Reliable Bin Blenders for Uniform Powder Mixing

GMP-compliant, contamination-free, and designed for pharmaceutical excellence

AIPAK Bin Blender

AIPAK bin blender can be also called an IBC blender, pharmaceutical blender,V blender,blender bin or blending bin,it can automatically complete lifting, clamping, mixing and descending tasks and can be matched with different specification pharmaceutical bins to satisfy large batch and various mixing. AIPAK bin blender is considered as ideal mixing equipment in pharmaceutical factory and widely used in pharmaceutical, chemical and foodstuff industries. Adopted with sensitive press and infrared sensors,AIPAK bin blenders could make uniform mixture of powers and granules.

Why Choose AIPAK Bin Blender?

High Mixing Uniformity

Ensures homogenous blending of powders and granules.

GMP & FDA Compliant

Hygienic stainless steel design with easy cleaning.

Flexible Batch Sizes

From R&D scale to large production batches.

Safe & Easy Operation

Automatic controls, safety interlocks, and low maintenance.

Applications of Bin Blender

AIPAK Bin Blenders are widely used across industries that require precise powder mixing:

Pharmaceuticals

APIs, excipients, and granule blending.

Nutraceuticals & Supplements

Vitamins, minerals, protein powders.

Chemicals

Pigments, fine chemicals, specialty powders.

Food & Beverage

Spices, cocoa, instant mixes.

Cosmetics & Personal Care

Powder-based skincare and makeup.

Agriculture & Veterinary Industry

AIPAK-Your Best Pharma Processing & Packaging Machinery Supplier In China

Download Our Latest Catelogue

Discover our full range of pharmaceutical processing&packaging machinery. Download the catalogue to explore specifications, features, and applicatons.

- Full product range

- Detailed technical specs

- Industry applications

Bin Blender FAQ

Q1: What is the working principle of a bin blender?

A bin blender works by rotating a container (bin) at a specific angle, allowing powders to tumble and mix evenly without generating excessive heat or friction.

Q2: What materials can be mixed in a bin blender?

It is commonly used for dry powders, granules, and pharmaceutical ingredients that require uniform blending without particle degradation.

Q3: How does a bin blender ensure uniform mixing of powders?

The bin rotates along a fixed axis, creating a three-dimensional movement that prevents segregation and ensures homogeneity.

Q4: What is the difference between a bin blender and a V blender?

A V blender is fixed with a limited mixing volume, while a bin blender allows multiple bins of different capacities, making it more flexible and efficient for batch production.

Q5: What industries commonly use bin blenders?

Pharmaceutical, food, chemical, and nutraceutical industries use bin blenders to achieve consistent powder mixing.

Q6: How to choose the right bin blender capacity for production?

Capacity depends on batch size, production scale, and material characteristics. Generally, bins range from 50L to over 2000L.

Q7: Is a bin blender suitable for handling sensitive pharmaceutical powders?

Yes. Bin blenders are designed to minimize dust, cross-contamination, and product loss, making them suitable for sensitive APIs.

Q8: What safety features are included in pharmaceutical bin blenders?

Safety interlocks, overload protection, and dust-proof designs are commonly integrated to comply with GMP requirements.

Q9: How easy is it to clean and maintain a bin blender?

The detachable bin design makes cleaning straightforward, and most models support CIP/SIP systems for efficient maintenance.

Q10: What are the GMP compliance requirements for using bin blenders?

Bin blenders must ensure validated cleaning, traceability, safety features, and uniform mixing performance according to cGMP guidelines.

The Buyer's Guide

What is Bin Blender or IBC Blender? The Complete FAQ Guide in 2025

Are you looking to mix, blend, disperse, or homogenize your pharmaceutical ingredients?

If yes, here may be right for you.

You may have known effective mixing is an essential part of the pharmaceutical industry. Even though in this application the requirement may vary, the ultimate achievement is generally the same, to have a homogenous pharma product.

Efficiency mixing may also influence the accuracy of dosage, stability, product appearance, and texture.

Proper mixer selection is therefore of paramount importance in the production of medicines or cosmetics.

In today’s guide, I will lead you to an overview of pharmaceutical bin blenders.

1. What is Bin Blender?

AIPAK Bin Blender

A Bin Blender is a free-fall blender which is also called a powder blender or V blender.

It is a mechanically and electrically integrated gear which have the technology of variable frequency control and a PLC control panel.

Bin Blender can naturally finish all activities of the blending container including cinching, lifting, and blending.

2. What is IBC Blender?

The intermediate bulk container is a special type of blending container that is designed for the homogenous mixing of the material in large quantities.

AIPAK IBC Bin Blender

Due to the irregular shape of this container, it is highly proficient in blending the material. It is easy to charge or discharge this container away from the blender. It is easy to mix different products in a short period with the Ibc Bin Blender.

3. Are there any Differences between a Bin Blender and a Mixer?

Yes, there are differences between a bin mixer and a bin blender these are the major differences;

| BIN MIXER | BIN BLENDER |

| 1.Bin Mixer works on low shear mixing for the production of homogenous solution due to this it has slow production.

2.Bin Mixer is working on the latest technology like NIR and light-induced fluorescent which improve the productivity 3.Bin Mixer does the work with an aggressive approach it beats the products that are mixing. |

1.Bin blender is a free fall type blending machine that makes the homogenous solution in much less time.

2.Bin Blender can naturally finish all the operations of the blending container including cinching, lifting, and blending of the material. 3.Bin Blender works on the gentle approach it handles the product very gently which enhances the quality of the product. |

4. What is Bin Blender used for?

Out of the many uses of the machines, below are some major uses are these

Bin Blender is used for the mixing of the powder and grainy material.

Powder and granules

- It is used for the mixing of the capsule filling material in the pharmaceutical Industry.

- It is used for the homogenous mixing of the material.

- It is used for doing all the action of mixing at one go, these are the actions that include lifting of the material, lowering of the material, rotation of the material, mixing and clamping of the material.

- It is also used for the charging and discharging of the material.

- It is used to blend the material in the bulk quantity using the intermediate bulk container.

5. Where is Bin Blender used? What are its Applications?

Bin blender is used in many industries for many different purposes. These industries are

Pharmaceutical Industry

Tablet and capsule

Bin Blender is a major tool in the pharmaceutical or drugs industry. It is used for the mixing of different materials which is used in medicine like chemicals and drugs.

Some chemicals may be dry powder, liquid, or granules. You can mix dry, liquid, or granular material chemicals altogether and make the solution with the bin blender.

It is used for the mixing of the product that the tablet is made of and the powder that is in the capsules.

Food Industry

Bin Blender is used in the food industry for mixing different products like blending syrup into chocolate powder.

Powder (Nuts)

Chocolate syrup

It is used in this industry for the making of chocolate syrup and many more products. You can blend any lubricant with any powder or granules with the bin blender.

Chemical Industry

In the chemical industry bin blender is used for the making of new chemicals by mixing different chemicals and it can maintain the quality of the product.

The major factor of bin blenders is that they can blend the material in large quantity that is why all the major industries use bin blenders.

6. How many types of Bin blenders are there?

There are three types of bin blender and these are

1- IBC Bin Blender

2-Double cone Bin Blender

3-Multi direction Bin Blender

IBC Bin Blender

IBC Bin Blender is the type of bin blender that is used to mix the different materials. This material can be powder or any lubricant.

AIPAK IBC Bin Blender

As you should know IBC stands for Intermediate Bulk Container. It is used for mixing the material in bulk. It is considered as the best machine for blending.

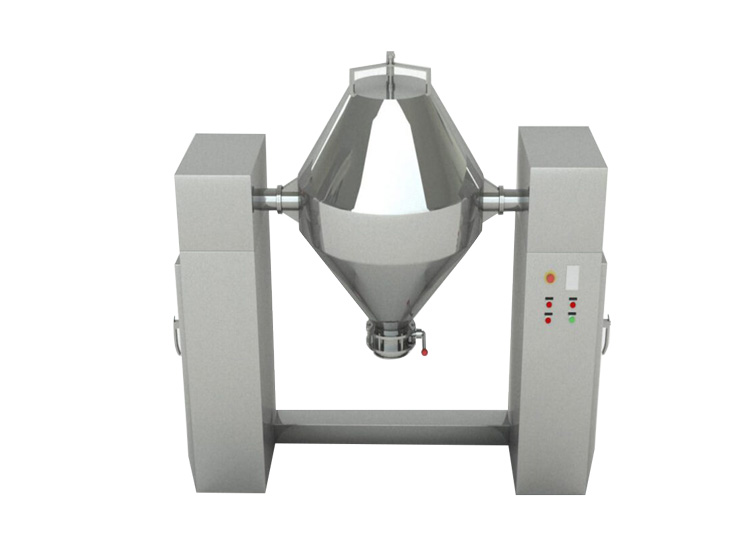

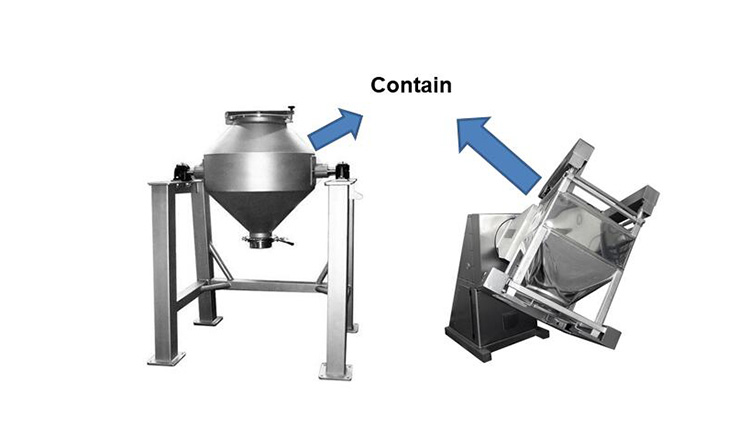

Double cone Bin Blender

Double cone bin blender is a type of bin blender. This machine is of a cone shape on both sides.

Double cone bin blender

It is used to mix granules and powder and make a solution out of it. It can mix the material up to 70 percent.

Multi-direction Bin Blender

Multi multi-direction bin blender is the type of bin blender that is very accurate in mixing the product because its mixing container goes in multiple directions. The mixing rate of a multi-direction bin blender is 99 percent.

7. What are the differences between the various types of Bin Blenders?

| IBC Bin Blender | Double cone Bin Blender | Multi-direction Bin Blender |

| The shape of the IBC Blender is customizable, it can be a square rectangle or V shape with the intermediate bulk container you can blend the material in bulk. | The shape of the Double cone bin blender is conical on both sides of the container. You can add the paddle-shaped baffles to improve the blending. | Multi-direction bin blender is the most efficient blender, it can blend the material by moving the container in all directions. It is up to 99 efficient. |

8. What is V Blender?

V blender is the most used blender. It is a V-shaped blender that mixes the product by rotation of the V-shaped container. It is very accurate, and it mixes the material in a very short period.

In this machine, two inclined cylinders joined each other to make a V-shaped container. The V-shaped container is made of stainless steel with an angle of 75 to 90 degrees. Due to the shape of this machine, it is also known as a twin-shell blender.

If you want the accuracy of this machine to be consistent you just must fill the container not more than 60 percent. If you fill the container more than 60 percent, there is not much space left for the mixing because of this the mixture is not homogenous.

It is very easy to operate the V blender. At first, you just need to put the mixing material in the v-shaped container. After that, you just must set the time and start the blending. After blending just discharge the product.

9. What is Bin Blender versus V Blender?

| BIN BLENDER | V BLENDER |

| The shape of the bin blender is customizable, you can customize the shape of the container according to your needs. This shape could be square, rectangle, or V. | The shape of the bin blender is not customizable. It has a V-shaped container which consists of two cylindrical containers joined at the angle of 75 to 90 degrees. |

| The container of the bin blender is movable, you can move the container anywhere on the shaft. | The container of the V blender is fixed to its shaft. You cannot move it anywhere you just rotate it. |

| It is not easy to charge and discharge the material due to its customizable shape of container. | It is easy to charge and discharge the material due to its V-shaped cylinder. |

| The speed of the bin blender is very high, and it can blend the material in less than 10 minutes. It can reduce the production cost. | The speed of the bin blender is less than the V blender. The production cost of a V blender is high. |

| Bin Blender is a free-fall type of blender.

Bin Blender is used for blending the product in bulk. |

V blender is not the free fall type of blender.

V blender cannot blend the product in bulk quantity. |

10. How will benefit from a V Blender?

It's crucial to think about the disadvantages & advantages offered, in choosing whether V blenders are the correct decision, just as secure more about the most suitable applications for this kind of equipment.

1-Mixers and blenders are available in the market in a different variety for commercial and industrial use. The right equipment selection for the industry & application in which it will be utilized is very important.

2-For the beverage industries and pharmaceutical, chemical, and food V blenders are the most famous kinds of blenders available.

3- The design and shape of a V blender additionally make it very simple to clean.

4- Accordingly, for use with delicate materials V blenders are appropriate. Besides, this sort of blender attempts to dispense with item pollution.

5- The dry blending of solids commonly utilizes a V blender that can do free-flowing. Because of that reason in the pharmaceutical business, this blender is frequently utilized.

Moreover, the V blenders can also be used with the following

Blended Material

- Coffee

- Baby foods

- Pigments

- Food products

- Pesticides & Herbicides

- Dry flavors

The V blenders can be a superb addition to many industries, given their many advantages and versatility.

This type of blender can limit molecule size decrease because of the nonexistence of any moving blades.

11. Why should you invest in a Bin-Blender?

Better Design

This machine has a very proper and well-maintained design.

Economical Investment

Bin Blender is an economical investment and affects the business in the long run.

Homogenization of the Material

The Bin blender assumes a significant helping hand in the pharmaceutical businesses where enormous volumes of material expect homogenization to meet demands, to limit the impacts of segregation, or to mix different pharmaceutical items.

Special Internal Blending System

Frequently, bin blenders are silos retrofitted or day bins with internal blending devices.

Improved Developments

The great association of the units has improved by the new turn of events. New advancements have broadened the scope of provisions that can be handled.

12. Are there any Disadvantages of Bin Blender?

Although the bin blender offers numerous advantages there are some expected disadvantages including the reality they are not regularly appropriate for blending/mixing of particles of various sizes and thicknesses that could separate as soon as they are released.

There are the following disadvantages of bin blender

- Cleaning problems.

- Intensifier bar tube close-up problems

- Element’s undesired wear and tear

13. What is the Function of the Rotating Angle of Bin Blender?

From the rotation axis, the gyrator is at 30 degrees angle. After giving the feed, you only have to set the cycle to start the mixing process & the desired speed.

To achieve the best mixing effect, it gives you a strong turning and high speed.

This can be done by operating the PLC Control System. Press the confirm button on the PLC touch panel. As you press the confirm button, the mixing process will be started.

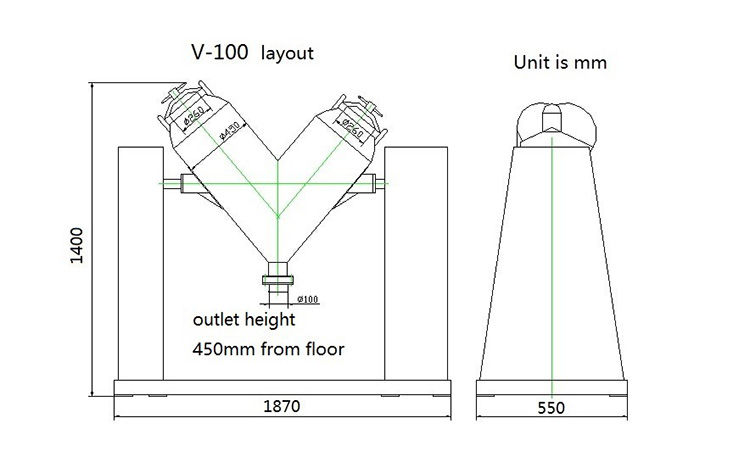

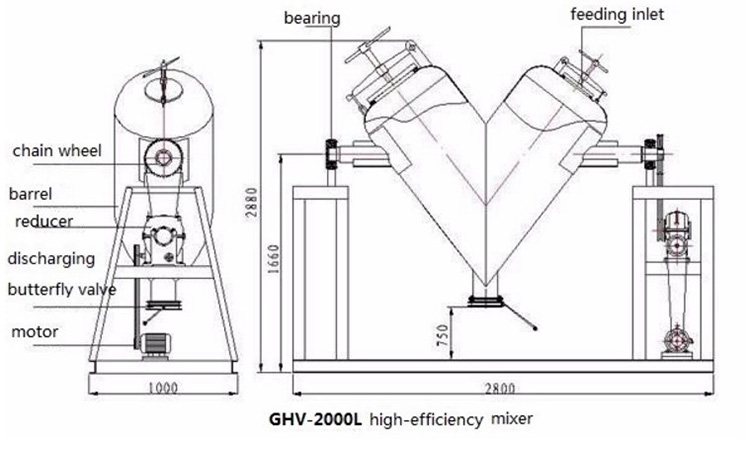

Technical drawing of Bin Blender

After completing the blending cycle, the brake system of the bin blender will force the rotating cage from turning to stopping. Once the rotating cage is on the ground, and at a parallel position, it means that the blending procedure has been done and now you can take the material for further processes.

14. What Materials can be processed by Bin Blender?

The material that you blend has a great impact on the general potency of this specific equipment. In general, the elements are available in distinctive characteristics.

For instance, you may comprehend that you have a large number of big particles

Powder Particles

In a few instances, the characteristics of substances to be blended also vary as well as the flow characteristics of the yield.

Mainly, you have to apprehend that distinct substances have distinct corrosives, temperature sensitiveness, and compaction characteristics amongst others.

So, you should make certain that you check out these kinds of factors since in one method or the other they affect the performance of this equipment.

15. What are the Main Components of Bin Blender?

If you want more production or efficiency then you have to focus on the parts of the machine i.e., Bin Blenders.

With low-standard components, it’s not possible to have the maximum output. Apart from having considerations like stability, user-friendliness, and structure you also have to think and explore various other components of Bin Blenders which have a great effect on the efficiency of machines.

As you all know the blenders and mixers are of various structures and designs. So, you should have technical knowledge about every vital part of the machine.

Following are the important parts of Bin Blenders, starting with

Rotation Counter

The rotation counter is one of the important parts of a Bin blender. To have a great homogeneous product it gives a mixing feature through ensuring that every one of the elements is blended effectively. particularly for a pedestal blender.

This component additionally gives extra competency in lifting and setting the Bin Blenders appropriately rotation counter plays a vital role.

The considerable element of the rotation counter is that it may accommodate numerous sizes of Bin containers. So, you also have to know about the length of the container you are going to use for the blending of the material.

This is accurate particularly if you have to mix distinct volumes of solid substances at distinct times.

Laser Guard

Laser Guard is also an important component of the bin blender. In the corner of the mixing suite, about 75mm above ground level the laser guard is placed.

Laser protection is important in terms of making sure of your security. Because it may locate humans as well as objects that might be inside or once they enter the threat region. It presents elegance and is more efficient in its capability.

So as a whole it prevents humans from harm, and it still does not have any effect on the elegance of the system.

The operators can pass around distinctive components of the secure location and conveniently operate the devices during material processing, the laser guard has an alarm system that is triggered upon the operator getting into the danger zone. every time the operator receives into the risk location the blender additionally plays an emergency stop.

This generally indicates how powerful this specific element is and the position it performs in material processing.

Clamping Bars

The clamping bars are generally supposed to offer assistance or balance to the unit. So, it stays solid regardless of the extent of vibration when it is under operation.

In maximum cases, you’ll discover that at the bin blenders, the clamping bars are welded. Considerably, through an elegant “C” frame blender those bars permit you to deal with the blender.

The different precise factor regarding this layout is that it permits having access to the valve and the lid & easy opening.

Operator Controls

These bin blenders are the most tech-orientated devices of the modern generation. So, it's really important to integrate the technology according to the duration of operations.

The simplest method of doing this is through the use of the controls present on the device. As a fact you can not operate if you don't know how the function of a machine works.

And secondly, it could be volatile even to try working it when you don't know how it works. So, the component controls, which luckily are properly marked facilitate you in making the project fairly easy.

Nevertheless, you want to recognize that it's far feasible to deliver a maximum of those operator controls to any specific stage of sophistication. Some are primary while others tend to be highly tangled.

So, for the duration of the process, you want to apprehend better what button does what. Only in this way you can have the production you want.

Light Guards

In improving the performance of the system at some stage in operation light guards assist you.

For a GMP finish these light guards consist of receiver units and a transmitter that you may flush mount in a wall.

This element helps the machine to give the maximum efficiency it can and it is also elegant.

Also, in the duration of the operation, they include the infrared beams which tend to be invisible.

Blending Container

The mixing or blending containers have various shapes and designs present in the market. This container is a place where all the processes take place.

Having the goal of greatest and homogeneous mixing, these containers are designed.

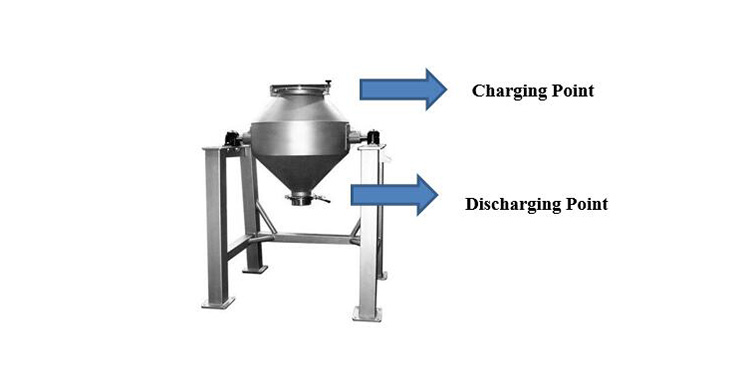

Discharging and Charging Ports

These are the two extreme points where all the fill and empty processes of the Bin Blenders happen.

Charging and discharging ports of IBC bin and mixer

While the bin is rotating to save your time from powder spilling the ends have to shape an airtight sealing. In general, they have powerful sealing mechanisms & valves.

These are the main components, and after having the technical knowledge of all of them it's easy for you to have maximum production.

16. What is the Bin Blender Working Principle?

Then there comes the most significant and vital question if you are going to buy Bin Blender. Yes, you guess it right. The working principle of the machine.

Working Principal

But before moving forward to have an idea of how this Bin Blender works you should watch this video.

As you all know Bin Blenders come in different shapes or structures or designs but the working principle is the same for all of them which is described below:

Step 1: Putting the best amount of material in the mixing container:

Before anything you have to fill your Bin Blenders container with the specific amount of substance or material you want to blend. The material shouldn’t be in a lesser amount or greater but it will be according to the capacity of the container.

Whether your blending container is removable or fixed the process will remain the same.

Step 2: Set the Mixing parameters from the PLC Panel

Once you fill the mixing container, clamp it as it should be on the primary stand of the system.

Then set suitable variables which can consist of blending or mixing time and velocity. After this, the system will start to revolve both in an anti-clockwise and clockwise course relying on the arrangement.

At the same time, the substance will circulate randomly in the mixing box or container. The final output or yield may be a uniform combination of the yield

Step 3: Stop the system and Empty the Product

After having the homogeneous mixing or blending, you have to stop the system and put out the blended material in a suitable container.

You should remember that your final product is homogeneous and blended uniformly.

17. What is AIPAK Bin Blender's Working Capacity?

You can have many Bin Blenders in the market having a wide range of their capacity but what machine should you choose?

Yes, you got it. AIPAK Bin blenders are present in the market with their best range of capacity which helps you to have the maximum output or production level.

Below, you can see some technical specifications for the AIPAK Bin Blender:

| Main Technical Specifications | General AIPAK Bin Blender Machine |

| A | 1500 |

| B | 1400 |

| C | 1900 |

| D | 3220 |

| L | 3054 |

| H | 2610 |

| Volume(L) | 1000 |

| Power(kW) | 5.5 |

| Weight(kg) | 2700 |

Technical specifications for AIPAK bin blender

Also, you have to be cautious while deciding on a bin blender holder. who can adapt to many material processing environments It's like a suggestion for those i.e., a system that could have a look at more than one bulk container. As you may know now, an AIPAK bin blender is an easy system, though in substance processing it performs an essential function.

From experience, the sourcing method has to be fine with the main functions of an intermediate bulk container blender.

18. What will affect the Efficiency of Bin Blender? What can you do to improve its Efficiency?

Before choosing an appropriate bin blender and mixer you always want to study thoroughly about its parts and other factors that may affect their efficiency.

The fact is that numerous traits affect how this type of unit operates.

Again, you need to recognize that strong pharmaceutical blending is an exceptionally complex system.

Now, we will discuss the numerous factors that affect the operation of the system in achieving its efficiency.

Cleaning of the Equipment

It is an essential issue that you want to keep in mind. This in particular involves while you want to combine batches of various natures concurrently in an equal unit.

It's very important to make sure that it is fairly much less hard to regularly and carefully clean the system. Plain tumbling is regularly less difficult to clean as long as there's the provision of enough openings.

Some of the sections that could be difficult to clean include the edges, crevices at baffle support, discharge points, and seals. If you come to know that it is rather hard and time-consuming to clean the system among one-of-a-kind batches, you must then not forget to do numerous small mixers.

Loading and Discharge Arrangements

These also are critical factors that additionally tend to be greater vital in terms of the non-stop operation mode.

Ideally, you need to keep in mind the entire managing machine to make it feasible for the system to achieve the most effective charging and discharging conditions.

Some of the elements that decide it consist of the usage of surge bins, weight hoppers, and the area of discharge gates.

In improving the continuation of the process others additionally consist of a minor aspect premixing in addition to every other specific extra tool utilized.

Mixing Homogeneity

Instead of enhancing an extended length of blending components is continually associated with worsening the performance of the procedure.

That's why you may speedily compare the mixing rate collectively with the mixing uniformity with the use of the layout graphs.

You furthermore may need to endure in thought the reality that the capacity for segregation additionally degrades the compatibility of the procedure.

Also, the solids blending can take place in a batch or a non-stop operation.

Powder ready for mixing

However, an important detail that you need to recognize is that a suitable blending layout produces the preferred mix in a quick time. However, if the placing is in batch mode this may best appear.

Power Requirements

These also are important issues that you have to have in thoughts while deciding on a Bin lender.

They do not appear to supersede the alternative concerns that are frequently essential in terms of figuring out the unit’s performance.

But still, there must be enough delivery of energy to assist in managing most needs apart from stopping adjustments throughout the blending process.

| Main Technical Specifications | General AIPAK Bin Blender Machine |

| A | 1500 |

| B | 1400 |

| C | 1900 |

| D | 3220 |

| L | 3054 |

| H | 2610 |

| Volume(L) | 1000 |

| Power(kW) | 5.5 |

| Weight(kg) | 2700 |

AIPAK blender system specifications

Again, while you deem speed variations desirable sufficient energy additionally turns into vital.

Residence Time

In a non-stop operation, it's far quite a hard assignment to decide the residence time. But in case you keep in mind the middle residences of mixing stable ingredients, you’ll realize that it occurs in the quickest time which can be possible.

Commonly, you may discover that in non-stop mixing ribbon kind mixer is utilized. you may use it for batch blending.

You additionally have to remember non-stop blending because the simplest opportunity on situations; while you may run a single system for a relatively lengthy period and while the fluctuations of the outgoing material fall inside the unique technique style.

Ingredients and Operating Conditions

The type of material which has to blend has a vital effect or influence on the general potency of this specific equipment.

In general, the elements are available in distinctive characteristics. For instance, you may comprehend that you have a large number of big particles

In a few cases, the characteristics of substances to be blended may differ along flow characteristics of the yield.

Mostly, you have to apprehend that distinct substances have distinct corrosives, temperature sensitiveness, and compaction characteristics amongst others.

So, you should make certain that you check out these kinds of factors since in one method or the other they affect the performance of this equipment.

19. Can Bin Blender Guarantee Homogeneous Blending?

Are you worrying about homogeneous mixing or blending?

You should not because, Yes! Bin Blender Guarantee Homogeneous Blending.

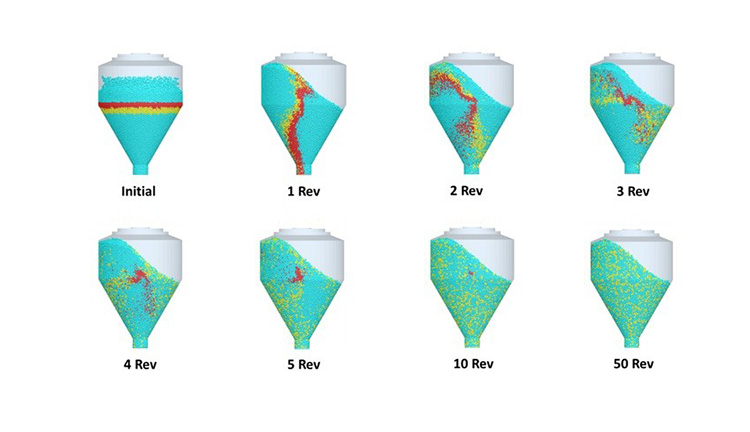

State of the blending process across different revolutions -Picture Courtesy: edemsimulation.com

Powder blending is an essential unit and keeping mixture uniformity or homogeneity is important because it dictates the standard of the very last tablet.

In those industrial sectors, they may be handy to handle as well as safe & secure. So, granular substances have regularly blended the usage of tumbling bin blenders.

20. What Quality Standards Should Bin Blender conform to?

Everyone knows that some quality standards are set by some famous organizations like cGMP, ISO, FDA, USP, Ph. Eur, and Japanese Pharmacopoeia.

Good Manufacturing Practices (cGMP)

The Bin Blender is being manufactured according to the standards of cGMP. It means that this product has a special certification from that organization.

Conformité Européenne (CE)

So, another well-known organization has given the certification to the Bin Blender. It means that the producer will take the guarantee of any inconvenience of the machine.

International Organization for Standardization (ISO)

The Bin Blender also has the certification from ISO which is another trusted authority. This assures us about the quality and safety of the product.

Food and Drug Administration (FDA)

The Bin Blender is also certified by FDA which is a very popular organization working in the country. So, this machine is well-approved and is responsible for the health of the public and the safety of the people.

Unique Selling Point (USP)

Bin Blender also has the verification from the Unique Selling Point (USP). It means that the product is better than your contenders. Also, it tells us that the product has the same components as listed on the label of the product.

European Pharmacopoeia (Ph. Eur)

The Bin Blender has also the certification from the best European organization. This organization has its own quality standards and Bin Blender has the same quality standards that are mentioned by the organization.

European Pharmacopoeia-Photo: europewatchdog.info

Japanese Pharmacopoeia

This certification of Japanese Pharmacopoeia tells us about the validity of the product. So, it means that the product has the same standards that are set by the company.

Japanese Pharmacopoeia-Photo: tsoshop.com

21. What should you consider when Importing a Bin Blender?

The Bin Blender is a great type of machine to blend materials like dry powders to make tablets from it and also you can do capsule production from it through the powder mixing method.

- It has a high-efficiency level.

- The accuracy of the machine is perfect as compared to the other machines.

- Also, the Bin Blender is very easy to maintain, we can mix large quantities of substance without much human effort.

- The Bin Blender is much more reliable as compared to the other devices.

- Although it is expensive and not easy to purchase it can give you comfort for a longer period.

22. How to Troubleshoot the Common Problems of Bin Bender?

Some common problems occur during blending. The first and the most ideal way to avoid the problems of a blender is to pick the right blender for work.

Following are the problems faced by the Bin Blender and the solution to fix those problems:

Erratic Dispensing

Dispense values are pneumatically activated, so to avoid that you have to provide better spotless, dry air at the pressing factor suggested by the producer.

After that, you have to check the air-chamber activity. In checking that problem, you have to cycle a few times with the manual actuator and check no air leaks.

Overloading of Bin

This problem occurred due to the overfilling of the Bin Blender. So, to avoid that problem don’t overload the Bin Blender otherwise it will not work properly.

No Filling of Bin

You have to check that the bin is filled with some material or it is unfilled before starting the Bin Blender. Also check that the material inside the blender is suitable for blending.

Otherwise, the blender may not work. And it may be

No Blending of Material

If this problem occurs during blending, you have to check whether the motor is working or not and also check all the components of the Bin Blender are working properly. If not then fix the problem and make it comfortable for working.

Improper Blending or Wrong Materials Proportions

This is a very common problem that takes place during the blending. To keep away from this problem you have to check the blades of the motor are working perfectly or uniformly.

Load Cell Operation

The last problem faced by the Bin Blender is the load-cell operating. To avoid that problem, you have to follow the instructions of the manufacturer. There is zero weight calibration action which will tell you by the producer to make it to the full weight calibration.

23. How to maintain Bin Blender?

Proper maintenance is necessary for bin blenders just like other machines required to be maintained for efficient and problem-free functioning.

Without maintenance, the working of these blenders can be difficult. Their annual inspection is advised for maintaining the blending accuracy.

1- You should ensure that all the valves open and close efficiently and quickly. The operator should check for wear and tear on different parts of the machine.

2- All the connections to the air cylinder should be checked to make sure they are not broken. One should check the cylinder's positioning.

3- Airlines and air pressure fittings must also be checked. Inspection of the bin blenders for any contaminants should also be done.

Dribbles should not be allowed from the valve when it is completely closed.

4- Weight bins should also be examined for consistency clearance on all sides for accuracy of measurement. If anything, wrong with it is found, it should be corrected before operating.

5- Mix chambers should also be examined for any sharp blades as they interfere with the working of the blender.

With the points mentioned above to maintain bin blenders, one can ensure their efficient blending for good results.

7- Bin Blender is a stain-free or dustproof machine. So, you have to know properly about the machine before importing.

8- Its flexibility is amazing. So that it can be easily fitted in the container during the method or importing.

9- It is a machine that can give you great help during blending. It is easy to use and very easy to clean. So before importing this machine, you have to keep these points in your mind.

Also, it is important to check how many voltages it uses during blending. So, the Bin Blender these days uses fewer voltages as compared to others.

10- You have to choose the Bin Blender which is efficient in working before importing. And also look at the performance of the Bin Blender in the sense that it can blend various kinds of materials. And the different sizes of material.

Also, they choose the best Bin Blender for working because it has many kinds and differs in sizes and shapes. Choose the one that can fit you and give you the work according to your needs.

Bin Blender Related Posts

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 156 0710 8630