Vibratory Sifter: The Complete FAQ Guide In 2025

Are you looking for a versatile vibratory sifter that can be used in various chemical, pharmaceutical, mineral gradation, minerals & food industries? How can you make sure their best performance, in terms of quality, quantity, and productivity, which makes it the right machine for any kind of screening purpose?

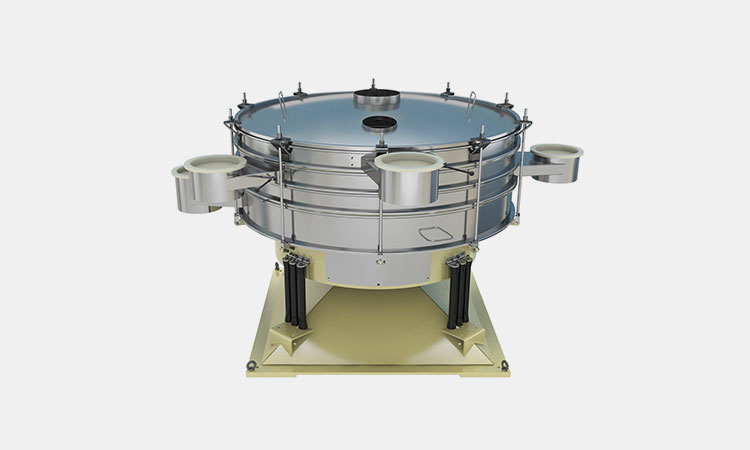

Vibratory Sifter-sourced: ALLPACK

How can you make the best use and advantage of the vibratory sifter? Do you need the most complete guide for vibratory sifter? This complete vibratory sifter guide will offer you the details about the vibratory sifter to help you with this equipment when you are using them. Let's figure out now!

1.What Is Vibratory Sifter?

Vibratory Sifter-sourced: sieving

Vibratory sifter, also called as vibro sifter, vibro screen, vibro sifter machine, vibratory screener, vibratory sieve, vibratory sifting machine, powder sifting machine, it is a circular integral rotary and vibratory screening machine.

Vibratory sifter has a variety of uses and is widely used in various industries. It can separate solids from mixtures according to particle size and classify them. This vibratory sifter can be used for sorting and grading granular solids in the pharmaceutical, chemical, food and cement industries.

You can use this tool to process solids or other mixtures. The entire process involves separation, scalping and grading. It uses the concept of a gyroscope to provide power for the rotary motion required for the powder screening process.

2.What Kind Of Applications Can The Vibratory Sifter Be Used?

Divided by industry, the vibratory sifter can be widely used in the pharmaceutical, chemical, food and cosmetics industries. According to purpose, it can be used for classification and screening, impurity removal, and solid-liquid separation.

Industry Application

Pharmaceutical Industry

Pharmaceutical Industry-sourced: supergreentonik

Various powders used in tablets and capsules in the medical industry require vibratory sifter to screen and classify the powders. The screened powder can help with subsequent tableting and capsule filling, such as aspirin, amoxicillin, oxidants, plasticizers, coagulants, penicillin, vitamins, etc.

Chemical Industry

Chemical Industry-sourced: gia

Various metal powders, electronic magnetic materials, coatings, ceramics, paper materials, chemically synthesized solid substances, resins, cleaning materials, fertilizers, adhesives, agricultural chemicals, biochemicals, nylon, paint, plastics, PVC chemicals, etc. are screened and processed by the vibratory sifter.

Food Industry

Food Industry-sourced: syntegon

Both powders and solids in the food industry can be screened using vibratory sifter. These powdered solids include, but are not limited to, food mixes like flour, wheat, dehydrated food, flavors, spices, plant-based meat substitutes, yeast, pet food, animal feed, etc.

Cosmetics Industry

Cosmetics Industry-sourced: withsimplicitybeauty

Nowadays, more and more powder filling substances are used in various cosmetics, including facial mask powder, loose powder, eyebrow powder, etc.

Main Use of Vibratory Sifter

Main Use of Vibratory Sifter-sourced: dahanmachine

Classification and Screening

Classification and Screening-sourced: particletechlabs

By using a specially involved vibration motor to generate multiple plane vibrations, the mass components of the solid are separated from the solid, and the separated solid material is size classified according to the size of the particles. The vibratory sifter can accurately and continuously classify materials of 2-6 specifications.

Impurities Removal

Using a specially designed strong spring to separate the entire vibration assembly from the base, the vibratory sifter can more easily and efficiently remove proportions of small and large particles, thereby removing impurities from various solid powder materials.

Solid-liquid Separation

Solid-liquid Separation-sourced: particletechlabs

Vibratory sifter can quickly remove insoluble matter in various slurries. It is suitable for filtering various ceramics, pigments and other liquids. And the efficiency can reach 100 cubic meters per hour.

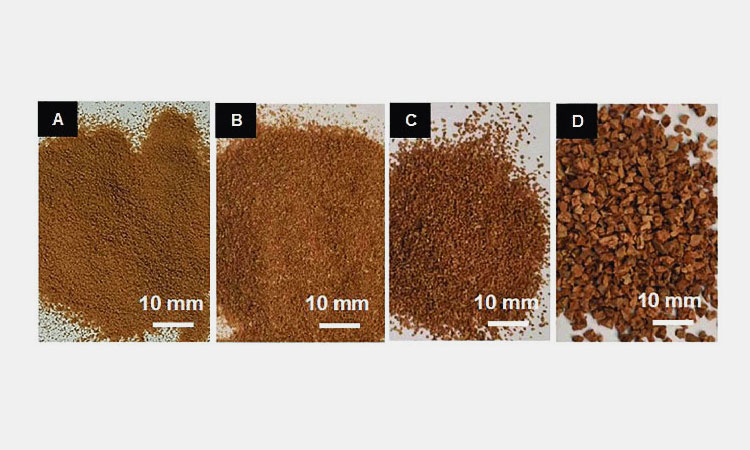

3.What Kind Of Materials Can Be Sieved With The Help Of Vibratory Sifter?

Most of the pharmaceutical materials can be processed and screened by the vibratory sifter. It can provide accurate, efficient and hygienic screening and classification of solid and liquid preparations.

Vitamins

Vitamins-sourced: It's Just

Vitamins are trace substances that humans and animals must obtain from food to maintain normal physiological functions. With the development of science and technology, various vitamin additives can replace vitamins in food to improve human health.

Minerals

Minerals-sourced: mckesson

Minerals are naturally occurring compounds or natural elements found in the Earth's crust. This natural element is also an essential element for the human body and cannot be produced or synthesized by itself. So mineral supplements are becoming more and more common in modern life.

Additives

Additives-sourced: biospringer

Additives are substances that can have a certain effect on the medicine during the production process. These include preservatives, plasticizers, sweeteners, flavorings, etc.

Most food powders and granules often use vibratory sifter.

Grain Powder

Grain Powder-sourced: georgianjournal

Grain powder includes powders ground from various cereals and coarse grains, including flour, corn flour, soybean flour, corn flour, walnut flour, oat flour, buckwheat flour, barley flour, black sesame flour, etc.

Spices

Spices-sourced: denverpost

Spices are important auxiliary ingredients in daily condiments, including pepper, fennel, cloves, cumin, bay leaves, pepper, tangerine peel, cinnamon, angelica, licorice, grass fruit, nutmeg, angelica, etc.

Pet Food

Pet Food-sourced: todaysveterinarybusiness

Pet food requires a vibratory sifter for processing. Pets of different sizes have different needs for pet food with different particle sizes. Pet food includes various dry foods, canned foods, soft puffed foods, pet biscuits, health products, etc.

Vibratory sifter helps in processing and screening various chemicals.

Cement

Cement-sourced: mineralseducationcoalition

Cement is a powdery hydraulic inorganic cementitious material. After adding water and stirring, it can become a slurry and harden in the air. Vibratory sifter can bring high quality and efficient screening of cement.

Metal Powder

Metal Powder-sourced: elcanindustries

Metal powder includes single metal powder and alloy powder. It is mainly used in powder metallurgy. By using vibratory sifter for screening and processing, we can provide you with metal powders of varying degrees of fineness.

Coating

Coating-sourced: ifscoatings

Coatings can be coated on the surface of objects to be protected or decorated after being dissolved in water, and can form a continuous film that is firmly adhered to the object to be coated. By utilizing a vibratory sifter, you can achieve a more delicate coating.

Fertilizer

Fertilizer-sourced: thespruce

Fertilizer can improve soil properties and increase soil fertility levels. By screening and processing with a vibratory sifter, you can improve the soil with fertilizers of varying particle sizes.

Vibratory sifter is also used in various cosmetics.

Facial Mask Powder

Facial Mask Powder-sourced: 100percentpure

By adding various active ingredients, the solids are ground into packages and hydrolyzed to obtain a slurry, which can be applied to the face to obtain effects such as whitening, spot removal, wrinkle removal, moisturizing, and anti-inflammatory.

Loose Powder

Loose Powder-sourced: Airspun

Loose powder is a powdery product used to set makeup. The finer the powder, the better it can cover up the blemishes on the face without feeling powdery.

4.What Are The Benefits Of Vibratory Sifter?

The benefits of vibratory sifter are:

Wide Application

Wide Application-sourced: dahanmachine

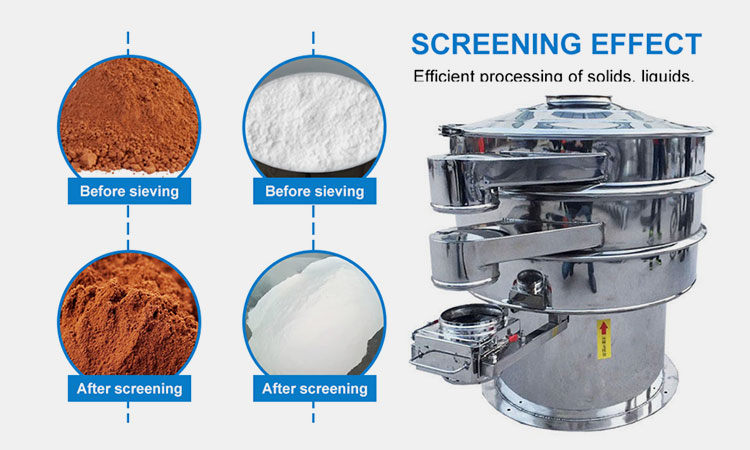

Vibratory sifter can not only separate solid and solid materials, but also solid and liquid materials. Its vibrating screen can screen, classify, dust and filter a variety of products.

Fine Sieving

Fine Sieving-sourced: dahanmachine

Different vibratory sifters may have different screening functions and limits. However, a general vibratory sifter can screen to 500 mesh (28 microns) and filter as fine as 5 microns, which can achieve high-efficiency screening and filtration. Through the installed frequency converter, it can also adjust the vibration speed of the screening.

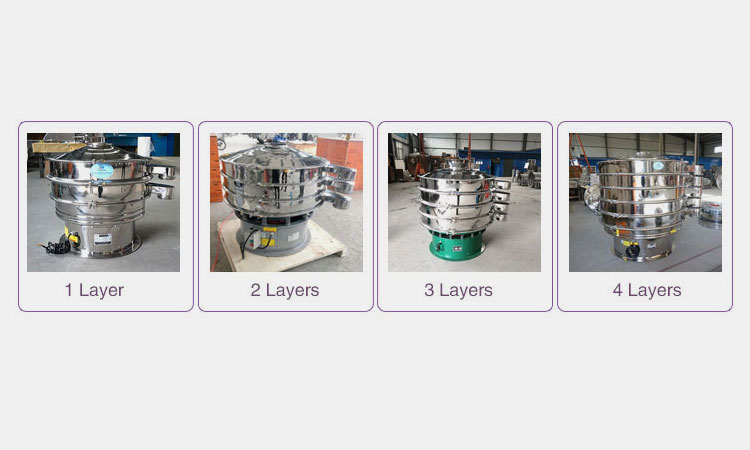

Single or Multi-layer Sorting

Single or Multi-layer Sorting-sourced: dahanmachine

According to the different needs of users, you can choose vibratory sifter with different layer sieve plates. So far, the options available are 1 layer, 2 layers, 3 layers, 4 layers, 5 layers, etc.

Different Materials Processing

The machine contact parts of the vibratory sifter are made of Q235 carbon steel, SS316L, SS304 stainless steel, etc. According to customer needs, they can choose their favorite materials.

Highly Efficient Processing

Highly Efficient Processing-sourced: dahanmachine

Vibratory sifter improves product quality by processing efficiently and removing impurities from materials quickly and easily.

Versatility

Vibratory sifter can be used to screen a variety of materials, including powders, granules, and liquids, making them popular across various industries.

Low Maintenance

Vibrating screens are made from durable materials and have been rigorously tested through continuous use. Therefore, this makes them cost-effective to maintain, thereby reducing overall operating costs.

5.What Are The Limitations Of Vibratory Sifter?

Vibratory sifter also has certain limitations. Therefore, other methods need to be used instead. Its limitations include:

Mesh Size Limitation

Sieves-sourced: yosion-lab

Vibratory sifters may not be able to effectively screen materials with very large or very small particle diameters. But most can meet the needs of laboratories, food industry, and industry.

Sticky Materials

Vibratory sifter is not suitable for screening sticky materials. In this case, an air classification or centrifuge may be more appropriate.

Sensitive Materials

Heat-sensitive materials or materials that are not suitable for handling mechanical stress may melt or be crushed after being treated with a vibratory sifter. In this case, a pressure or gravity based filter may be more appropriate.

6.What Is The Working Principle Of Vibratory Sifter?

Working Principle Of Vibratory Sifter-sourced: dahanmachine

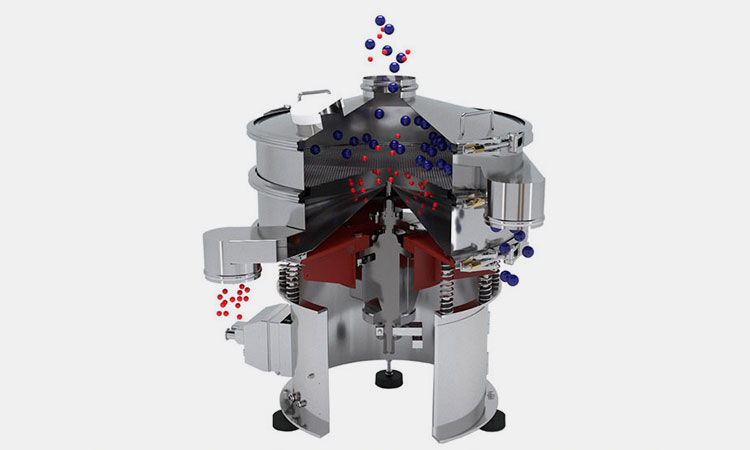

The vibratory sifter uses a vertical vibration motor as the excitation source. Through the eccentric gravity hammers at the upper and lower ends, the rotational motion is converted into horizontal, vertical and tilted three-dimensional motion, and is transmitted to the top of the screen. The whole process includes:

- Pour the materials to be processed into the vibratory sifter through the feed port.

- According to different screening requirements, the materials will pass through sieves with different mesh sizes from 1 to 5 layers.

- The vibratory sifter continuously makes the materials pass through the sieve holes of different meshes in a circular motion on the sieve with decreasing mesh size.

- During this process, the bouncing balls under each layer of sieves will continuously hit the sieves, allowing the materials to be fully screened and effectively preventing the materials from clogging the screen holes.

- Materials close to the screen holes can also be fully screened through the sieve.

- Materials located below the screen that are larger than the screen aperture are discharged from the discharge port of this layer, completing the purpose of screening or filtering.

7.What Are The Vibratory Motion Of Vibratory Sifter?

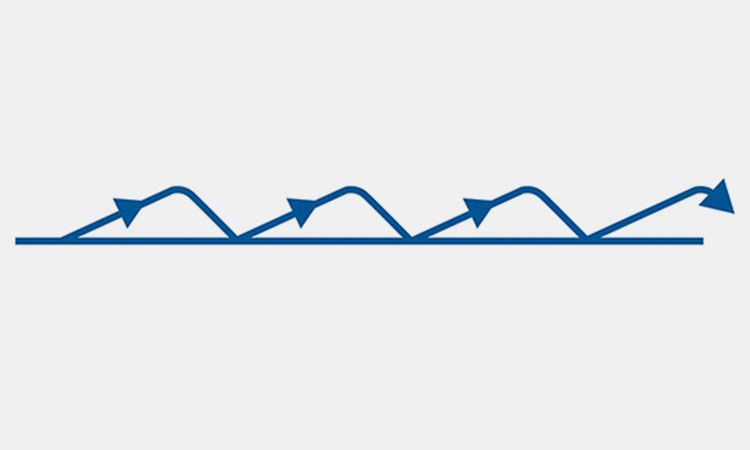

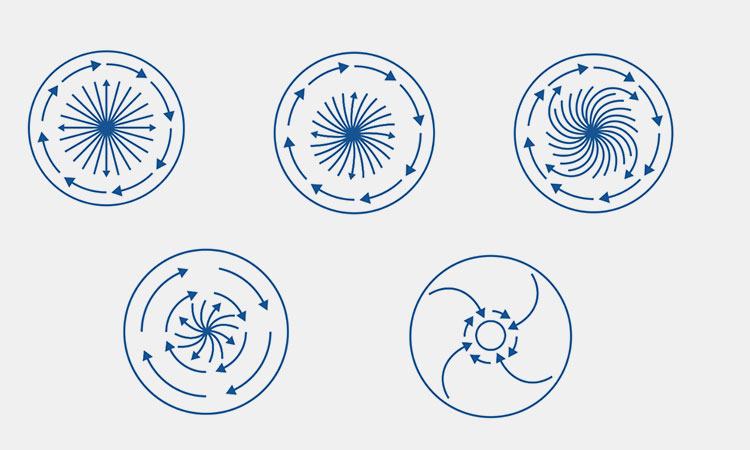

Vibratory Motion of Vibratory Sifter

Vibratory Motion of Vibratory Sifter-sourced: rotex

The vibratory motion of vibratory sifter into rotational uniform linear motion. Through the action of centrifugation, when the material moves in a straight line at a constant speed on the screen, the vibration will cause the material to pass through the screen according to the size of the screen.

Vibratory Motion-sourced: rotex

At first, the material will be thrown out in a straight trajectory, and then distributed in a spiral shape. Later, there will be an arc-shaped rotational movement along the circle.

As the amplitude becomes larger and larger, the vibration of the machine accelerates, and the materials will gather toward the center of the circle while being screened. Eventually, the material will rotate along the center of the circle.

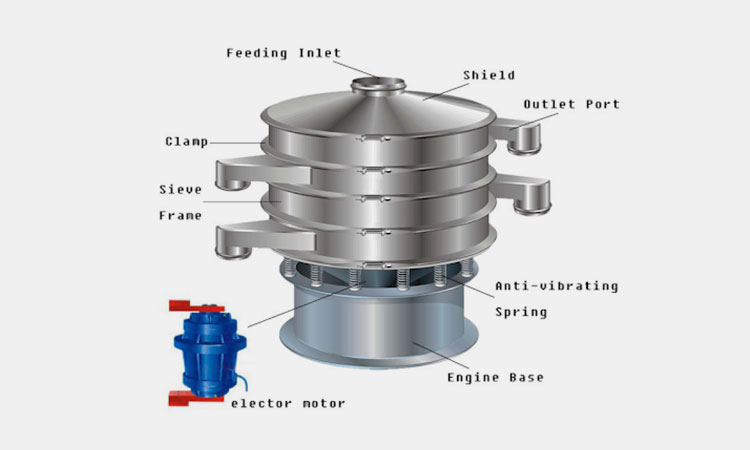

8.What Are The Main Parts Of The Vibratory Sifter?

Vibratory sifter is a screening tool used for production materials in pharmaceutical, chemical, food and other industries. It has sieves with different mesh holes and layers. Their designs are finely structured and made up of different parts. These include:

Main Parts Of The Vibratory Sifter-sourced: pharmaceuticalindustrydotblog

Feeding Inlet

The feeding inlet is designed for loading the sieving materials. Its hole size can facilitate the loading of materials of various particle sizes.

Shield

The shield, also called as the dust cover, is to prevent dust in the workshop from falling into the materials when the vibratory sifter is working. The commonly used materials for the shield materials include stainless steel, carbon steel, plastic, etc.

Outlet Port

After the materials are screened, it will be discharged through the outlet port of this layer. It is the last step before materials are screened and filtered.

Clamp

The clamp is used to fix the screen. It can continuously fix about 5 layers of screens.

Sieve

The sieve also called as the screener. When the material passes through the screener, it will be screened into materials of different particle sizes. Different screens have different mesh sizes.

The more mesh the screen has, the finer the materials will be separated. Models include 600, 800, 1000, 1200, 1500, 1800, etc., and materials include stainless steel, carbon steel, and plastic.

Frame

The frame is made of rolled and welded steel plates. It is divided into upper and lower bearing rings. There is a flange ring on the inside of the lower part, which is used to fix the structure of the screen components.

Anti-vibrating Spring

The anti-vibrating spring is a shock-absorbing device when the machine vibrates at work. Each body has 12-20 vibration isolation springs along the outer circle. The base of the machine is welded from steel coils, and the isolation spring is connected to the vibrating body and the base.

Engine Base

The engine base is made of welded steel coils, and the base is equipped with access doors and electrical switch seats. An annular flange is welded to the upper part of the base wall, and the flange is connected to the vibration isolation body through a vibration isolation spring.

Electro Motor

The electro motor is divided into 4 specifications, including levels 2, 4, 6, and 8, and the vibration times are 2870, 1460, 980, and 740RPM respectively. It has an explosion-proof design and can be used in flammable and explosive situations.

9.What Are The Optional Equipment When Using Vibratory Sifter?

Some optional equipment can better assist you in using vibratory sifter. While improving your efficiency, it can bring you great convenience. There are:

Mesh De-blinding Kit

Mesh De-blinding Kit-sourced: galaxysivtek

The mesh de-blinding kit including maximizer decks, rotary brush cleaning system, it can improve the service life and efficiency of mesh.

Deck Cover

Deck Cover-sourced: galaxysivtek

The deck cover can help vibratory sifter to prevent dust in the factory from entering the machine and contaminating the internal materials.

Screw Conveyor

Screw Conveyor-sourced: galaxysivtek

The screw conveyor can help materials to be loaded automatically. If the material to be processed is powder, the screw conveyor can feed the material into the machine more efficiently.

Magnetic Grill

Magnetic Grill-sourced: galaxysivtek

The magnetic grill can help improve the hygienic standards in final material's quality. To check the measures of the material quality and hygiene, the magnetic grill can do you great favor.

10.What Are The Types Of Vibratory Sifter?

There are different vibratory sifters on the market that users can choose from. Their appearance is similar, but their functions are also different. The following are some of the more mainstream vibratory sifters on the market.

Distinguish by function there are:

Ordinary Vibratory Sifter

Ordinary Vibratory Sifter-sourced: bhalanigroup

The ordinary vibratory sifter is capable of providing 5-stage screening capabilities to achieve precise particle size distribution. The mesh size of screening can reach about 500 mesh. It can simultaneously meet a wide range of uses in the pharmaceutical, chemical, food and cosmetic industries.

Ultrasonic Vibratory Sifter

Ultrasonic Vibratory Sifter-sourced: guan-yu

The ultrasonic vibratory sifter uses an ultrasonic system to prevent screen clogging, thereby increasing screening capacity by approximately 10 times. Compared with ordinary vibratory sifter, this ultrasonic vibratory sifter can significantly improve your productivity.

Inline Vibratory Sifter

Inline Vibratory Sifter-sourced: dahanmachine

The inline vibratory sifter is also called the central discharge vibrating screen. It can quickly remove foreign matter in raw materials, and is suitable for safety screening, process screening, inspection screening, material dust removal, etc. of various raw materials. This vibratory sifter is mainly used for material screening before packaging.

Tumbler Vibratory Sifter

Tumbler Vibratory Sifter-sourced: navector

The tumbler vibratory sifter adopts the design of circular motion and parabolic motion to complete the screening of materials. It uses an ordinary vertical motor to drive an eccentric wheel to complete the parabolic double pendulum motion. Seven screening movements can be performed simultaneously on each machine.

Centrifugal Vibratory Sifter

Centrifugal Vibratory Sifter-sourced: ALLPACK

The centrifugal vibratory sifter uses centrifugal force generated on the vibration machine to obtain exciting force. The exciting force makes the sieve body and materials move up and down repeatedly.

After filtered by two layers of net, the materials are divided into three levels according to diameters of the sieve so as to reach ideal goal.

Distinguish from appearance design, there are:

Circular Vibratory Sifter

Circular Vibratory Sifter-sourced: bhalanigroup

The circular vibratory sifter is a circular integral rotary screen. It is a three-dimensional vibrating screen adjusted by a counterweight on the motor shaft. This vibratory sifter can separate solid mass components from solids and classify materials according to particle size.

Rectangular Vibratory Sifter

Rectangular Vibratory Sifter-sourced: ALLPACK

The rectangular vibratory sifteris suitable for screening all of dry material (from 0.074mm to 20 mm) or mesh size (from 2-600 mesh). It supports at most 6 layers. But 3 layers at most is highly recommended. The dimension size and voltage are both supported to be customized. The largest screening area can arrive to 2000mm*4000mm.

11.What Are The Mesh Size Up To Which The Vibratory Sifter Can Sieve?

The vibratory sifter sieve is made of the highest quality materials. Generally, different mesh sizes of sieve are designed according to the needs of users. The higher the precision of the sieve, the more delicate the screened materials will be.

Woven Wire Sieves

Woven Wire Sieves-sourced: endecotts

The mesh sizes of woven wire sieves range from 125 mm to around 20 microns. It is suitable for screening all kinds of laboratory materials. Because it can meet the laboratory's screening needs for finer materials. These sieves are available in diameter sizes of 200, 300, 400 or 450 mm.

Perforated Plate Sieves

Perforated Plate Sieves-sourced: endecotts

The mesh sizes of perforated plate sieves range from 125mm to around 4mm. Its diameter range is around 200, 300, 400 or 450 mm. This mesh size screen is widely used in the food industry.

Microplate Sieves

Microplate Sieves-sourced: endecotts

The mesh sizes of microplate sieves range from 75 to around 5 microns. It can screen out extremely fine powders and granular materials. It is specially used to screen solid and liquid mixed materials to maintain the accuracy of the materials.

Wet Washing Sieves

Wet Washing Sieves-sourced: endecotts

The mesh sizes of wet washing sieves range from200 to around 100 mm. It can use wet sieving to separate samples with the help of liquid.

Diamond Sieves

Diamond Sieves-sourced: endecotts

The diamond sieves mesh sizes range from 8 mm to 100 micron. It can meet the different screening requirements of most materials.

12.What Are The Solutions Provided For The Unclogging Of The Mesh From Vibratory Sifter?

There are various arrangements to avoid clogging of the mesh. These solutions are effectively used in all major processing industries such as pharmaceuticals, food processing, minerals and metals. There are:

Wire Mesh-sourced: directindustry

Use Good Quality Mesh

Use top quality stainless steel materials for your vibrating sifter. Because it can provide you with maximum steel wire strength, it can not only extend the service life of your mesh, but also effectively avoid clogging of the mesh.

Accurate Wire Diameter

The larger and thinner the wire diameter, the larger the opening area. It is very important to choose a mesh with appropriate wire diameter based on your own materials and needs.

Ensure the Correct Weight Setting

Every time when using the vibrating sifter, the weight and residence time of the materials on the mesh must be well controlled. If the material weight and residence time are set incorrectly, clogging of the mesh may easily occur.

Correct Mesh Cleaning

Different materials have different properties. Some materials are sticky and some materials are dry. The correct method for cleaning mesh varies depending on the material. Clean the mesh first, then use detergent, and finally blow dry with compressed air.

Conclusion

This complete vibratory sifter FAQ guide covers all details about the vibratory sifter. The machine is ultimately designed to meet the needs of the user. Bring efficiency and convenience to your production and operations. Do you think the design of the vibratory sifter meets your needs? Do you have any other questions? Come and consult us now!

Don't forget to share this post!

Centrifugal Sifter Related Posts

Centrifugal Sifter Related Products

Centrifugal Sifter Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine