AIPAK High-Speed Automatic Tablet & Capsule Counting Line: Precision & GMP Compliant Solutions

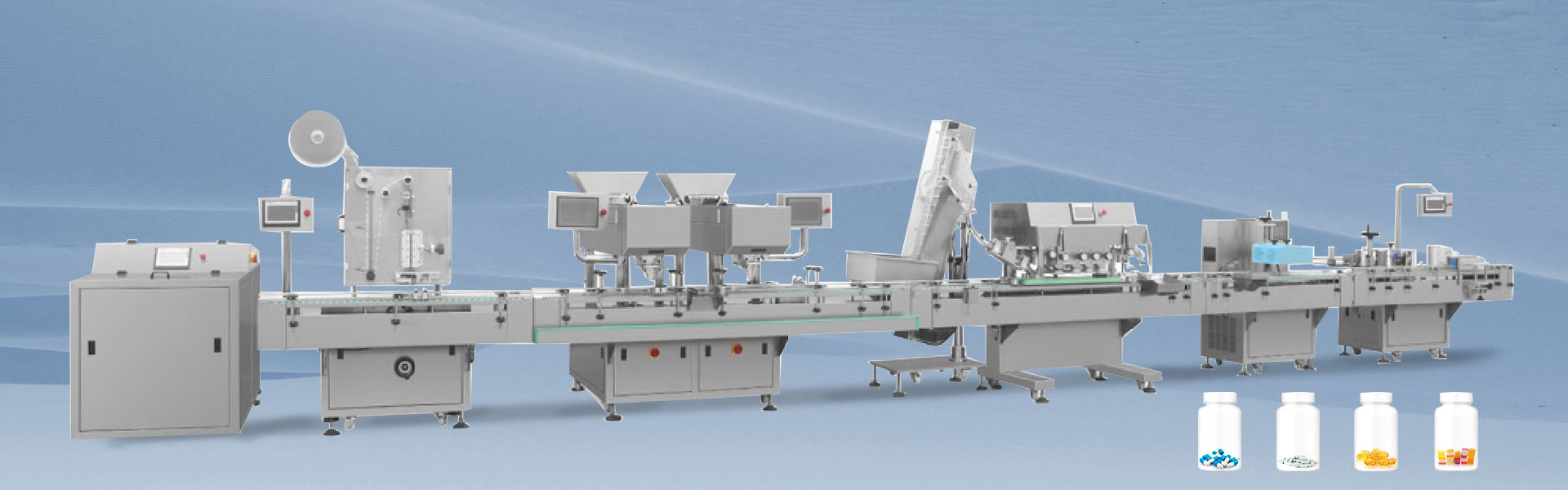

AIPAK tablet counting line is made of bottle unscrambler,desiccant insert machine,tablet counting machine,capping machine,induction sealing machine and automatic labeling machine.It is the main workhorse in capsule production process.With the advanced anti-dust technology,it can be used for tablets(including abnormal tablets),capsule gels(including abnormal gels,transparent gels and opaque gels)pearls and most kind of tabloids. Each machine have intelligent design,with interactive operating multi-language panel can save 10-20 kinds of different operating parameters and easy to load for different products.Self-diagnose,display errors and make alarms.Well cooperation between each machine and in the whole line. Take purposed to operate,easy to adjust, clean and maintain, low working cost,low maintain cost 3 workers will be enough to operate.

Applications of Tablet Counting Line

Pharma Tablets & Capsules

From coated tablets to hard and soft capsules, ensuring accurate dosage per bottle.

Nutraceuticals & Supplements

Vitamins, fish oil capsules, herbal pills, and dietary supplements packaged with consistency.

Softgels & Gummies

Adaptive counting system handles transparent, sticky, or irregularly shaped products.

Granules & Small Solid Products

Veterinary & Animal Health Products

Cosmetics & Personal Care Products

Counting and bottling soft capsules containing collagen, vitamins, hyaluronic acid.

Functional Foods & Nutritional Oils

Softgel or tablet counting ensures minimal product loss and accurate labeling for nutritional supplements.

Supporting R&D Trials and Pilot Production

Supports testing of new formulations, different capsule sizes, or specialized packaging without full-scale investment.

AIPAK-Your Best Pharma Processing & Packaging Machinery Supplier In China

Download Our Latest Catelogue

Discover our full range of pharmaceutical processing&packaging machinery. Download the catalogue to explore specifications, features, and applicatons.

- Full product range

- Detailed technical specs

- Industry applications

Tablet Counting Line FAQ

1.What types of tablets or capsules can be handled?

AIPAK tablet counting lines support standard tablets, coated tablets, hard and soft capsules, gummy products, and irregular-shaped solids.

2.How accurate is the tablet counting line?

Counting accuracy is better than 99.5% under standard operating conditions. Accuracy may vary slightly depending on product size, shape, and speed.

3.How many operators are required?

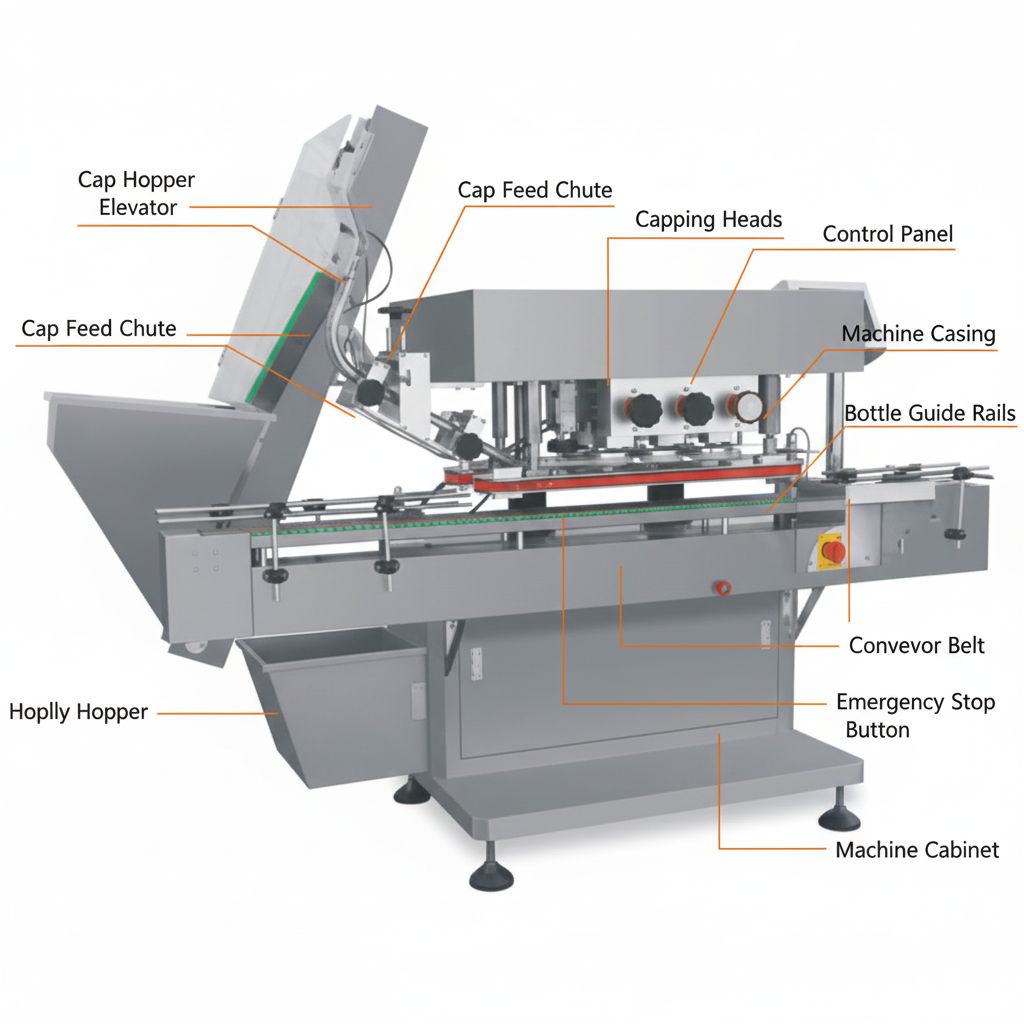

A standard line typically requires 2–3 operators, depending on automation level, line speed, and additional equipment integration.

4.How easy is cleaning and maintenance?

The tablet counting line is designed for easy disassembly and tool-free access to contact parts. Anti-dust covers and CIP-compatible components ensure fast, hygienic cleaning.

5.What is the maximum production speed?

Production speed varies by model:

Low-speed line: 1,000–5,000 bottles/hour

Medium-speed line: 5,000–15,000 bottles/hour

High-speed line: 15,000–30,000+ bottles/hour

6.Can the tablet counting line handle irregular-shaped tablets or softgels?

Yes, adaptive counting systems and anti-jamming mechanisms allow the line to accurately handle irregular or sticky products.

7.What bottle sizes and types are supported?

The tablet counting line supports plastic or glass bottles, round or square shapes, and sizes ranging from 30 ml to 2,000 ml, depending on the model.

8.Does the line include quality inspection features?

Yes, the tablet counting line can include check-weighers, missing/broken tablet detection, and reject mechanisms to ensure product quality.

9.Is the line compliant with regulatory standards?

All lines are designed according to GMP, CE, and ISO 9001 standards. Product-contact parts use food or pharmaceutical-grade stainless steel.

10.What is the lead time and spare part availability?

Lead time depends on the model and production complexity. Critical spare parts such as counting plates, sensors, and belts are stocked regionally for fast delivery.

11.Can the line be integrated with existing packaging equipment?

Yes, the counting line can be connected with capping machines, labeling machines, and packaging lines for a fully automated production workflow.

12.Do you provide installation and training?

Yes, AIPAK provides on-site installation, operator training, manuals, and remote technical support to ensure smooth operation.

Why Choose AIPAK

Working with market leaders in the On-demand manufacturing industry, without the busyness and risk.

Consistently High Quality

Every parts applied in our machines are through precise R& D and design,all our machines must be inspected before delivery.All AIPAKmachines are automatic that is easy to use and maintain.

Competitive Prices

In China, the competition between suppliers keeps the prices fair. Our fully optimized equipment helps us maintain a low price without sacrificing the quality and performance of your parts.

Broad Range of Capabilities

AIPAK advanced technologies mean we can offer hundreds of service to our customers.AIPAK expert team will propose the most suitable machines as customer budget and raw materials.

Higher Efficiency

AIPAK automatic machines that is economical to use ,will help you achieve your tasks within target time.All our machines feature many pre-fitted tools that lead to rapid tool changes.

Instant Quotes

We offer instant quotes based on your materials and budget without complicating the processes through long email chains. We calculate prices based on millions of orders we've previously processed.

Economy Lead Times

For your time-sensitive production line, AIPAK offers economic lead-time options. You can submit your order through our online quoting system,we will quote to you in less than 5 minutes.

The Buyer's Guide

Tablet Counting Line: the Ultimate Buying Guide in 2025

Optimizing a tablet counting line in 2025 requires more than just high speed; it demands uncompromising accuracy and seamless integration.

Whether you are handling dusty herbal tablets or delicate softgels, this guide explores the advanced synchronization of unscrambling, counting, and packaging technologies.

Let's go straight to the subject:

Module 1: System Integration & ROI

1. What is a Pharmaceutical Tablet Counting Line?

A tablet counting line is a fully synchronized automated packaging system designed to unscramble, count, fill, cap, seal, and label solid dosage forms (tablets, capsules, pills). In 2025, a professional line is defined by its logic control integration, where all machines communicate to ensure zero-error packaging and maximum OEE (Overall Equipment Effectiveness).

2. What is a Tablet Counting Line Made of?

A comprehensive AIPAK line consists of the following modular units:

-

Automatic Bottle Unscrambler: For consistent container orientation.

-

Electronic Tablet Counter: The high-precision core of the system.

-

Desiccant / Cotton Inserter: For product stability and moisture control.

-

High-Torque Capping Machine: For hermetic sealing.

-

Induction Sealer & Labeling System: For tamper-evidence and branding.

3. What is the Primary Application of the Line?

Our lines are engineered for versatility, handling:

-

Hard & Soft Gelatin Capsules: Including transparent and opaque variants.

-

Coated & Uncoated Tablets: Including oddly shaped or fragile pills.

-

Gummies & Soft Chews: Optimized with anti-sticking technology.

4. Key Benefits: Why Invest in an Integrated Line?

-

Precision Compliance: Reduces "Product Giveaway" to near-zero with ±0.1% accuracy.

-

Contamination Control: Enclosed systems and dust collection ports ensure a GMP-compliant cleanroom environment.

-

Scalability: Modular design allows you to add inspection or boxing units as your production grows.

5. Which International Quality Standards are Met?

Our equipment is built to meet the world’s most stringent regulations:

-

US FDA 21 CFR Part 11: Full audit trails and electronic signature support.

-

EU GMP Annex 11: Optimized for pharmaceutical hygiene.

-

CE & ISO 9001 Certifications.

Module 2: Pre-Counting Preparation

6. What is a Pharmaceutical Bottle Unscrambler?

It is the entry point of the line, responsible for taking bulk bottles and placing them onto the conveyor in a vertical, oriented position at high speeds.

7. Types of Unscramblers: Why Centrifugal is Best for Pharma

Unlike old water-floating or manual systems, iCapsulePack focuses on centrifugal & hook-type unscrambling.

-

Advantages: Gentle handling to prevent micro-scratches on plastic bottles and high-speed compatibility (up to 200 BPM).

8. Core Features of the APC Series Unscramblers

-

Tool-less Changeover: Adjust for different bottle diameters in under 10 minutes.

-

Integrated Ionized Air Cleaning: Effectively removes static and fine dust inside the bottle before filling.

9 - 10. How Does a High-Speed Unscrambler Work?

Bottles are fed from a bulk hopper into a rotating disk. Centrifugal force pushes them to the edge, where an orientation hook ensures they exit neck-up onto the conveyor. Sensors monitor the downstream flow, automatically pausing if a backup occurs.

11 - 12. Troubleshooting Common Unscrambler Issues

| Issue | Cause | Solution |

| Bottle Jamming | Improper speed synchronization. | Adjust PLC frequency to match downstream demand. |

| Static Build-up | Dry environment or friction. | Enable the Ionized Air Module for static neutralization. |

Module 3: Precision Counting Technology

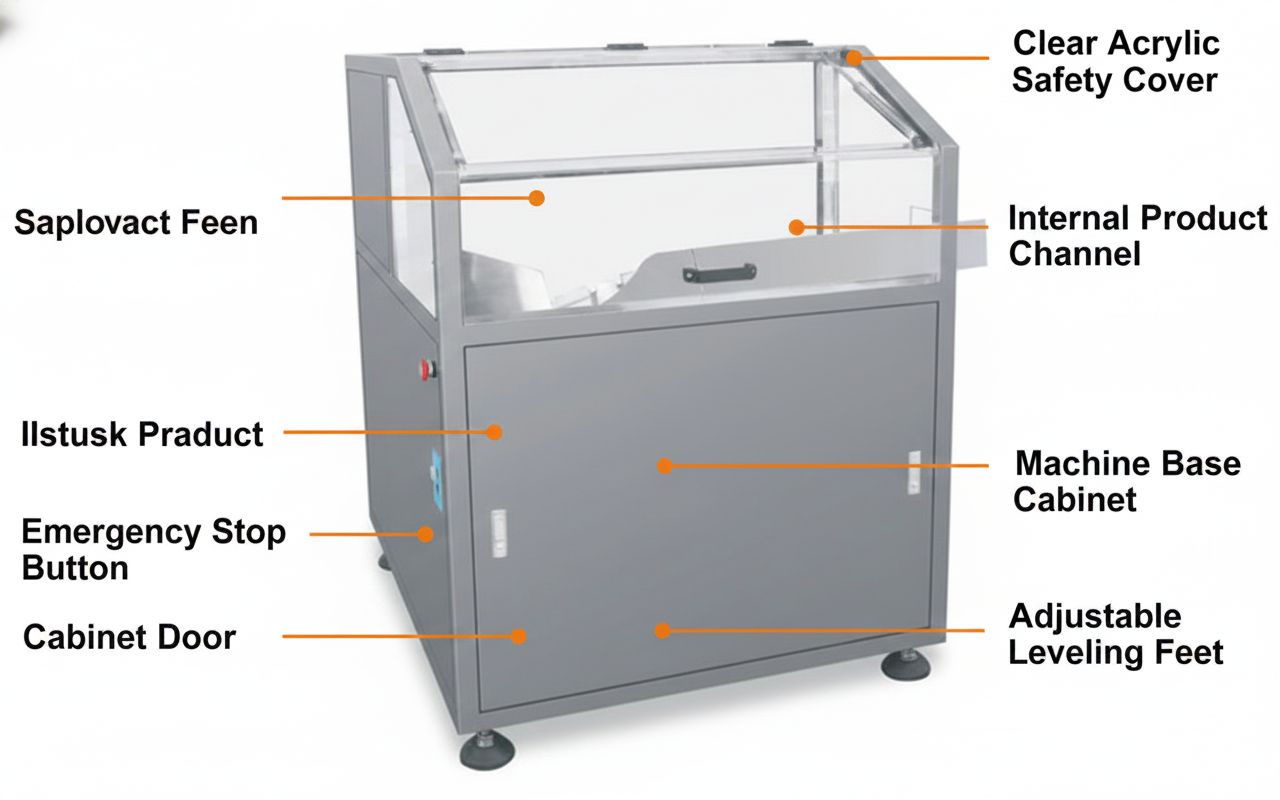

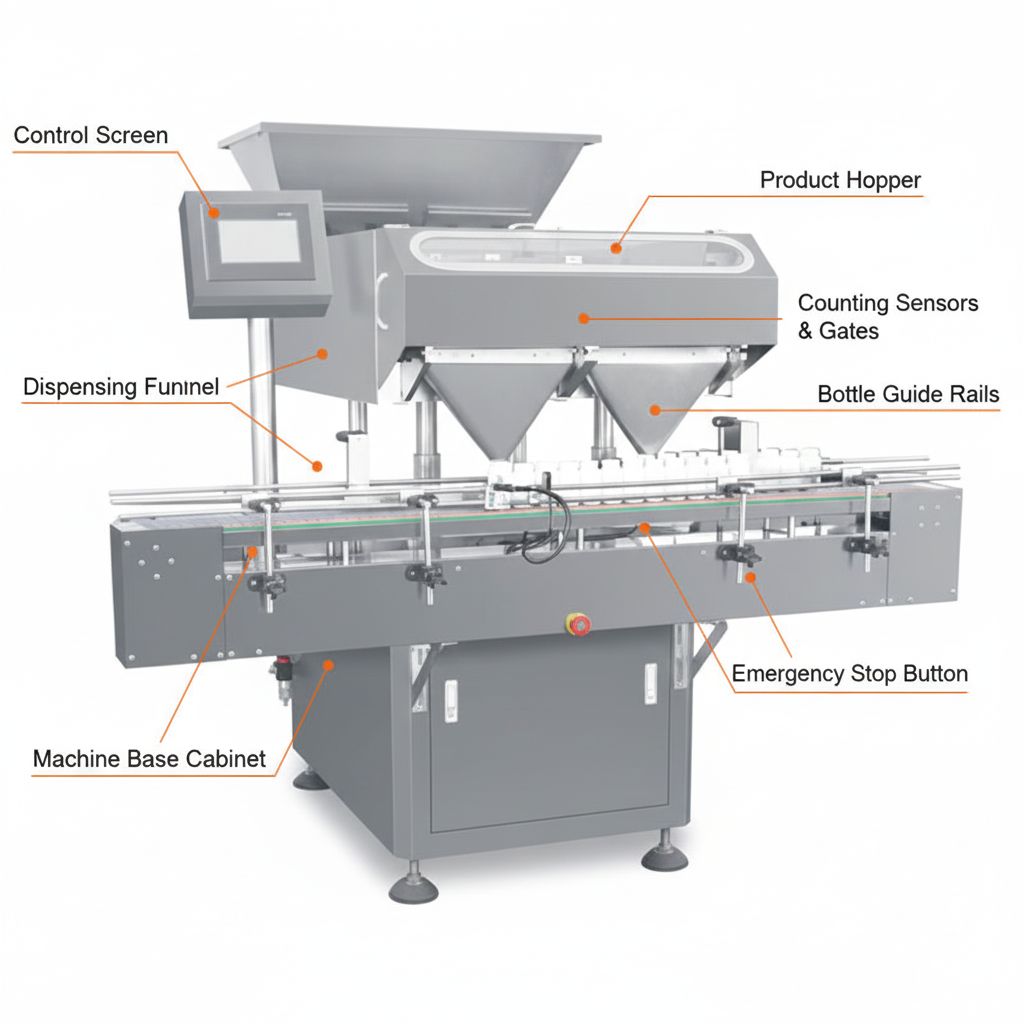

13 - 14. What is a 2025-Era Electronic Counting Machine?

It is a multi-channel sensing system that uses infrared array technology to count solid particles in motion. It is the most critical machine for ensuring dosage accuracy.

15 - 16. Professional Features & Components

-

SS316L Contact Parts: All surfaces touching the medicine are medical-grade.

-

3-Stage Vibratory Trays: For perfect product separation.

-

Anti-Dust Sensing Array: Capable of accurate counting even in high-dust herbal environments.

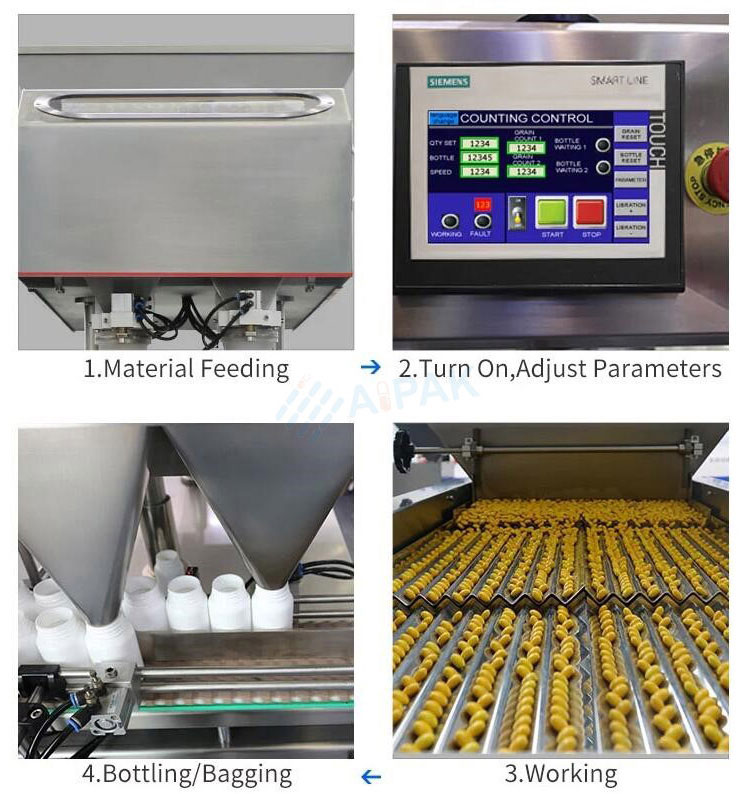

17. The Working Principle: 3-Stage Feeding Logic

-

Stage 1: Spreads bulk material from the hopper.

-

Stage 2: Separates the tablets into individual lanes.

-

Stage 3: Ensures single-file entry into the sensing zone for 100% detection.

18 - 19. Operation & Product Safety

Operation is managed via a Siemens HMI. Key care must be taken to ensure material is dry; damp capsules can stick, leading to counting errors.

20. Critical Factors Affecting Counting Accuracy

-

Dust Accumulation: Dust can block sensors. Our Solution: Intelligent signal compensation logic.

-

Static Electricity: Causes tablets to leap or stick. Our Solution: Anti-static coating on discharge chutes.

-

Sensor Speed: Fast response is required for small pills. Our Solution: High-frequency FPGA microprocessors.

21. Buyer’s Checklist for Automatic Counters

-

Accuracy: Does it reach 99.98%?

-

Ease of Cleaning: Can trays be removed without tools?

-

Vision Integration: Can it detect broken tablets?

22 - 25. Desiccant Inserting: Ensuring Shelf-Life

A desiccant inserter automatically cuts and places silica gel packets. Our system uses a high-precision mark sensor to ensure the cut is always in the center of the seal, preventing packet rupture and product contamination.

26. What is a High-Precision Capping Machine?

A capping machine (or bottle closer) is the critical safeguard for product stability. In a 2025 pharmaceutical line, it is no longer just a "screwing tool" but a torque-controlled system that ensures every bottle is hermetically sealed to prevent oxidation and leakage.

27. What are the Main Types of Capping Technology in 2025?

Modern facilities select capping technology based on cap design and line speed:

-

Automatic Inline Capping (Linear): Best for high-speed lines with multiple bottle sizes. It uses multiple pairs of rubber wheels to tighten caps incrementally.

-

Rotary Servo Capping: The premium choice for pharma. Each capping head is driven by an individual Servo Motor, allowing for precise digital torque control and data logging.

-

Vacuum Capping: Essential for glass jars (e.g., nutrition supplements) that require a vacuum seal for extended shelf life.

28. What are the Advantages of an Automatic Capping System?

Upgrading from semi-auto to a fully integrated iCapsulePack capping module provides:

-

Zero-Damage Handling: Oscillating or centrifugal cap feeders prevent scuffing on polished or child-resistant caps (CRC).

-

Rejection Logic: Automatically detects and rejects skewed caps, missing foils, or cocked caps without stopping the line.

-

Compliance: Our systems feature Torque Feedback Loops, ensuring every bottle meets the pre-set Newton-meter (Nm) requirement for GMP audits.

29. What are the Core Components of a Servo-Driven Capping Machine?

-

HMI (Human-Machine Interface): A Siemens/Schneider touch screen for digital torque adjustment (no manual wrenching required).

-

Cap Elevator & Sorter: 304 Stainless steel construction with sensors to ensure only correctly oriented caps reach the bottle.

-

Active Torque Heads: Utilizing magnetic clutches or servo motors to apply the exact closing force.

-

Bottle Clamping Belts: Synchronized side-belts that stabilize the bottle during the high-speed tightening process to prevent rotation.

30. How Does a High-Speed Automatic Capping Machine Work? (The Process)

-

Orientation: Caps are sorted and fed via a chute to the "pick-and-place" or "pick-up" station.

-

Bottle Synchronization: The line’s PLC times the arrival of the bottle to match the cap release.

-

Pre-Tightening: The cap is stabilized onto the bottle neck.

-

Final Torquing: Multiple pairs of friction wheels (or a single servo head) tighten the cap to the exact digital specification.

31. Troubleshooting: Common Capping Challenges & Expert Solutions

| Problem | Potential Root Cause | Professional Solution |

| Loose Caps | Insufficient torque or worn friction wheels. | Adjust torque setting on HMI; replace wheels with High-Friction Silicone rollers. |

| Cap Damage/Scuffing | Excessive pressure or incorrect feeder speed. | Adjust the magnetic clutch tension; synchronize the cap elevator with line speed. |

| Skewed/Cross-Threaded Caps | Misalignment between the cap chute and bottle center. | Recalibrate the Bottle Clamping Belts for precise center-line alignment. |

| High Rejection Rate | Inconsistent bottle neck diameters or cap quality. | Verify bottle tolerances; integrate a Vision Inspection System for early detection. |

32. Critical Factors to Consider When Purchasing a Capping System

-

Torque Repeatability: Does the machine maintain the same Nm force across 10,000 bottles?

-

CRC Compatibility: Is the system designed to handle Child-Resistant Caps which require both downward pressure and rotation?

-

Cleanability: Are the surfaces smooth and tool-less for quick GMP-compliant washdowns?

-

Validation: Does the supplier provide Torque Validation Reports as part of the IQ/OQ package?

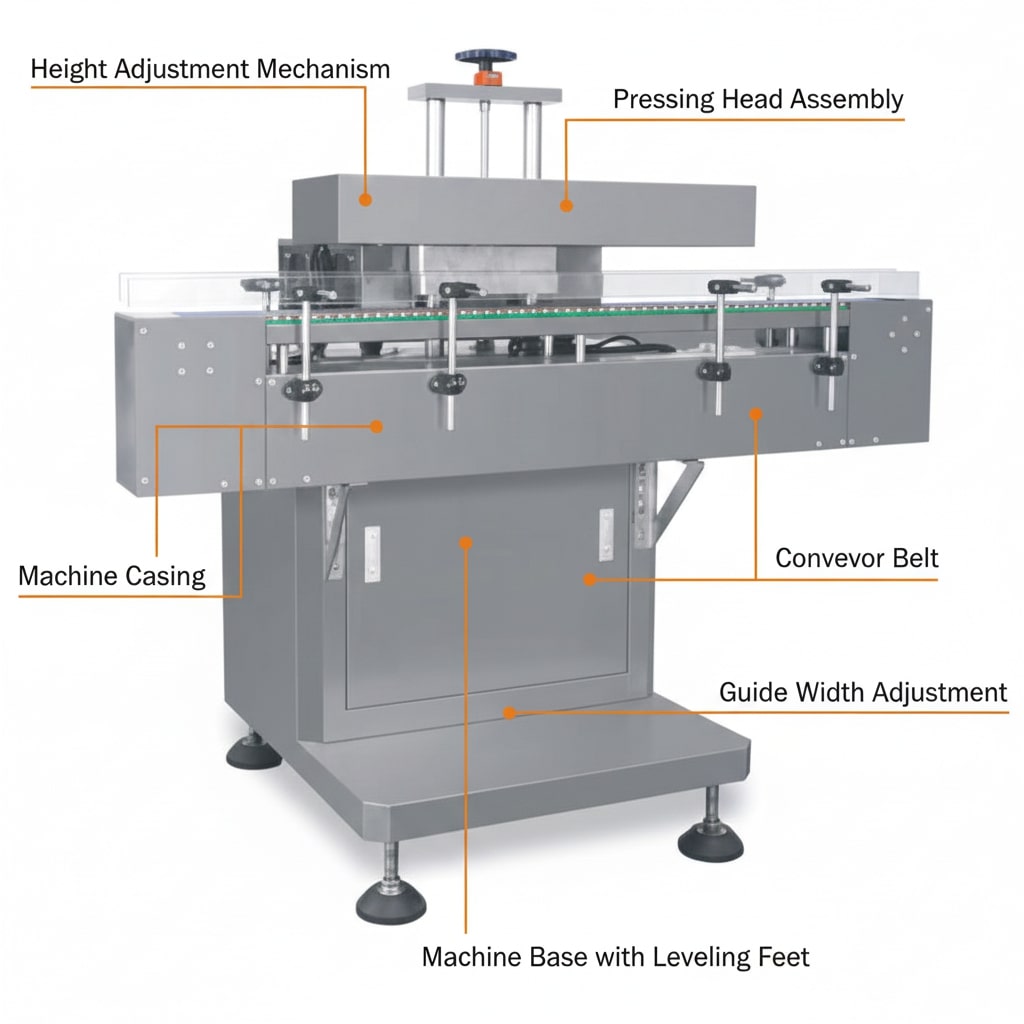

33. What is an Industrial Induction Sealing Machine?

An induction sealer is a non-contact heating process used to hermetically seal the mouth of plastic and glass containers with an aluminum foil liner. In pharmaceutical production, this is the "Critical Control Point" to ensure tamper-evidence, leak prevention, and oxygen barrier integrity.

34. Which Materials are Optimized for Induction Sealing?

While the induction process works with PE, PP, PET, and Glass, the success of the seal depends on the liner-to-container compatibility.

-

Note: The bottle must be non-metallic. For 2025 standards, we recommend using Clean-Peel or weld-bond liners depending on whether your product is a daily supplement or a prescription drug.

35. Why Choose Continuous Induction Sealing over Manual Methods?

For a tablet counting line, a manual sealer is a bottleneck. Our APC-M Series provides:

-

High-Speed Synchronization: Sealing speeds up to 200 bottles/min, matched to your counting line.

-

Consistency: Unlike hand-held units, the power output is stabilized by a digital frequency Inverter, ensuring the same heat energy is applied to every bottle.

36. What are the Main Components of a Professional Induction Sealer?

-

Induction Tunnel (Sealing Head): Designed with a high-efficiency coil that focuses the magnetic field exactly on the foil, preventing heat damage to the bottle neck.

-

Cooling System: Utilizing dual-fan air Cooling or Water Cooling (for ultra-high-speed lines) to ensure the power supply stays stable during 24/7 operation.

-

Height-Adjustable Column: Features a calibrated scale for fast, repeatable setups when switching between different bottle heights.

-

Integrated Conveyor: Constructed with anti-static SS304, ensuring smooth movement without magnetic interference.

37. The Working Principle: How Does Induction Sealing Ensure Safety?

When a capped bottle passes under the induction head, an oscillating electromagnetic field generates eddy currents within the aluminum foil liner.

-

The foil heats up instantly.

-

The heat melts the polymer coating on the liner.

-

The pressure of the screwed cap bonds the liner to the bottle lip, creating an airtight hermetic seal.

38. What are the Merits of the AIPAK Induction System?

-

Non-Contact Heating: No direct contact with the product, maintaining 100% sterile conditions.

-

Smart Detection (Optional): Can be equipped with a foil detection Sensor that automatically flags or rejects any bottle missing a foil liner.

-

GMP Housing: All-stainless steel, easy-to-clean design with no exposed wires or crevices for dust accumulation.

39. How to Calibrate Your Sealing Process for 100% Integrity?

Don't just turn it on. Professional operators follow the sealing window logic:

-

Heat Setting: Too low leads to poor bonding; too high causes liner scorching.

-

Conveyor Speed: Must be synchronized so the bottle stays in the "induction zone" for the exact required duration.

-

Torque Consistency: Remember, the Capping Machine (Module 4) provides the pressure—without consistent capping torque, the induction seal will fail.

40. Troubleshooting: Solving Induction Sealing Failures

| Failure Mode | Possible Root Cause | Technical Solution |

| Partial Sealing | Skewed cap or uneven bottle lip. | Check Capping Module alignment; inspect bottle quality for "flash" on the lip. |

| Burnt Liners | Conveyor speed too slow or Power too high. | Increase conveyor speed or decrease the Induction Power % on the HMI. |

| "No-Foil" Bottle Passing | Sensor malfunction or missing liner. | Test the Rejection System; verify liner presence in the cap supply. |

| Weak Peel Strength | Incompatible liner material. | Consult with our engineers for a Liner-to-Material Compatibility Test. |

41. Maintenance Checklist for Long-Term Reliability

-

Daily: Clean the induction head surface to remove any residue.

-

Weekly: Check cooling fans for dust buildup to prevent power supply overheating.

-

Monthly: Verify the Height Adjustment mechanism for smooth movement and lockability.

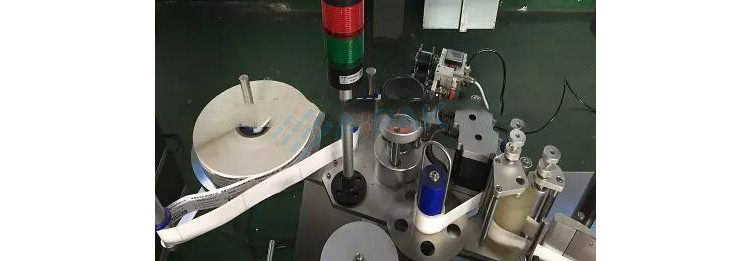

42. What is a Pharmaceutical-Grade Labeling Machine?

A labeling machine in a tablet counting line is a high-precision system that applies self-adhesive labels to bottles. In 2025, it must be integrated with coding and vision inspection units to ensure that every bottle carries the correct Batch Number, Manufacturing Date, and Expiry Date.

43. What are the Industry-Standard Types of Labelers?

-

Vertical Round Bottle Labeler: The workhorse for pharma bottles, ensuring 360° alignment.

-

Top/Flat Face Labeler: Used for labeling carton boxes or bottle caps.

-

Wrap-Around Labeler: Ideal for small vials or thin bottles where high stability is required during application.

44. How Does AIPAK Ensure "No-Bubble" Labeling?

Our 2025 series uses a synchronized three-point positioning or wrap-belt system. By matching the bottle’s rotation speed exactly with the label dispensing speed, we eliminate wrinkles and air bubbles, even on tapered bottles.

45. The Working Principle: High-Speed Synchronization

- Bottle Separation: An integrated star-wheel or screw-feeder ensures consistent spacing.

- Label Dispensing: A high-torque stepper or servo motor drives the label roll.

- Application: As the bottle passes the sensor, the label is "wiped" onto the surface.

- Compression: A sponge or rubber belt applies uniform pressure for a permanent bond.

46. What are the Main Components of an Intelligent Labeler?

-

Servo Drive System: Provides sub-millimeter accuracy at speeds up to 150 BPM.

-

HMI Control Center: Stores up to 50 product presets for instant changeovers.

-

Coding Engine: Integrated thermal transfer (TTO) or laser coder for real-time printing.

-

Label Tensioner: Prevents label breakage by maintaining constant web tension.

47. Advantages of Full-Line Integrated Labeling

-

OCR/OCV Vision Readiness: Our machines are designed to mount high-speed cameras that verify the presence and correctness of printed codes.

-

Auto-Rejection: Bottles with skewed labels or unreadable codes are automatically diverted to a rejection bin without stopping the production flow.

48. Modern Labeling Methods: Wipe-on vs. Tamp-on

For tablet counting lines, wipe-on (synchronous) labeling is preferred for its speed and reliability. tamp-on is typically reserved for top-labeling cases where the surface height might vary.

49. Key Performance Indicators (KPIs) for Your Labeler

-

Labeling Accuracy: Within ±0.5mm to ±1mm.

-

Rejection Rate: Should be <0.01% for high-quality label stock.

-

Changeover Time: Should be under 10 minutes using tool-less adjustments.

50. Critical Operation Protocols for GMP Compliance

-

Static Elimination: Integrated ion-bars prevent static buildup on plastic labels, which can cause sensor errors.

-

Label Roll Direction: Ensure the "Wind Direction" matches the machine’s unwind configuration (Standardized as Industry Type 3 or 4).

51. Troubleshooting: Solving Label Warping and Wrinkling

-

Warping: Usually caused by poor adhesive or "memory effect" in stiff labels. Solution: Increase the wrap-belt pressure or use a more aggressive adhesive.

-

Wrinkling: Caused by speed mismatch. Solution: calibrate the encoder feedback to synchronize the conveyor and label dispenser.

52. How to Prevent Label Breakage in High-Speed Lines?

Frequent breakage is often due to micro-cuts in the backing paper during the die-cutting process. We recommend using PET liners for high-speed applications as they offer 3x the tensile strength of paper liners.

53. Maintenance for 24/7 Operations

-

Glue Removal: Regularly clean the "Peel Plate" with isopropyl alcohol to prevent adhesive buildup.

-

Sensor Calibration: Wipe the "Gap Sensor" daily to ensure it distinguishes accurately between the label and the backing paper.

54. The Ultimate Buyer's Checklist: Purchasing a Labeling System

-

Accuracy: Request a test run with your specific bottle and label material.

-

Integration: Does the labeler communicate with the upstream Counting Machine to stop if a bottleneck occurs?

-

Verification: Is the machine pre-drilled for camera inspection systems?

-

Documentation: Ensure the supplier provides a full parts list and wiring diagram for local maintenance.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Tell us your material or budget, we'll reply you ASAP within 24 hours