing different powders with optimized speed with energy saving features.

Quick Mixing & Easy Discharging

Quick Mixing & Easy Discharging- Picture Courtesy: Grand

The V mixer has a V-shaped design, formed by joining two shells at a slanted angle of 75°-90°. This configuration promotes constant splitting and recombining particles in blending substances. With the rotation of twin shells, supplement powders flow freely in the mixing chamber and leave no dead spot, which results in uniform mixing. The tumbling action of the V mixer allows homogenous distribution of particles in the mixture and improves mixing efficiency in a shorter time. However, the V structure enables easy discharging of material without any leftover.

Maintains Product Integrity

Maintains Product Integrity- Picture Courtesy: Nutra Organic

As compared to other mixers, the V mixer has no agitators or blades, and its mixing is tumbling-based. It doesn’t generate intense shearing forces that could break down the structure of particles. This property helps in maintaining product quality by preventing its breakdown. In this way, products agglomeration is also avoided and evenly dispersion of material promises standard formulation.

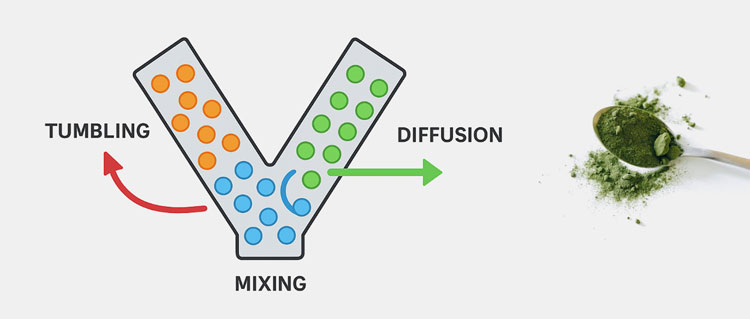

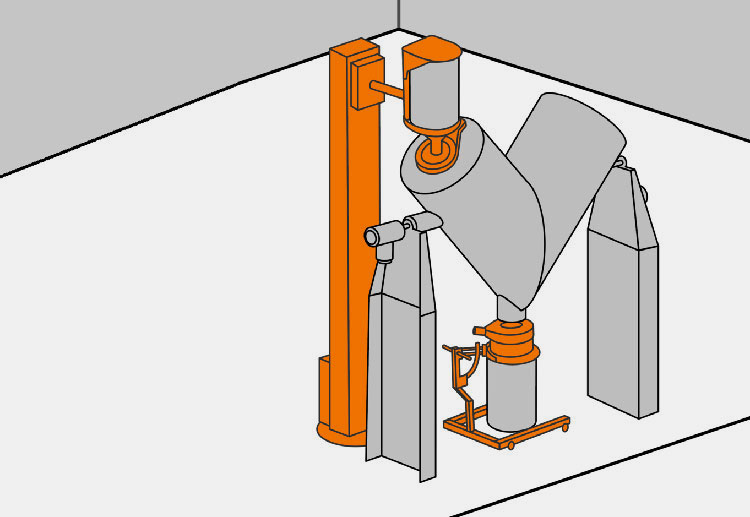

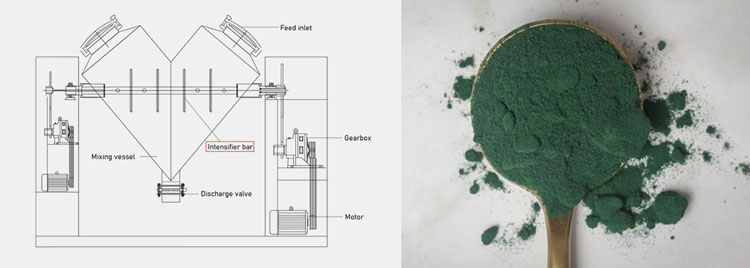

4.How a V mixer works: principle of tumbling and diffusion mixing?

A V mixer operates on the simple, yet effective working mechanism of diffusive mixing caused by tumbling or rotation of the mixing vessel. Its V-shaped design naturally boosts particle movement. The details of the principle of the V mixer are described below:

Tumbling Mixing

Tumbling Mixing V Mixer

In tumbling mixing, a V- mixer rotates along its horizontal or central axis. Its rotation is fairly slow at about 5 to 25 RPM, causing lifting and cascading of substances due to gravitational force. This phenomenon, called tumbling, instigates continuous division of materials into two streams when twin shells rise. These streams recombine when they drop down towards the center of the vessel. Hence, the main reason for mixing in a V mixer is repetitive separation and rejoining of substances.

Diffusion Mixing

Diffusion Mixing V Mixer

Diffusive mixing is also termed as random mixing. It is the core principle at play in the V mixer. The diffusive mixing is produced by the tumbling motion, which causes a random flow of particles in the vessel. Cascading of substances against the walls of the mixing chamber continuously exposes new surfaces in which particles flow and distribute themselves. This promotes maximum particle movement and intermixing, producing a highly uniform blend over time.

5.What are common powder types in nutraceuticals?

Diverse types of nutraceutical powders are produced by the nutraceutical supplement powder processing. They each have distinct physical and chemical characteristics that impact flowability and blending procedures. By understanding these various kinds of powders, manufacturers can easily choose the right type of V mixers. Different types of nutraceutical powders are as follows:

Common Nutraceutical Powders

Protein Powders

Protein Powder- Picture Courtesy: CRAYV

One of the widely used nutraceutical powders to create dietary supplements in industries is protein powders. Usually, they include whey, soy, pea, and casein proteins. Their particle sizes have variability, and they may generate dust. Hence, even diffusive mixing of the V mixer is essential for ensuring consistent nutrient dispersion in each serving.

Amino Acids Powders

Amino Acid Powders- Picture Courtesy: QFC

Some of its examples are L-glutamine, L-carnitine, and BCAAs. They’re commonly consumed to increase muscle mass. Although they’ve a crystalline structure and good flowability, they tend to accumulate static charges. V mixers are employed to process these powders because the gentle blending of these machines reduces static charge production.

Fiber and Prebiotics Powders

Fiber and Prebiotic Powders

They’re increasingly gaining traction in the modern diet-focused era because of their gut-related benefits. One of the fluffiest, bulkiest, and low-density nutraceutical powders includes inulin, psyllium husk, and resistant starch. Since they create dust, so slow and steady mixing action of the V mixer maintains a uniform density of the resultant mixture.

Herbal Extract Powders

Herbal Extract Powders

As the name indicates, these powders are obtained from plants, such as ashwagandha, turmeric, or ginseng. They provide various anti-inflammatory nutrients and antioxidants, essential for cognitive functioning and overall wellness. Gentle and thorough mixing of the V mixer prevents clumping of these fluffiest and lightest powders.

Vitamin and Mineral Powders

Vitamin and Mineral Powders- Picture Courtesy: ChainBaker

Vitamin C, calcium carbonate, and magnesium oxide are routinely used types of vitamin and mineral powders. Normally, they’re fine and dense but can segregate due to the inconsistency of particle size; consequently, manufacturers employ diffusion-based tumbling mixers, for instance, a V mixer for mixing them.

Functional Additives and Sweeteners

Functional Additives and Sweeteners- Picture Courtesy: FWDfuel

Functional additives and sweeteners are fine as well as cohesive powders. Thus, can have lumping. For this reason, a V mixer with an intensifier bar is required for achieving a mixture with a uniform texture.

6.How to Choose the Best V Mixer for Your Nutraceutical Supplement Powder Processing?

Creating the nutraceutical powder processing starts with genuine understanding about what formulation will set to be achieved. Every formulation in the market is specially designed related to nutritional requirements. Therefore, choosing the best V mixer for your nutraceutical supplement powder processing will help in ideal mixing of core ingredients and can benefit you. How to choose the best solution is discussed below.

Knowledge of Powder Physical Properties

Knowledge of Powder Physical Properties – Picture Courtesy: Nutraceutical World

When choosing the best V mixer, you must know the proper knowledge of physical properties of the nutraceutical powder. It is involved with flowability, bulk density, and humidity ratio. If the powder is non-free flowing, then it cannot be suitable to treat with V mixer. Moreover, powder with caking or cohesiveness or compaction necessitates to have an intensifying bar for mixing.

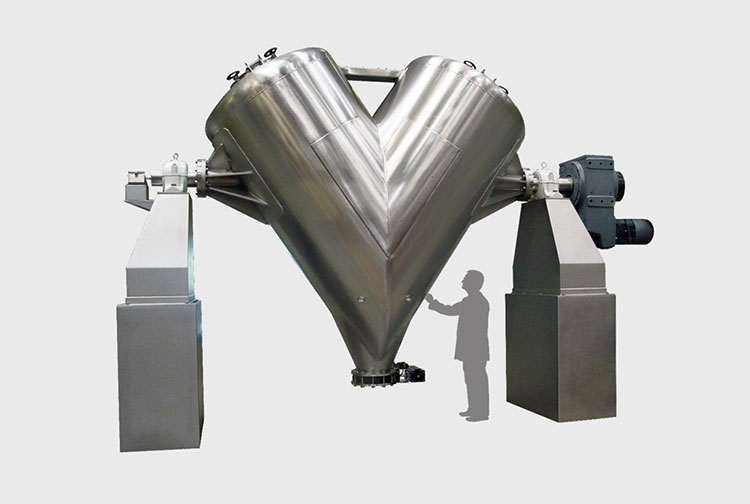

Estimating Production Volume

Estimating Production Volume- Picture Courtesy: Rheo Engineering

Go for V mixer that is ideal for meeting up with your nutraceutical powder production volume. Because too much filling or under filling can affect the mixing efficiency. It is suggested that excellent mixing is possible when mixer is filled up to 50-60% of the machine. By this way, efficient tumbling mixing and diffusion mixing is likely to occur.

Select Right Material & Prioritize Automation

Select Right Material & Prioritize Automation

In the manufacturing world of constant struggle, this is ideal to opt for machine with anti-corrosive properties and made up with GMP compliant standards. This is safe in terms of easy and flexible cleaning and contacting with nutraceutical powders. The smooth and polish inside (Ra ≤ 0.4 μm) surface protects the powder stickiness or retention. On the other hand, automation and digital processing helps in reliable and professional mixing requiring lesser operator involvement. Therefore, put automation primarily in mind to get straightforward processing.

7.V Mixer vs Double Cone Mixer vs Ribbon Blender

V Mixer vs Double Cone Mixer vs Ribbon Blender

The three most common types of industrial mixers are the V mixer, double cone mixer, and ribbon blender. They’re vastly different from each other because of their construction, working principle, and material suitability. To learn about their differences, go through the table below:

| Aspects | V Mixer | Double Cone Mixer | Ribbon Blender |

| Design | V-shaped design formed by two slanting shells | Two conical cases fused at the center | A U-shaped trough with a rotating shaft and helical ribbons |

| Mixing Principle | Diffusive mixing and tumbling movement | Diffusion mixing and tumbling of the double cone vessel, resulting in particle cascading and intermixing | Convection mixing with shear. The helical ribbons rotate inside a fixed trough and push materials axially and radially. |

| Mixing Action | Very gentle | Gentle | Intensive mixing with high shear |

| Internal Agitator | Basic design with no agitator | No agitator | Central shaft with ribbon blades |

| Blending Speed | Slow | Low RPM speed | Very fast due to agitators |

| Product Discharge | The V-shape design acts as a funnel and promotes complete discharge | Conical ends allow for near-complete product discharge | Due to the complex design, some product is still left in the trough and on ribbons. |

| Cleaning | Easy | Smooth interior surfaces aid in easy cleaning | Hard to clean because of ribbons and baffles |

| Headroom | Requires substantial space for rotation and installation | Needs substantial headroom | Since the vessel is horizontal so it needs less headroom |

| Material Suitability | Free-flowing dry powders and granules, as well as fragile ingredients | It is ideal for blending dry and fragile powders. Also, it can handle a more cohesive substance than the V mixer | Best for non-free-flowing and cohesive powders, slurries, and pastes. In addition, it can carry out solid-liquid mixing. |

8.When to Choose a V Mixer Over Other Blending Equipment?

In commercial preparations, mixers and other blending equipment play an integral role for effective products. Check the following points to understanding when to choose a V mixer over other blending equipment.

Heat and Moisture Sensitive Product

Heat and Moisture Sensitive Product- Picture courtesy: Nutra group

In case of material that degrades rapidly in the presence of high heat as well as moisture. You can opt for V mixer over other blending equipment. This is because, V mixer facilitates low shear mixing to maintain integrity of vitamins, and trace elements which are not possible with blender. Powders or substances under heat and moisture can lose stability due to high blending speed, rotations of blades and dispersion of liquids.

Free Flowing or Non-Flowing Nutraceutical Supplement

Free Flowing or Non-Flowing Nutraceutical Supplement- Picture Courtesy: Sanyuantang & MD Anderson

There is a big ‘Yes’ for V-mixer if the nature of powder is free flowing. The type of powder is mostly ideal for diffusive and tumbling mixing and that is possible with counter stroke of V mixer tank. Additionally, this powder can efficiently mixing without needing any supportive material or blades, so in such cases you can choose V mixer over other blender equipment.

State of Nutraceutical Supplement Formulation

State of Nutraceutical Supplement Formulation- Picture Courtesy: Nuritas

The type of nutraceutical supplement powder processing preparation mostly requires homogenous mixing without any pressure over materials. The V mixer generally allows subtle and robust mixing of solid-solids materials. Whereas, in some cases when you need involvement of liquids, non-free flowing or compaction, other blending equipment is preferred. Although, the prime objective of both equipment is to provide homogenize and consistent blend.

9.What are Tips for Choosing a V Mixer?

As technology rises, the innovation and evolution of V mixer in the field of manufacturing is growing. Here we have tips for choosing the best V mixer for your nutraceutical supplement powder processing which will improve work performance and productivity.

Approach Smart Sensor and Fine Tune Mixing Parameter

Approach Smart Sensor and Fine Tune Mixing Parameter

This is one of the emerging trends you should consider where integration of smart sensors helps in optimizing the nutraceutical powder mixing process. It ensures real time data of various parameters such as mixing velocity, temperature of tank, pressure, etc. you can modulate the fine tune mixing, and can adjust the speed goals to obtain ideal quality.

Test or Run the Machine Before Finalizing the Purchase

Test or Run the Machine Before Finalizing the Purchase- Picture Courtesy: lleal

You may be provided with product brochures or manuals from suppliers. But the wise decision is to run the machine by own to understand the actual parameters. Check if it works as you want or shows desirable results. Your smart observation will save you time, money, and effectively value your production goals.

Operating Noise & Vibration

V mixer Operating Noise & Vibration

A well-constructed machine is one that works smoothly with no noise or vibration. If there is noise or the machine’s vibration, for long term use, it may annoy you in many ways. Therefore, when testing the machine, keep observing if it is working seamlessly and subtle performance.

Never Ignore Documentation & Validation

V Mixer Documentation And Validation- Picture Courtesy: LLeal and Kneat

This is important to get important relevant documentation related to the V mixer. These are included with IQ, OQ, PQ, and some certifications related to calibrations. Also, the purchased equipment must be compliant with international regulatory requirements and working validation.

10.How to select a reliable V mixer supplier?

Select A Reliable V Mixer Supplier

Identifying a reliable V mixer supplier is tricky, though following the mentioned points would be helpful in choosing a trustworthy company.

Points for Reliable V Mixer Supplier

Accomplished Experience

You can pick a reputable company with knowing about their experience in providing machinery to nutraceuticals or the related industry. This means, company must be in association with businesses for the past several years with a constant successful track record. This can be assessed from websites, reviews, directories, and various specified machines that they’re offering to customers.

Quality Standard Compliance

The reliable V mixer supplier must follow the international standards like cGMP, ISO, CE, etc. The certified company will give you assurance that the supplier and machinery are reliable and the offered solutions are ideal for nutraceutical powder supplements.

Ideal Customer Response & Training

A reliable supplier is one that knows customer demands and makes actual efforts to solve the basic problems before and after the sale. This is included with offering guidelines, machine testing, 24/7 strong communication, installation, training, and troubleshooting any customer needs.

Open and Clear Pricing

Your supplier must be the one who discusses clear communication related to the pricing of the machines. There should be no room for hidden charges for the machine and delivery. Transparent discussion is always helpful in building professional and long-term relationships.

Conclusion

In conclusion, How to Choose the Best V Mixer for Your Nutraceutical Supplement Powder Processing encompasses all major points that a manufacturer must know for ideal production. By understanding, we believe you can create an optimized mixing practice using the V mixer for a consistent product quality. With time, V mixer advancements have led to improved performance and technical capabilities. Whether you’re in the nutraceutical, pharmaceutical, food, or any related industry, investing in AIPAK can help you achieve your target goals. If you’re interested in exploring more. We are here to help. Get in Touch for quick communication from our experts now.

Don't forget to share this post!

Bin Mixer Related Posts

Bin Mixer Related Products

Bin Mixer Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 156 0710 8630

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine