Milk Powder Packaging: The Complete FAQ Guide in 2025

The recent boom in the milk powder packaging sector has stimulated a transformation in the processing, packaging, and distribution of urban sectors.

Let’s consider milk powder production where processing and packaging are two equally important entities. The milk powder packaging phase comes in the last but a critical phase; Do you know why?

The aim of this comprehensive article is to introduce the fundamental background of milk powder packaging such as the principle of packaging, materials, styles, and importance correlated to its extended shelf life.

1.What Is Milk Powder Packaging?

The rising demand of milk powder has offered the cascade of packaging demand in the production chain of manufacturing sector. That’s’ why various automation strategies employed by companies to achieve smarter, durable, and an economical solution.

Milk powder packaging a constant need if you really want to consume adequate nutritional content. Milk powder packaging is suitable way to store milk powder for a longer time.

It offers better storage and cascade of benefits to value end user by extended shelf life without requiring refrigeration. Moreover, it ensures the end-user that product is safe from triggering factors to maintain potency and efficacy, especially microbial contamination.

2.What Factors Diminish the Goodness of Milk Powder?

Packaging of any food item is necessary to prevent it from deterioration, likewise, packaging of milk powder is important too to protect it from spoilage.

Parameters like an invasion of moisture that rises more than the wanted content, damage caused by oxidation, and light reactivity reactions which diminish the product’s goodness deem it essential for milk powder’s packaging. Let’s have a look at what each parameter causes to bring a change in powder quality.

Moisture Transfer

In order to effectively preserve the qualities and characteristics of milk powder from domination of moisture and the formation of cake or lumps, packaging is taken into account. In high temperature, surface fat of the powder particles undergo sticking forming a fatty bridge that causes the powder’s appearance to look lumpy. At low temperature, milk fat is turned into crystallized powder particles which forms a partial or completely crystalline bridge resulting in caking.

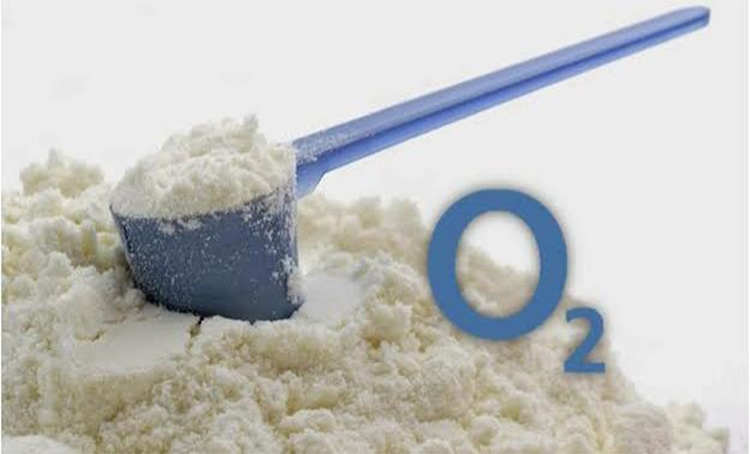

Oxidation

Oxidative degradation diminishes its initial form through enzymatic and microbial reactions. There is certain acceptable moisture content in milk powder whose limit must be known. Oxidation of milk powder is linked to the presence of unsaturated fats which turns the milk flavor rancid, also affecting the nutritional status and altering the taste at the same time.

Light

As is the case of the reactivity of oxygen, the same goes for light. Milk-based products are usually sensitive to light due to the presence of riboflavin, which is a strong photosensitive vitamin that turns light particles into singlet oxygen again contributing to oxidative degradation.

Therefore, to ensure the safety and efficacy of milk powder’s characteristics and nutritional benefits it is mandatory to package it in such materials that provide barrier against these aforementioned problems and enhance shelf life and product’s quality.

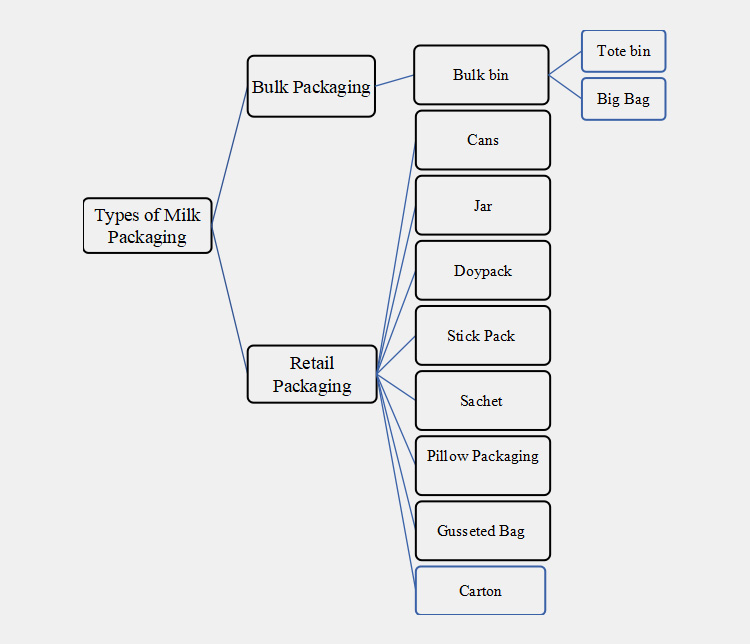

3.What are the Different Types of Milk Powder Packaging?

Usually, a milk powder’s packaging style is carried out in either of two ways, bagging or canning. Both of the types have their individual benefits and some setbacks as well.

The type you’re going to choose for packaging your brand’s milk powder depends on your budget, customer preferences,and what quality of preservative shelf life you would be giving to your product.

We shall be discussing a few types of various packaging styles that you can opt for:

Bulk Packaging

This is the most versatile mode of packaging allows a bulk or hundreds kgs of powdered milk to accommodate in polyethylene lined multi-layered paper covering. Due to its great benefits it is still used in many industrial sectors for storage.

Bulk Bin

The fundamental concept of bulk bin is entirely new; offering a great value to repack and reprocess the whole material. This is considerable interesting mode of packaging as it limits excessive expenditure during handling and transportation.

The following types of bulk bin are:

Tote Bin

They are used to store milk powder of 800 to 1000kgs of mass. This packaging is ideal for transportation of bulk i.e., internal transfer to central stations, or shipment. Moreover, it helps in reducing cost by about one half than stainless steel. Airtight stacked bins are emptied directly into hopper via elevating.

Big Bag/Bag in Box

This concept of packaging has somewhat surpassed tote bin as a large sized multi-layer bag of polythene with milk powder is protected by woven plastic or triple laminated corrugated board. They are considerably low-cost filling and packaging method.

Retail Packaging

The retail packaging is first dominated by metal cans; with more advancement and high market competition, a number of other packaging options such as bags, pouches are being introduced. Let see various packaging options.

Can Packaging

In this type it depends on what source of can material you will select. Metal cans provide good airtight preservation and durability in shelf life for the milk powder. Usually, milk powder can be stored for 2 to 3 years approximately in a metal can packaging. This way they are also able to ensure nutritional protection by safeguarding the milk powder from moisture or any other factor.

Jar Packaging

Nowadays plastic jar is more common for packing milk powder as it presents sustainable packaging strategy. A high quality plastic jar can present durability and strength in terms of being unbreakable. They preserve the rich nutrients found in milk powder because of being airtight and also protect the product from environmental degradation.

It is lighter in weight and thus easier to be transported.

Doypack Packaging

Doypack offers sustainable access towards packaging options. They are light in weight, adjustable ,and thus convenient for storage and transportation. They offer protective and preservative quality for the powder inside so that it stores its standard characteristics during the shelf life.

Stick Pack Packaging

The greatest advantage of this type is that they are very convenient for people to carry around and use for single servings because of their small and narrow size. Stick packs are utilized for various purposes owing to their easy use, prolonged shelf life, and being ecological as it requires less material for their production and thereby controlled wastage.

Sachet Packaging

Sachet packs come convenient for use. The small sized packaging can be easily transported and carried and they can also be used by consumers if they require less amount of product for a single time use according to less price they are able to purchase at.

Pillow Packaging

This type of packaging is one of the most common types which involves a pillow-shaped packet that is sealed from three sides. Pillow packs provide remarkable product

showcasing glossy appearance. They assure product safety and odor lock ability. It can be employed for a variety of product packaging and guarantee cost reliability due to less material use.

Gusseted Bag Packaging

Such packaging display flat base that can stand erect without any support. As compared to other types of packaging they can easily be adjustable in little space and so more pouches can accommodate on a store shelf.

Carton

There is no doubt that carton packaging is way more friendly than other form of packaging. Many international brands prefer cartons for powder milk packaging as it is simple and cost-effective. Nevertheless, the moisture resistance property is somehow very less. Also, during transportation and storage procedures, it is prone to crush injury, and protection of the essential nutrients is also very less. That’s why it is not used frequently in many regions.

4.Is Milk Powder Packaging a Good Alternative to Regular Milk?

Yes! According to scientific evidence, milk powder packaging is beneficial to retain the same nutrients as fresh milk and can easily prepared and drink. But, when it comes to packaging it is way more tricky and challenging that requires expensive machinery and process steps.

Milk powder packaging is done when dairy milk is evaporated and passed through series of procedures like pasteurization, and freeze drying etc.,. Since milk powder has limited shelf life, it is stored in airtight system where unfavorable effects are being limited.

A good packaging blocks the surrounding environment thereby minimizing the effects of oxygen, moisture, light, microbes. That’s why you can count it as the healthiest option in your diet.

5.What Machines Are Used for Milk Powder Packaging?

Milk powder packaging machines are available in diverse design styles and structures. These equipments can pack various dose quantities of milk powders in creatively designed containers for product production. Some common milk powder packaging machines are:

Vertical Form Fill and Seal Machine (VFFS)

Hermetic pouches or bags are best for packaging milk in powdered form. Vertical form fill and sealing machines are an integral part of various industry, especially food industry. These equipments are routinely employed for accurate and precise dosing of milk powders.

VFFS machines are capable for filling various style bags such as zip lock pouch, doypack pouch, pillow pouch, standup or gusset pouches. This capability of VFFS machines makes them an ideal fit for dosing various volumes of milk powders. Moreover, with their fast changeover, multiple types of pouches are processed in a short time.

Milk Powder Packaging by VFFS

STEP 1

In VFFS machines packaging of milk powders occur in vertical direction. Initially, the film roll is placed on film unwind and then this is uncoiled by means of film rollers which ultimately pass the film to forming tube. Dancer’s arms present on VFFS equipments prevent the slippage of film.

STEP 2

The film is wrapped around the forming tube and folded into pouch shape. Sealing jaws present at bottom of machine perform lateral and bottom sealing.

STEP 3

Auger fillers or other dosing systems installed with VFFS machine aid in volumetric metering of milk powders in partially formed pouches. Next topside sealing and trimming of pouches are done by horizontal sealing jaws and cutting blades respectively.

Stick Packing Machines

For optimal packaging, stick packing machines are employed for packing small dose of milk powders. These are equipped with auger fillers and weighers for measuring and metering exact quantities of powders in stick packs. These equipments are well suited for filling carry-on packs instant milk powders in food industry.

These equipments are preferred choice for various industries due to minimal wastage of milk powders wastage as well as immaculate sealing closures. Dust free filling is one of their many advantages.

Milk Powder Packaging by Stick Packing Machine

STEP 1

The film roll is unraveled by film unwinder and passed over rollers. Cutting blades cut the film into numerous strips depending upon lanes present in stick packing machines. These strips proceed to forming area where they are wrapped around done like forming tube. Forming tubes fold strips and convert them to stick pack like structure.

STEP 2

Next heat-sealing jaws are employed for sealing sides and bottom part of stick parts. For filling of milk powders, auger or tipping fillers are employed. These fillers aid in gradual filling of stick packs.

STEP 3

After filling, the stick packs are sealed by sealing bars at upper side. Cutting blades separate each stick pack.

Premade Pouch Packaging Machine

Pre-made pouch packaging machines are versatile and eco-friendly machines, routinely used in medium or large scale for packaging of various granular or powdery products. These equipments have flexible processing capabilities and can process diverse pouch styles. Moreover, these machines can fill pouches made with different materials.

Low energy consumption is the biggest benefit of these machines since there is no need of pouch manufacturing in these machines. Thus, these equipments can contribute in low carbon emission movement.

Milk Powder Packaging by Premade Pouch Packaging Machine

STEP 1

The packaging process begins by loading pile of pre-formed pouches on the loading area. Grippers grip individual pouches and carry them to opening system. The air is passed into pouches for inflation which aids in filling of convenient milk powders.

STEP 2

After inflation, the next step is filling of powders in pouches. For this purpose, feeders are employed which control the filling rate.

STEP 3

For hermetic and airtight sealing of pouches, sealing elements are used. These join two sides together by pressing and heating them.

Sachet Filling Machines

Sachet filling machines are ideal for dosing and packaging small volume of milk powders in sachet for retail distribution. This significantly reduces price per pack thus making the sachet quite wallet friendly.

These stand-alone equipments are flexible and versatile with rapid format change hence they can fill numerous sachets per minute. These equipments consist of modern cutting systems that safely cut and trim the edges of individual sachets.

Milk Powder Packaging by Sachet Filling Machines

STEP 1

In these kind of packaging machines, the process of packaging milk powders in sachets is started by loading of film rollstovk on the film unwinder. Film is then unwound via unwinding rollers by controlling tension of the film.

STEP 2

Film is cut into front and back panels which move to forming area where these panels are shaped into sachets. Forming tube can create different sized sachets depending upon the programmed size option.

STEP 3

Sealing bars assist in sealing these sachet from sides and at the lower end. After partial seal, the powdered are loaded inside the sachets which later on are sealed at top end.

Can Packaging Machines

These equipments are commonly employed for packaging bulk quantities of powdered milk especially baby formula. Can packaging machines are furbished with cutting-edge technologies that aid in hygienic filling of milk powder.

Can packaging machines not only provide bulk quality control but can also process powders gently thus assisting in maintaining product integrity and nutrition.

Milk Powder Packaging by Can Packaging Machines

STEP 1

These machines employ screw-type-mechanism for uniform dosing of powders in cans, bottles and jars. First empty can is loaded on the conveyor belt and sterilized after passing through the sterilization tunnel.

STEP 2

Auger doser or other fillers are used for loading precise quantities of milk powder inside the containers.

STEP 3

After that filled cans are carried out capping, lidding, or sealing area where vacuum systems and high temperature seal the opening of containers with closure such as caps or lids.

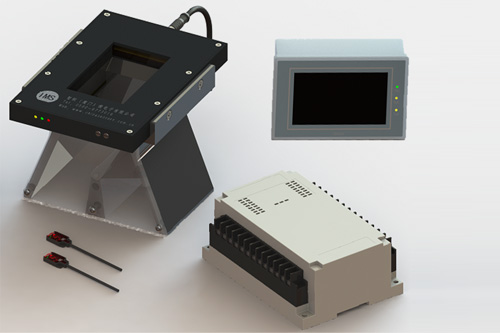

6.What Are Main Parts of Milk Powder Packaging Machines?

| Part | Description | Picture |

| Hopper

|

The hopper part of milk powders packaging machines is employed for loading large quantities of powders. The powdered milk is stored inside the hopper and is gradually passed onto the feeders for dosing. |  |

| Smart HMI

|

It is an integral part of modern milk powder packaging machines. Smart HMI is touch screen interface that make programming and monitoring of packaging machine easy and effortless. Parameters like temperature, vacuum settings and pouch length can be easily adjusted on smart screen by choosing pre-programmed options. |  |

| Sealing Unit | This is the main component which is imperative in maintaining product integrity by ensuing airtight protective sealing to packaged milk powders. The sealing bars are heated for gluing two layers of film together. These parts seal the pouches, bags, sticks, or sachets sideway as well as at bottom and top end. |  |

| Cutting Knife

|

This part cut and separate various individual packs. These components are present in the middle of sealing jaws and carry out cutting function after bags are fully formed and sealed. |  |

| Forming Tube

|

This part is like a human collar and is present in almost all kinds of packaging machines. These components fashion different style packs according to desired shape programmed by operator. For creating bags or other packaging containers, the plastic or aluminum film is wrapped around forming tube. |  |

| Auger Fillers or Dosing Unit

|

Auger fillers are necessary in accurate dosing of powdered milk. These components aid in gradual loading of powders in various containers. Adjustable wheels present inside these fillers help in filling various doses of powders as per requirement. |  |

| Weighers

|

The function of these parts is to statistically measure accurate quantities of milk powders for filling | |

| Sensors

|

Futuristic milk powders packaging machines are equipped with sensors that are part of no-container-no-fill systems. These sensors are essential in preventing hazardous incidents since they can detect failure in machine and sound alarm. |  |

7.What Industry Used Milk Powder Packaging Machines?

For meeting higher demands of consumer for powdered goods, milk powder packaging machines are employed in far and wide industries of world. These equipments have high production rate thus help in generating higher revenue.

Few basic applications of milk powder packaging machines are penned below.

| Pharmaceutical Industry

For precise dosing of pharmaceutical, nutraceutical, herbal powders, and granules milk powder packaging machines are used. These equipments fill pharmaceutical powders in airtight containers which offer strong barrier against environmental conditions, microbes, and chemicals. |

| Food Industry

Food packaging is incomplete without milk powder packaging machines. These equipments have integral place in food industry since they are used for filling of various food powders such as milk powders, spices, sugars, salts, peppers, chili flakes, coffee, etc. |

| Chemical industry

In chemical industry milk powder packaging machines are increasingly employed for hermetic airtight packaging of various household chemicals such as bleaching powders, dishwashers, detergents, and cleaning agents. |

| Agriculture Industry

Powdery and granular fertilizers, organic humus, insecticides, and pesticides are filled and packaged in tear-resistant containers by milk powders packaging machines. These airtight packaging prevent product damage by harsh conditions of temperature, moisture, and oxygen. |

| Cosmetic Industry

In the cosmetic industry, these equipments are used for the packing of various cosmetic and aesthetic powders such as foundation, face masks, skin care or dermal powders in pouches or jars. Various kinds of bath powders and fragrances are also packaged inside the pouches by milk powder packaging machines. |

8.What Is the Shelf Life Of Different Milk Powder Packaging?

For the retailing purpose, milk powder packaging is done either in metal cans or bags. The structure and construction of packaging material is based on the type of milk powder, i.e. skimmed, whole, or vitamin-added milk powder, surface area, mode of transportation and much more.

Metal Cans

Milk powder gives an excellent shelf life when stored in a metal can because it offers ultra-barrier properties against the exchange of moisture and oxygen. Moreover, the influx of light is entirely not possible. This is well-known that milk powder with high fat content is more prone to oxidation and susceptible to degradation such as lumping, caking, change of taste, etc.,

with adequate construction i.e. Metal cans with reclosable lid and aluminum foil lamination ensures firm storage environment, and ensure the shelf life of up to 5 years.

Multilayer Pouche

Today, plastic or aluminum foil laminations have emerged that successfully replaced metal cans. The laminated pouches or bags are formed, filled, gas flushed and sealed via one machine from rollstock.

The shelf life of milk powder packaging in pouches varies depends upon the environment of transportation region. However, a two-year shelf life is normally required when distributing to harsh environments whereas regions with highly strong economies are offered with shelf life up to one year.

Always keep in mind, the shelf life solely not depends on construction or amount of product. Certain external factors such oxygen, moisture, transportation is fairly important in maintaining performance of packaging.

9.Why Is Nitrogen Gas Used in Milk Powder Packaging?

The milk powder packaging process uses a vacuum unit and vacuum pump. The purpose behind this is to entirely evacuate the oxygen and then displace it with nitrogen or inert gas. This procedure is done to extend the shelf life of powdered milk.You cannot observe nitrogen gas filled in cans, but you must have observed inflated pouches. Moreover, air is composed of 78% of nitrogen and 21% of oxygen and some variables.

However, atmospheric oxygen reacts with unsaturated fatty acid rapidly which catalyzes the process of rancidity. This is the most challenging problem faced by the food industry.Nitrogen has a long history of food preservation; also cushions and protects delicate ingredients of milk powder. Nonetheless, only food-grade nitrogen should be utilized for food application in order to get 100% safe products and preserve quality.

10.Which Is the Suitable Form of Infant Milk Powder Packaging?

Infant milk powder packaging is the most strictly regulated phase of the food industry. This is because babies’ tummies are super sensitive to tolerate any alter constituent.

Apart from the critical formulation procedure, its special packaging offers a barrier against environmental factors such as oxygen, light, temperature, etc.,

To ensure you’re providing high quality, safe, and potent powder milk; it is commonly packed in gas tight composite cans, cartons, green papers, pouches, and bags.

A multi-laminated wall storage has ability to combat unwanted parameters.

This also enhances the value of your baby’s feed, offering a good replacement to mother’s milk securely, also effectively promoting a brand.

Conclusion

In recent years, the tremendous increase in the use of milk powder has changed the packaging world with new advancements and innovations. That’s why today you can consume milk powder without worrying about its quality, potency, and efficacy. Thanks to strong milk powder packaging material that protects products against environmental and chemical hazards. If you’re looking for the best milk powder packaging equipment or need consultation, then we’re here to serve you. Please contact us for queries and product quotes.

Don't forget to share this post!

Powder Filling Machine Related Products

Powder Filling Machine Related Posts

Powder Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine