Your Premier Automatic Condom Cartoning Machine

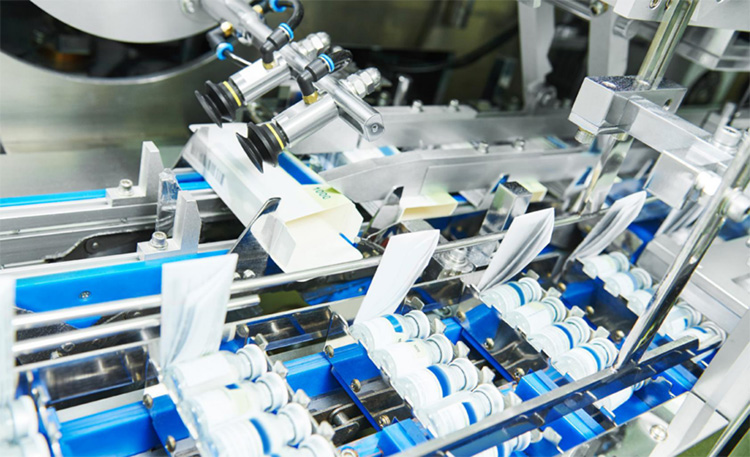

Automatic Sachet Feeding Device

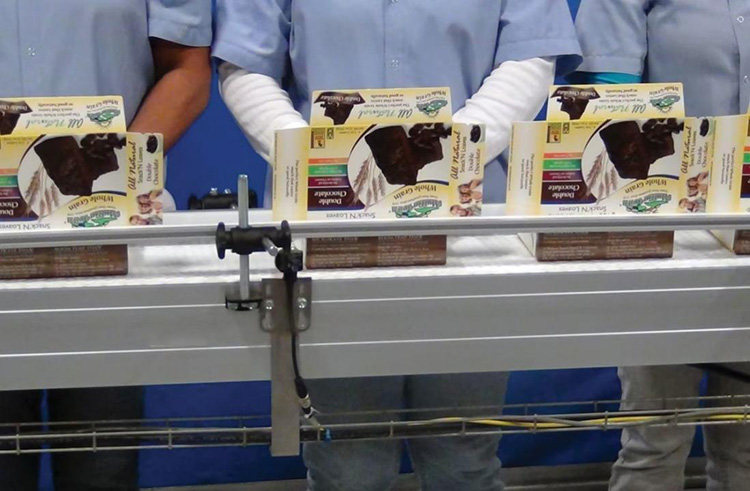

Product Inspection

Unqualified Product Rejection

Box Sucking & Shaping

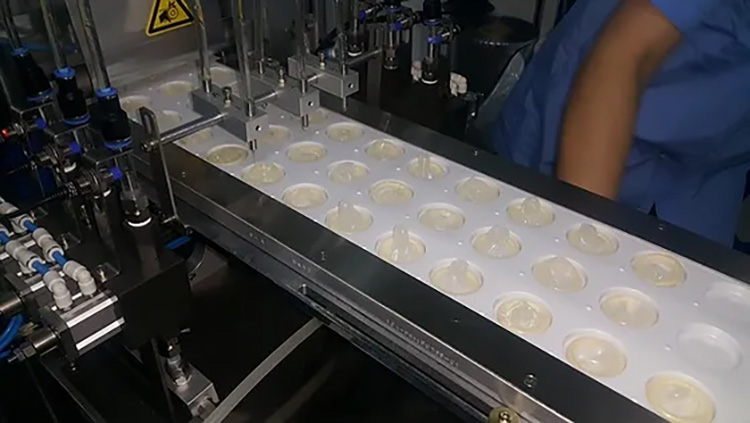

AIPAK Condom Cartoning Machine

AIPAK condom cartoning machine is suitable for packaging sachet,condom,adhesive bandage,soft ALU strip,plaster,coffee bag,face mask and similar product.It is new model developing based on integrated domestic and foreign vanguard technology. It is high technology product incorporates pneumatic-photo-electro-mechanic which improve by a large on performance of equipment and working efficiency, realize encasing fast, keep running steady and reliable when fast running.The machine is suitable for packaging sachets into carton. On line product feeding and detecting, leaflet fold(1-4folds) and feeding, leaflet detecting, carton opening and forming, products and leaflet pushing into carton, printing batch number, sealing carton with tuck-in or hot melt glue device. Automatically reject lacking of leaflet or product and finished product out.

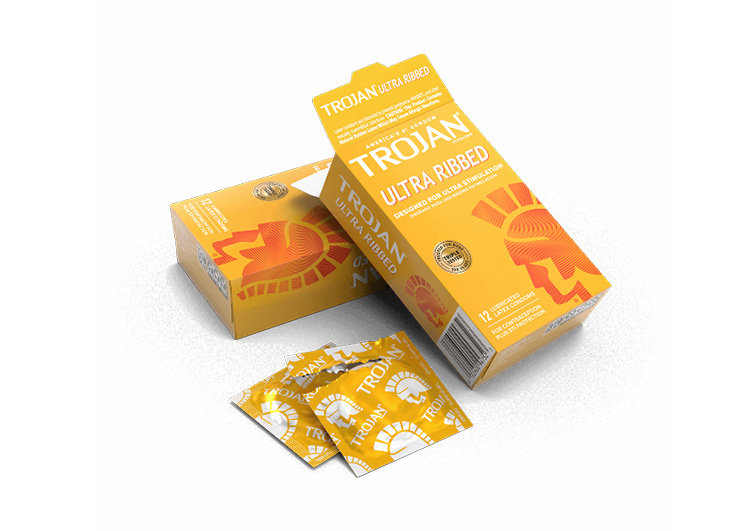

Condom Cartoning Machine Application

Condom Cartoning Machine Videos

The Buyer's Guide

Condom Cartoning Machine: The Complete FAQ Guide In 2025

A condom cartoning machine has Revolutionized the packaging industries around the globe. From the very first, it helped every business streamline in countless ways in terms of sprouting productivity, high demand, and better outcomes.

For companies, who’re willing to buy condom cartoning machines; we suggest reading this article for better procurement, operational, and troubleshooting steps.

So, Let's Get Started!

1.What Is Condom Cartoning Machine?

A condom cartoning machine is the most suitable equipment for storing condoms. Condoms require ultra-hygiene therefore the machine is ideal where entire processes are taken place automatically.

This is a specialized packaging unit that produces, closes, fills, and seals the cartons. The process begins with a flat card where the erection, loading, and flipping of the carton are carried out smoothly.

It offers visual monitoring of the entire procedure such as product transferring into the boxes, inkjet printing, leaflet insertion, adhesion, and folding cartons, etc.,

2.Which Products Does Condom Cartoning Machine Specially Use For Packaging?

Just like pants, condoms are also designed in various shapes like slim fit, snug, tight fit, etc., A condom cartoning machine is specially used for packaging products like:

| Product Type | Description |

| Straight Wall Reservoir Tip

|

A standard condom structure with equal width from the base to the head. |

| Tapered, Flared, or "Baseball Bat Shape"

|

A condom with gradual widening from the base to the tip. |

| Small Bulbous End

|

A condom that is designed with the same width (base to the head). |

| Snug Base

|

A snug base condom where a central structure is wider than the base has a band narrow tip. |

| Straight-Walled, No Reservoir

|

With a rounded end, the entire condom is of the same width from the base to head. |

3.What Is the Significance Of The Condom Cartoning Machine?

In this age, many industries require condom cartoning machines because of their benefits, some of them are:

Concurrent Filling and Packing

This machine performs a simultaneous filling and packaging job with different auto-feeders. You can set a number of products and adjustments every time by using a touch screen.

Packing Multiple Pieces

The condom cartoning machine offers ultimate flexibility and high speed. It is easy to use where condoms are packed as 1/2/3/4/5/6/10/12 pieces into each carton. Thus, the machine has magically reduced the footprint of the entire system by two third.

Rejection of Unqualified Cartons

A condom cartoning machine offers user-friendly functionality. It rejects cartons without condoms or instruction paper. It can alter during trouble; you can analyze the problem via visualizing the process on the screen. Moreover, the entire process is simple to operate following supportive keys and software on HMI touchscreen.

Safety and Sanitation

A condom cartoning machine is often a good solution where there is a humid conditions. A hot glue sealing allows tuck in closing that eliminates chances of water pooling or moisture content. A sanitary vacuum unit ensures a dry and hygienic environment.

Compact Structure

Condom Cartoning Machine- Photo Courtesy-cspacker

A high-speed condom cartoning machine now eliminates the need for extra integrated devices, such as a conveyor. The whole process takes place under an inline and smooth conveyor without requiring additional perpendicular platforms for transferring cartons.

Easy Changeover

Switching from one size carton to another is not an easy job. The automatic condom cartoning machine has transformed this hectic job into a flexible way while simply pushing a button. The machine allows rapid changeover by feeding the protocol on the HMI.

Excellent Performance

An excellent condom cartoning machine defines your business with more output that utilizes little energy. The machine’s enhanced performance is highly effective for you in terms of bespoke production and speed variability.Moreover, the machine is equipped with a leaflet folding unit that allows tremendous performance that saves time.

Cut-Down Production Expenditure

Indeed, the manual procedure is time consuming, expensive as well as difficult to manage. The condom packaging machine is, therefore, a great solution for reducing manual labor and allowing beneficial packaging with low production costs.

4.What Is the Working Principle Of A Condom Cartoning Machine?

The working principle of condom cartoning machine is described as followed:

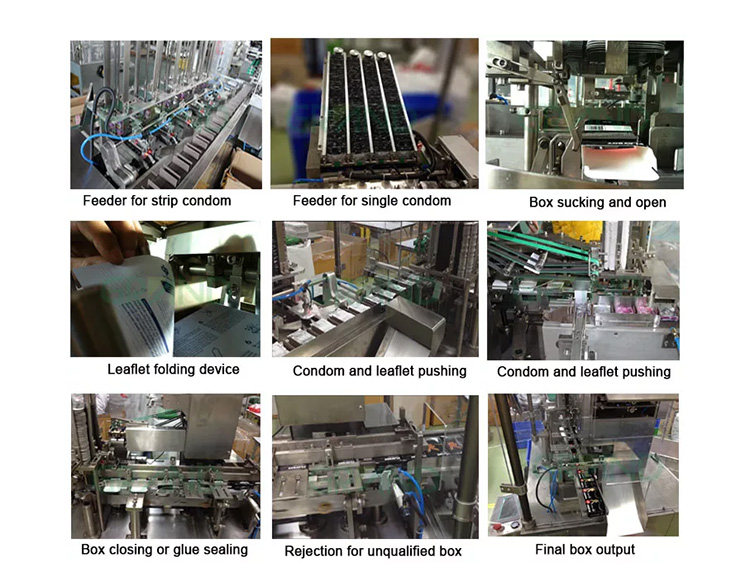

FEEDING CONDOM

The condom packaging process starts when a condom is received from the feeder, while cartons are released from the carton magazine for opening.

BOX SUCTION AND OPENING

A suction box helps in taking out and opening the edges of the carton on the moving rail. Cartons are then conveyed to the loading bay where it is opened and erected for loading purposes.

FOLDING AND PUSHING CONDOMS &LEAFLETS

The guide rail fixes the cartons, condoms, and leaflets are pushed smoothly inside the box via an opened end.

BOX CLOSING OR GLUE SEALING

Now, a filled carton is subjected to folding and sealing by the application of adhesive or hot melt glue.

OUTPUT

A filled carton is discharged through a carton chute.

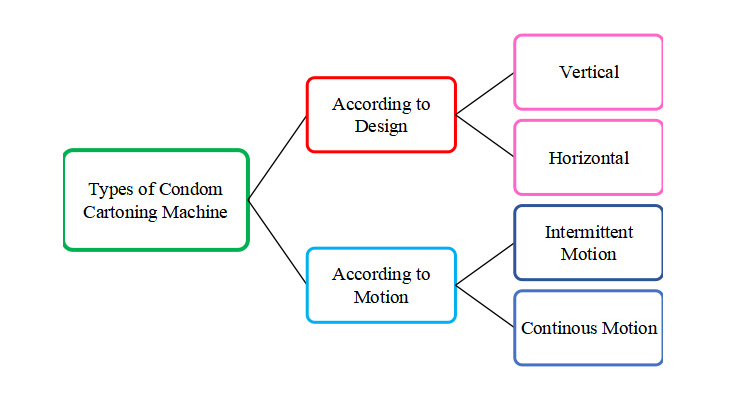

5.What Are The Types Of Condom Cartoning Machines?

The condom cartoning machine is divided into two following types.

A Vertical Intermittent Condom Cartoning Machine

A Horizontal Continuous Condom Cartoning Machine

ACCORDING TO DESIGN

Vertical Condom Cartoning Machine

A vertical condom cartoning machine can pick cartons from stacked boxes that move through the system in an upright position. In this machine, condoms are introduced into the carton from an opened end. The machine turns the corners of the carton and with the help of glue, it is sealed firmly.

Horizontal Condom Cartoning Machine

In terms of machine design, a horizontal condom cartoning machine is different from a vertical one as the product is horizontally introduced into the carton. Once, the product is entered inside the box, it is then closed and sealed.

ACCORDING TO MOTION

Intermittent

This motion allows condoms into the carton via back-and-forth movement of the pushrod. Once the procedure of loading, filling, and leaflet insertion is completed the carton moves and the next comes.

Continuous

This is a fast procedure where entire steps such as loading, folding, filling, and sealing takes place in a continuous motion.

6.What Are The Components Of A Condom Cartoning Machine?

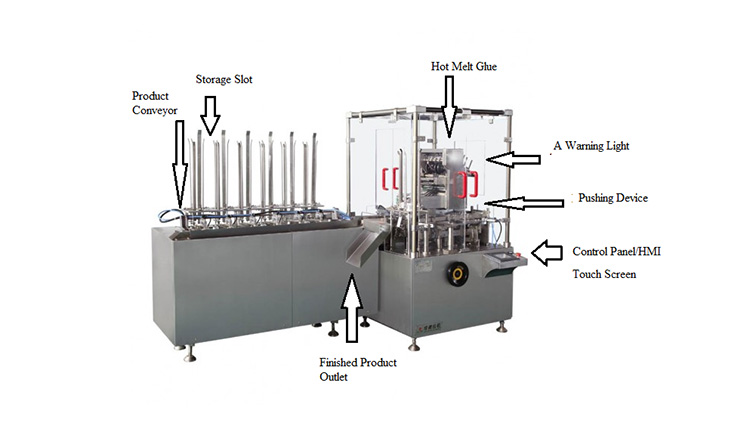

Main components of AIPAK condom cartoning machine

A condom cartoning machine is a complex piece of equipment in the term of parts yet offers a simple operational solution. The common parts of condom cartoning machines are as followed:

Product Conveyor

Conveyors are employed to transfer cartons. The system is driven by motors that have a gearbox attached. It is close to ‘eye-detector’ and adjustable up to carton size and style.

A Warning Light

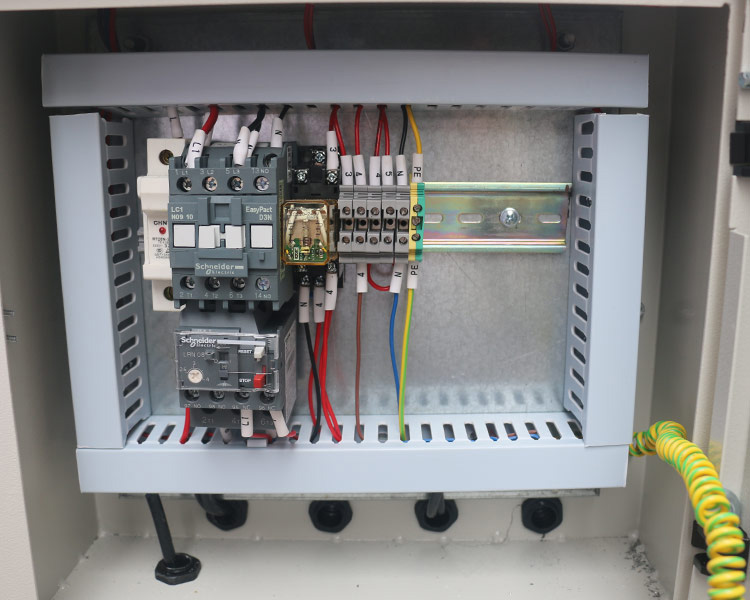

To ensure safety, a warning light is equipped that is connected to the electrical panel.

Control Panel/HMI Touch Screen

The control panel is utilized to supervise and adjust the production process of a machine, as well as to inform operators of any malfunctions. The equipment is inculcated with a Programmable Logic Control (PLC) system more commonly known as the Human Machine Interface (HMI) which provides flexibility in the production process.

Pushing Device/Carton Pushrod (Pneumatic Unit)

The pneumatic system consists of a motor and pushes plates. The electricity from components is used to push the carton for loading purposes.

Storage Slot

A set of packed condoms are fed into this section for the packaging process.

Finished Product Outlet

This section ensures discharging of filled cartons from the system.

Leaflet Inserter (Optional)

This device helps in folding and insertion of instruction paper into each carton.

Hot Melt Glue

This is suitable for carton closures where a nozzle spray facilitates hot melt glue over the carton’s edges to seal it.

Carton Picker/Feed Inlet

The process begins when the feed inlet ensures the entrance of the flat carton into the system. This is also known as a feed inlet. Upon receiving the command from PLC, this device picks a blank carton from the carton magazine and places it on the bucket rail or conveying rail.

An Ink-Jet Printer

The condom cartoning machine is equipped with an inkjet printer that has three lines of text. This printer provides options for including the date of manufacture, expiry date, and any other information

Gearing System

The electrical system provides energy to the pneumatic system and the electric panel is where all the wires are connected. When a cartoning machine is working properly, the motors in its gearing system transmit mechanical movement to other parts of the machine.

Vacuum Suction Device

In the cartoning process, vacuum suction is utilized to pick the blank cartons. This system is made up of back, mid, and front plates, which are modifiable. Here, a press button is available which is there to push if the carton gets damaged during the procedure so that the machine stops.

7.What Are Essential Certificates When Buying Condom Cartoning Machine?

When buying a condom cartoning machine, it's important to ensure that the machine has the necessary certifications to ensure that it meets industry standards and regulations. Here are a few essential certificates that you should look for:

| 1. CE Mark | The CE Mark is mandatory that certifies that the condom cartoning machine meets the safety, health, and environmental requirements of the European Union (EU) directives. |

| 2. UL/CUL Certifications | UL and CUL certifications ensure that the condom cartoning machine meets the safety standards for electrical and mechanical equipment in the US and Canada. |

| 3. ISO 9001 | This is a quality management system certification issued by the International Organization for Standardization (ISO). It certifies that the condom cartoning machine manufacturer has a robust quality management system in place to ensure that the machines they produce meet the needs of their customers and are of good quality. |

| 4. GMP Certifications | GMP stands for Good Manufacturing Practices. This certificate guarantees that the machine has been manufactured with strict hygiene and quality standards, which is of great importance if you produce food, pharmaceuticals, or similar products. |

| 5. FDA Certifications | FDA Certifications are issued by the US Food and Drug Administration (FDA) and are applicable for condom cartoning machines that are used in the food and pharmaceutical industry. The FDA certifies that the machine meets the relevant safety standards for food and drugs. |

Finally, when buying a cartoning machine, it's important to ensure that the machine has certifications such as CE Mark, UL/CUL, ISO 9001, GMP, and FDA, which assure the machine meets the safety and quality standards for the region where it's going to be used and for the industry, you operate in.

8.What Are Common Technical Problems And Solutions Of Condom Cartoning Machines?

Condom cartoning machines, like any other type of machinery, can experience technical problems that can affect their performance and efficiency. Some common technical problems that can occur with the machine, along with their potential solutions, include:

Jamming

| Problem | Solution |

| Condom Cartons can become jammed in the machine, causing it to stop. This can be caused by cartons that are not properly aligned or that have been damaged. | To solve this problem, operators should check the alignment of the cartons and ensure that they are not damaged before loading them into the machine. |

Product Feed Problems

| Problem | Solution |

| The products that are being packaged may not be feeding correctly into the carton, causing the machine to stop. This can be caused by a number of issues, such as poor product alignment, faulty product feeder or damaged product. | The solution would be to inspect the alignment of the products, ensure that the product feeder is working properly, and check the products for any damage before loading them into the machine. |

Glue or Tape not Applied Correctly

| Problem | Solution |

| The machine may not be able to apply glue or tape on the carton properly, which can lead the to cartons not being sealed correctly. This could be due to the wrong type of adhesive being used, a faulty glue or tape dispenser, or a lack of adhesive. | To solve this problem, operators should check the type of adhesive being used and ensure that it is suitable for the carton material, check the glue or tape dispenser for any issues, and ensure that the dispenser is supplied with enough adhesive. |

Incorrectly Coded or Labeled Cartons

| Problem | Solution |

| Cartons that are not coded or labeled correctly can cause problems with traceability and inventory management. This can be caused by a faulty printer or incorrect settings on the machine. | To solve this problem, operators should check the settings on the machine to ensure that they are correct, and that the printer is working properly. |

Electrical or Electronic Problems

| 9. Problem | 10. Solution |

| Condom cartoning machines can experience a range of electronic problems, such as faulty sensors or PLCs, or power supply issues, which can cause the machine to stop working. | The solution would be to check the sensors, PLCs, and power supply, troubleshoot, and fix them if they are an issue. |

Conclusion

When choosing a condom cartoning machine, it is important to consider the manufacturer's reputation, expertise, and after-sales service, as well as the proximity and customizability of the manufacturer's production range. We recommend contacting us to purchase affordable, bespoke, and high quality equipment for your business. We promise reliability. Send Us Message Now!

Cartoning Machine Related Posts

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586