15 Powerful Benefits Of Aluminium Foil Seal You Must Know

How many medicine products you may find in pharmacy with no applying of aluminum foil? Aluminum foils sealing is widely welcomed in current market for its nice sealing and cheap price. How much you know about aluminum foil seal? Do you want to make benefits from it?

This post concluded 15 powerful benefits of aluminum foil seal you must know. Besides, do you know the machines applied for the aluminum foil seal? Does aluminium foil seal environment friendly? What challenges you may meet for aluminum foil seal ? Come on and have a reading for the answers.

1.What Is Aluminum Foil Seal And Its Main Feature?

Aluminum Foil Seal-Sourced:streuter

Aluminum foil seal is a kind of technique which applied for the sealing and bonding of plastic and aluminum materials. It often combined with paper and plastic for the laminating. From heating of conductive object, you may get the efficient and stable sealing. You may find its applying for the sealing of bottle, jar, tube and so on.

Aluminum foils seal is widely used for the sealing of various material and from its main feature, you may get the reasons for its wide applying.

Flexibility and durability

Flexibility-Sourced:southernliving

Aluminum foils is soft but flexible. It can be wrapped and tensed by products with higher gravity while it makes no tearing. The great durability also makes aluminum foil and aluminum foil seal the great choice for sealing.

Stability

Stability-Sourced:khandelwalplasticindustries

Aluminum foil seal is stable enough to make the long time protection for your products. It can resist corrosion while the aluminum foil makes the stable protection barrier. The electrical oxidation processes can make your aluminum foil seal more stable.

Reflectivity

The great reflectivity of aluminum foils is also the great feature of aluminum foil. It can make the even distribution of heat and maintain temperature condition. The great reflectivity of aluminum foil seal make it widely applied for various industries.

2.What Industry Can Aluminum FoilSeal Be Applied?

What industry can aluminum foil seal be applied? Here are the industry you may find the applying of aluminum foil seal.

Food and beverage industry

Food And Beverage Industry-Sourced:paramountglobal

You may find the wide applying of aluminum foil seal in food and beverage industry. From snack, fruit drink, yogurt, chips, baked food, candy, meat, fish and so on, aluminum foil seal can prove the hygiene and safety of your food and drink products.

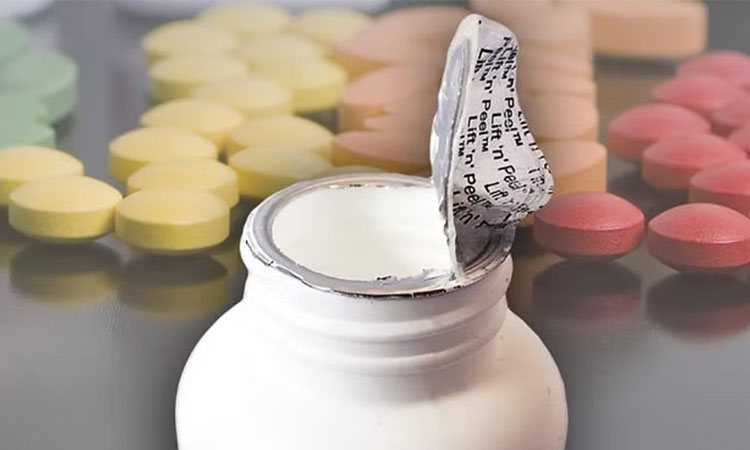

Pharmaceutical industry

Pharmaceutical Industry-Sourced:ptasia-group

Aluminum foil seal is frequently applied for your medical products packaging. You may find the pack from aluminum foil seal with high protection and tamper-proof ability. For medical powder, tablet, pharmaceutical bottle and so on, you may find the great applying of aluminum foil for the product protection.

Cosmetic industry

Cosmetic Industry-Sourced:dhgate

Aluminum foil seal can be applied in cream, lotion and such products in cosmetic industry for the defending of pollution and prolonging of shelf life. With the protection of aluminum foil, you may be relaxed while your cosmetic products make the wide distribution in world.

Chemical industry

Chemical Industry-Sourced:paramountglobal

For chemical products like cleaning products, glue, paint, glue and so on, you may find the widely applying of aluminum foil for the sealing. The aluminum foil can prove the stability of your products and durability of packaging. It is essential for the packaging work in chemical industry.

3.15Powerful Benefits Of Aluminium Foil Seal You Must Know

Aluminum foil seal can benefit your products in a comprehensive way, and here are the 15 powerful benefits of aluminum foil seal you must know.

KeepsFresh

Keeps Fresh-Sourced:tastingtable

Aluminum foil seal can keep fresh for your various products. It makes the air tight proving for your various products. The tight binding is the prove of the freshness of your products. To keep fresh, please apply the aluminum foil seal in your various products. For food products, the applying of aluminum foil seal is a great choice.

Prevents Leaks and Spills

Prevents Leaks and Spills-Sourced:ebay

You can also have the leaks and spills prevented here from aluminum foil sealing. The tight binding of aluminum foil seal can make sure the hygiene of your products. After heating, there is the air-tight seals for your powder products, liquid products or solid products. Aluminum foil seal can prove the leak and spill and prevent moldy of your products well.

Provides Tamper Evidence

Aluminum foil seal can also provide the tamper proof service for your products. It can show whether the products are tampered. It can thus prove the completeness of the products and show the high safety level of your products for customers. For medical products with high request on tamper prove, you should adopt aluminum foil seal as the important methods.

Improves Hygiene

Improves Hygiene-Sourced:yshengseals

The great protection from aluminum foil seal can help prevent moisture and light and prove the hygiene of your products. With the great work in preventing, it can make sure the high hygiene of your products. For pharmaceutical industry, cosmetic industry and so on, there is the high request on hygiene prove of your products.

High compatibility

High Compatibility-Sourced:realtopmachine

Aluminum foil seal is high compatible in dealing with various machine and sealing process. The high compatibility of aluminum foil seal makes the manufacturing of this process easier. This feature makes the various manufacturing from different machine and different products type easier.

Lightweight

Aluminum foil seal is light weight. It avoids the high weight which makes the great trouble for your products manufacturing and so on. The low profile and light weight make it welcomed in many places for different industries. The light weight can thus make it practical for the use for your customers.

Eco-Friendly and Recyclable

Aluminum foil seal is recyclable. It is more environmental friendly compared with paper and plastic. You may have the great recycling for the bottle and cap which has the aluminum foil seal applied. It reduces the cost in recycling. For eco-friendly products manufacturing, there is the great need of aluminum foil seal.

Easy to use and remove

Easy To Use And Remove-Sourced:alicdn

Aluminum foil seal is easy to use and remove. The great protection it makes can help prove your products quality. And the easy replacing make the application of your aluminum foil in your various products more welcomed. It saves the energy in using and removing greatly.

Cost-effective for short runs

In short runs, the applying of aluminum foil seal is cost effective. Compared with other sealing material, aluminum foil is effective in energy and low in cost. The simple sealing of it also makes saving in time and energy for this products.

Available in a variety of thicknesses and widths

Available In a Variety Of Thicknesses And Widths-Sourced:5.imimg

Aluminum foil seal is highly flexible. You may adjust the thickness and width of your aluminum foil with your products need easily. Besides the casual cap size, you may also apply it for different container size for the sealing job. The great availability in thickness and width makes the applying field wider.

Air-tight seal

Aluminum foil seal can make the air-tight seals for your products. For different container and different products material, there will always make the great sealing effect for your products. The efficient, quick, air-tight and safe seals are the seals many companies need.

Inert materials

Inert Materials-Sourced:istscientific

Aluminum foil seal makes great resistance for high temperature and bad environment. The inert material applied for aluminum foil seal is the base for its great resistance for different torture. The special material makes the great work for your various products protection.

Low profile after application

Aluminum foil seal makes great convenience for you and your products. It takes little space after applying and makes no efforts for your using and removing. The low profile after applying makes the great benefits for your products applying and protecting.

Extended Shelf Life

Extended Shelf Life-Sourced:vecteezy

Aluminum foil seal makes the excellent protecting for your products. It can shield dust, light, moisture and any invader from outer environment. The great protection can thus make sure the freshness of your products and extend the shelf life of your products.

User-Friendly

Aluminum foil seal is user-friendly. It applies little efforts to know the dealing for your aluminum foil-sealed products. It is easy to peel and makes no further trouble for your later work. The user-friendly feature makes it widely welcomed for different industries in current market.

4.Are There DisadvantageOf Aluminum Foil Seal?

Are there disadvantages of aluminum foil seal? Of course there are, and here are the disadvantages you should know about aluminum foil seal?

Health risk

Health Risk-Sourced:kingsdaughtershealth

Aluminum foil seal may lead the health risk for your food products. The leaching of aluminum in your food may lead disease including neurodegenerative disease and so on. Besides, here are also kidney and bone damage risk in the applying of aluminum foil seals. The taking of aluminum foil in your body may lead your body calcium absorption, weakening bones and osteoporosis.

Developmental disorder

The long exposure to high level of aluminum can cause series of problem particularly for children. You should make sure the high quality of your aluminum quality and aluminum foil seal quality for the preventing of developmental disorder. Or aluminum of aluminum foil seal may affect cognitive development and behavior.

Environmental impact

Environmental Impact-Sourced:kingchuanpackaging

Aluminum foil is recyclable and makes great benefits for environment. Aluminum foil cannot break down naturally in environment. This may lead the pollution. Besides, the production of aluminum foil is energy consuming. It may have contamination for soil and water for environment and also consumes lot energy in the manufacturing process.

5.What Are The Methods For Aluminum Foil Sealing?

For aluminum foil sealing, there are the common methods applied. Do you know the methods applying for aluminum foil sealing?

Heat sealing

Heat Sealing-Sourced:labsource

Heat sealing is the common methods applied for aluminum foil sealing. By heating aluminum foil and packaging material, there will be tight sealing for products. The heat sealing machines are thus applied for the heat sealing of heat sealing methods. The high speed and strong seals make it widely applied for the products with high request on hygiene and sanitary.

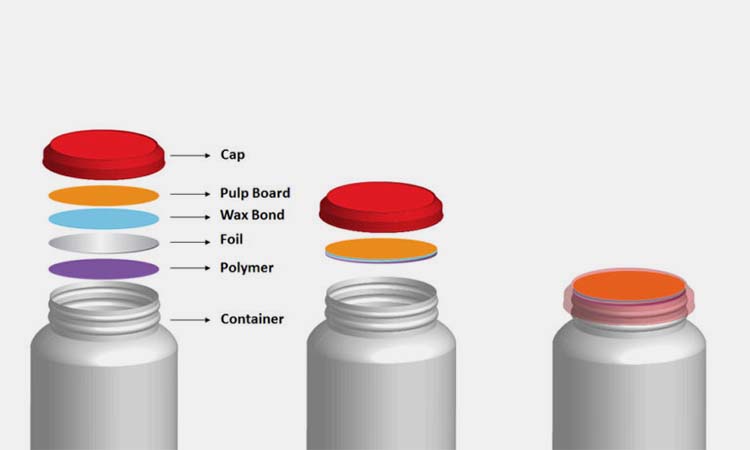

Induction sealing

Induction Sealing-Sourced:saintytec

Induction sealing applied the electromagnetic induction for the heating producing for air-tight sealing for your products. You may find its applying in cap or closure. The work is suitable for the products with great request on safety. Induction sealing is tamper proof and high barrier properties.

Pressure sealing

Pressure sealing is the technical method which apply mechanical pressure to bind aluminum foil and other layer. Pressure sealing can be applied for rigid and flexible packaging. The economical cost, strong seals and wide applying make it suitable for various food products packaging.

Crimp sealing

Crimp Sealing-Sourced:tube

Crimp sealing refers to the folding and crimping of aluminum foil of packaging material edge to create a air tight seals. Crimp sealing makes great suitable for tube sealing and packaging. The special technique makes it suitable for tamper-evident. You should equip specialized crimping equipment for the smooth crimp sealing work here.

6.What Are The Machines Applied For The Aluminum Foils Seal?

What are the machines applied for the aluminum foil seal? Here are the machines which have the wide applying of aluminum foil seal.

Induction Sealing Machine

AIPAK Induction Sealing Machine

Induction sealing machine adopts the electromagnetic induction theory which connects container and aluminum foil with the melting energy. There is the airtight bond with container by the great work of induction sealing machines. AIPAK induction sealing machine makes the outstanding work in sealing container with various materials.

Electro-magnetic Induction Machine

Electro-Magnetic Induction Machine-Sourced:realtopenergy

Electro-magnetic induction machine is the kind of sealing machine which is widely used for the sealing and binding of various material in business environment. By applying electromagnetic induction, there is the consistent heating for the aluminum foil. Electro-magnetic induction machine can always give you the outstanding work in making the reliable sealing.

Automatic Aluminum Foil Sealing Machine

Automatic Aluminum Foil Sealing Machine-Sourced:saintyco

Automatic aluminum foil sealing machine is designed for the manufacturing of large production scale. This machine can deal with container of various sealing needs and different container size. Automatic aluminum foil sealing machine enjoys great reputation for its high efficacy in manufacturing and great reliability for its product quality.

7.IsAluminium Foil Seal Environment Friendly?

Environment Friendly-Sourced:renouvo

As mentioned above, there is pollution and contamination in the process of manufacturing aluminum foil and making aluminum foil seal. But with reasonable managing, aluminum foil seal can be recyclable and sustainable. The applying of aluminum foil seal can reduce the plastic material applying and make the great job in making circular economy.

The great recycling of aluminum foils can make the further sustainable and environmental friendly work here. You should clean the old aluminum foil seal and then melt it to the new products. The recycled aluminum foil can be further applied for the aluminum foil seal job.

8.What Challenges You May Meet For Aluminum Foil Seal Manufacturing?

Aluminum foil seal is so beneficial for the various industry and various products. Do you know the challenges you may meet for aluminum foil seal?

Manufacturing environment

Manufacturing Environment-Sourced:enerconind

Manufacturing environment makes great impact for the quality of aluminum foil seal manufacturing. High moisture may lead the water in sealing process and lead the low binding performance of aluminum foil seal. And the high temperature may lead problem for your aluminum foil testers. You should make the great manufacturing environment for your aluminum foil seal work.

Sealing technique

Sealing Technique-Sourced:inductioncapsealing

Different sealing technique can also lead the different sealing work here. The great sealing technique comes from the excellent machines, right heat sealing parameters, compatible container material and so on. Nice sealing technique is also the challenges you should handle for your manufacturing work. You should make quality control, material choose, parameter optimize for your technique benefits.

Pollution managing

Pollution -Sourced:adnanimpex

You should make the great managing of waste for your aluminum foil seal manufacturing. For the aluminum foil seal manufacturing, you should make the great dealing of waste issues or it will comes the bad influence for environment. Aluminum foil seal will make pollution to soil, water and other plants or aquatic life. The pollution may get into food chain and makes the large trouble for people health. Thus, in the manufacturing of aluminum foil seal, you should make sure the preventing of soil and water polluting.

Conclusion

Aluminum foil seal is so beneficial for different industries and different products. And here are the 15 powerful benefits of aluminium foil seal you must know. After the reading, do you have any confusion or question about aluminum foil seal? If you do, be free to contact AIPAK now.

Don't forget to share this post!

Induction Sealing Machine Related Posts

Induction Sealing Machine Related Products

Induction Sealing Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine