Powder Packing Machine:The Ultimate Buying Guide In 2025

Whether it be pharmaceutical, proteins, spices, milk powder, or nutraceutical products, you always require a powder packing machine, and is broadly implemented too. Automatic powder packaging machines help out you to meet current demands and offer to maintain production requirements among competitive manufacturing units.

Are you planning for a powder packing machine? and afraid of missing important details when purchasing a new machine? Read this blog for complete information and buying guidelines to determine the right selection for the powder packaging process.

Powder Packaging Machine

Let’s have a deeper look!

1.What is a powder packing machine?

A powder packing machine is a suitable choice for packing dry powder substances. The main advantage of using a powder packing machine is that it has a closed housing unit which is an ideal choice for packing extremely fine powders such as pharmaceutical substances, talc, spices, etc.

It has rich production experience whether you are handling manual, semi, automatic, require high- speed or high torque applications powder packing machine is perfect for you.

The construction and engineering standards of powder packing machines always help you to conquer pricy downtime and needless waste.

A powder packing machine represents packaging equipment employed for automating the manufacturing of powder products in industrial sectors.

Powder Packing Machine

Without a powder packing machine, there is no other way to deal with packing powder in an efficient manner, unless you perform it manually that is not possible especially when you are dealing with large production.

2.What are free-flow and non-free-flow powder? why it is important to determine powder packing?

A powder product is referred as free-flowingwhen their particles are not cohesive. Cohesive is state of stickiness. Example of free-flowing powders is coarse sugars or table salt that are easily dispensed or flow freely. These type of particles does not form a shape or compact even applying extra pressure.

non-free-flowing powders are cohesive in nature. Examples of non-free-flowing powdered is brown sugar or powdered milk.

This type of powder tends to hold shape and can easily be compacted under applying extra pressure.

A very unscientific way to determine the free-flowing and non-free-flowing powders is the ‘finger test’. For that, you need to poke your finger into a powdery container.

If the product squeezes and displays indentation of your finger when you remove it, so it is non- free-flowing. If you remove your finger and leaves no indentation it is referred as a free-flowing powder.

For a successful powder packaging point you must require:

- determining your product is free-flowing or non-free-flowing, as it affects the filler type and may require to deal properly for dispensing powder.

- Free-flowing powder falls easily due to the force of gravity while non-free-flowing powder can easily be compacted and packed due to its cohesiveness properties requiring an entirely different packing system. Generally, free-flowing can be used for volumetric or free-flowing auger fillers and non-free-flowing powder packing requires auger filler specialized to dispense the cohesive products.

3.What is the importance of bulk density in powder packing?

The ‘bulk density of the powder is important to determine ‘flowability’ and ‘compactness of powder under pressure’. For this a basic formula is applied to compute the bulk density (total mass over total volume), furthermore, other methods are also used to compute bulk density for high degree accuracy. Customarily, a bulk density is denoted as g/cm3.

As mentioned earlier, free-flowing substances usually do not compress very much and present a low bulk density. Whereas non-free-flowing or cohesive materials such as brown sugars have greater bulk density and easily be compacted when applied pressure.

So what does powder packing machinery have to do with bulk density?

Consider packaging of 50gram of moist sand and 50 gram of roasted coffee. Both of them would have the same weight but their packaging dimensions and types would be extremely different due to the amount of empty space around as well as inside the products. The sand covers little space and is able to be compressed more can be packed in smaller pouches while coffee beans can cover more space due to little compressibility and more empty spaces, which requires a much larger pouch.

That’s why you should pay special consideration to bulk density when packaging powders. Because it attributes, types of filling, and packaging speed.

4.What is the working principle of a powder packing machine?

The mentioned below points explains the working principle of powder packaging machine:

Powder Filling and Sealing Machine- Working Principle

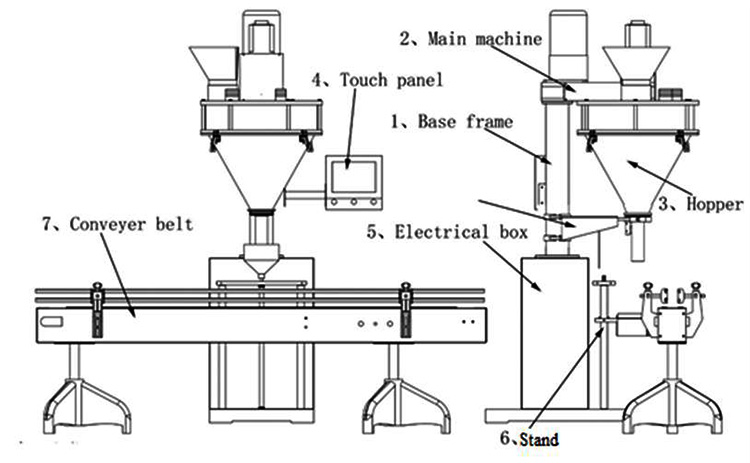

- Firstly, the user may introduce the bulk amount of powdery substance into the hopper and allow the powder packing machine with empty containers.

- The conveyor enables the empty containers and places them just under the filling head.

- The machine can measure the filling content before dispensing it into each container.

- The filling head distributes constant amounts of the powder ingredients into each assigned container.

- Then, filling containers proceed toward the sealing station where they are sealed by a powder filling and sealing machine.

5.Do you know the major components of the powder packing machine?

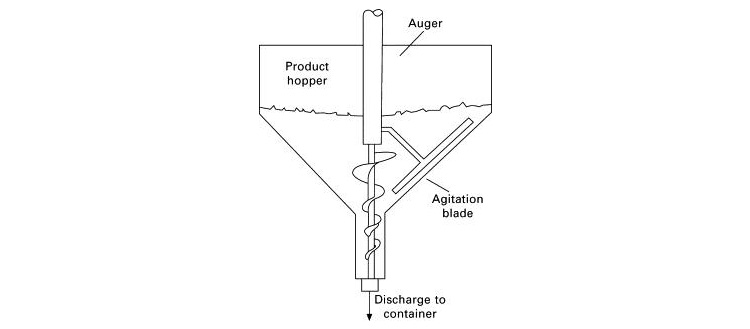

1.Agitator Blades

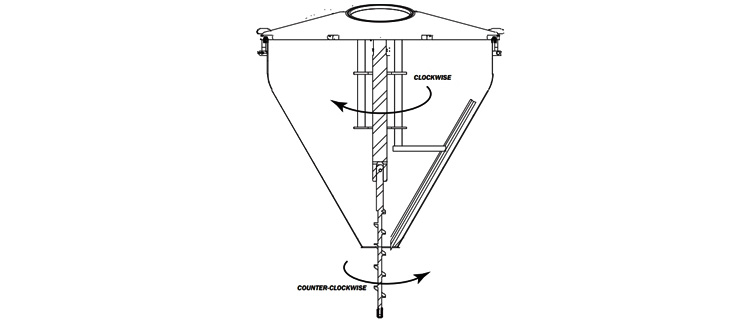

The powder packing machine is comprised of agitator blades that facilitate products into flights of the auger. There are high-speed and low-speed agitators.

- The high-speed agitator is fixed on the auger shaft that operates at the same speed as the auger.

- The slow-speed agitator is powered by a distinctive motor, gearbox, and chain drive. It turns in the opposite direction against auger.

- Both slow speed and high-speed agitators are installed prior to using powder packing machines.

Agitator Blade- Powder Packing Machine

2.Auger

A powder product is dispensed into the assigned containers direct from the auger. An auger is mounted on to auger shaft at the Fill head and can easily be removed for maintenance and service.

Auger Shaft

There are many augers available that are used according to the type, application, and filling properties of the products. Auger must be installed before using a powder packing machine.

Auger accessories may include a drip washer; spinner plate an adapter shaft or auger locking collar.

Auger- Powder Packing Machine

Auger- Auger Shaft- Powder Packing Machine

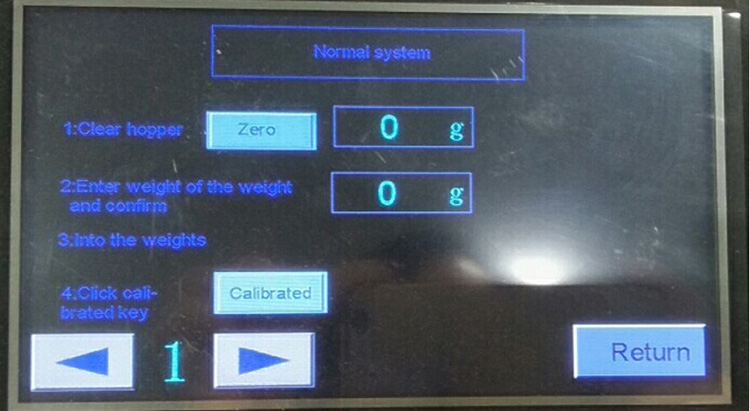

3.PLC- Controller

The powder packing machine is controlled by a specific packing controller that is mounted on or nearby the machine. A PLC controller included a servomotor controlled by a Programmable Logic Controller (PLC) along with a touchscreen displayed Human/Machine Interface (HMI).

Automatic- Powder Packing Machine

4.Fill Motor

The powder packing machine is operated by high performance along with a permanent magnet synchronous servomotor. This servomotor and corresponding motion control enable precise controlled movement of the machine to dispense the acquired quantity of product.

Semi-Automatic Powder Packing Machine- Components of Powder Packing Machine

5.Footswitch

The powder packing machine may include the foot-operated external switch to enable the user to initiate the packaging cycle based on selected information on the powder packaging PLC controller.

External Accessories- Foot pedal

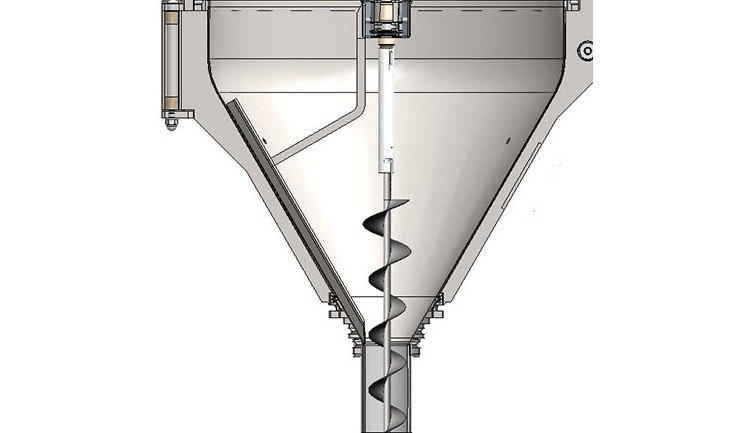

6.Hopper

The packaging product is filled in the hopper of the powder packing machine which is surrounded by the Fill Head. This hopper is included a quick disconnection coupling that allows easy removal for purpose of cleaning and product shifting etc. During installation, the hopper must be aligned with other components of the packing machine for accurate, precise, and regulated delivery of the content.

Small- Powder Filling Machine

7.Fill Heads

A filling head is fixed just below the hopper and enables dispensing of powder content into assigned containers.

8.Level Control- Sensors

The hopper of powder packing machine is accompanied with ON/OFF level control system to determine the quantity of powder remaining in the hopper. The sensor assembly is installed on the top of the hopper and used to trigger equipment to re-supply the hopper with extra/additional products.

9. Safety Disconnect

Safety disconnect is installed with electrical power connection of powder packing machine for safe removal of electrical power during maintenance. If the machine does not equip with safety disconnects, it is recommended to install disconnect appropriately.

10. Dusting Unit

It is well-known that dealing with powdery substances is a sensitive procedure. The powder has ability to lock up dust during mixing. Thus, the powder packing machine is equipped with a dust removal device which is specifically designed to collect dust particles when it passes into the powder packing machine.

Powder Packing Machine- Closed Housing

11.Measuring Cup or Weigher

Measuring cup or weigher of powder packing machine ensure filling of containers or bag with an accurate amount of content.

12.Discharge Unit

The discharge unit of the powder packing machine offers discharging of the specific quantity of powder into assigned containers, bags or pouches.

13.Bottle Detector

The powder packing machine features a bottle detector that identifies the presence of a bottle or container in the conveyor prior to filling.

14.Bottle Positioning

A bottle positioning stabilizes the body of the container and avoids any inclination setting.

15.Conveyor Unit

The powder packing machine is designed with a conveyor unit that enables the continuous transportation of packed containers.

Powder Packing Machine- Components of Auger Packing Machine

6.What is the classification of powder packing machines?

Automatic Powder Packing Machine

An automatic powder filling machine is equipped with high technologies that facilitate the packager with more efficient, cost-effective, and robust equipment.

- This machine includes a PLC control touch screen, with a servomotor efficient drive that provides continuous work performance.

- The body of the powder packing machine is made up of stainless steel.

- It is easy to access machine that enables a feedback-controlled system to allow filling volume adjustment.

Automatic Powder Packing

Semi-Automatic Powder Packing Machine

- The working principle of a semi-automatic powder filling machine is the same as an automatic powder packing machine except this machine requires a manual filling process.

Semi-Automatic Auger Filling Machine

- Furthermore, an automatic powder packing machine uses a conveyor unit for powder packing, whereas a semi-automatic powder packaging machine needs an operator who initiates the process using a finger or footswitch.

Manual Powder Packing Machines- Small Powder Packing Machine

The manual powder packing machine determines material by manipulating the rotation speed or time of the auger widely used for quantitative measurement of powders. The working principle of a manual powder packing machine is similar to a semi-automatic powder packing machine. These machines are smaller in size and do not require the power source require for smaller production demands.

Small Powder Filling Machine

7.Can you explain the industrial applications of powder packing machines?

Industrial applications of powder packing machines are as followed:

Pharmaceutical Industry

Pharmaceutical powder packing machine facilitates solution for all types of pharmaceutical powders used for the preparation of dosage forms. With more advancement in technologies, today powder packing machine is integrated with powder sealer, labeling applicator, and packing stations. Furthermore, this machine is the best fit for precise measurement of unit dose and flexible packing process required for each or large batch packing procedure.

Food Industry

If you are packing delicate powders or spices, a powder packing machine ensures highly accurate and safe filling of products such as dry milk, sugars, coffee, flour, etc.

Powder packing machines feature compact housing with a large holding capacity, a stainless-steel construction, and user-friendly operation to ensure secure packing and sealing of food products to end-user.

Chemical Industry

There are various chemicals used in the chemical industry that are harmful to human use. You can’t pack them manually as their exposure may harm you. That’s why powder packing machines are frequently used in packing chemicals in the chemical industry. These machines are reliable, efficient and enable safe volumetric dispensing of non-free-flowing and free-flowing substances.

Plastic Industry

Powder packing machine has broad application in the plastic industry for dispensing powders such as polypropylene (required for manufacturing of plastic). They are generally used for the preparation of containers, bottles, etc.

Cosmetic Industry

A powder packing machine is required for packing cosmetic products such as loose powders, talc, cosmetic detergents, and much more. A fine powder filling machine is suitable for dealing with free and non-free-flowing cosmetic products in their filling jars.

Powder bottle filling machine application in the cosmetic sector.

Agriculture Industry

Powder packing machine applies to all kinds of agricultural powder for filling, weighing material like fertilizers, herbicides, pesticides, etc.

Auger Packing Machine- Agriculture Industry

8.What are the essential installation points for a powder packing machine?

For installation powder packing machine, there are some essential points that you must follow:

Positioning the Filling Machine

- The first thing you must consider is to locate a stable, level surface that must include fine environmental, electrical, and pneumatic supply requirements.

- The machine must be placed in the vertically operating position.

- The machine must be secure to the floor by using lag bolts over base or equipped with using casters and firmly lock caster to avoid unnecessary movement and vibration.

Selecting Motor Shaft Rotation

- The filling drive motor and a slow-speed agitator blade must be rotated in a specified direction.

These motors must operate in the following dimension, Filling motor:Counter-clockwise, Agitator Motor: Clockwise

Pneumatic Connections

- Pneumatic or hydraulic operated devices and parts of powder packing machine should be properly connected with a suitable source of compressed air during installation.

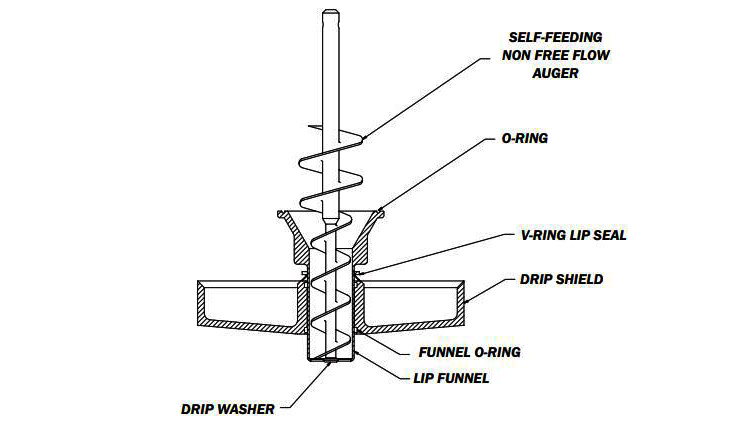

Non-Free-Flowing Product Setup

- Non-free-flowing products that are cut out at the end of a fill cycle very clearly include a self-feeding auger, with a slow speed agitator blade along with a lip funnel.

Lip funnel- Powder Packing Machine

- A drip washer is used for those products that drip at the end of fill. The drip washer is a small circular platform that enables the surface area to the bottom of a self-feed auger. (Self-Feeding Augers: are applied for non-free-flowing powders)

It is designed to minimize drip. It may appear insignificant, but it plays a huge role in overcoming the dripping of non-flowing products.

Self-Feed Auger Filler

- A drip shield, enable a spilled product to accumulate prior to cleaning. The funnel is protected against contamination by an O-ring.

Drip Washer

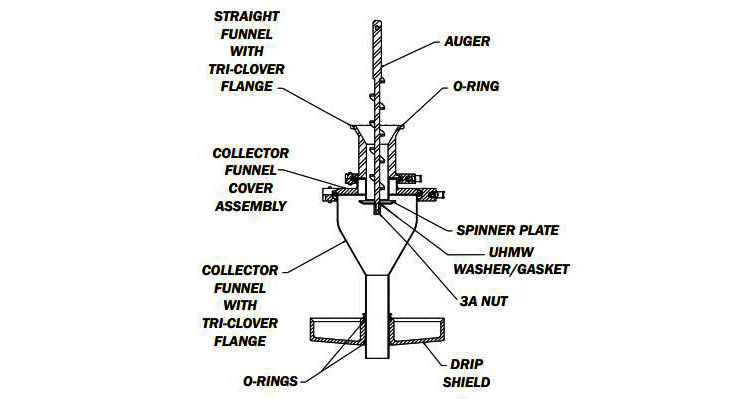

Free-Flowing Product Setup

A free-flowing product requires a straight auger, a spinner plate with washer, a collector funnel assembly, cover funnel, and clamp.

9.What are the cleaning and maintenance procedures of the powder packing machine?

To extend the shelf life of the powder packing machine you must follow regular maintenance and cleaning factors. Discussed below are the following important points that will assure a continued, smooth, and reliable operation of the machine.

Daily Maintenance

- Examine all electrical connections. Find loose or frayed wires and reconnect as required.

- Clean the accumulated product, dirt, moist with a cleaned and dry cloth.

- Remove unwanted or loose tools around the machine to avoid damage or injury.

Monthly Maintenance

- Examine agitator and gearbox, allow proper oil levels and assess oil leakage.

- Examine the worn or missing teeth for all gears and allow proper alignment.

- Examine bearing seals. Lubricate the idler sprockets.

- Clean and lubricate the chain of the agitator.

- Clean the foreign particles accumulated in and outside the Fill Head.

Performing Washdown

- All power must be turned off prior to performing washdown.

- All mounds/ heaps of content must be vacuumed up carefully prior to washing down.

- Avoid washing inside Fill Head and electrical cabinets.

- Avoid water spray on HMI- it should only be wiped down.

- All removed Tooling can be washed and sterilized.

10.What is the failure and troubleshooting of the powder filling and sealing machine?

A powder packing machine is a technical and efficient tool for the powder packing process. This machine is suitable for dealing with dry, nonsticky powdery material. Sometimes, during production, you may face failure problems with this machine. This is mandatory to understand technical issues and master to deal with these problems to minimize process downtime.

We have enlisted some technical problems and troubleshooting related to the auger filler packing machine below:

1.Machine does not start

Probable Cause

- No electrical supply

- Tripping of motor starter

Check

- To deal with this problem you must examine the circuit breaker

- For tripping, Reset overloads. Furthermore, an air compressor must be assessed and set in functioning mode.

2.Machine does not dispense

Probable Cause

- This problem occurs due to initiation switch or accessories

Check

- You need to energize the switch circuit

- Examine the direction of motor rotation

3.Accuracy Problems

Probable Cause

- Agglomeration of powder

- Product dripping

- inappropriate Auger revolution and acceleration

- Improper alignment of hopper

Check

- For agglomeration, Turn ON the blender for uniform mixing and dispensing in the hopper.

- For product dripping, you must adjust the setting of accessories.

- Hopper head pressure must be set at 2-3 variation, and it should be set at 2’ to 3’ at top of the hopper. The acceleration of the auger must be high for a consistent product.

- Alignment of hopper must be properly done during installation and should be aligned with other parts of the machine. As misalignment may lead to excessive wear and tear to machines and accessories.

4.Poor Functioning of Clamp & Holding Device

Probable Cause

- This is a commonly occurred fault with the powder pack machine based on overall installation and improper structure alignment of the machine.

Check

- The operator must follow machine alignment criteria before installation them.

11.What are the advantages of a powder packing machine?

Products of powder packing machine

With sturdy construction and touch screen-controlled powder packing machine you may get high standard, high speed and high-torque working applications. Powder packing machine offers unique advantages and features such as:

Servomotor- state of the art

The direct servomotor powers, brushless powder packing machine ensures packing accuracy. The high degree end variable of the agitator system removes a bevy of unwanted parts.

High Packing Precision

A powder packing machine is of prime importance when you require high accuracy with each batch. This machine controls and packs highly precise weight every time.

Cost-effective

Servo drive operates according to the selected controlled parameters and slows down gradually to form a repeatable packing of cycles. every time you will notice lesser wastage of product and improved saving.

Improved Productivity

A PLC operator interface enables instant access to fill required parameters, on-screen detection with HMI- touch screen, and settings variation. Powder packing machine allows more than 30 programmable storage. For the bulk filling, hopper made up of stainless maintain steady and uniform supply while variable speed allows better control for packing process, hence it improves overall productivity.

Safe and Lesser Chances of Contamination

The powder packing machine is made up of stainless steel with restricted housing. It is easy to clean and the anti-dust device protects the powder content from foreign particles. Hence it allows 100% safe and hygienic packing suitable for pharmaceutical and food industries.

Lesser Maintenance

Powder packing machines accelerate the packing process and reduce maintenance requirements. The parts of the powder packing machine have a consistent product flow and it is aligned with an auger screw devoid of additional setting/adjustments. every part of the machine is constructed with stainless steel and easily dismantle and clean without using hectic procedures.

Easy Customization

The powder packing machine has an option for customized tooling according to designated containers or products for accelerated workflow. You can attain improved and cost-saving options like Filling Heads, casters, conveyors, etc., required for a different type of powder or dosage formulations.

12.What is the future prospect of a powder filling machine?

The powder filling machine market is categorized into types and applications.

It has been assessed for the period of 2021 to 2028 that cross-segment growth enables accurate forecast of sales by types and usage in terms of volume as well as value. The following analysis may help you to understand the growth of your business by focusing on qualified niche markets.

Powder Packing Machine Market Development by Type

- Automatic Powder Packing Machine

- Semi-Automatic Powder Packing Machine

Powder Packing Machine Market Development by Application:

- Food & Beverages

- Pharmaceuticals Industry

- Industrial Chemicals

- Fertilizers Industry

- Others

Estimated revenue in USD million & CAGR from a period of 2021 to 2027. Powder packing machines will raise manufacturer production and supply for the progress of human life. It is a suitable option for a manufacturer dealing with tiny to large volumes of powder, with simple and easy operation and reduced environmental pollution.

13.Explain buying considerations of powder packing machines- How to choose right powder filling machine?

When you are planning to procure a powder packing machine, you will find different types of powder filling machines in the market. Each machine offers a specific solution for your requirement as well as the kind of product they are suitable for packing.

It is your job to analyze the right option for the smooth running of the manufacturing unit as well as to determine the type of product that would fit with the machine.

Assess the Product Type

Before buying a machine assess your product type that would be intended for the packing process like free-flowing or non-free-flowing powders. Furthermore, there are certain products that are intended to be packed in bottles, containers, or bags. For that, you should determine the product type and accommodation criteria.

Installation Space

Before buying a powder packing machine, you must consider the space and place for installing the machine. For uneven floors, you must consider adjustable pads to avoid interruption during and after installation.

Stainless Steel Construction

The particular feature ensures a long-lasting machine life and safe processing although it may cost you a little bit higher, it will give better results.

The Cost of Machine

The cost of a powder packing machine is another important factor you must consider before buying the machine. You must not always look for the cheapest source, rather you must look for equipment that efficiently meets your work requirements.

- For instance, User friendly,

- Parts availability

- cost-effective

- high throughput

- Comply with international quality standards, etc

Competitive Vendor

You must look for a competitive vendor before buying any equipment. You must consider the warranty of the machine, as well as excellent customer services, pre-sale and post-sale services, their availability, and good feedback report from previous clients.

Conclusion

A powder packing machine is a perfect tool that provides efficient work progress relevant to powder packing such as accelerated, error-free and accurate dispensing of different types of powders. If you want to obtain 100% packing outcomes in a cost-effective manner, then we recommend you automatic powder packing machine would be the best fit for successful packing and business.

Find out different powder packing machines and choose the right machine that meets your requirements today!

Happy Shopping!

Powder Filling Machine Related Products

Powder Filling Machine Related Posts

Powder Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget,we'll reply you ASAP within 24 hours