Spray Filling Machine – Precision Spray Filling for Pharma & Personal Care

Automated spray-nozzle filling & capping with GMP compliance, high accuracy, and minimal waste

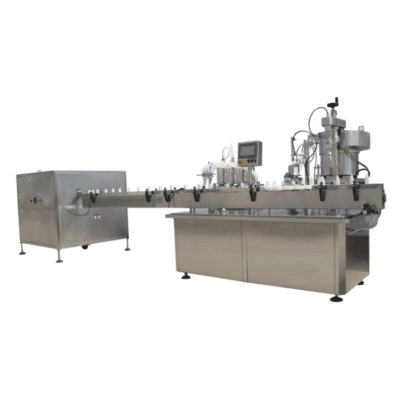

AIPAK Spray Filling Machine

AIPAK Spray Filling Machine is developed by our company on the basis of absorbing advanced foreign technology, and is a special equipment for spray filling. Suitable for filling and capping of round and shaped bottles of various materials and nozzles of various specifications. Adopt disc positioning type filling, disc positioning type upper sprinkler, screw cap, high degree of automation, solve the inconvenience of manual sprinkler.AIPAK spray filling machine uses peristaltic pump filling, pneumatic capping, lifting cap,man-machine interface control has the advantages of accurate filling measurement, stable capping, simple operation and so on. AIPAK spray filling machine is widely used in medicine, daily chemical and other industries. Fully comply with GMP requirements.

Applications of Spray Filling Machines

AIPAK spray filling machines are designed to handle a wide variety of liquid products across multiple industries, ensuring precision, hygiene, and efficiency in every batch.

Pharmaceuticals & Healthcare

Ideal for nasal sprays, throat sprays, antiseptic solutions, and medical-grade liquids that require strict GMP compliance and dosing accuracy.

Cosmetics & Personal Care

Perfect for perfumes, body mists, facial toners, and hair sprays, providing consistent spray patterns and preserving product integrity.

Household & Cleaning Products

Used for air fresheners, disinfectant sprays, and surface cleaners, guaranteeing leak-free filling and stable capping.

Food & Beverages

Suitable for flavor mists, edible sprays, and food-grade sanitizers, manufactured with stainless steel 316L to ensure safety and hygiene.

Agricultural & Veterinary

Applied in plant protection sprays, pesticides, and veterinary disinfectants, with flexible filling options for different container types.

Chemical & Industrial Solutions

Effective for lubricants, protective coatings, and specialty industrial sprays, offering precision filling for both small and large-scale production.

Download Our Latest Catelogue

Discover our full range of pharmaceutical processing&packaging machinery. Download the catalogue to explore specifications, features, and applicatons.

- Full product range

- Detailed technical specs

- Industry applications

AIPAK-Your Best Pharma Processing & Packaging Machinery Supplier In China

Spray Filling Machines FAQ

1.What is a spray filling machine used for?

A spray filling machine is designed to accurately fill liquid products into bottles equipped with spray nozzles, ensuring consistent dosage and leak-free packaging. It is widely used in pharmaceuticals, cosmetics, personal care, household, and chemical industries.

2.What types of products can be filled with a spray filling machine?

These machines can handle a wide range of low- to medium-viscosity liquids, including nasal sprays, throat sprays, perfumes, disinfectants, air fresheners, lubricants, and more.

3.Can one machine handle different bottle sizes and spray nozzles?

Yes. Most spray filling machines are designed with adjustable filling heads and flexible holders to accommodate various bottle sizes, shapes, and spray nozzles. Customized solutions are also available for unique packaging requirements.

4.How accurate is the filling process?

AIPAK spray fillingmachines maintain a typical filling accuracy of ±1–2%, depending on the liquid’s viscosity and production speed. Precision pumps and sensors ensure consistent results across every batch.

5.Are spray filling machines GMP compliant?

Yes. All spray filling machines are manufactured with stainless steel 316L and follow Good Manufacturing Practice (GMP) standards, ensuring hygiene, safety, and regulatory compliance for pharmaceutical and cosmetic production.

6.How easy is it to clean and maintain the machine?

The spray filling machines are designed with quick-release parts and smooth stainless-steel surfaces. Optional CIP (Cleaning-in-Place) systems are available, making cleaning fast and efficient while minimizing downtime.

7.What is the production capacity of a spray filling machine?

Production speed varies by model, ranging from small semi-automatic machines (hundreds of bottles per hour) to fully automated lines (thousands of bottles per hour).

8.Do you provide after-sales service and spare parts?

Yes. We offer comprehensive technical support, operator training, spare parts supply, and a standard 12-month warranty to ensure stable long-term operation.

9.Can the machine handle viscous or foamy liquids?

Yes, depending on the pump system used (piston, peristaltic, or diaphragm). We recommend evaluating your product viscosity before choosing the right model.

10.How do I choose the right spray filling machine for my business?

Key factors include product type, bottle design, production volume, automation level, budget, and regulatory requirements. Our team can provide professional consultation and tailored solutions.

The Buyer's Guide

Spray Filling Machine: The Complete FAQ Guide in 2025

Are you new to the spray filling machine?

In fact, the nasal sprays and spray toners we commonly used are all processed by the spray filling machine.

There are many applications of the spray filling machines. So it is very popular in the market now.

If you are interested in this spray filling machine, but don't know a lot about it, you must not miss this guide.

It includes every aspect from the conception,composition, working principle and advantages to FAQ of this machinery.

Let’s begin directly.

1.What is Spray Filling Machine?

AIPAK Spray Filling Machine

Different kinds of liquid filling machines are present in the market according to their specific product line and Spray Filling Machine is also one of them.

This machine is used for filling different sorts of bottles and containers with the help of a spray nozzle that is present on the head of the filler tap.

A spray filling machine is used to fill the spray head bottles and vials with a different type of liquid material. It has a wide range of applications & uses.

Spray Filling Machine is used to fill the bottles up to the right amount of the liquid material and when the filling is done spray heads are put on the bottles for personal and business use.

When the liquid filling is done then the sealing of the bottles is made sure so that the product may not get wasted. The cap heads that are put on the bottles after the filling are called actuators.

Actuators have a small hole at one side when the pressure is applied on them then the liquid came out of the bottle like a spray perfume.

This machine is used in the medical industry for filling medicine dosage & other liquid materials as well in the liquid vials.

Some specific and special products require some special types of equipment for filling like a reaction may happen in the liquid during the filling so this machine is very helpful in filling the bottles with a continuous flow of the liquid.

2.Which Industries are Spray Filling Machines Widely Used?

Mainly there are a lot of industries in which spray filling machine is used up to some minor level but here are the main industries in which Spray Filling Machine is used.

Detergent Industry

Different Detergent bottles

Different sorts of detergents are available in the form of liquids these liquids are filled in the bottles with the help of a spray filling machine.

Products like hand sanitizers & liquid soaps are filled in the bottles and spray heads are put on the bottles. Furthermore, dishwashing detergents & other detergents are also used for filling in the bottles with the help of a Spray Filling Machine.

You know the liquid that is put inside the bottles came out through a small hole because a small pressure when applied on to the cap head of the vials then the liquid came out through the tiny hole.

Hand sanitizer bottles are also one of the forms of spray filling because they required some small amount of pressure on the bottle head for getting the liquid out.

Cosmetics Industry

Different size cosmetic bottles

In the beauty industry many of the liquid products are required for filling in the bottles and when the filling is done the bottles are made seal packed.

So, it is one of the major industries that use the Spray Filling Machine to fill different sorts of bottles with different sorts of liquid material.

The perfumes that came in the spray head bottles are one of the applications of this machine. There is a wide range of products in this industry that is filled with the help of this machine-like, liquid perfumes, body lotions, face lotions, the liquid base used in the makeup process & many other products.

This is one of the major industries that get a lot of production with the help of this machine. And widely used applications of this industry make the machine more important for filling different types of products in the spray head bottles.

Chemical Industry

When it comes to the chemicals they need a special type of treatment for their products because they may react during the filling. So, Spray Filling Machine is very helpful in filling different types of chemicals with the same continuous flow of liquid.

Chemicals are explosive and reactionary when they are used for filling in the bottles. So, by using this machine the toxicity of the chemicals will remain in the chemicals because it will not disturb the chemical layers between different types of products.

Chemical bottles that are used to kill insects they also came in the form of spray bottles for killing different sorts of flying & other insects like, mosquitoes spray and other insects spray bottles are also used for killing different type of insects.

Lubrication Industry

Different forms of oils and lubricants are filled in the containers with the help of a Spray Filling Machine without foaming and bubbles.

Engine oil that we use for our vehicles often came in the bottles and these bottles are filled with the help of this machine. This machine plays a very important role in this industry.

Some of the lubricants are very dense and hard to fill with less time consumption but Spray Filling Machine assists you to do this in a very short time and you can easily maintain any type of liquid.

3.What Types of Bottles can be Filled by the Spray Filling Machine?

Many types of bottles are present in the industry for filling different types of liquid materials in them.

Some following types of bottles can be filled with the help of a Spray Filling Machine.

Plastic Bottles

Different plastic bottles are present in the market with different types of design are used in Spray Filling Machine for the liquid filling because they are very flexible and reliable.

You can fill an accurate amount of liquid and air pressure in these bottles because plastic can be expanded according to product filling.

Glass Bottles

Empty glass bottle for liquid filling

At some specific level glass bottles can be used for filling in the Spray Filling Machine. But you will not be able to fill at a much high rate than you can do the filling in plastic and steel bottles.

Because if you fill the glass bottles while applying great air pressure they may be broken because of too much pressure.

4.What Types of Dispensing Nozzles can be Used by the Spray Filling Machine?

Mainly there are three different types of dispensing nozzles that can be used by the Spray Filling Machine.

Swirls Nozzles

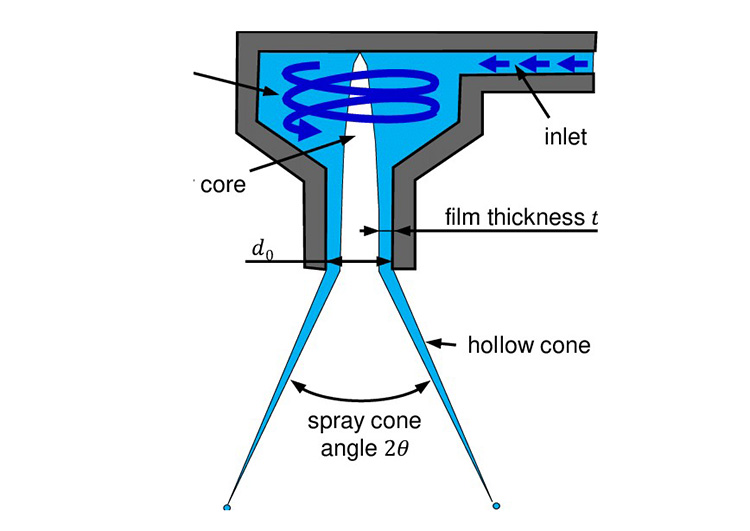

Swirl Nozzle with its components-Picture Credits: researchgate

These nozzles provide the cone-type spray when the liquid came through them and very helpful when you need good pressure liquid.

On a spray boom, they are very rare in use because the amount of the liquid drops are less as compared to the air pressure.

Furthermore, these nozzles have two other classes as well.

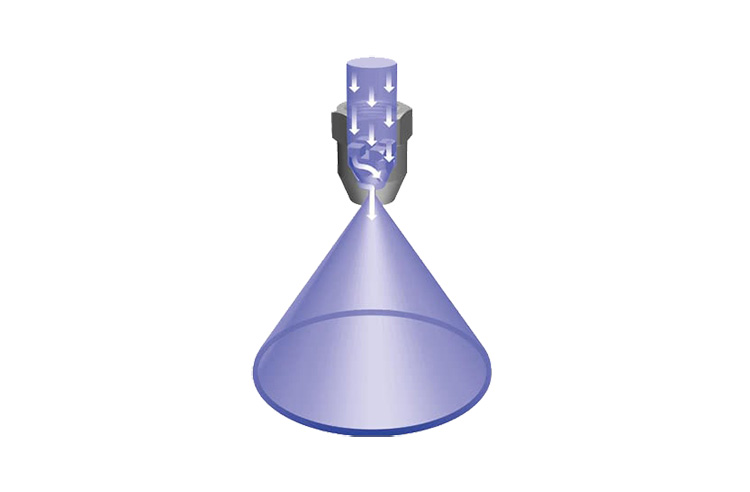

Full Cone Swirl Spray Nozzle

Liquid coming out from Full cone swirl nozzle-Picture Credits: Lechler

When the liquid came through this nozzle it makes a dense form of a cone with full liquid drops coming through it that is why it is called the full cone spray nozzle.

Hollow Cone Swirls Spray Nozzle

As you know hollow means some space inside or emptiness in the object when the liquid flows through the hollow cone spray nozzle it makes a boundary of liquid drops but the inside of this cone is hollow that is why it is called hollow cone swirls nozzle.

Floodjet Nozzles

Flood jet nozzle

These types of nozzles are used to cover more volume with the liquid drops flowing through the nozzle.

When you want a wide range of liquid flow through the nozzles these nozzles are best to cover a wide range of areas.

Both dense and light liquid drops can come through these nozzles and these drops can cover up to 160 degrees angle area.

Split Top Nozzles

Split valve nozzle

When it comes to spray the liquid drops in the form of ellipse like, the bath shower that we use in daily life. The liquid drops coming from this nozzle have come through very low air pressure.

There are two more types of Split Top Nozzles.

Split Top Nozzle of basic type

This is one of the basic and most used nozzles types in the split top. If you want to split small liquid drops through the nozzle then this is the most used nozzle for you.

Venturi Split Top Nozzle

This nozzle is used for splitting bigger types of liquid drops. Inside of the nozzle, this nozzle contains air pressure for splitting larger liquid drops into small liquid drops.

5.Why should you Invest on the Spray Filling Machine?

If you want to grow your business with more efficiency and want to get more production in less time then you need to invest in this machine for more productivity.

Here are some following points that you need to keep in mind that you are going to gain while investing in this machine.

Increase Productivity

As you know the world is full of technology with the increasing rate of advanced technology you will get quick production & efficient quality production with the help of this machine.

Your labor will easily operate the machine and in just a few hours you will get more production.

Some of the machines are faster & quicker in operation they will take fewer hours of operation time to reach your production demands.

Great Business Opportunities

By investing in the machine you will compete with the market for greater and better opportunities to grow your business up to an extreme level.

It will be easy for you to meet customer requirements in less time consumption and you will produce more production. Newmarket opportunities will also come for you if you reach the customer needs by providing them the quality production.

Future of your Investment

Before investing in the machine you need to make sure that your production is going to benefit you in the future. Always invest in the machine but first make sure that your production line will be beneficial for you in the future.

If you invest at the right time in the right business then you will get more benefits from this machine. As you know the coming days are full of technology so, you need to invest in the machine as it will secure the future of your business.

Efficient Production

If you want your product to be more efficient and of greater use then invest in the Spray Filling Machine because it will give you uniform liquid filling production.

By doing the manual liquid filling you will not get that efficient and uniform filling production but with the help of this machine you will get more efficiency in your production line and greater future opportunities will fell at your doorstep.

6.What are the Advantages of Spray Filling Machine?

Here are some following benefits that you will get by using the Spray Filling Machine.

AIPAK Spray Filling Machine

- Sneaked long needles present in the Spray Filling Machine can go to the base level or bottom of the cane to fill it with a Spray of liquid and air without making any foaming.

- Your liquid will not get wasted during the filling the sealing of the bottles is made sure in such a manner that no dripping will happen.

- The machine is capable of filling liquid in 20-25 bottles at the same time with the same level of the liquid.

- During the filling, no liquid will accumulate on the inner side of the bottles because the plunger pump present in this machine will not let this happen.

- There is a small liquid container/tank present in the machine that can be used for making the bottles infection-free by doing the water cleaning.

- The guiding and manipulator system in the machine makes sure that the spray head of the machine is ready to enter the head of the bottle.

- You can set the filling time from the screen panel and every type of bottle can be filled with the help of this machine with accuracy and quick speed.

- The nozzle present in the spray filling machine will help the bottles to get filled up to the right level without making any bubbles.

- Both pneumatic and electric functions can be performed at once on the material for filling purposes.

- You can use any type of liquid for filling into the bottles with a strong performance rate it is very reliable for you to use any type of liquid material.

- You can easily adjust the claw size for holding the bottles according to the width and the length of the bottle.

- If you want a uniform and accurate filling then this machine is the best solution to your requirement.

- You can fill any type of pharmaceutical liquid dosage with the help of this machine & every type of bottle can be filled with the help of this machine.

- In the medical industry, different kinds of injection vials can also be filled with the help of this machine.

7.Are there any Drawbacks of Spray Filling Machine?

Every machine has some drawbacks because no product can deliver 100% of its performance rate.

Here are some following drawbacks of the Spray Filling Machine.

- You will find difficulty in the formation of some liquid product that is going to be filled in the bottles.

- If the size of the nozzle is larger or not adjusted properly then it will affect the base of the bottles & your bottles may get damaged during the filling.

- Some chemicals & other liquids if not tested properly then they will affect the inner side of the bottles/vials and some sort of reaction can happen.

8.How many Types of Spray Filling Machines are there?

Mainly three types of Spray Filling Machines are present in the market for filling different types of products and liquid materials.

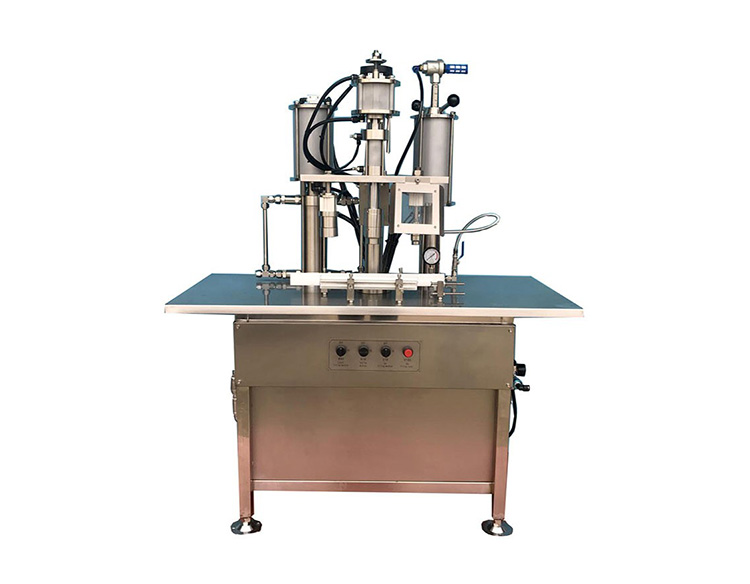

Manual Spray Filling Machine

Small scale manual liquid spray filling machine

As you know by the name of the machine this machine will help you to fill the liquid in the bottles with the help of a spray nozzle but you need to operate it manually.

This machine will require some persons to operate it because it is not automatic in filling you will require labor to work with this machine.

You need to put the bottles manually in the chamber for filling and then fill the liquid tank up to the right level and then with the help of the liver daw the spray nozzle into the bottles and fill them according to the required level.

This machine is not much expensive as compared to the others but it will cost you in terms of labor to operate it.

Semi-Automatic Spray Filling Machine

Small scale semi-automatic liquid filler-Picture Credits: tradeind

Some components of the machine in this machine will require to operate manually and the others will work automatically for filling.

This machine type is more expensive and requires less labor to operate as compared to the manual Spray Filling Machine.

This machine is available in different sizes according to your need and business requirements so, that you can use it according to your production line.

It will help you to reduce your labor expenses. As you know the primary use of every type of machine is filling the liquid in the bottles but their working may be different.

This machine will require some human effort for filling the bottles and move the product from one place to another.

Mainly this machine will not work with full automation it will need some laborers to handle the product at some specific point.

Fully Automatic Spray Filling Machine

AIPAK fully automatic spray filling machine

A full automation level present in the machine makes this machine quicker and speedy as compared to the other ones.

It can perform every task automatically you just need to operate it through the touch screen and start the operation by setting the right values in every operation.

From beginning to the end this machine can handle the filling product at every step you just need to operate it correctly. In the spray filling process, the nozzle present in the Spray Filling Machine will go inside the bottle and fill it up to the right filling level.

This machine is costly as compared to manual and semi-automatic but it will help you to meet your product requirements in less time.

If you want to invest for the long run of your business then this machine is best for you to work with.

The chamber which holds the bottles for filling can automatically load the bottles and when the filling is done the chamber will unload the bottles from the supply line and the process will continue.

9.What are the Main Components of Spray Filling Machine?

Every machine has some main working components that help the machine to do the work properly. Here are some following components of the Spray Filling Machine that help the machine to work.

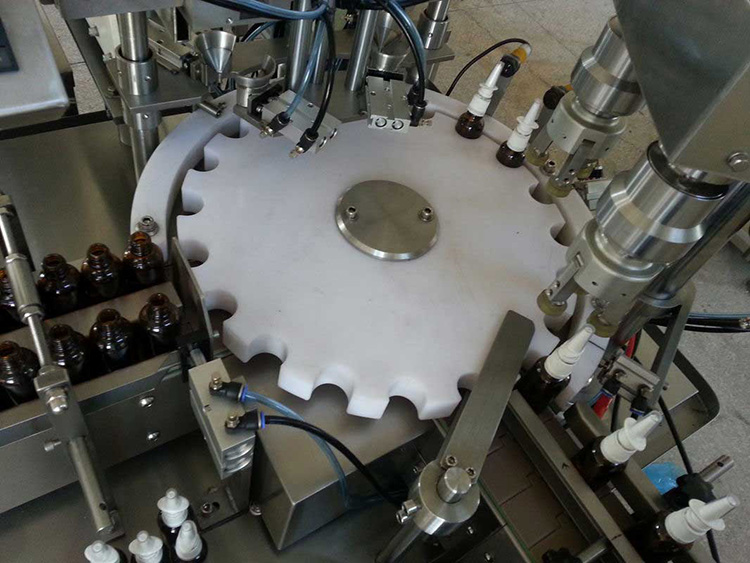

Rotary Machine

This part of the machine does the rotary motion on the bottles when the bottles are placed in the claws for liquid filling and when the filling is done then bottles are removed and moved towards the next line this is done with the help of a rotary machine.

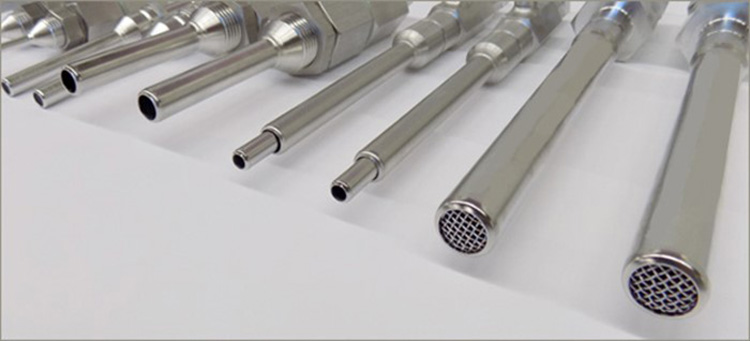

Filling Nozzle

Different type of nozzles used in spray filling machine-Picture Credits: Filamatic

This is one of the basic components of the Spray Filling Machine. This component of the machine can fill the bottles by going into the depth of the bottles without making any bubble formation.

Liquid Tap

Liquid tap in liquid filling machine

The filling liquid that is present in the liquid chamber comes into this tap and goes into the bottles from these taps.

Conveyor Belts

Bottles present in the Spray Filling Machine are moved from one place to another with the help of these belts.

It helps the machine to easily transfer the bottles from one place to another before and after the filling.

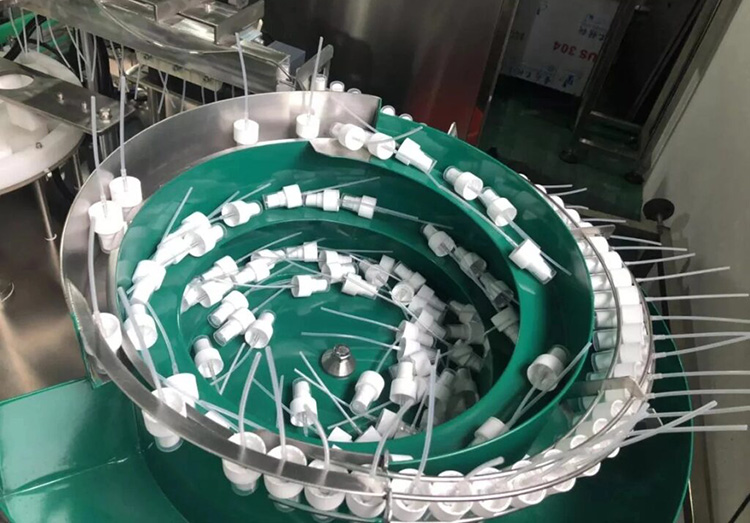

Spray Heads Sorter & Inserter

Spray head sorter-Picture Credits: Edible oil

This is one of the main components of the Spray Filling Machine that helps to insert the caps on the bottles when the filling is done.

This component works automatically to place the caps on the bottle's head after the filling.

Check Weigher

This part of the machine will check the accuracy of the filling liquid in the Spray Filling Machine. It checks the right quality and quantity of the material that is going to be filled.

Liquid Tank

This tank is usually used for holding the liquid that is going to be filled in the bottles and requires to be filled up to the right level for Spray filling.

10.What is the Working Principle of Spray Filling Machine?

There are different sorts of Spray Filling Machines present and the primary working of these machines is same.

Here is the working principle of the Spray Filling Machine.

Step-1

In this step when the bottles/vials are loaded into the chamber then they are moved into the filling conveyor for liquid filling.

Conveyor belts are used for transferring the bottles from one part of the machine to the other. These conveyor belts move the bottles towards the filling conveyor and place them in their preferred position for liquid filling.

Step-2

When the empty vials/bottles are placed on the filling conveyor then the feeding nozzle that is present at the head of the filler tap is placed inside the bottle.

When the feeding nozzle is placed inside the bottle it goes to the bottom of the bottle and then the liquid came through the filler tap fills the empty bottles.

The nozzle present at the filler head helps to fill the bottles without making any bubbles formation.

Step-3

When the bottles are filled up to the right level then they are moved towards the cap inserter for packing the bottles.

The cap inserter is used to insert the caps on the bottle's head and get your bottles packed so that no liquid gets wasted during the transfer.

Your liquid will not get dripped when the packing is done on the bottles. Spray Filling Machine is quicker as compared to other liquid filling machines.

Step-4

Just after packing the check weigher make sure that every bottle is filled with the right amount of liquid. It checks the filling level of the bottles with the help of sensors.

When the bottles are capped the rotary machine rotates the bottles towards the conveyor belts & these belts transfer the bottles towards the discharging chamber.

The discharging chamber removes the bottles from the conveyor belts and removes them from the machine.

So, that is the whole working principle of the Spray Filling Machine. This machine is very reliable and flexible for filling every type of liquid.

11.What is the Specification of AIPAK Spray Filling Machine?

AIPAK provides you a fine quality Spray Filling Machine according to your business requirements.

Here are some specifications of the AIPAK Spray Filling Machine.

- You can fill the bottles with having a volume from 5ml to 250ml.

- The machine can work automatically in many different operations like bottle feeder, automatic liquid filling, automatic cap inserter & pre cap structure.

- The machine is designed simply and very reliable for you to use in any kind of environment.

- As per the customer needs Spray Filling Machine provides a very efficient work rate and high-speed production.

- If the bottle size changes you can adjust the machine or use other types of equipment as an attachment for better working.

- Proper testing is done before delivering it to the customers and every general and basic certification is to make sure to be attached while delivering the machine.

Here is the specification table of the AIPAK Spray Filling Machine.

| Product# | APK-PWJ |

| Product Specification | 5ml to 250ml |

| Production speed | Double header 50 to 100 b/m

Single header 30 to 60 b/m |

| Weight of the machine | 15000KG , 25000KG |

| Machine Dimensions | 8000*2000*1750 |

| Supply power | 380/220V, 3KW |

| Air Consumption | 0.6 to 0.8Mpa, 10/30m³/h |

| Stopping and add cap rate | >99% |

| Error rate during filling | ± 1 ˜ 2 % |

12.What Other Equipment are Needed to Cooperate with Spray Filling Machine to form a Complete Production Line?

First of all fully automatic filling process is done with the help of a liquid filling machine or spray filling machine.

Spray Filling Machine

AIPAK Spray Filling Machine

When the bottles are placed in the claws of the machine then the spray nozzle goes into the bottle and fills the liquid into it.

PLC control systems in the machine make it easy for you to operate every step of the machine perfectly.

Built-in pump technology in the machine makes it very quick in liquid filling with less rate of dripping material.

Automatic Send-cap Process

When the filling is done this equipment comes into action to send the caps towards the cap inserter to place these caps on the bottle's head.

This fully automatic equipment is used for the capping process when the bottles are filled with liquid.

Automatic Vibration Cap Plate

Cap vibration plate

When the caps are sent from the Automatic Process Send-cap then this plate vibrates and sorts these caps to place them on the conveyor belts for further processing.

With the help of vibration, caps are sorted in order so, that it easy for the conveyor to hold them at the right angle.

Caps when placed on the conveyor belts then sent towards the cap inserter to insert them on the bottle heads.

So, this is the complete production line of the Spray Filling Machine that requires some other pieces of equipment to fulfill his work efficiently.

13.What is Aerosol Filling Machine?

Small scale aerosol filling machine

The aerosol filling machine is almost the same as the spray filling machine but when it comes to the product filling both of these machines fill different kinds of materials in bottles.

Basically, Aerosol Filling Machine is used to fill the gas in the bottles/vials with the help of a nozzle and air pressure.

Different kinds of gas or liquified products can be filled with the help of an Aerosol Filling Machine. When the pressure is applied on the cap head of the bottles these gaseous materials came out of the bottle in the form of gas.

In the pharmaceutical industry, Aerosol Filling Machine is used to fill different kinds of liquified dosage that can be used for different body parts like, ear, nose, etc.

The first aerosol product was made in 1951 and was used for medical purposes.

14.What are the Differences between the Spray Filling Machine and the Aerosol Filling Machine?

In this passage, you will know some basic and general differences between these two machines that are used in many different industries.

AIPAK Fully automatic spray filling machine

Main & Basic Difference

The main difference between the Spray Filling Machine and Aerosol Filling Machine is that the Spray filler uses the liquid to fill in the bottles.

On the other hand, Aerosol Filling Machine uses gas or liquified gas to fill the empty bottles.

In Spray Filling Machine liquid is filled without using any gas pressure or gas but in Aerosol Filling Machine gas is used for filling the bottles along with other solvents in a very small amount.

Aerosol Filling Machine works on the principle of gas filling while the Spray Filling Machine works in the form of liquid with the help of a very small rate of air.

Pressurized dosage is prepared with the help of Aerosol Filling Machine but in Spray Filling Machine liquid is filled with the simple spray nozzle and it uses a very low rate of air pressure.

Aerosol filling machine

A fine mist can be formed with the help of Aerosol filler for oral inhalation but a liquid dosage is prepared with the help of Spray filler.

The liquid that is used in the spray filling machine is less reactive as compared to the liquefied gas that is used in the aerosol filling.

Working Difference

The working principle of both of these machines is almost the same using the same working components but the main difference lies when it comes to the filling.

The filler tap in the Aerosol Filling Machine holds the liquefied gas and fills the bottles with pressurized gas.

In Spray Filling Machine the filler tap only uses the liquid for filling the bottles.

The cap header & inserter also work differently in both of these machines. The pressure is applied during the cap insertion on the bottle's head in the Aerosol Filling Machine but in the Spray Filling Machine, no major pressure is applied on the caps.

15.Can AIPAK Spray Filling Machine be Used for Filling Aerosol Products?

The answer is No! As you know there is a huge difference between Aerosol Filling and Spray Filling so, you can not use the Spray Filling Machine for Aerosol Products.

The liquid can be used for filling with the help of the Spray Filling Machine but Aerosol Filling Machine works with the gaseous material.

The spray filling machine works only for the liquid that is going to be filled. If you want to fill liquid in different types of bottles then AIPAK Spray Filling Machine is very reliable and flexible.

Aerosol products contain gaseous materials. Gas molecules are condensed with the help of an Aerosol Filling machine in this way many gas molecules can come in one bottle.

16.How to Troubleshoot Common Problems of Spray Filling Machine?

There are some sorts of basic and common problems that can occur during the Spray liquid filling. You must need to know these problems so, that you can troubleshoot them.

1.Different Filling Level

Plastic bottles

When the bottles are filled you may counter the liquid filling level changes in the bottles. Some of the bottles will have more liquid filled in them and on the other hand, some of the bottles may have less amount of liquid filled in them.

Solution

When you notice the filled liquid level changes then you must consider cleaning all your filler taps. Try to clean the filler taps and see if there is any kind of foreign material that gets stuck in the taps this will help your production to have an accurate filling level if they are filled with less amount.

And if more liquid is filled in the bottles try to adjust the filling time by using the same speed of filling.

2.Dripping of the Liquid

When the liquid is filled in the bottles then they are further sent towards the packing line where the bottles are made seal proof and leakage proof.

Some of the bottles may have some dripping liquid problem. It may damage your other packed products.

Solution

To solve this problem you need to check the bottles are capped perfectly and make sure the packing production line is working well.

3.Dive Head Missing

This problem in the Spray Filling Machine happens because of any leakage in the air system that controls the movement of the diving head with the help of air pressure.

When the bottles are placed in the specific position for filling the diving head may not reach the level of the bottle and spill the liquid outside of the bottle.

Solution

As you know this problem happens because of some mechanical issue so, you need to check all the airline system and make sure there will be no leakage in them.

All the air compressors must be checked before starting the filling operation. Another tip for you when you are working with the Spray Filling Machine just check the PLC control settings before starting the operation as it will help you to solve timing & other minor problems.

17.Which Factors should you Consider when Buying the Spray Filling Machine?

There are some major factors that you need to keep in mind while buying the Spray Filling Machine.

Automation Level

PLC control system of fully automatic liquid filler-Picture Credits: techfee

Different kinds of Spray Filling Machines are available in the market with different levels of automation it depends on you that how much you are going to invest in it.

If you invest more you will achieve more automation level in the machine because Automatic Spray Filling Machine is costly as compared to semi-automatic and manual.

A fully automatic machine will be costly but on the other hand, it will save your labor cost as well & easy to operate with some basic knowledge.

If you buy semi-automatic or manual Spray filler then it will cost you less amount but you need to require some labor as well for its working.

So, always choose the fully automatic machine according to your business requirement.

Production Rate

Whenever you have decided that you are going to buy the Spray Filling Machine for your business requirement does not rush for it. Stay calm and overview the whole market by asking the sellers about the production rate of the machine.

This is one of the major factors that you need to keep in mind while buying the machine because it will help you to reach the market requirements in less time.

Always choose the moderate production rate machine so, that you can fulfill your customer requirements by consuming less time.

Speed & quick production rate of the machine will open new doors for your business in the market & more opportunities will knock on your door.

Product Details

Before buying the Spray Filling Machine you must know about your product that what type of bottles, containers, etc you are going to use for filling.

The shape, type, and size of the bottle must be considered while choosing the machine as it will help you to buy the right size of the machine according to your product requirements.

AIPAK provides you one of the finest Spray Filling machines and it can fill different sizes of bottles from 25ml to 250ml. This flexibility is provided by the AIPAK Spray Filling Machine so, that you can easily adjust the machine according to your product requirements.

Large size containers will require large size claws in the machine for bottle handling and vice versa.

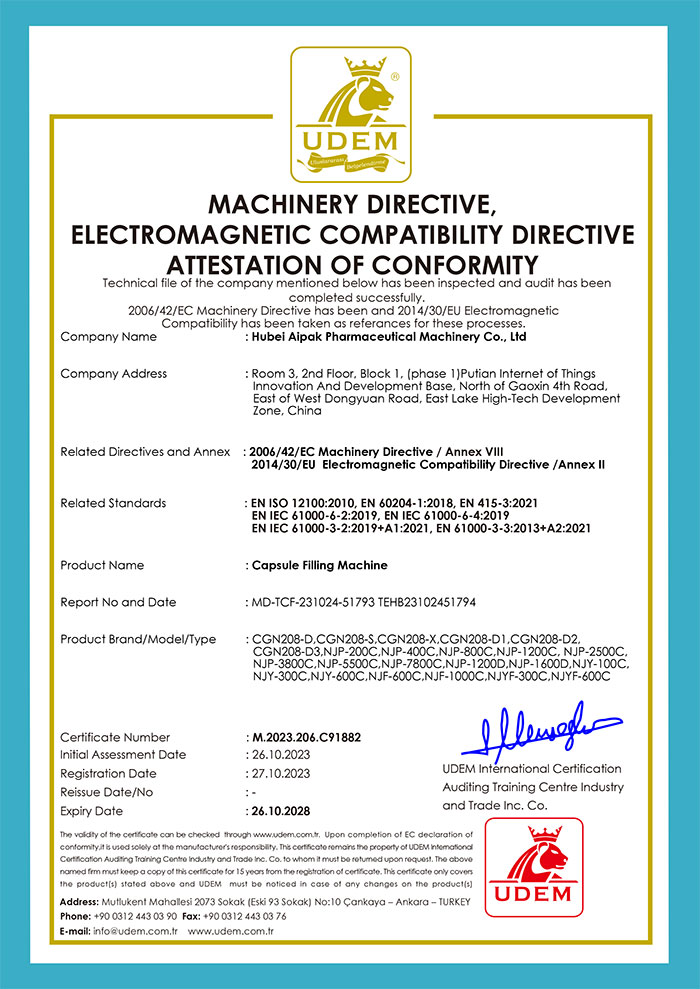

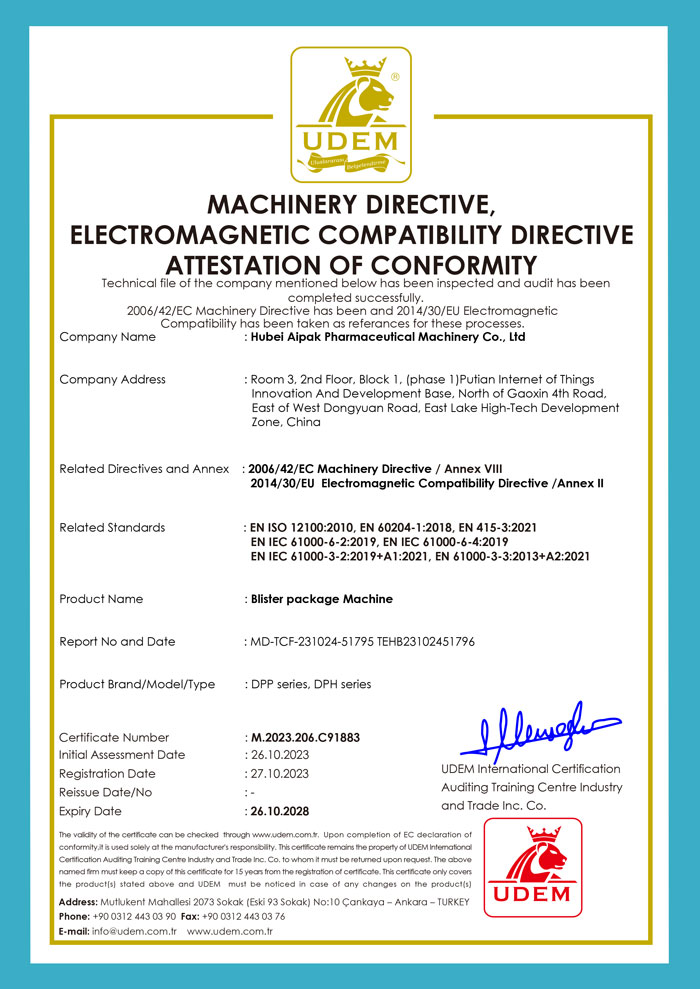

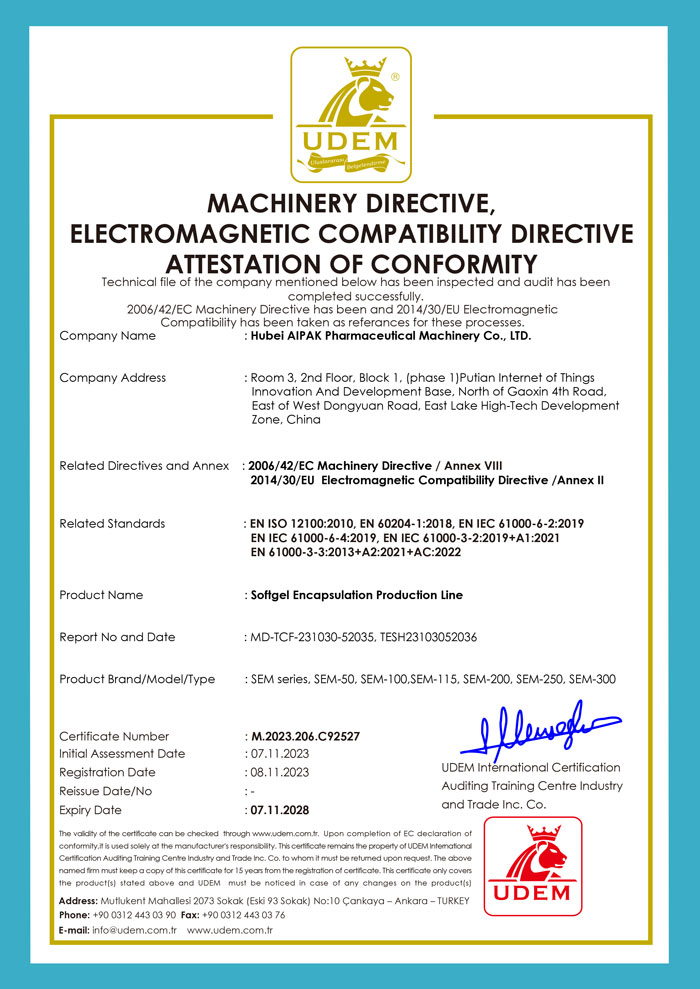

Certification Level

cGMP

Certification of the machine provided by the seller tells you about the worth of the machine. A basic Spray Filling Machine must be certified by the following firms, CGMP, CE, CCC & GMP, etc.

You must consider these certification levels during the Spray Filling Machine purchasing these certificates are provided by the European and other unions which satisfy that your machine is made with best practices and the material that is used during the manufacturing of the machine is proved by the FDA having standard quality.

Future of your Business

Bright future -Picture Credits: Chris

In medical and in other fields as well you must know the future aspects of your business because it will help you invest in the right machine.

If you see your business in the long run then you need to invest in the production line for fulfilling market needs.

Reliability of the Product

When you are buying the Spray Filling Machine it must be flexible and reliable for your production so, that in the future you do not need to invest more in solving other problems.

Maintenance of the machine must not be that much expensive that you will face difficulty in replacing spare parts of the machine.

You must consider that how much easy it is for you to operate the machine.

What type of control system is available in the machine?

Will it be used for the long-term run or not?

Conclusion

As the above-mentioned points tell you about some factors that you need to consider while choosing the Spray Filling Machine. If you are a newbie in this field then there are some other factors that you also need to keep in mind.

Always check the future of your production line and make sure how much you are going to invest in the machine. When you are ready to buy the machine AIPAK provides the best possibilities for buying the best product.

All your requirements are kept in mind to provide you the best quality machine for your business.

18.What is the Future Prospect of Spray Filling Machine?

The prospect of any machine is very important to grow your business up to maximum level and here are some of the Spray Filling Machine prospects.

Container & Product Versatility

Different types of products are getting filled with different types of production lines and people are looking for more versatile production lines for the safety of their product.

The container that is going to hold the liquid must be very reliable and versatile with every kind of liquid like juice and other dense liquids like yogurt.

And to fulfill this duty the pistons are available in the hopper are use to pump the product out from the liquid tank.

Even distribution can also be done while working with these moveable pistons that are available in the machine.

With more, advanced technology customers not only want the safety of the product they also need a versatile Spray Filling Machine that can handle different sizes and types of containers for their production line.

AIPAK machine is designed and manufactured in such a way that the versatility of your product and container will remain perfect. It provides you adjustable claws for handling different kinds of containers.

AIPAK provides you a very wide range of filling volume containers that can be filled with the help of it. It can work on 350 bottles per minute with greater than 85% of work efficiency.

You can fill the different sizes of bottles/containers by using the same machine.

Efficiency & Accuracy

Accuracy is major-Picture Credits: ExpensePoint

The accurate filling level is one of the major aspects of the Spray Filling Machine and if you can achieve the accurate filling level then your product demand will grow faster.

The low filling level will take away your customers from you and they might complain about your filling level in the court and your firm may get suspended.

On the other hand, if the filling level is greater than your liquid product will get wasted and turn out to be a nightmare for you.

So, the Spray Filler must satisfy the accurate and moderate amount of liquid filling in the containers.

The accurate and efficient filling can not be only gained from the machine but it includes different working parts of the machine that can work at high efficiency to provide the accurate filling level.

PLC control system plays a very vital role in the accurate filling so, you just need to understand the logical programming of the Spray filler.

One of the basic tips that you need to know for getting the right amount of filling level is by abolishing the lane-to-lane filling and instead of this use sterile pressurized air inside the hopper high up on every piston.

One of the experts Serac’s Bonanno with his expertise told the people that flow rate is the key to get the accurate amount of filling. If you can control the flow rate of the liquid from the filling monitor and servo drives then accurate filling can be gained.

To get the efficient and accurate filling AIPAK provides you the built-in servo drives that will help you in many other ways as well. This unique technology in the machine senses the flow rate of the liquid and electronically sets the speed of flowing liquid coming from the liquid tank going towards the filler valve.

Less Changeover Time & Hygienic Design

The plus point for the long life of your machine is its cleaning and changeover time. CIP design present in the machine can help to solve cleaning and changeover time consumption.

The clean in place (CIP) helps clean the machine with high speed. Some people might say that cleaning is not necessary for every part.

But you know the moving pistons and valves need regular cleaning for a smooth work rate.

The self-draining system in the machine can help to solve the cleaning issue for filler bowls and inlet valves.

These self drained systems are only available in some specific piston fillers like JBT.

Auto-cleaning system in the Spray Filling Machine will raise the hot water and then this hot water will flow through different parts of the machine and remove all the stains.

In this way, pistons and valves are cleaned for better working without any labor’s basic effort for inside cleaning.

The Spray Filling Machine automatically cleans the inside components of the machine and makes it visible & easy to operate the machine.

The design of the machine will tell about its working aspects and will help you to determine the cleaning level of the product.

Some of the liquid are present in dense form so, the hygienic design of the machine will help you to know what type of cleaning you need to do after the filling.

Some of the products require ultra cleaning after the filling it depends on what type of technology you are using.

AIPAK self drained system in the Spray Filler with the hygienic design will be helpful for every kind of liquid filling just making sure some basic techniques.

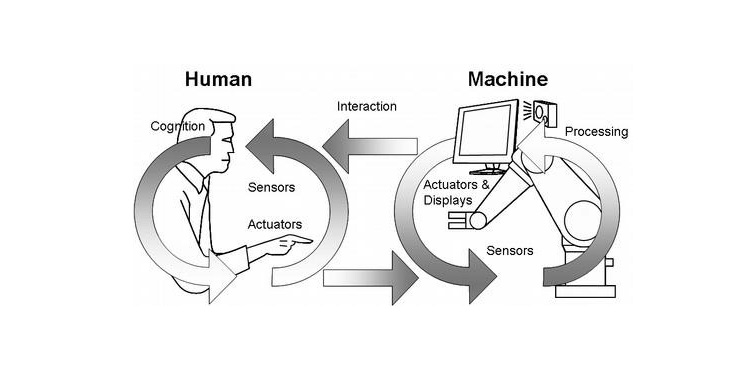

Operator Interaction

Human interaction with machine -Picture Credits: research gate

With the increasing automation level in the machines, it must be easy for you to operate the machine and perform every single operation easily.

The (HMI) human-machine interface is considered as one of the major aspects during the designing and development of the machine so, that everyone can operate it with some basic and general knowledge without any difficulty.

One of the technical person name Sundberg said that if HMI of any equipment keeps in mind while designing it then it should be easy for the operator to find an error if occurs during the operation and you can find that error with the blink of an eye if the machine is made under strong HMI.

The PLC touch screen present in the machine helps your labor to easily work with the machine and they can easily perform every kind of operation.

Interaction with the machine can also be made easier if all of the operations are made to the ground level and it will be easy for your labor to give the command by staying at the ground level rather than climbing on the stairs and look for the command button.

AIPAK provides you ease in operating the machine by staying at the ground level and work with your production line with a reachable area to cover in less time to give commands.

With the help of these small redesigned efforts, you will get more efficient and accurate production by consuming less time.

During the working with the Spray Filling Machine, the labor must know about what lies next after this step and what they will do after the specific operation in this way your production line will remain perfect during the filling process.

Spray Filling Machine Related Posts

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 156 0710 8630