Automatic Tablet Counting Machine

- Over than 99.99% accuracy counting rate

- High dust resistance

- Three-stage vibrators

- Simple Operation & Easy Maintenance

AIPAK Tablet Counting Machine

AIPAK Tablet counting machine,can be also called tablet bottle packing machine, capsule counting machine,tablet counter machine,is one of the main parts of a capsule tablet counting line.It is the main workhorse in capsule production process.With the advanced anti-dust technology,AIPAK capsule counter machine can be used for tablets(including abnormal tablets),capsule gels(including abnormal gels,transparent gels and opaque gels)pearls and most kind of tabloids. Each tablet counter machine have intelligent design,with interactive operating multi-language panel, can save 10-20 kinds of different operating parameters and easy to load for different products.Self-diagnose,display errors and make alarms.Well cooperation between each machine and in the whole line.All AIPAK tablet counter machines are easy to operate,adjust, clean and maintain, it will save your labor cost.

AIPAK Tablet Counting Machine Applicable Products

Main Structure Of Tablet Counting Machine

The Buyer's Guide

Tablet Counting Machine: the Ultimate Buying Guide in 2024

As is well-known, tablet counting machine is a common equipment in pharmaceutical industry, it can be used separately, and it can also be used in a complete production line. This machine can count pills such as capsules and tablets efficiently and precisely so that it is in great demand.

Do you think you really know tablet counting machine? As a matter of fact, many people only know the function of tablet counting machine, however, they know less about other aspect of this machine. Do you want to learn tablet counting machine deeply?Here is a blog in which you can learn the detailed knowledge of this machine, don’t wait, let’s explore together!

1.What is a tablet counting machine?

Simply speaking, tablet counting machine is an equipment whose function is to count tablets, besides, you can use it count capsules or other forms of medicines. In pharmaceutical industry, there is a certain number of tablets in a bottle, therefore, counting is a basic thing in the tablet packaging process.

However, if you count the number of tablets and pack them into bottles by human labor, it is quite slow, as a result, people use tablet counting machine to do this operation. Generally, tablet counting machines are highly automatic, so they can count tablets fast and accurate, this is the reason why they are widely used.

2.What are the advantages of tablet counting machine?

As a type of common pharmaceutical equipment, there must be some advantages of tablet counting machine so it is indispensable, next, let’s discuss the main advantages of it.

High Efficiency

Tablet counting machines have high efficiency cause they are highly automatic, they can count a certain number of tablets in a short time, therefore, this machine can increase the production efficiency for you, which is beneficial for your business.

High Accuracy

If you are familiar with tablet counting machine, you will know that a tablet counting machine is equipped with many sensors so it can count medicines, these sensors are sensitive so that they can count the number of tablets accurately even if they are in high speed movement.

Save Cost

As is mentioned, tablet counting machine has high efficiency and accuracy, therefore, this machine can save your cost. To count a certain amount of tablets, a tablet counting machine will use less time than human labor, similarly, in the same time, a tablet counting machine can count more tablets than human labor.

In this way, of course you can say that a tablet counting machine can save your cost, as well as increase your profit.

Ease of Use

Usually, tablet counting machine is equipped with a advance touch screen, which can turn on and turn off the machine, and set all kinds of parameters such as amount, speed and so on. With such a smart touch screen, operators just need to click some buttons, isn’t it easy?

3.What are the applications of tablet counting machine?

As is less known, actually tablet counting machine can not only be used in pharmaceutical industry, besides, there are other applications of it.Are you interested in the applications of tablet counting machines? The main applications are as follow:

Pharmaceutical Industry

As the picture shows, the most common application of tablet counting machine is pharmaceutical industry, the machine can count all kinds of solid form medicines, such as hard capsules, soft capsules, tablets, etc. Tablet counting machines are often used in pharmaceutical production line, it plays an important role.

Food Industry

There are many solid form food products, such as candy, gummy, nuts, chips, dried fruits, coffee beans and so on, need to be counted before packaging, therefore, tablet counting machine can also play its role in food industry to help them count and fill food products.

Agriculture Industry

Maybe you have never considered that tablet counting machine can also be used in agriculture industry, there are many cereals need to be counted, such as rices, corn niblets, beans, and all kinds of seeds. Therefore, tablet counting machine can also help a lot in agriculture industry.

4.How many types of tablet counting machines there are?

In terms of automatic degree, tablet counting machines can be divided into manual tablet counting machine, semi automatic tablet counting machine and fully automatic tablet counting machine. And in terms of design, there is another type of tablet counting machine which is called multi channel tablet counting machine.

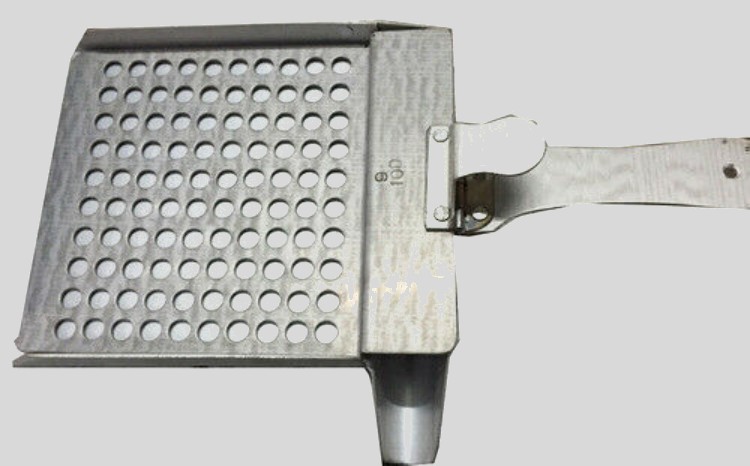

Manual Tablet Counting Machine

As the picture shows, the structure of manual tablet counting machine is simple, it is a stainless steel plate which have many holes on its surface. Using a manual tablet counting machine is easy, you need to pour tablets on the plate, and put them into the holes by hands.

The number of the holes is certain, this is the working principle of tablet counting machine.However, using a manual tablet counting machine is too slow and troublesome, so it is only suitable for small scale production of family usage.

Semi Automatic Tablet Counting Machine

Semi automatic tablet counting machine is designed compact, it can count tablets automatically and precisely, but there need a operator to set up the parameters and change bottles if they are full.Semi automatic tablet counting machine is suitable for medium scale production.

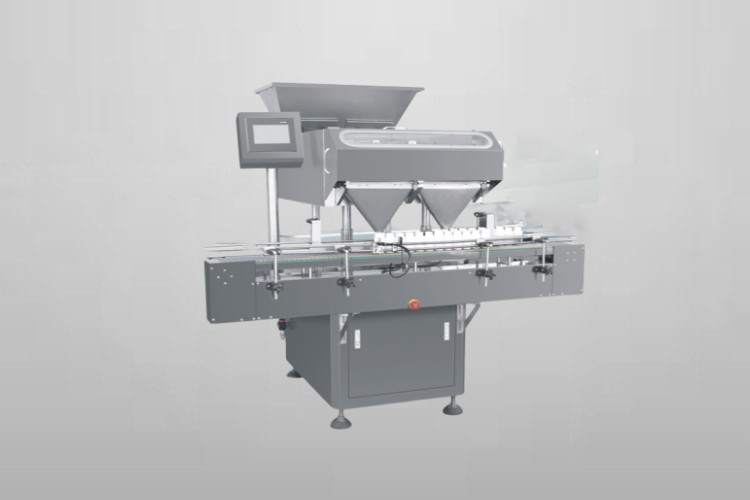

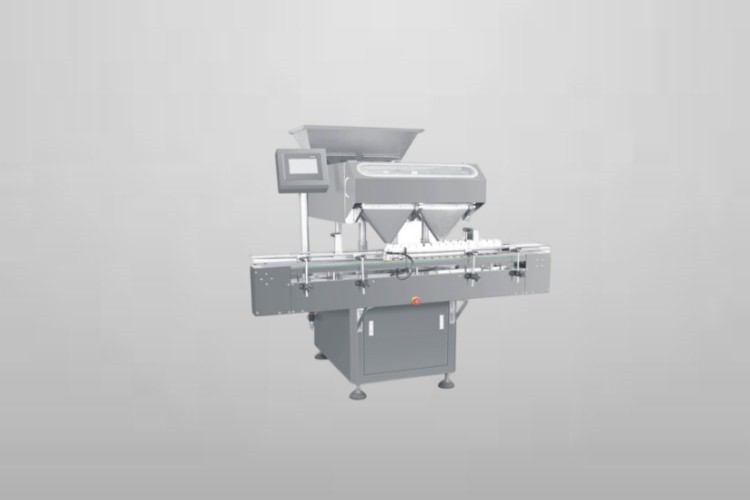

Fully Automatic Tablet Counting Machine

Fully automatic tablet counting machine, as the name implies, it has high degree automation, it can automatically count tablets, fill them into bottle and deliver the bottles, the only thing what should be done by operator is to set up all kinds of parameters so that the machine can work separately.

Multi Channel Tablet Counting Machine

To be honest, multi channel tablet counting machine belongs to fully automatic tablet counting machine, the only difference is that it has more bottle feeders than normal fully automatic tablet counting machine, as a result, the machine has higher production capacity, it is suitable for large scale production.

There are many multi channel tablet counting machines which have different amounts of channels such as 2, 4, 6, 8...32.

5.Fully Automatic Tablet Counting Machine VS Semi Automatic Tablet Counting Machine.

Perhaps most of you want to know the difference between fully automatic tablet counting machine and semi automatic tablet counting machine, in other words, you want to know which one is more suitable for you. Next you will see a complete comparison between them.

Appearance

You can observe the picture of the two machines, in fact, the size of fully automatic tablet counting machine is much larger than that of semi automatic tablet counting machine. Therefore, if you have enough space, you can choose the fully automatic tablet counting machine, if you don’t have, you can choose the semi automatic one.

Speed

The fully automatic tablet counting machine is much faster than semi automatic tablet counting machine, in general, a fully automatic tablet counting machine can count 4000 tablets per minute while semi automatic tablet counting machine can count 1000-2000.

Working Principle

The working principles of fully automatic and semi automatic tablet counting machine are similar, tablets are filled into the feeder, and then be counted the counting system which is equipped with sensors, and finally be filled into bottles.

Automatic Degree

Of course that the automatic degrees of fully automatic and semi automatic tablet counting machines are different, fully automatic tablet counting has higher automatic degree than semi automatic tablet counting machine, it doesn’t need manual intervention during the working process.

6.What is the main structure of tablet counting machine?

To learn a machine, one thing you must know is its main structure, the main components of a tablet counting machine are touch screen, hopper, vibrating track, counting system, bottle feeding mechanism, conveyor.

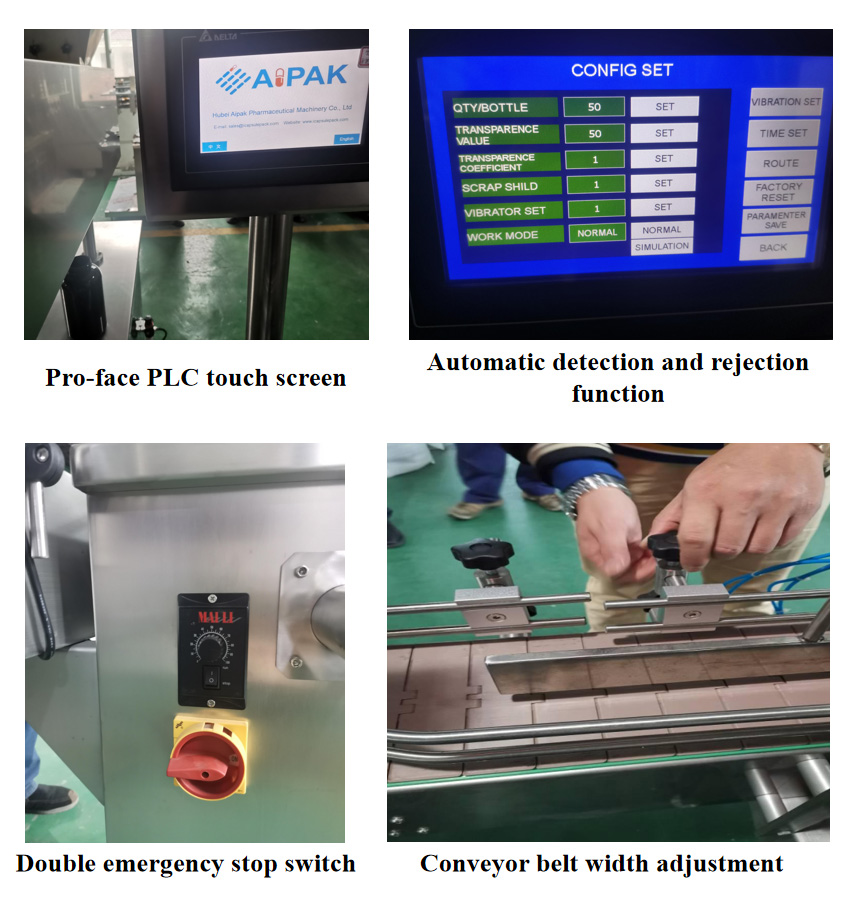

Touch Screen

You can also call it control system of the machine, it is component which is used to control the whole machine, there are many buttons on it, you can turn on and turn off, and set up all kinds of parameters of the machine through these buttons. The smart touch screen makes the machine easy to operate, and save the operators’ time.

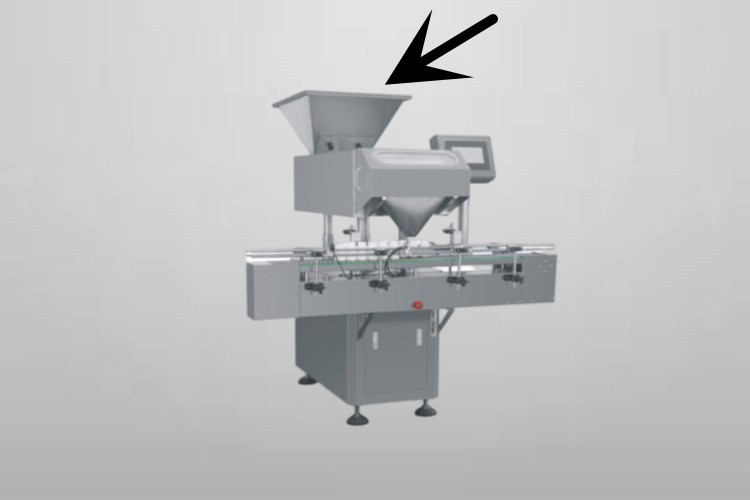

Hopper

Generally speaking, the hopper of a tablet counting machine is on the top of it, this part is an entrance of tablets, if you need to count tablets, at least you need to pour them into the machine through hopper.

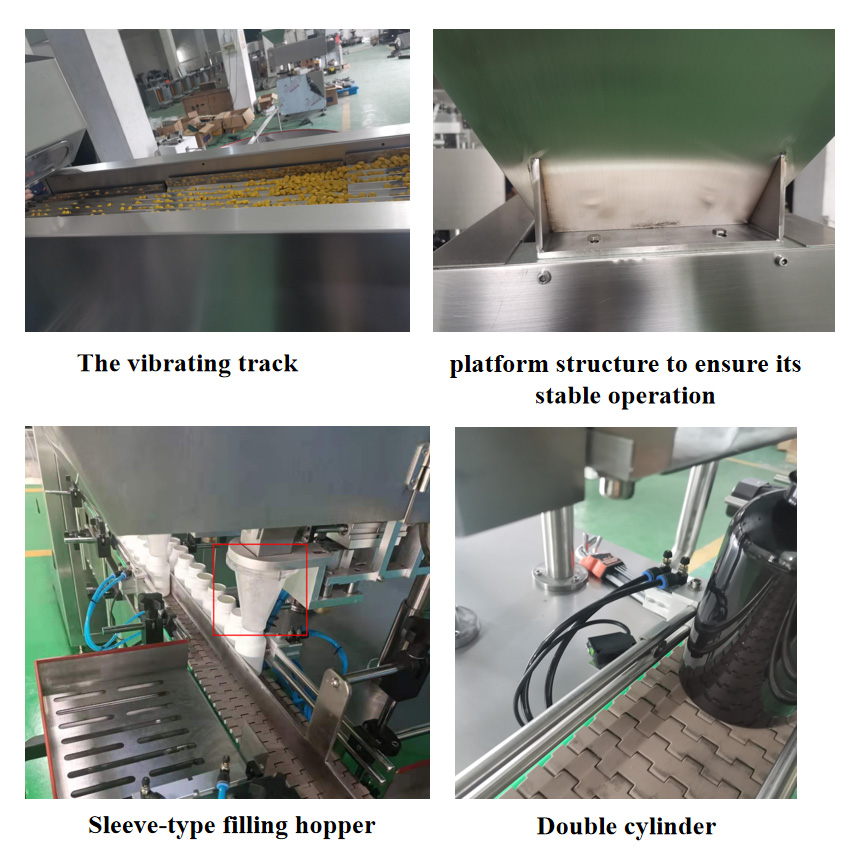

Vibrating Track

As the picture shows, the tablets will be delivered to vibrating track after they are fed into the machine, vibrating track will adjust the position of tablets to let them be put in order, which is convenient for counting.

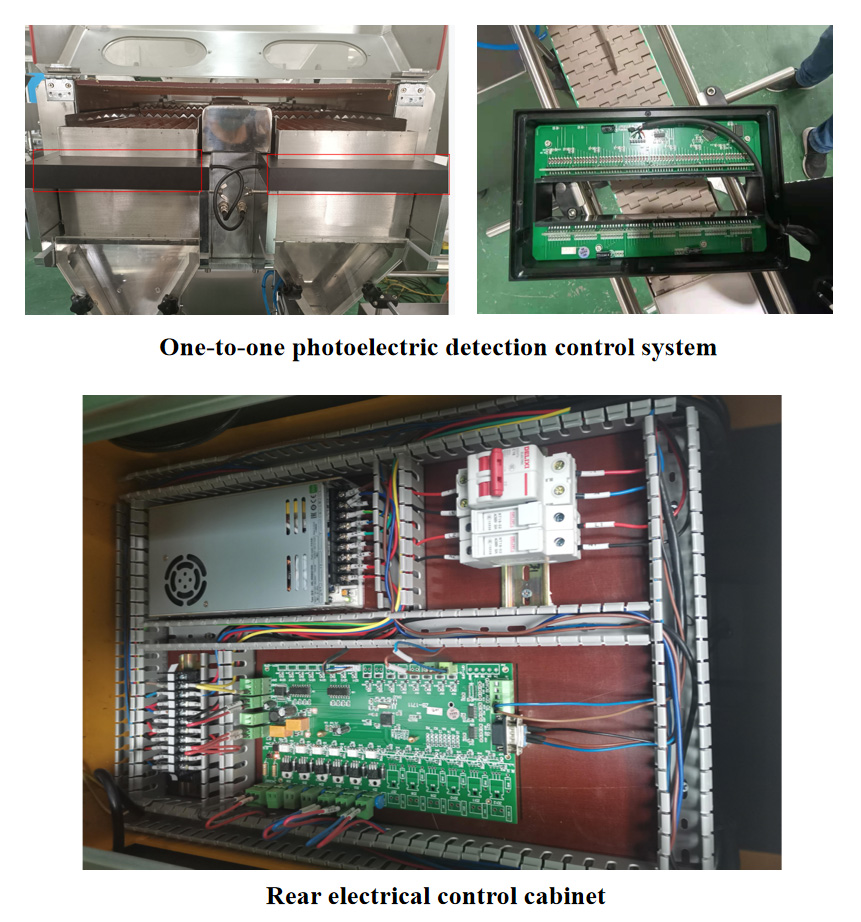

Counting System

The counting system is a vital part of tablet counting machine, it consists of many counting heads and sensors, which are sensitive and used to count the amount of tablets.

Bottle Feeding Mechanism

After counting, the next step is to fill tablets into bottles, well, there is a component to play this role, that is, bottle feeding mechanism. As you can see, the tablets are filled into bottles through this dropper which is adaptable to the bottle mouth.

Conveyor

As a matter of fact, conveyor is an important character in tablet counting machine, its function is to deliver the bottles, it delivers the bottles to the feeding mechanism and then delivers them away, this is this part that let the machine realize high automation and continuous filling.

7.What is the working principle of tablet counting machine?

Maybe some of you guessed the working principle of tablet counting machine when you read the answer of the last question, in fact, the working principle of tablet counting machine can be divided into three steps: tablet feeding, counting, bottle filling.

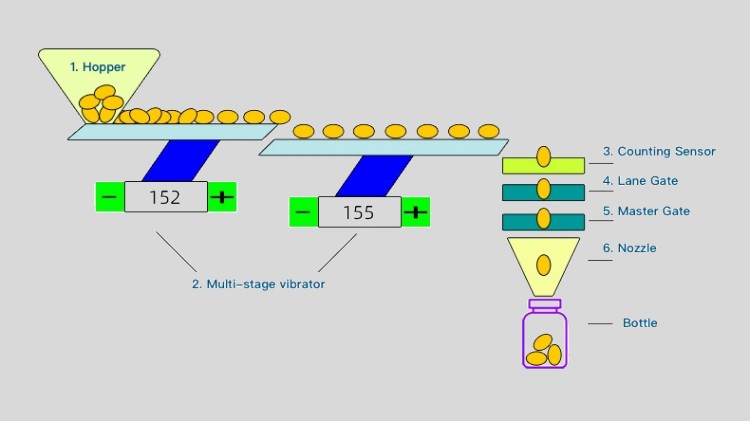

Working Principle of Tablet Counting Machine-Photo Credit: ShineBen

Look at the process diagram, it can show the working process of tablet counting machine to you visually, at first, the tablets are feeding into the machine by hopper and then go through the vibrator.

Next, they are delivered to the counting system and be counted by counting sensors, at the same time, the amount of tablets will be shown on the touch screen.

After counting, the tablets are filled into the bottle by bottle feeding mechanism, they pass by the nozzle and then fall into the bottles. Finally, when the bottle is full, it is delivered away and the next bottle takes its place.

You can see the whole working process of a tablet counting machine is quite easy so that you can quickly understand it.

8.How to operate a tablet counting machine?

To operate a tablet counting machine, at first you need to figure out which type of tablet counting machine will you use, if it is a manual tablet counting machine, you just need to put tablets into its holes in order, it is so simple. Next, you will learn the operation procedures of automatic tablet counting machines.

The first step is to debug the machine, turn on the power supply, let the machine run , check whether it can work normally, if it can, you can continue doing the next operations, if it can not, you need to check what’s wrong and solve problems first.

The second step, when you ensure the machine can work normally, you can prepare to set up the machine, there are many buttons on the touch screen such as start button, stop button, speed adjustment button and so on, you need to set up the parameters in advance so that the machine can count and fill tablets smoothly.

Next, when you finishing set up parameters, you need to pour tablets into the machine, as is mentioned, pour them into hopper, then you just wait for the working of the machine.

The final step is the bottle feeding, pat attention that if you operate a semi automatic tablet counting machine, you need to change another bottle when the last bottle is full, you need to do this operation manually.

If you operate a fully automatic tablet counting machine, it will be much more convenient, the machine will deliver the bottles by itself.

9.How can you improve the accuracy of tablet counting machine?

As is well known, there are some industries have high requirements of the accuracy of tablet counting machine, as a matter of fact, there are some precautions which influence the accuracy, they are as follows:

●When you install the tablet counting machine, you need to ensure that the machine is placed stably and horizontally, if the machine is oblique during the working process, of course that the accuracy will be low.

●Do not let the machine begin working directly, when you turn on the power supply, let the machine run for several minutes so that it can adapt to the following counting process.

●In fact, the material which need to be counted can also influence the accuracy of the machine, you need to set up different parameters which include vibration frequency and transmission speed for different materials.

●You need to monitor the working of the tablet counting machine, feed material into the machine timely, or there will be a situation of incorrect counts.

●Another important factor is the surrounding, as you know, the tablet counting machine count tablets by its sensors, these sensors will be influenced by temperature, light and moisture in the air, therefore, you need use your tablet counting machine in a proper dry environment.

●Pay attention to the maintenance of tablet counting machine, you need to maintain and clean your machine regularly, the dust on the surface of the machine will reduce the accuracy of it.

In a word, when you use your machine, you need conform to the instruction and guarantee the whole working process is normal, these above details will help you improve the accuracy of the tablet counting machine.

10.How to troubleshoot a tablet counting machine?

During the operating process, there may be some malfunctions of your tablet counting machine, therefore, it is necessary for you to know how to troubleshoot the machine, you will learn some common situations and their solutions to the below.

●Tablet Blockage

Cause:

①The rotating speed of the tablets is too high so that there is a blockage, as a result, the machine can not count tablets normally.

②The materials which are fed into the machine are too many.

Solution:

At first you need to stop the machine and deal with the blockage, then adjust the feeding speed of the machine and the vibrating frequency of vibrator, or reduce the amount of the feeding materials properly

●The Machine Occurs Alarm

Cause:

①There are not enough empty bottles.

②There are dusts on the sensors so that the sensitivity is reduced

③The bottles which you use are white bottles that can produce bright light.

Solution:|

①Supply empty bottles on time.

②Clean the sensors and adjust the sensitivity voltage of the machine.

③Clean the photoelectric head of the machine with a soft cloth or brush.

●Wrong Counting

Cause:

①There sensors are polluted so their sensitivities are reduced.

②The set counting time is incorrect.

Solution:

①Clean the sensors, adjust the sensitivity of them.

②Resent the counting time, increase or reduce it according to the real situation.

●Tablet Spoilage

Cause: The distance between the dropper and the mouth of bottle.

Solution:Adjust the distance between the dropper and bottle, notice that this distance should be no more than the diameter of the tablet.

11.What factors should be considered when purchasing a tablet counting machine?

If you have the demand of purchasing a tablet counting machine, you can not choose a model casually, there are many factors to consider before purchasing, next you will see some of them.

Production Capacity

Production capacity is a basic factor to consider since it will directly determine which type and model of tablet counting machine should you choose. You need to figure out whether your business is large scale, whether you need tablet counting machine which has high production capacity.

Quality & Performance

Of course that the quality and performance of a tablet counting machine are important for you, before purchasing a machine, you need to study the famous manufacturers and machine models in the market. Try to choose those manufacturers who have good reputation, and select tablet counting machines which are critically acclaimed.

Size Of The Machine

As is mentioned before that there are many different types of tablet counting machines and they are distinguished in size. Some of them are designed compact so that they can be used on a table top while others are very large that they need a special workshop.

Therefore, you need to consider that where will you use your tablet counting machine, this is a important factor to choose the right machine for yourself.

Budget

Certainly, what kind of tablet counting machine you can buy depends on your budget, how much can you spend on this machine. If you have a high budget, you can purchase high end tablet counting machine, on the opposite, you can choose a cheaper machine.

Keep in mind that you need to choose the best tablet counting machine within your ability.

After-Sales & Warranty

The after-sales service and warranty are also vital factors for you to consider, when you choose a tablet counting machine, you need to judge whether the seller is reliable, and make it clear that whether it provides after-sales service and warranty for customers.

Buying a tablet counting machine from a manufacturer which provides complete after-sales service and warranty, if the machine occurs malfunction, you can ask its manufacturers for help, which is very convenient for you.

Conclusion

Besides the function of tablet counting machine, until now you have learned many knowledge that at the technical level after reading this useful buying guide.Do you think you have a deeper realization of this machine? Hope that this blog can really help you, and if you have some queries which are not mentioned in the blog, you can contact us, we are 24/7 online for you.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586