Filling accuracy can reach ±1%

Unique filling valve design, no leakage

With no bottle no filling

Want A Free Consultation

Spice Coffee Powder Filler Glass Bottle Filling Machine Automatic Protein Powder Filling Machine

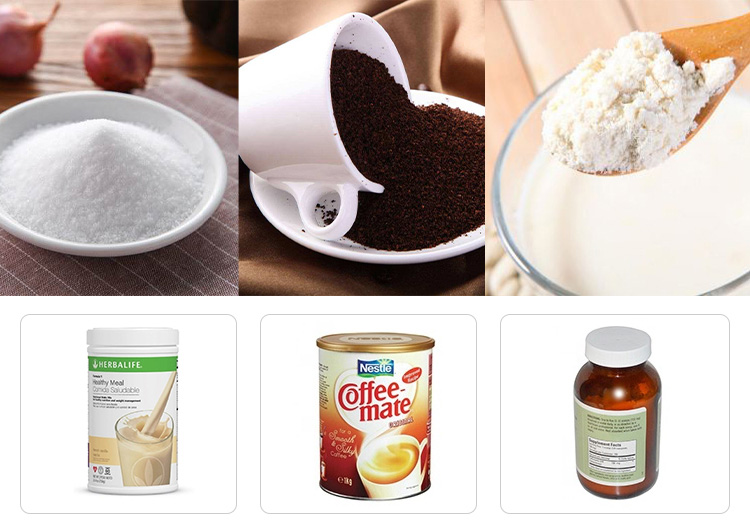

AIPAK APK-Q1-S protein powder filling machine is an automatic dual lanes filling machine,designed to dose all kinds of dry powder into rigid containers,such as bottles, cans and jars etc. With two filling lanes design,this protein powder filling machine can make two containers get filled at the same time.The machine has high filling capacity, compact design, stable performance ,good price ,high reliability and it is easy to operate. It could fill both fluidic or low-fluidity materials, like milk powder, albumen powder, pharmaceuticals, condiment, solid drink, white sugar, dextrose, coffee, agriculture pesticide, granular additive, and so on.

The protein powder filling machine works by the bottle direct feeding system is combined with the powder vertical feeding system. When empty bottles arrive at the filling station and are stopped by the indexing stop cylinder (gate control system) after a preset time delay, filling will automatically start. When the powder set by the preset pulse number is released to the bottle, the stop cylinder will retract, and the filled bottle will move to the next station.

AIPAK APK-Q1-S Protein Powder Filling Machine Applications:

FEATURE

1.Stainless steel structure。The quick disconnecting hopper or split hopper could be washed easily without tools.

2.This is a automatic auger type can/bottles metering filling machine ,designed for metering and filliing various dry powder into different rigid containers: can/bottle/jar etc.

3.The machine provides powder metering and filling functions.

4.Bottles and cans are introduced by conveyor belt combined with gating system.

5.There is a photo eye sensor for bottles detection so as to achieve bottle-fill ,no-bottle no-fill.

6.Automatic bottle positioning-filling-releasing,optional vibration and elevation.

DATA SHEET

|

Model |

APK-Q1-S100 |

APK-Q1-S160 |

|

Working position |

2 lines + 2 fillers |

2 lines + 2 filler |

|

Filling weight |

1 - 500g |

1 - 2000g |

|

Filling Accuracy |

≤ 100g, ≤±1.5%;100 – 500g, ≤±1% |

≤ 100g, ≤±1.5%;100 – 500g, ≤±1%;500 – 2000g, ≤±0.5% |

|

Filling Speed |

50 – 70 bottles per min |

50 – 70 bottles per min |

|

Power Supply |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

|

Air Supply |

6 kg/cm2 0.05m3/min |

6 kg/cm2 0.05m3/min |

|

Total power |

2.0Kw |

2.6Kw |

|

Total Weight |

240kg |

400kg |

|

Overall Dimensions |

1185×940×1930mm |

2000×1050×2030mm |

|

Hopper Volume |

45L |

85L |

VIDEO

CONTACT

Get in touch with an expert

Andrew Yang

Engineer Director

Phone: +86 189 7157 0951