8 Key Factors When Choosing a Pharmaceutical Powder Filling Machine

Are you looking for an exemplary pharmaceutical powder filling machine? Well, it’s not as effortless as selecting the first shiny machine you spot! Whether you are filling life-sustaining antibiotics or nutritional supplements, choosing the appropriate pharmaceutical powder filling machine can make your production flawless and successful.

From precision to cleanliness, every detail counts, and here you get the guide about every aspect. You are going to comprehend about the 8 key factors when choosing a pharmaceutical powder filling machine. Along with this, benefits of choosing a perfect machine will also be delivered to save your time and money. This article will prove to be helpful in making a wise investment. Let’s dive in!

1.What is powder filling and a pharmaceutical powder filling machine?

Powder Form Of Substance Is Filled By The Process Of Powder Filling-Picture Courtesy: Making.com

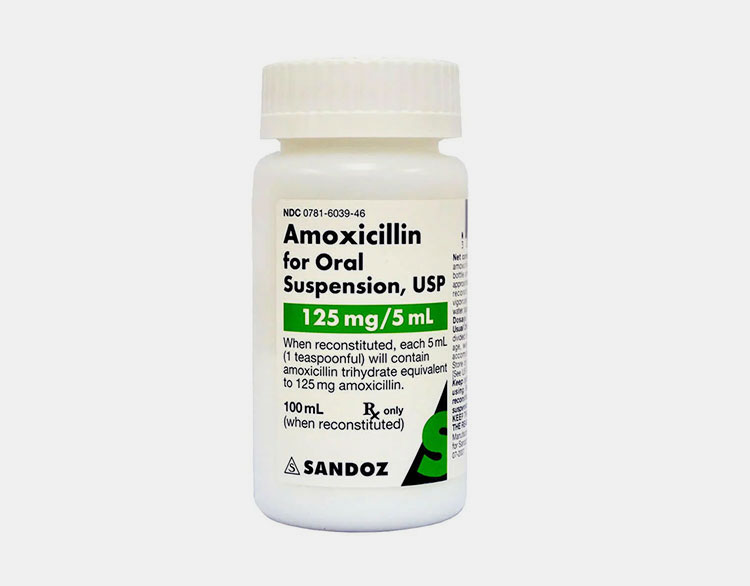

Have you spotted different packaging containers in a pharmacy, filled with antibiotic or nutritional supplement? They all went through a process which we are going to discuss here, and this process is called powder filling.

Powder filling is mainly a process of precisely dispensing a particular quantity of powdered substance in to various packaging containers like bottles, sachets, jars, vials or capsules. This process is integral in pharmaceutical industry, as right dose of drug needs to be filled in powder form. The benefits of powdered form drugs are several which make this process demanding and crucial.

A pharmaceutical powder filling machine is specifically designed equipment, used in pharmaceutical production facilities to fill dry powder formulations into desirable packaging. This machine proves to be versatile, precise, quick and compatible according to the needs of production. Pharmaceutical powder filling machine can be of different types and work on distinct mechanisms.

2.Can you describe 8 key factors when choosing a pharmaceutical powder filing machine?

5 Key Factors For Choosing A Pharmaceutical Powder Filling Machine

Whether you are going to fill valuable powdered medicine or nutritional supplement in a bottle or jar, choosing a perfect pharmaceutical powder filling machine is like finding the secret ingredient to your flourishing production. A wrong choice can cost you failure of production, loss of important ingredients and regulatory trouble. But there is no need to worry, here you are going to learn about requisite factors that you must look into pharmaceutical powder filling machine.

Factor 1: Determining Properties Of Product

Determining Type & Texture Of Powder

Before choosing a perfect pharmaceutical powder filling machine, you have got to see what kind of product you are dealing with? Either it is silky and free flowing like flour or moody or sticky like cocoa powder in rainy days!

Determining properties of product has vast effect on picking up the type of filling technology that can give you right results. Powders come with their own characteristics and your duty is to deal with them nicely.

Free-flowing powders are so easy going; they flow smoothly and do not demand for high maintenance. They can go well with auger or gravity filling techniques.

Non-free-flowing powders require high maintenance and filling techniques like vacuum or vibration system can be proved suitable for dealing with them.

If you neglect this step and brought an unmatchable machine, you might witness troubles like clogging, rough filling and a very puzzled production facility. Before losing your heart over a shiny machine, make sure it compatibles with powder you are going to fill.

Factor 2: Figuring Out The Accuracy Of Machine

Figuring Out The Accuracy Of Machine

You need to comprehend that accuracy is not just a characteristic but it is the throb of your pharmaceutical powder filling machine. One excess milligram or minute under-fill can make a life-saving dose into a failed batch. Now it is necessary to figuring out the accuracy of machine, either it can produce the same correct result every time or not?

A pharmaceutical powder filling machine with great accuracy comprises of high-tech dosing system, well-defined monitoring, and weighing feedback control system. It fills precisely and creates less wastage. It can give you uniform result even during prolong production. So you must always look for below features regarding accuracy of machine:

Dosing system: you must see that which dosing system is going to be compatible with powder you need to fill. Whether it is auger filling system or vacuum or volumetric dosing system, each technology is designed to deal with particular powder characteristic. The main concern is to get precise and accurate filling of powdered medicine in desirable packaging containers.

Weighing system: you must look for a machine that possesses weighing system. Each time weight should be checked and it must be filled automatically if the weight detects less to the expected one.

Tolerance levels: you should know that highly efficient machine can keep fill accuracy within ±1 or even better over long production process.

You can request for validation data to verify the accuracy of machine. Always go for a machine that can deliver you fine results batch after batch.

Factor 3: Knowing Your Production Type

Knowing Your Production Type; Small Or Large

Before going to find a pharmaceutical powder filling machine, ask yourself a very important question, what type of production I am going to have? Let’s be straightforward, choosing an automatic, rapid speed and high-maintenance powder filling machine for a small scale production is like choosing a helicopter to deliver pizza.

In pharmaceutical setup, production can be performed in two ways:

Batch production: this type of production is seemed to be appropriate for small processes, multiple formulations or clinical trials. If you are going to have batch production then choose to have a semi-automatic or small capacity automatic powder filling machines. In this way, you get a high precision outcome with easy to use and low maintenance machine.

Continuous production: this type of production is carried out on large scale, when you have to fill the same product without being stopped for hours. For such type of production, you go for a high-tech, fully automatic pharmaceutical powder filling machine. It must have dust control system, check-weighers and integration with other machines.

You should always prefer that machine, which can match your production type; otherwise you might face downtime, incompetence and regulatory headaches.

Factor 4: Considering Your Packaging Type

Considering Your Packaging Type-Picture Courtesy: The Guardian

Do you know the impact of your packaging type on choosing a pharmaceutical powder filling machine? Seeking for compatibility of packaging type with machine is the golden rule of pharmaceutical production. Packaging type has great dominance on design, configuration and filling technology of powder filling machine. When you are considering your packaging type, ponder on following points:

Shape & size of packaging: you have a variety of containers to fill with powder, like bottles, jars, vials, sachets, or capsules. Each packaging type requires distinct machine design and filling technology. For example, vials need a very high precision, on the other hand sachets demand for integration with VFFS (vertical form fill seal) system.

Packaging material: packaging can be made of different materials, depending upon the requirements of product. You observe rigid packaging like glass, plastic and flexible packaging like laminated paper, foil.

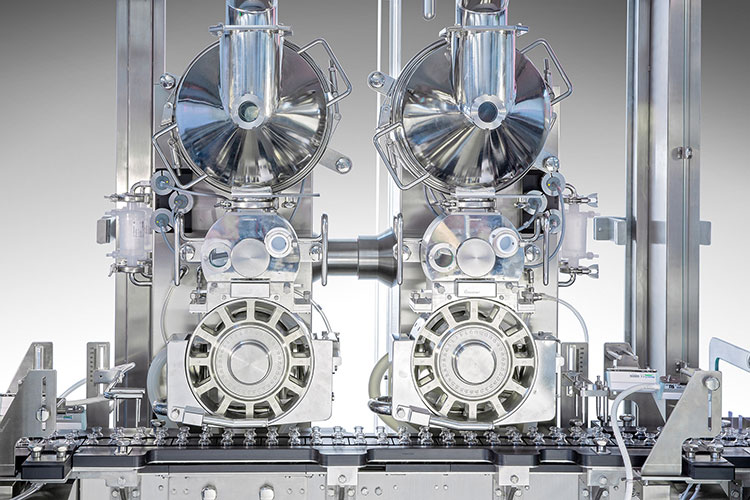

Factor 5: Looking For Material Of Machine

Looking For Material Of Machine-Picture Courtesy: Romaco

Looking for material of machine is not just about the structure, it’s about maintaining the safety, hygiene and compliance. A wrong choice can cost you much trouble. It affects the quality of product and invites regulatory headaches, corrosion and expensive downtime.

Here you get the knowledge about best material for machine, which is competent to GMP and FDA. Stainless steel is regarded as the ideal material for pharma-grade production. It proves to be highly resistant to corrosion, acids or cleaning agents. You find it suitable for high moisture or reactive powders as product comes in contact with machine many times.

Factor 6: Inspecting The Driving System

Inspecting The Driving System Of Machine-Picture Courtesy: Chemtech International

Do you perceive the role of driving system of a pharmaceutical powder filling machine? It holds great importance as it refers to the system that strengthens the movement of machine. For inspecting the driving system, you need to observe following aspects:

Mechanical system: you look for the parts that directly influence the filling mechanism of machine. This includes gears, shafts, linkages etc.

Electrical system: for checking this system, you analyze motors, control panels and wiring. You need to drive the mechanical parts by using electrical energy.

Automation: you evaluate the machine about its functioning and control. Semi-automatic machine can perform some processes on its own, while few require your contribution. On the other hand automatic machine is far more quick and efficient, as all steps are carried out by machine.

Integration:you have to look for a machine that supports integration. Pharmaceutical powder filling machine requires integration with bottle feeding machine, labeling or capping machine to carry out the operation in a rapid and robust way.

Factor 7: Checking The Control System

Checking The Control System-Picture Courtesy: Mitsubishi Electric Factory Automation

Do you know the place of control system for pharmaceutical powder filling machine? It regards as the brain of machine that helps to coordinate, monitor and manage all the necessary functions. Whether it is the precise filling or rapid speed, all rely on control system.

Control system of a pharmaceutical powder filling machine comprises of hardware and software, which conducts all operations. Let’s sort out the main components of control system!

PLC (programmable logic controller): it’s like a small computer that receives input signals in the form of sensors and gives an output command like the motor movement.

HMI (human machine interface): touch screen you find at the machine, it facilitates the operators to interact with the machine.

Sensors: sensors are present to inspect about any fault. They can detect product fill levels, alignment of containers etc.

Servo drives: servo drives has contribution in providing accurate control over filling speed, product volume or even auger rotation.

Alarms or safety interlocks: in case of any trouble, machine starts sending alarms or even it stops working. This is possible just because of alarm or safety interlocks.

Factor 8: Evaluating Dust Control And Containment

Evaluating Dust Control And Containment-Picture Courtesy: Cablevey Conveyors

Do you know dust control and containment is a non-negotiable factor when it comes to choose a pharmaceutical powder filling machine? It is not just messy but it influences the product quality, personnel protection and regulatory competence.

In order to evaluate the dust control and containment, you have to look for dust extraction system.

Dust extraction system is based on vacuum suction ports. You can find it around hopper, filling nozzle or conveyor. This system grabs the air-borne particles on the spot during the filling process. This helps to limit the cross contamination and support the adherence to GMP guidelines.

3.What can be the privileges of choosing a relevant pharmaceutical powder filling machine?

Privileges Of Choosing A Relevant Pharmaceutical Powder Filling Machine-Picture Courtesy: Cleveland Clinic Health Essentials

Choosing a relevant pharmaceutical powder filling machine is not just a noticeable initiative, but a paramount step to get seamless production. As it is not only about filling powder but it’s related to fill smartly, safely and competently. Here you get to know about the privileges you could earn by it. Let’s discover!

Every time you get precise filling:

Every Time You Get Precise Filling

How beneficial it is, to have a right machine in your production. You get precise powder fill weights every time, with no fear of excess filling or under-filling. This also avoids the wastage of your valuable ingredients. This helps you to get competence to regulatory standards, then what could you desire for?

Accountability of high quality product:

Accountability Of High Quality Product

A relevant pharmaceutical powder filling machine ensures you improved, efficient and successful outcome. It is capable of running the whole process smoothly, rapidly and uniformly. You do not find lacking even in long production runs. It shows complete accountability of high quality product.

Least chances of contamination:

Least Chances Of Contamination

You get a well-matched powder filling machine, which is designed according to the needs of your production and the powder you are dealing with. It possesses proper system to handle flow properties of powder, and prevent the blockage & dusting. It can result in least chances of contamination and adherence to GMP guidelines.

Reduce maintenance & downtime:

Reduce Maintenance & Downtime

When you get a right machine for your manufacturing, you invest wisely for long term benefits. Everything is particular as per your needs. With correct materials, design and automation level, you witness less maintenance & downtime.

Conclusion:

Choosing the perfect pharmaceutical powder filling machine isn’t a matter of selecting random equipment, it’s the matter of picking machine that fits your needs. This decision is really impactful when it comes to efficiency of production and quality of product. So take your time, assess your requirements and invest thoughtfully. Are you willing to get more sterling knowledge about pharmaceutical powder filling machine? You can visit AIPAK for quick learning at any time!

Don't forget to share this post!

Powder Filling Machine Related Products

Powder Filling Machine Related Posts

Powder Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours