Accurate measuring ,advanced structure

Stable operating ,low noise ,large adjusting range

Fast filling speed

Want A Free Consultation

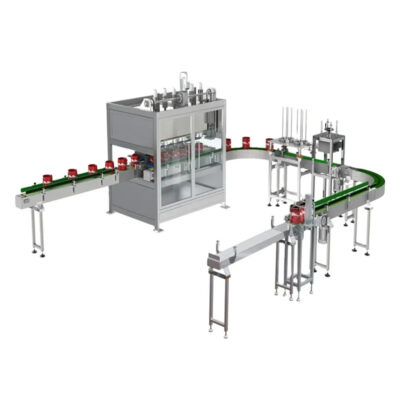

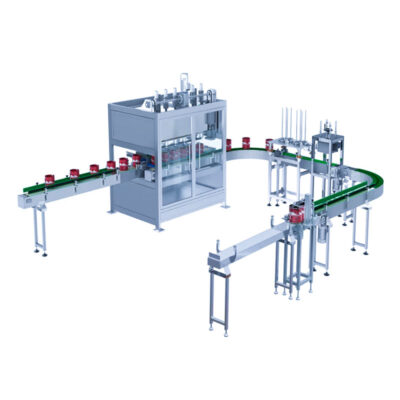

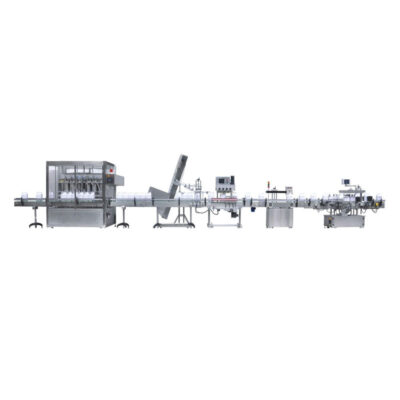

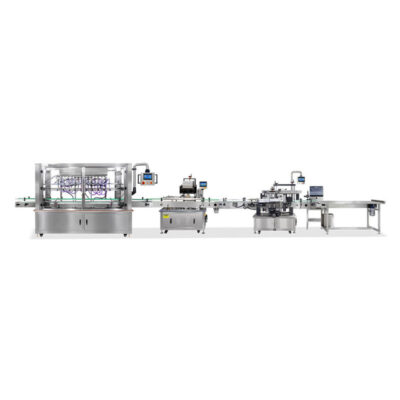

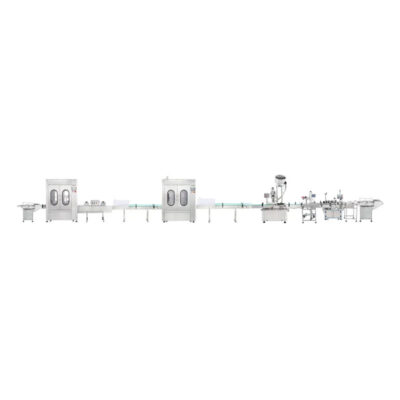

High Speed Shower Gel Body Cream Lotion Shampoo Filling Machine Automatic liquid filling line

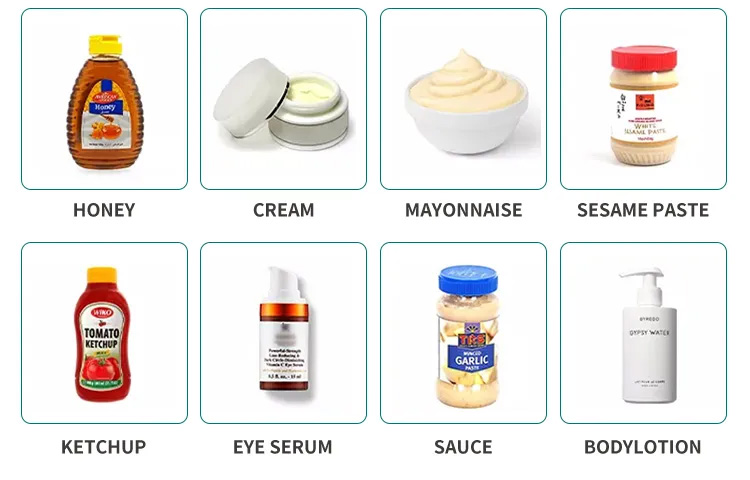

AIPAK shampoo filling machine production line can be also called high viscosity viscous liquid volumetric filling sealing and capping machine piston filling machine ,it has been widely used in daily chemical industry, cosmetic, food industry ,high viscosity materials, shampoo, hair condition cream, hand cream dish washing liquid and so on, the effect is obvious. Its filling method can be customized according to your different material , if your material is low viscosity material , suggest use gravity flow filling machine, if your material is high viscosity material , suggest use piston filling machine .

If your material have many foam, also can customize vacuum filling and diving filling , If you don’t have fluidity, easy to precipitation , you can customize mixer and heating hopper above filling machine.

Difference:

Use servo motor double rod driven system make the filling volume accuracy reach 99% and machine running very stable. Filling volume adjustable no need change any part.

AIPAK Shampoo Filling Machine Products

FEATURE

- It is suitable for filling containers of different specifications, and the filling specifications can be switched within a few minutes, the filling cycle is short, and the production capacity is high.

- Users can choose the number of filling heads to determine the number of filling heads according to their own production capacity.

- The electrical components of international brands are adopted, with low failure rate and reliable performance.

- Setting parameters through the touch screen can display the production status, operation procedures, filling methods, etc., with simple operation and convenient maintenance.

- The material contact part is made of 304# stainless steel, which has the advantages of strong wear resistance, good insulation and strong corrosion resistance, and meets GMP standards.

DATA SHEET

|

Filling Range

|

50-1000ml

|

50-1000ml

|

|

Filling Speed

|

15-25bottles/min (Base on 100-500ml)

|

20-35bottles/min (Base on 100-500ml)

|

|

Measurement Accuracy

|

±1%

|

±1%

|

|

Power

|

220V, 2.2kw

|

220V, 2.5kw

|

|

Working Air Pressure

|

6-7kg/m³

|

6-7kg/m³

|

|

Gas Consumption

|

1mpa

|

1.2mpa

|

|

Weight

|

600kg

|

700kg

|

CONTACT

Get in touch with an expert

Andrew Yang

Engineer Director

Phone: +86 189 7157 0951