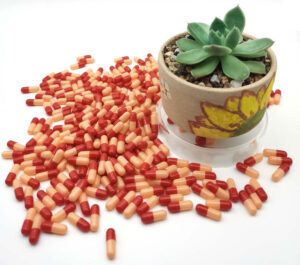

000 capsule machine

000 capsule machine automatically joins and ejects filled capsules – Faster and easier to use than other

Have you ever wondered how to fill your medicine capsules?

In fact,the capsule filling process refers to the encapsulation and lots of various techniques that are used to enclose the medicines into a stable shell,normally called an empty capsule,that can be taken orally or as a suppository.

A capsule filler is to fill powder into empty capsules and then lock the capsules.

Capsule filler machines are available in different types,like the automatic,semi-automatic,manual capsule filler.

And automatic capsule filler machines can also automatically reject the failed filling capsules.

How to choose the best capsule filler to meet your requirement,today I am going to give you more knowledge about that.

Spend a few minutes reading through,you will find the best answer to suit your needs.

Pharmacists face a ton of difficulties when filling powder items.

Above all while picking the proper powder filling hardware for their particular application.

What if some contamination gets into the powder?

Have you ever imagined filling unequal amount of powder in capsules? What would possibly happen?

They need to discover filling arrangements that meet their necessities to create a sensible quantifiable profit.

For, drug enterprises filling and shutting machines is assuming a significant part.

The drug business has explicit rules and necessities regarding amount and quality.

In this guide, we will explain you all if and thats of the Powder Filling Machine. Starting from the definition, benefits, types, parts, working principal and troubleshoot etc.

Have you been facing difficulties filling capsules?

Now, imagine you don’t fill the capsule properly and according to the given standards.

Capsule filler is one of the most vital machine in the pharmaceutical industry and it is widely accepted too.

There are very bright chances that capsule filler will give a boost to your business.

In this guide, i will explain you each aspect of the business, starting from brief introduction , the benefits, parts, working principals, different quality standards, different types of the machine and even the troubleshoots.

Let’s not wait anymore and read this guide to boom your business.

Between manual filling machine and automatic filling machine there is a machine called semi automatic capsule filling machine.

A semi automatic capsule filling machine uses manual labor force as well as automatic function for filling of the capsule. Today, this machine is the need of every booming business in the world.

Today,I am going to use this article to explain why these machines are mandatory in your capsule filling company.

Let’s dig more in details from the machines information to the working as well as for applications.

Automatic capsule filling machines are largely used in the pharmaceutical industry worldwide for production of hard gelatin capsules in formulation with powder, pellets, and granules separately or in different type’s combination of powder & pallets.

Now there are many different types of automatic capsule filling machines in the market,you may find it hard to choose from.

Then,I will give you a complete guide.

Reading through,you will get some of the true principle of buying the most suitable automatic capsule filling machine.

Semi automatic Capsule Filling d Machine is actually designed for different set standards that are demanded by the different pharmaceutical industries. A Semi capsule Filling Machine is reasonable to fill size 00 to 5 capsules with powder, granules or pellets.

There are many different and distinct models in the semi automatic capsule filling machine which give a maximum running result from 25000 capsule for each hour to 45000 capsule for every hour.

Machines furnish the serious extent of computerization with more significant levels of filling weight precision. Semi automatic capsule filling machine is made according to GMP principles having all Stainless Steel covering. Semi automatic capsule filling machine having wide utilization in R&D labs, Research Institutions, Herbal and Nutraceutical arrangements, Unani & Ayurvedic prescriptions, Pilot group creations and so forth.

The semi automatic capsule filling machine is easy to use with some advantages that a normal capsule machine can’t provide you.

Up to 25,000 capsules in 60 minutes, an exceptionally effective semi automatic capsule filling machine mechanism which guarantees a high degree of precision and can work with a scope of capsule sizes!

Thus, this article is about insights of the semi automatic capsule filling machine and it will explain 10 most vital advantages of using this machine.

Drugs in capsules are usually powder or pallets that are irritating to the esophagus and gastric mucosa, or drugs with poor taste, easy to volatilize, easy to be decomposed by saliva in the mouth, and easy to inhale into the trachea.

While filling into capsules not only protect its properties from being damaged,but also being a protective barrier to the digestive organs and respiratory tract.

Actually,you shall owe all these to the automatic capsule filling machine who will help you fill all kinds of sensitive drugs into the capsules.

Now there are lots of automatic capsule filling machines with various structure designs in the market,but come with the same function-filling materials.

Facing the large market,you must be very confused how to choose the most suitable automatic capsule filling machine for your mass production.

Or you may spend a lot of time comparing the difference between each type of automatic capsule filling machine.

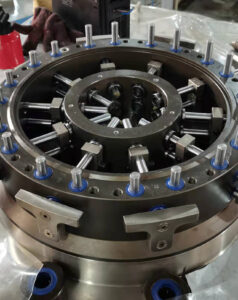

In fact,for the precise functional process of your capsule filling process,you must get to know what are the most important parts of an automatic capsule filling machine or how are they aligned for the better work with each other.

Now,I have summarized 13 most critical parts of automatic capsule filling machine,spend a few minutes reading through,you will get a brand new understanding of this machinery.

You must know that the pharmaceutical industry must have the ability to provide a variety of fine quality capsules for their medical purposes.Therefore,it is only natural that they must have the necessary types of machines to meet their needs.

Among the various pharmaceutical machineries,you will find an automatic capsule filling machine will act as a panacea for the fine capsule makers.

An automatic capsule filling machine is mostly applied by most pharmaceutical companies to assist with the production of soft/hard capsules.

Granules,pellets and powers are filled either individually or in unison to make different functional capsules

Semi Automatic Capsule Filling Machine is configured according to the precision manufacturing requirements of the pharmaceutical industry.

Semi Automatic Capsule Filling Machine mainly consider in medium scale pharmaceuticals, herbals and nutraceutical companies where the higher production output is required with medium lost.

The machine provides a high degree of automation with higher levels of weight accuracy in filling hard gelatin capsules. Semi Automatic Capsule Filling Machine suitable to fill capsules of all sizes & it is constructed by quality Stainless Steel covering according to GMP standards.