These Things You Can’t Ignore About Dryer Machine

The dryer machine refers to a kind of mechanical equipment that uses heat energy to reduce the moisture of materials and is used to dry objects. This machine by heating the wet content of the material (generally refers to water or other volatile liquid components) vapor escape, in order to obtain a specified wet content of solid materials.

The purpose of drying is for material use or further processing needs. According to the operating pressure, the dryer is divided into atmospheric pressure dryer and vacuum dryer. According to the operating pressure, it can be divided into atmospheric pressure and decompression (decompression dryer is also known as vacuum dryer machine).

Working Principle of dryer machine

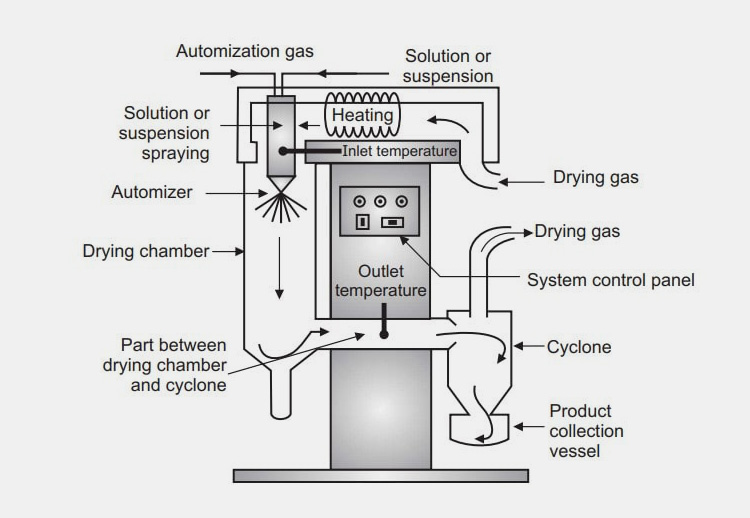

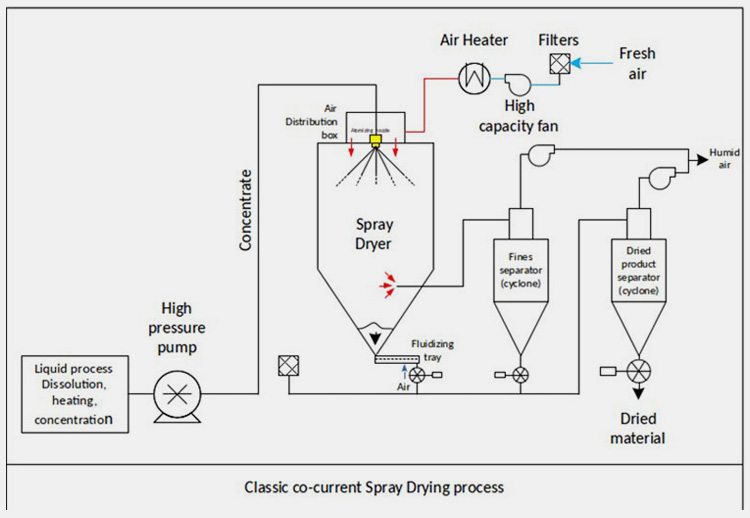

Humid and high temperature compressed air flows into the front cooler (high temperature special) after heat dissipation into the heat exchanger and the cold air discharged from the evaporator for heat exchange, so that the temperature of compressed air into the evaporator is reduced.

After heat exchange, the compressed air flows into the evaporator and exchanges heat with the refrigerant through the heat exchange function of the evaporator. The heat in the compressed air is taken away by the refrigerant and the compressed air cools rapidly.

Compressed air cools rapidly, moisture in moist air reaches saturation temperature and condenses quickly, and condensed water condenses to form water droplets.

After the high-speed rotation of the unique gas-water separator, the water is separated from the air due to the action of centrifugal force, and the water is discharged from the automatic drainage valve after separation. The dew point of air pressure after cooling can be as low as 2℃.

After cooling, the cold air flows through the air heat exchange to exchange heat with the hot and humid air at the entrance. The cold air after heat exchange absorbs the heat of the inlet air and increases the temperature.

At the same time, the compressed air also passes through the secondary condenser of the freezing system (unique design in the same industry) and the high temperature refrigerant to exchange heat again, so that the temperature of the outlet is fully heated, to ensure that the outlet air pipeline does not condensation.

It makes full use of the cold source of the outlet air, which ensures the condensation effect of the refrigeration system and the quality of the outlet air of the machine.

Circulation theory

After starting the dryer machine, the refrigerant is compressed by the compressor from the original low temperature and low pressure to high temperature and high pressure vapor.

The steam at high temperature and pressure flows into the condenser and the secondary condenser. Its heat is taken away by the cooling medium through heat exchange, and the temperature drops. The steam at high temperature and pressure becomes liquid at room temperature and pressure because of condensation.

Liquid refrigerant at room temperature and high pressure flows through the expansion valve, because the throttling pressure of the expansion valve decreases, making the refrigerant into liquid at room temperature and low pressure.

After the liquid at room temperature and low pressure enters the evaporator, because the pressure decreases, the liquid refrigerant boils and evaporates into a low-pressure and low-temperature gas. When the refrigerant evaporates, it absorbs a lot of heat from the compressed air, making the temperature of the compressed air drop to achieve the purpose of drying.

After evaporation, the low-temperature and low-pressure refrigerant vapor flows back from the suction port of the compressor, is compressed and compressed and then discharged into the next cycle.

Main spare parts

compressor

At present, most of the refrigeration compressors used in the dryer machine are fully sealed reciprocating compressors of medium and high temperature, which are characterized by compact structure, small volume, light weight, small vibration, low noise and high energy efficiency ratio.

Because the motor of the fully sealed compressor and the main body of the compressor are sealed in a steel shell, the motor runs in the refrigerant gas environment, the cooling condition is good, and the service life is long.

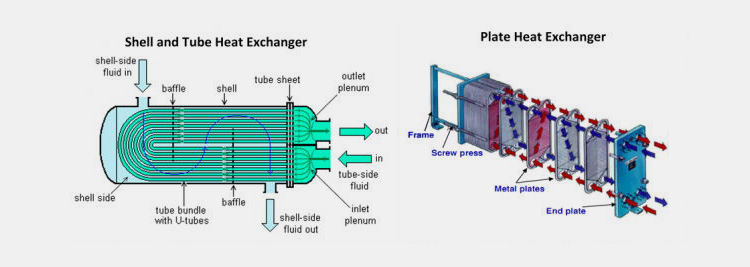

Heat exchange, evaporator

Heat exchange in the main role in the dryer machine is the use of compressed air after being evaporator cooling carried by the amount of cold (this part for the vast majority of users is a waste of cold energy of cold).

This part of the cold energy to cool and carry a large amount of water vapor in high temperature of compressed air, so as to reduce the heat load of cold person mechanism system, achieve the goal of energy saving.

The evaporator is the main heat exchange component of the dryer machine. The compressed air is forced to cool in the evaporator, and most of the water vapor is cooled and condensed into liquid water and discharged out of the machine, so that the compressed air can be dried.

Condenser, secondary condenser (precooling reheater)

In the dryer machine, the role of the condenser is to cool the high-pressure and superheated refrigerant vapor discharged from the refrigerant compressor into liquid refrigerant, so that the refrigeration process can be continuous.

Because the heat discharged by the condenser includes the heat absorbed by the refrigerant from the evaporator and the heat converted from the compression work.

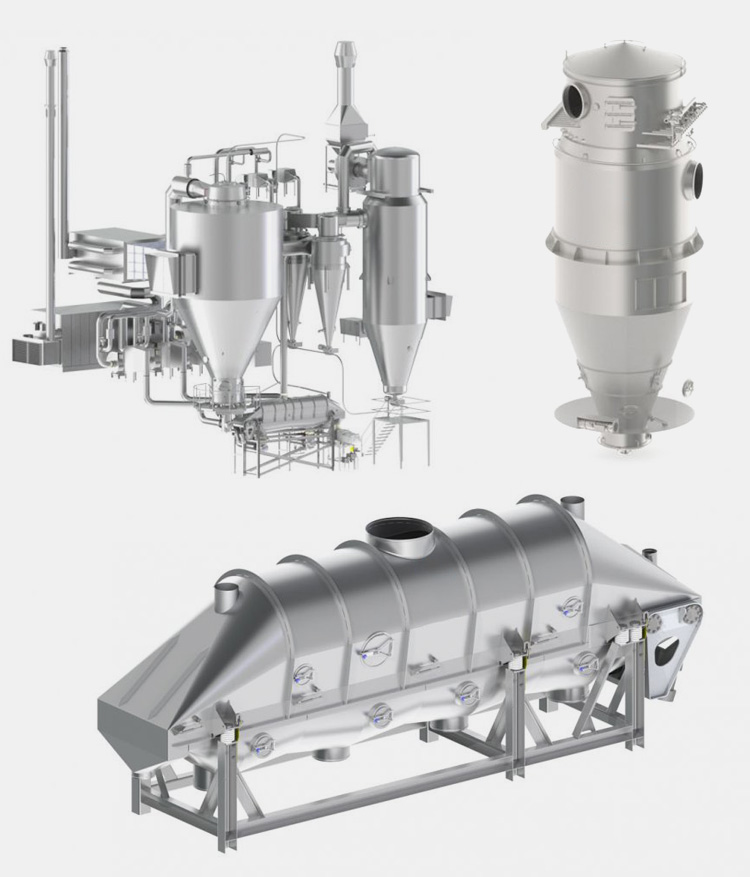

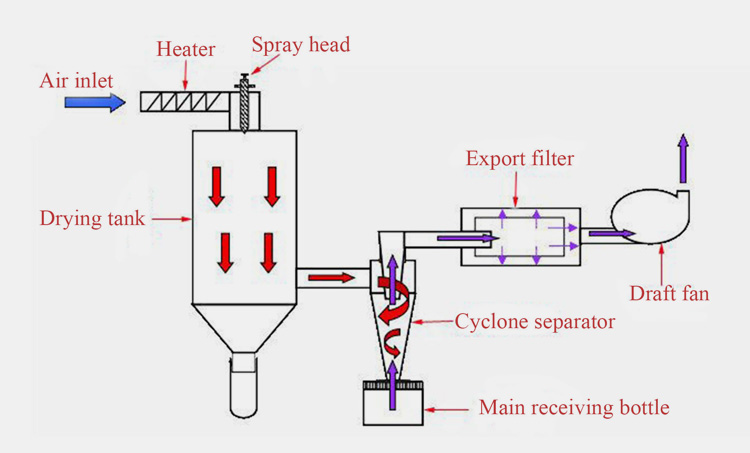

Cyclone separator (gas-water separator)

Cyclone separator is also an inertial separator, more used for gas-solid separation.

After the compressed air enters the separator along the tangential direction of the cylinder wall, it rotates inside, and the water droplets mixed in the gas also rotate together and generate centrifugal force. After hitting the outer wall (also the baffle), it will grow up and separate from the gas.

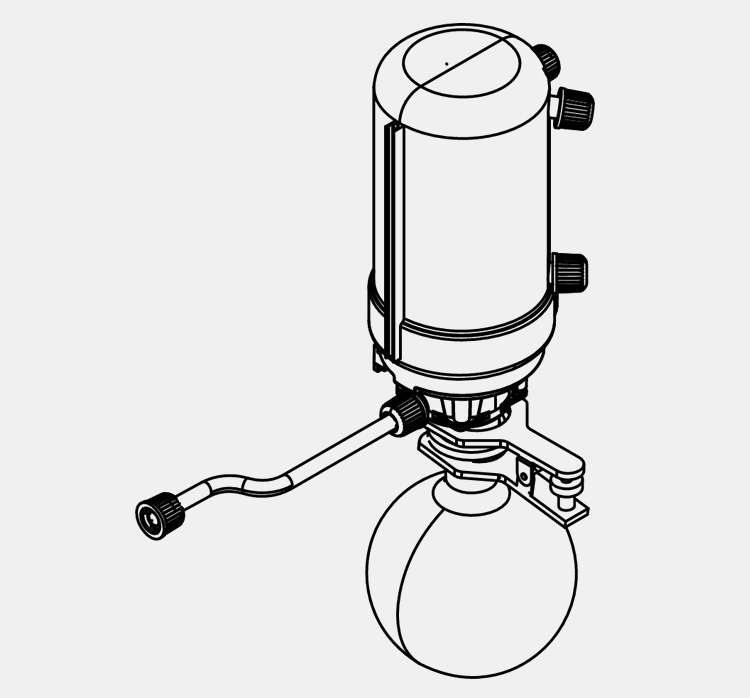

Thermal expansion valve or capillary (throttle)

The expansion valve (capillary) is the throttling mechanism of the refrigeration system. In the cold drying machine, the supply of evaporator refrigerant and its regulator are realized by throttling mechanism.

Throttling mechanism enables refrigeration from high temperature and pressure liquid into the evaporator. When the load changes, the thermal expansion valve passes the detection pressure.

The future development of dryer machine will be in the in-depth study of drying mechanism and drying characteristics of materials, master the optimal operating conditions for different materials, the development and improvement of dryer;

In addition, large scale, high strength, high economy, and improve the adaptability of raw materials and product quality, is the basic trend of dryer development;

The development of dryer machine should also pay attention to energy saving and comprehensive utilization of energy, such as the use of a variety of combined heating methods, transplant heat pump and heat pipe technology, the development of solar dryer.

The automatic control technology of dryer should be developed to ensure the realization of optimal operating conditions.

In addition, as people attach more important on environmental protection, promoting the dryer machines’ environmental protection measures to reduce the leakage of dust and exhaust gases is also a direction that needs to lucubrate.

Don't forget to share this post!

Drier Machine Related Posts

Drier Machine Related Products

Drier Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine