6 Things You Should Know About The Suppository Filling Machine

For many reasons, the suppositories, which have not received much attention from the industry in the past few years, are attracting more and more attention from enterprises. In the clinical field, especially in gynaecology, anorectal and urology, suppositories have been widely used, and the competition in a certain market segment has begun to show.

Compared to other drug dosage forms, suppositories are straightforward to administer, convenient and insidious, with few side effects and significant therapeutic effects.

Deng Shumin, director of the Department of Urology at Beijing Hospital, said that suppositories are particularly suitable for younger children or patients who have difficulty taking drugs orally, because they can avoid damage to the liver or avoid the adverse absorption of drugs caused by the first-pass effect of the liver, and some drugs are absorbed more quickly and rapidly through the anus and rectum than through oral absorption, especially for local tissues, such as the rectum, vagina, urethra.

However,suppository is especially effective in the treatment of local tissues, such as the rectum, vagina, urethra and its surrounding tissues, pelvic tissues and other pathological areas that are closely associated with the tissue at the site of administration.

Then you may begin to wonder how that suppository plays such an important role in the pharmaceutical field?Actually,the credits should go to the suppository filling machine.

Regarding the suppository filling machine,below I have summarized some things you must know about it.Spend a few minutes reading through,it will help boost your business when you want to start the manufacturing of suppositories.

Is it difficult to control the program of a fully automatic suppository filling machine?

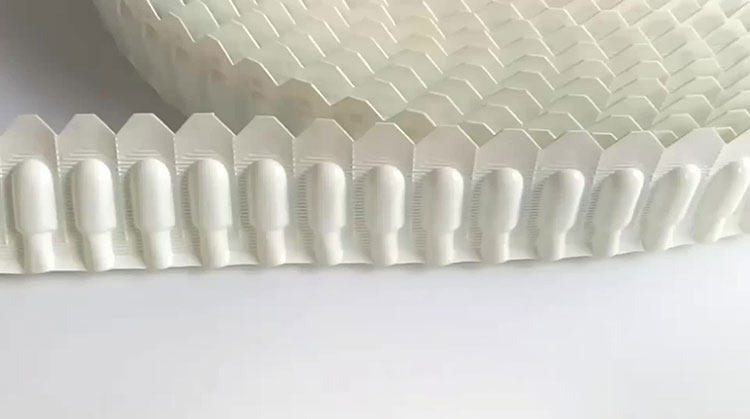

Automatic suppository filling machine has stable and efficient preheating mould, heating mould, forming mould, belt making, filling, freezing, sealing and other production processes to complete the entire process of making suppositories, with a production capacity of 5,000-6,000 capsules/hour.

The conveyor belt of the whole line is made of POM steel, which is wear-resistant and corrosion-resistant, low noise and easy to clean.

The pneumatic components of the whole line are JYC, which are of reliable quality.

Guardrails, sensors, filling nozzles, positioning cylinders, all can be easily adjusted in position to suit various sizes of containers.

The filling machine adopts self-flowing insertion filling, which reduces foam and does not spill when filling.

The machine adopts Taiwan Wellenton 5.7" colour man-machine interface, reflecting the human-centred theory, with relevant buttons to display the program and sensor actuators.

4 heads are independently dispatched and have alarm functions for lack of material and touching nozzles. The filling production line uses a computer to precisely control and adjust various parameters, with parameter storage and replacement functions.

The working principle of the suppository filling machine

Colour-coded positioning and photoelectric tracking: In order to ensure the integrity of the trademark pattern on the finished packaging bag, a colour-coded label for positioning is usually printed on the packaging material when it is made.

When using such packaging materials printed with colour coding, photoelectric switches (electric eyes) can be used to track the positioning of the colour coding, through the control system to drive the stepper motor rotation and automatic stop according to the distance between the colour coding, to achieve complete and accurate packaging finished trademark pattern and plastic hose, filling valve using 3.4 # stainless steel materials, corrosion-resistant and easy to clean and disinfect, in line with national requirements on food machinery and food hygiene

How to effectively control contamination during the production suppository filling machine?

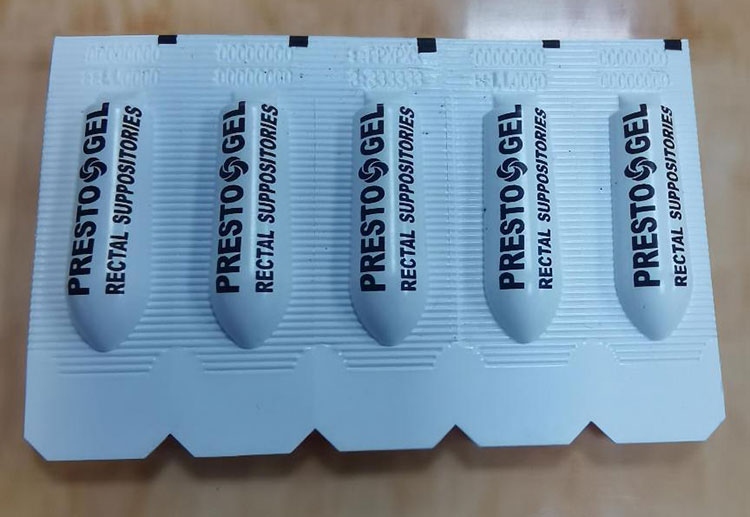

The suppository production equipment has a one-time immersion filling of the moulded suppositories with a filling accuracy of ± 2%.

The filling drum is equipped with an electric heating and insulation system and the top is equipped with a stirring motor to keep the drug in a homogeneous state.

Suppository production equipment requires effective contamination control during the production process to reduce the risk of non-compliance and to reduce downtime.

Most biological preparations are made by microbial fermentation or mammalian cell culture. Microbial contamination can affect the robustness and reproducibility of the biomanufacturing process, as well as the purity, efficacy and safety of the final drug product.

This therefore places greater demands on biopharmaceutical companies as well as pharmaceutical equipment suppliers.

As competition in the drug market becomes increasingly fierce, and as market regulations on drug safety become stricter, many biopharmaceutical companies are increasingly demanding intelligent, automated and digitalised process production.

Automated production processes offer the advantage of more robust production and greater flexibility than traditional production models.

As a result, peristaltic pumps have become the preferred choice for most biologics filling processes in aseptic filling operation units.

What are the reasons for poor suppository sealing?

There are 4 reasons for the poor suppository sealing:

The heat sealing film quality is poor.

If the composite lining material corona treatment is not uniform, the effect is not good, and happens to appear in the seal, certainly can not seal.

However,this situation is rare, once it occurs, the product is bound to be scrapped.

Too fast heat sealing speed.

It is the sealing speed that will affect the sealing quality or if it can be sealed.

If the speed is too fast, the seal has not yet had time to heat up the traction roller transfer to the cold press for cooling processing, naturally it will not meet with the heat sealing requirements.

Theheat sealing temperature is not enough.

Usually, when the total thickness of the bag-making 80 ~ 90μm, heat sealing temperature to reach 170 ~ 180 ℃; composite bag-making total thickness of 85 ~ 100μm, the temperature should be controlled at 180 ~ 200 ℃.

As long as the total thickness of the bag-making increases, the heat sealing temperature should be increased accordingly.

Thecold pressure rubber wheel pressure is not appropriate

There is cold pressure rubber wheel up and down , the pressure between them should be moderate, the you can adjust the pressure just clamping spring.

What precaution should you take after the suppository filling machine finishing production?

Full automatic suppository filling machine is widely used in the packaging line of petrochemical, daily chemical, pharmaceutical, food, pesticide and other industries, which can provide the required filling of the packaging bottles to the packaging line without interruption.

The use of stepless speed regulation, adjustable size of the transport mouth, suitable for the needs of different packaging lines linear filling machine .

It is all at the touch of a button on the man-machine interface, which is both convenient and straightforward.

Materials that are prone to blistering, the machine carries out side filling and lifting to reduce material blistering.

The filling principle uses atmospheric negative pressure type fixed flow channel parameters to control the filling material (volume,) to achieve different measurements. The filling structure is simple and easy to adjust.

It can be used in the filling operation of paste and thin viscous body. In the design, it adopts mechanical-based linear movement method, using PLC logic controller and various detecting and sensing devices and cylinder collection and discharge to achieve the purpose of automatic control.

The machine is simple to operate and can be used to fill different containers within a short period of time to achieve the cost effectiveness of one machine with several uses.

When the filling is completed, the barrel is simply pushed out of the weighing table manually; in case of emergency press the emergency stop button to release this filling; when the filling gun is not inserted into the barrel but topped outside the barrel mouth, the filling gun is automatically lifted and no filling is executed; anti-drip device to avoid material dripping on the barrel.

Don't forget to share this post!

Suppository Filling Machine Related Posts

Suppository Filling Machine Related Products

Suppository Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine