Continuous machine operation& complete automation

Simple operation

Easy maintenance&low labor costs

Want A Free Consultation

LPG50 High Speed Atomizer Centrifugal Spray Dryer /liquid spraying drying machine

AIPAK LPG50 high speed centrifugal spray dryer is the high efficient drying equipment, to make dry powder or granule from liquid, emulsion, suspension and pumpable pasty liquid, especially for thermosensitive material, it can keep color, original flavor and chemical feature of raw material, and the finished dry powder or granule have good quality,purity, fluidity and solubleness. This equipment features high accuracy & speed & efficiency, simple production process, labor-cost saving, widely applied in the industry of chemical, food, pharmacy, biochemistry, light industry,etc.

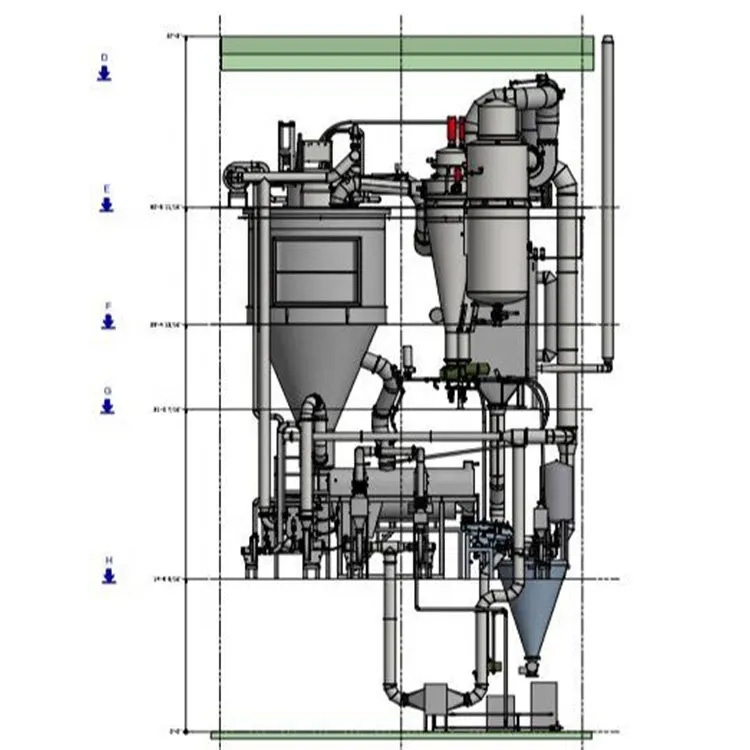

LPG50 Centrifugal Spray Dryer Working Principle

After filtering and heating, the air would enter into upper air-deployer of drying tower, and then come in in hot spiral form. At the same time, the raw liquid material would be atomized by tower from upper inside, become the super tiny globule in mist type, the surface of which would contact the hot air fully, then finished dry powder would be achieved in short time and collected at the bottom of tower and be discharged from cyclone separator, the gas would be exhausted outside.

LPG50 Centrifugal Spray Dryer Application

FEATURE

1.Drying speed,the atomized liquid after the greatly increased surface area,in the hot air flow,instantaneous evaporation can be 95%-98%moisture,and only a few seconds to complete drying time,is particularly applicable to dry thermosensitive material.

2.Product has good uniformity,mobility and solubility,high purity products,good quality.

3.Simplify the production process,convenient control.The humidity of 40 to 60 percent(up to 90 percent of special materials)to the liquid into a dry powder products,dried without crushing and screening to reduce production processes,improve product purity.

4.The product size,pine density,moisture,in a certain range by changing the operating conditions can be adjusted,control and management are very convenient.

DATA SHEET

| Model | LPG-50 |

| Inlet air temperature | ≤ 350°C |

| Outlet air temperature | 80-90°C |

| Evaporate capacity (kg/h) | 50 |

| Atomizer type | mechanical drive |

| Rotary speed | 21500 |

| Diameter of atomizer disc (mm) | 120 |

| Heating source | Electricity/LPG/Natural gas/Oil/Steam |

| Electric-heating power (kw) | 48 |

| Dry powder yield (%) | ≥ 95 |

CONTACT

Get in touch with an expert

Andrew Yang

Engineer Director

Phone: +86 189 7157 0951