Vacuum Emulsifying Mixer for Creams, Lotions & Ointments

Achieve superior homogenization, stable emulsions, and GMP-compliant production for pharmaceuticals, cosmetics, food, and chemical industries

AIPAK Vacuum Emulsifying Mixer

AIPAK vacuum emulsifying mixer is suitable for emulsification of pharmaceutical, cosmetic, fine chemical products, especially the material having high matrix viscosity and solid content, such as cosmetic, cream, ointment, detergent, salad, sauce, lotion, shampoo, toothpaste, and so on.

With advanced processing technology, imported brand motor, and converter that ensures AIPAK vacuum emulsifying mixer has a stable and good working performance. The mixing system of AIPAK vacuum emulsifying mixer is designed to manufacture different viscosity of creams and liquids,its speed can also be adjusted according to client preference. And all AIPAK vacuum emulsifying mixer vacuum system ensures successful operation by preventing bubbles from forming in the materials.

Comparison Table of Models

| Model | Best Suited For | Key Advantage |

| APKZRJ Up Homogenizer | Low-to-medium viscosity emulsions such as lotions, serums, cosmetic emulsions | High-speed top homogenizer, easy to maintain and clean |

| APKZRJ Bottom Homogenizer | High-viscosity creams, ointments, and heavy cosmetic pastes | Strong bottom shear force, ensures uniform mixing without dead corners |

| APKZRJ Fixed Type | Large-batch, continuous production in pharmaceutical and cosmetic plants | Stable design, fewer moving parts, long service life, low maintenance |

| APKYGJ Toothpaste Production Machine | Toothpaste, dental pastes, or other products requiring powder feeding and vacuum deaeration | Complete system with premixing, powder feeding, vacuum deaeration, and homogenization |

Applications of Vacuum Emulsifying Mixer

Pharmaceutical Industry

Vacuum emulsifying mixers are widely used for producing ointments, topical creams, gels, and syrups. The vacuum system eliminates air bubbles, ensuring smooth textures and stable formulations, while the GMP-compliant design guarantees product safety and regulatory compliance.

Cosmetic Industry

In cosmetics manufacturing, this equipment is essential for lotions, serums, foundations, and emulsions. The high-shear homogenizer delivers fine and uniform particle size, improving skin absorption, stability, and long shelf life.

Food Industry

Vacuum emulsifying mixers are applied in the preparation of sauces, mayonnaise, salad dressings, dairy products, and condiments. The vacuum environment prevents oxidation, preserves flavor and color, and ensures long-term product stability.

Chemical Industry

In the chemical sector, they are suitable for lubricants, emulsions, detergents, and coatings. The powerful homogenizing system ensures uniform dispersion of solid and liquid phases, improving product performance and consistency.

AIPAK-Your Best Pharma Processing & Packaging Machinery Supplier In China

Download Our Latest Catelogue

Discover our full range of pharmaceutical processing&packaging machinery. Download the catalogue to explore specifications, features, and applicatons.

- Full product range

- Detailed technical specs

- Industry applications

Vacuum Emulsifying Mixer FAQ

Q1: What is a vacuum emulsifying mixer and how does it work?

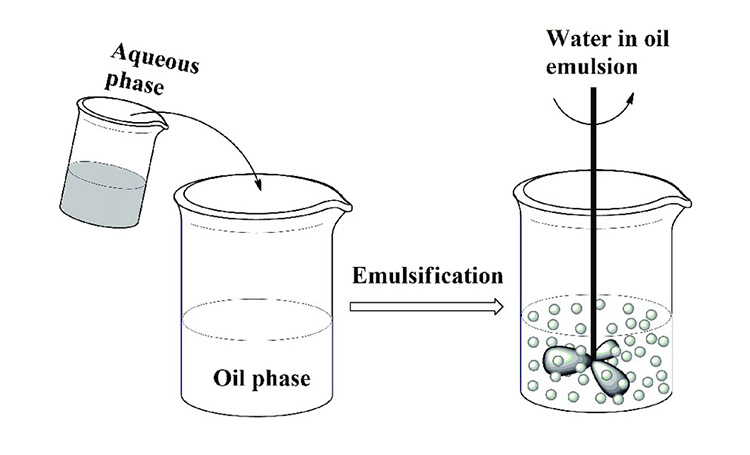

A vacuum emulsifying mixer combines mixing, homogenization, and vacuum technology to produce smooth, stable emulsions. The vacuum removes air bubbles, while the high-shear homogenizer ensures uniform particle size and consistent texture.

Q2: Which industries commonly use vacuum emulsifying mixers?

They are widely used in pharmaceuticals (ointments, gels, syrups), cosmetics (lotions, serums, creams), food (sauces, mayonnaise, dressings), and chemical products (emulsions, lubricants, detergents).

Q3: How do I choose the right capacity for my production needs?

Capacity depends on your batch size. Small-scale R&D typically uses 10–100L models, while mass production requires 200–2000L models. Our sales team can recommend the best model for your process.

Q4: What is the difference between top homogenizer and bottom homogenizer models?

Top homogenizer models are suitable for low-to-medium viscosity liquids and easy cleaning. Bottom homogenizer models are ideal for high-viscosity creams and heavy pastes, providing stronger shear at the bottom for uniform mixing.

Q5: Can the mixer handle high-viscosity materials?

Yes, models with bottom homogenizers or high-power homogenizers are designed to handle thick creams, ointments, and toothpaste-like products efficiently.

Q6: Does the equipment comply with GMP and other standards?

Yes, our mixers are made from SS304 or SS316L stainless steel, with polished surfaces and hygienic design, fully compliant with GMP, CE, and ISO standards.

Q7: How long does the emulsification process usually take?

Emulsification time depends on material viscosity, batch size, and desired texture. Typical ranges are 30–90 minutes for medium batches, but high-viscosity pastes may require longer.

Q8: Is CIP/SIP cleaning supported?

Yes, the vacuum emulsifying mixers support CIP (Clean-in-Place) and SIP (Sterilize-in-Place) cleaning, making maintenance efficient and ensuring hygienic operation.

The Buyer's Guide

How to Choose A Vacuum Emulsifying Mixer: the Definitive Buying Guide in 2025

A Vacuum Emulsifying Mixer is generally used for mixing of high viscosity material for emulsification.

Then produce the most common products we see like cream, ointment, lotion.

Now if you are looking for a vacuum emulsifying mixer, you may come to the right place.

Today, I am going to use this guide to explain everything including classifications, working principle, benefits, FAQ and common problems about the vacuum emulsifying mixer.

Getting to know all of them, you will make some of the best choice choosing the most suitable vacuum emulsifying mixer to skyrocket your business.

Let’s get started now.

1. What is Vacuum Emulsifying Mixer?

AIPAK Vacuum Emulsifying Mixer

The vacuum emulsifying mixer is a system for manufacturing dispersion, viscous emulsion, and the product suspension in large and small scale. The mixer work on the basic mechanism to prevent dead or hard corners and to purify products.

The system is used to purify and disperse several products which included ointments, lotions, creams and other liquids.

2. How does Vacuum Emulsifying Mixer Compare to Homogenizer?

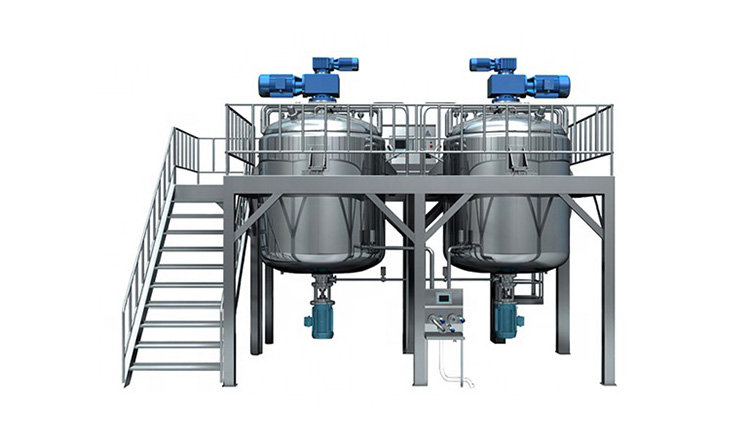

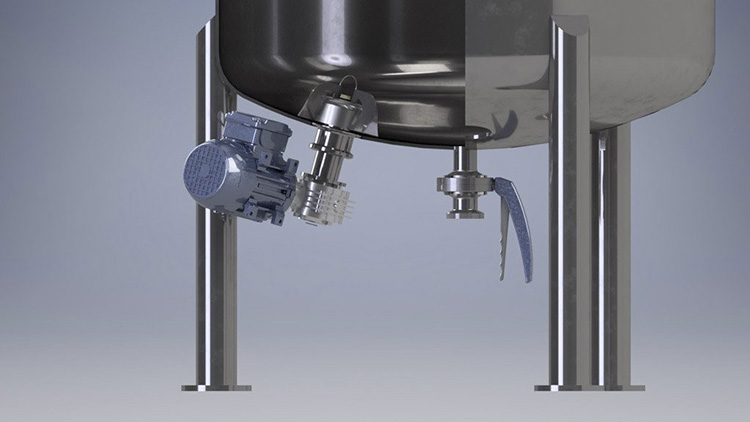

AIPAK Bottom Homogenizer

They both work on same mechanism of emulsification and dispersion. But as compared to the homogenizer, the vacuum emulsifier mixes the material uniformly and rapidly. The system work at high shear speed level and the dispersion happen in either one or few phases in less time.

In the vacuum emulsifier the kinetic energy is strong enough to force all heavy materials into the gap of rotor and stator. The mechanism will operate many shears within a limited time.

3. What is the Function of Vacuum Emulsifying Mixer?

The main functions of the vacuum emulsifying mixer like these:

Control the blending process

Controlling the blending climate into a vacuum state won't just forestall air circulation, which will prompt be blending sharp edge corruption. However, it will likewise accomplish sans void finished result combinations. Different manufacturing companies fabricate different kinds of vacuum emulsifier mixers to suit customer needs.

Offer medium clumps

The vacuum emulsifying mixer of RS type is suitable for little to medium clumps with similar limits as the RX Emulsifier of around 50L-2000L. However, it is generally reasonable for purifying creams or more liquid items. Then again, the emulsifying mixer RB mixture is appropriate for huge and nonstop bunches of emulsions.

All of these emulsifying mixer models can likewise have varieties for little and best budget hardware. For instance, if a customer has a low financial plan and needs an RX emulsifying mixer, the company or customer may pick a simplified mixer for the emulsifying process.

4. Which Industries Are Vacuum Emulsifying Mixers Widely Used?

Those industries who are allowed to use this mixer include:

Pharmaceutical industry

Pharmaceutical products by the vacuum emulsifier mixer

The vacuum emulsifier mixer is widely used in the pharmaceutical industry for making mixing products. The industry focuses on different mixing procedures which include making gels, preparations, ointments and product suspensions. The vacuum emulsifying tank is fully enclosed which will allow the product material to heat and disperse in fully save environment. The mixer will meet all requirements of sterility and hygiene.

Cosmetic industry

Cosmetic products by the vacuum emulsifier mixer

In the Cosmetics Equipment, or hardware in a beautifiers creation line, they are made out of a majority of corrective gear, and the emulsifying mixer assumes a fundamental part in these hardware or creation lines. The Emulsifying Mixer gear are generally utilized in the creation of restorative creams, treatments, moisturizers, toothpastes, and so forth

Chemical Industry

Liquid Detergent

In chemical industry,vacuum emulsifying mixer has been widely uesed ,such as product: washing powder, liquid detergent that we commonly used.

But also product like coatings and inks,ano materials,printing and dyeing auxiliaries and pesticide and fertilizer that as to its high shear mixer and emulsion.

Food Industry

Dairy Products- Photo Credit: Silversonmixer

Mayonnaise, dressings, jam, spread, and margarine are additionally being emulsified utilizing this machine in the food business. The business likewise utilizes this innovation to deal with thick source, cheddar, oral fluids, child food, chocolate, and sugar.

Apart from that ,in fact,there are other widely application of the vacuum emulsifying mxier,for example:the paper industry, plastic rubber industry and power electronics industry ,etc.

5. What Products Can Vacuum Emulsifying Mixers Produce?

vacuum emulsifying mixer product

The emulsifier used to purify cosmetic products which include

- Creams

- Ointments

- Liquids

The cosmetic industry uses this equipment to mic body lotions, creams, detergents shampoo and honey.

Drug ventures have likewise discovered this machine applicable in their product making field. They use it to handle treatments, oral syrups, latex, emulsions, and infusions.

Mayonnaise, jam, spread, and margarine are additionally being emulsified utilizing this machine in the food business. The business additionally utilizes this innovation to deal with thick source, cheddar, oral fluids, infant food, chocolate, and sugar.

6. What will you Benefit from Vacuum Emulsifying Mixer?

- A vacuum mixer for emulsification controls the blending climate, and it helps the manufacturers to prevent air circulation. It may cause blending sharp edge degeneration.

- The controlled blending climate additionally helps in getting without void final results.

- It is ideal for creating little, medium, and enormous clumps and huge amounts of fine items. Also the mixer can provide work limits of between 30L-2000L.

- It is become easy to purify and blend creams and other liquid items like hack syrups.

- It saves time since the manual technique takes a generally significant time-frame. The computerized machine gives a considerable energy input that speeds up the whole interaction.

- It overcome the rate of wastage that happened during manual blending. In this way it is making acceptable re-visitations of the handling business.

7. Is there any Disadvantage of Using the Vacuum Emulsifying Mixer?

- Likewise, the scrappers which are available in the vacuum mixing tank are not appropriate for making some abrasive items. They are likewise not suggested for items that are oily or sticky.

- Persistent rotation of the vacuum blades can cause excessive friction which can produces heat. The excessive heat can harm those products which are heat-sensitive.

8. What is a High Shear Emulsifying Mixer?

AIPAK High Shear Emulsifying Mixer

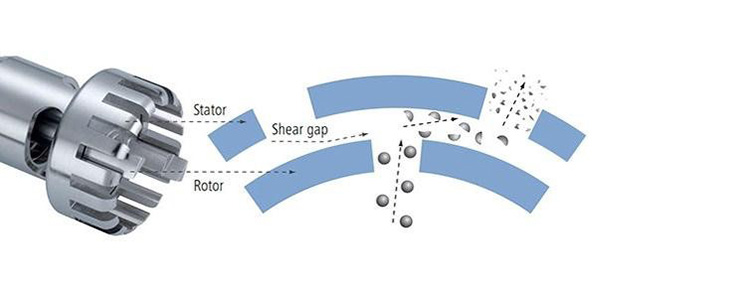

High Shear Mixers are also known as stator blenders. They are usually utilized in the creation of low-to medium-consistency emulsions up to around 10,000 cps. The customary rotor/stator blender produces its high shear attributes through the communication between a rotor running at tip speeds in the scope of up to 4,000 feet per minute.

Industry-wide, High Shear Mixers are utilized in the creation of emulsions for such different end employments. These machines are accessible in various designs and value, which depend on the blending power the industry needed to make dairy care products.

9. What is Low Shear Emulsifying Mixer?

Most of the companies that have low-class mixers use low shear emulsifying mixers. But some of them don't have a clear idea about the function and quality of their emulsifying mixers. Usually, the low shear mixers are used for making a different type of coffee. It has been reported the almost 50% of America's populace are espresso consumers that devour about 3.1 cups a day. That comes out to around 159 million individuals.

Low shear blending or low energy blending can clearly be meant the overall mixing of an item without compromising on the coffee blending cycle. Low shear mixers are a perfect option for those who have a low spending plan or want to make products that require minimum energy.

10. How does High Shear Emulsifying Mixer Compare to Low Shear Emulsifying Mixer?

| High Shear Emulsifying Mixer | Low Shear Emulsifying Mixer |

| The High shear emulsifying mixers depend on rotor/stator shearing activity. | The low shear mixers used to make those products require less fixing and energy. |

| High pressing and blending factor usually refers to the high shear mixers that provide high measures of energy to shape different products. | Because of their low rotor energy, the mixer is often used to alter low-energy products. |

| High shear mixers provide high velocity at the time of blending. | If you use the low mixer, then there are many chances that the blending quantity decreases. |

What to Choose?

High Emulsification homogeneous hardware tackles the issues of beauty care products, drugs, compounds, food, and different ventures professionally. The amazing engine of this mixer is based on the high-velocity theme to operate a vacuum between the rotor and the stator. The mechanism will allow the mixtures to blend properly in less time.

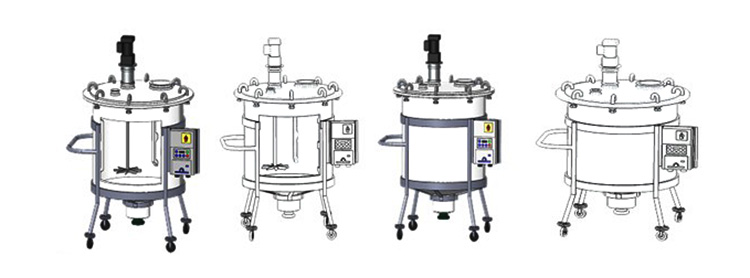

11.How Many Types of Vacuum Emulsifying Mixers are there?

There are different sorts of vacuum emulsifying mixers that can work according to their design & manufacturing level.

These mixers work in their way to give you uniform mixing.

Here is the list of some Vacuum Emulsifying Mixer that I am going to explain to you.

Laboratory experiment Vacuum Emulsifying Mixer

Laboratory Vacuum Emulsifying Mixer

This mixer comes in a small size as it is mostly used for laboratory purposes. When you want to mix different sorts of chemicals with a specific mixing value then this small-scale mixer is very helpful for you.

Some laboratory experiments are made based on the mixing of the different chemicals & this mixing must be uniform to make practical successful and for this purpose, this machine is very stable.

Up Homogenizer Vacuum Emulsifying Mixer

AIPAK APKZRJ Up Homogenizer Vacuum Emulsifying Mixer

A Homogenizer mixer is used to make different types of cosmetic & medical products. It works in a very effective manner to give you uniform mixing.

Different types of products like, ointments, lotion, cream mixing & making, & other emulsion products can be made with this machine.

The vacuum system completely controls the mixing environment in the homogenizer mixer to control the airflow in the mixing.

This is one of the highly used vacuum mixers that is used for getting precise mixing.

Bottom Homogenizer Vacuum Emulsifying Mixer

AIPAK APKZRJ Bottom Homogenizer Vacuum Emulsifying Mixer

This machine is very precise in terms of giving you uniform mixing every mixing material is disturbed evenly in such a manner that continuous mixing can be done easily & effectively.

Bottom base mixing is done in this mixer with the help of kinetic energy provided by the motor present in it.

Hydraulic shear mixing is done in this machine.

Fixed type Homogenizer Vacuum Emulsifying Mixer

AIPAK APKZRJ Fixed Type Vacuum Mixer

Different types of daily life products & other medical products can be made with this mixer it also uses kinetic energy along with hydraulic shear mixing to give you accurate & precise products.

This machine is used in many industries for different sorts of product mixing like paints, ink, fertilizers, printing & many more products that we use in our daily life.

Micro Vacuum Emulsifying Mixer

Micro vacuum emulsifying mixer

A micro vacuum emulsifying mixer is usually a mixer used for mixing different sorts of solutions & liquids more refinedly.

Multi blades are present in the mixer that help the mixer to remove the sticky particles from the walls of the mixer & grind the product well with high shear mixing technique.

Nanometer Vacuum Emulsifying Mixer

Nanometer Vacuum Emulsifying Mixer

The nanometer-based mixer is very used in terms of making a sensitive & precise mixture of products because when the mixing is done it checks the mixing quality in a small measuring unit to get the precise mixing.

The high speed & precision of this Nanometer Vacuum Emulsifying Mixer make it more versatile & adaptable.

It is easy to work with & easy to operate for different sorts of mixing.

Suppository Vacuum Emulsifying Mixer

Suppository Vacuum Emulsifying Mixer

The Suppository Vacuum Emulsifying Mixer is utilized to deliver suppository medication and exceptionally utilized emulsification of high solids content oil Like

- Pectic material

- Stroma

- Cream stroma

- Solvency material

Overall it is high tech manufactured machine with the best standards kept in mind. A high production rate is the best thing because of the triple mixer, the whole auto-feeding, the dust-free system makes it one of the best choices.

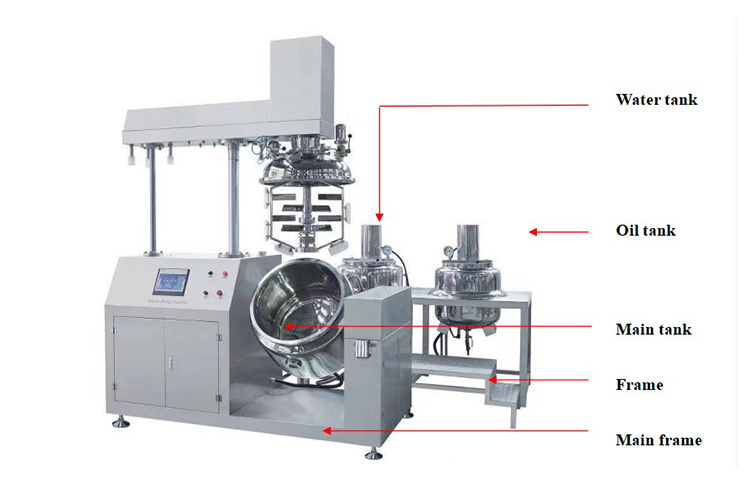

12.What are the Main Components of Vacuum Emulsifying Mixer?

Main part of vacuum emulsifying mixer

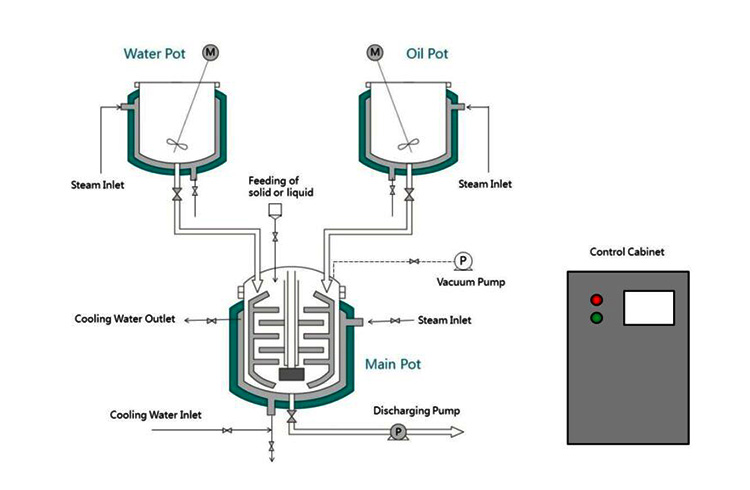

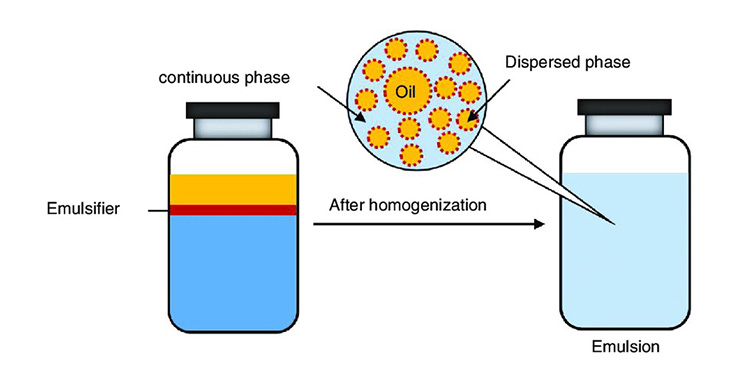

Main structure of vacuum emulsifying mixer including :emulsifying pot, water pot ,oil pot and work frame。

- Usually the oil pot is used for dissolving some solid that the product can just only be dissolved into oil, then the dissolved solvent will be sucked into the emulsify pot by soft pipes.

- The function of water pot is the same to the oil pot.

- Emulsify pot is used for emulsifying the products that suck from the oil pot and water pot.

Main frame

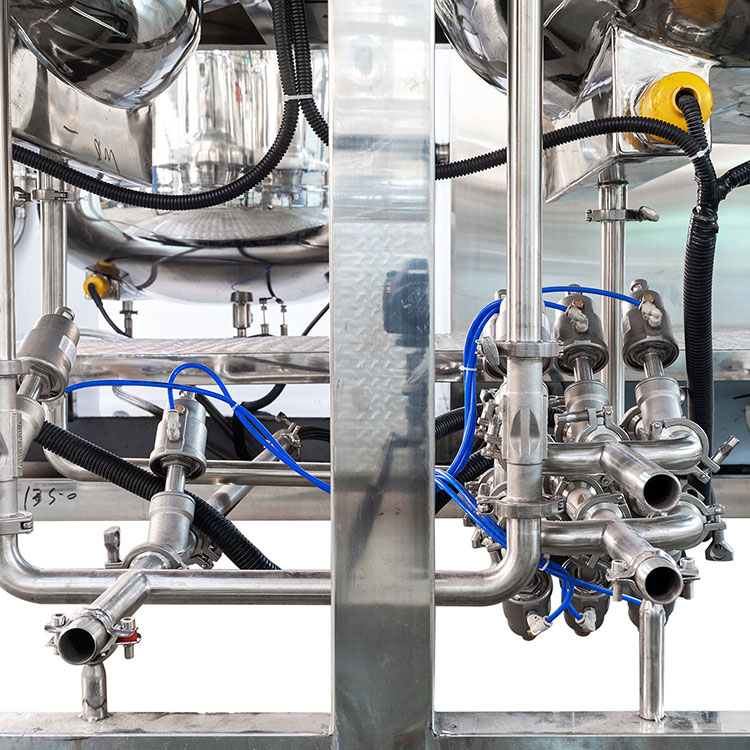

The mainframe includes the emulsify pot, lifting system, discharge system, vacuum system, electric control system, rotate system, mixing system.

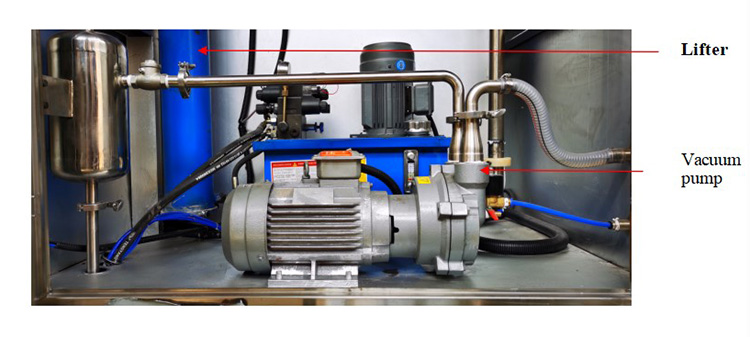

Vacuum pump

The vacuum pump is connected by two soft pipes, one is connected the water tank by soft pipe which is used for sealing when the pump is operating; the other connected to main emulsify pot through pipes and gas—liquid separator, so that the pump can make the main emulsify pot under vacuum condition. The gas—liquid separator is separating the gas and water, because the steam is sucked into vacuum pump when it is working, the steam through gas---water separator, some of steam become into water which flow out at the bottom of the separator.

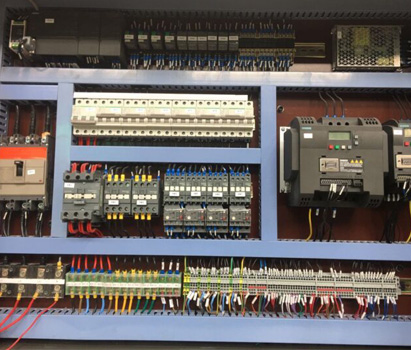

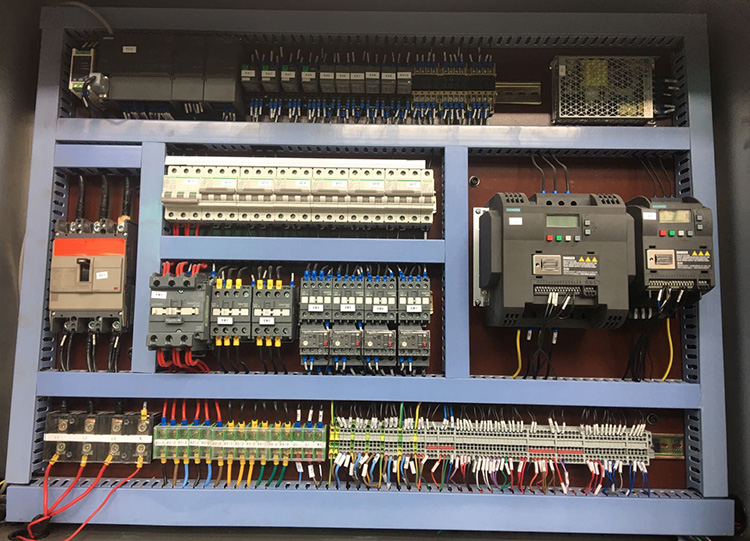

Electric control system

The vertical motor is high speed motor which can rotate between 0—3500 rmp/min

You can demolition the motor by open the screws and one wire.

Mixer

It include low speed mixer and high speedy mixer (homogenizer)

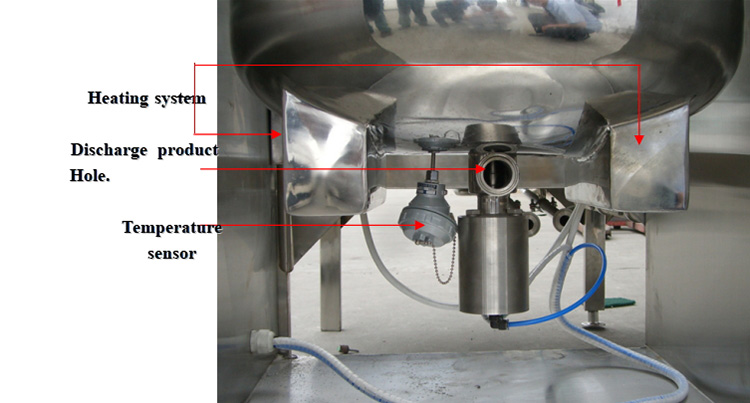

Emulsifying pot

The Emulsifying pot Includes cover, pot, bottom valve, temperature sensor, heating system.

This machine is heated by electricity, you just fill water into jacket, then turn on the heating system, the water is heated by electricity according to your requirement.

This machine also can be heated by steam, you just connect to steam producer when you heat the machine by steam.

Discharge hole

It is used for discharging the product just open the valve by pressed air.

Temperature sensor

It is used for check the temperature the product inside pot.

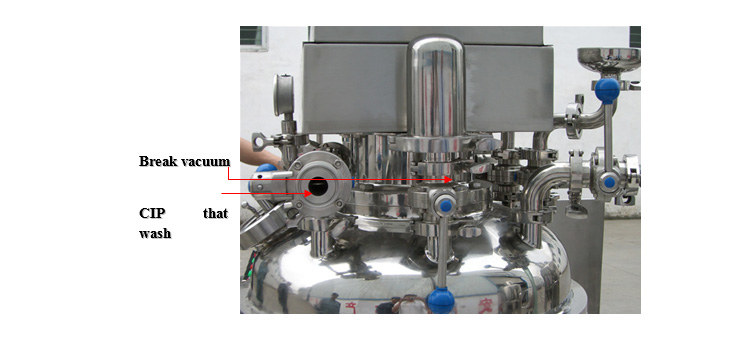

Accessories on the cover: including vacuum protection system, pressed air inlet hole, negative and plus pressure meter, mirror, CIP that for washing, break vacuum hole, material inlet hole, prepare hole for inlet perfume, automatic control vacuum valve and so on.

Negative pressure meter

It is used for check the pressure inside pot.

Pressed air inlet hole

It is connected with Air Compressor by blue soft pipe. it can press the product by air when the product is finished so that the product will be discharged under the plus pressure.

Mirror

You can see inside pot by turning on the light.

Break vacuum hole

It can break the vacuum inside pot by turning the valve, there is air filter inside valve. The product can not be discharged under vacuum condition, it just can be discharged without vacuum.

CIP

It is used for cleaning the inside pot by connecting tap water

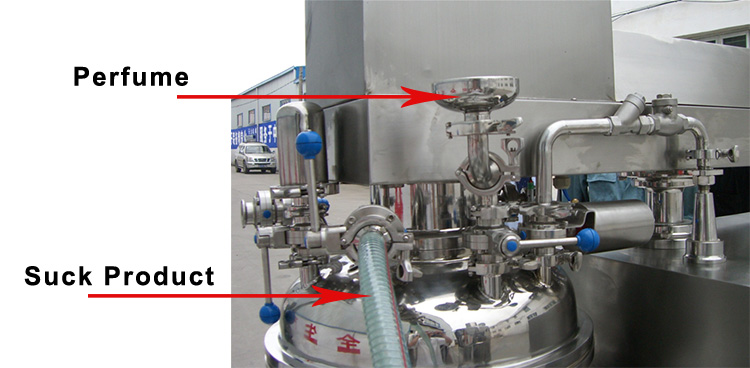

Perfume inlet

It is prepare hole for put perfume into the pot.

Suck product inlet pipe

It is used for sucking products from the oil pot and water pot.

You also can suck the product from oil pot and water pot to emulsify pot by vacuum through the stainless steel pipe.

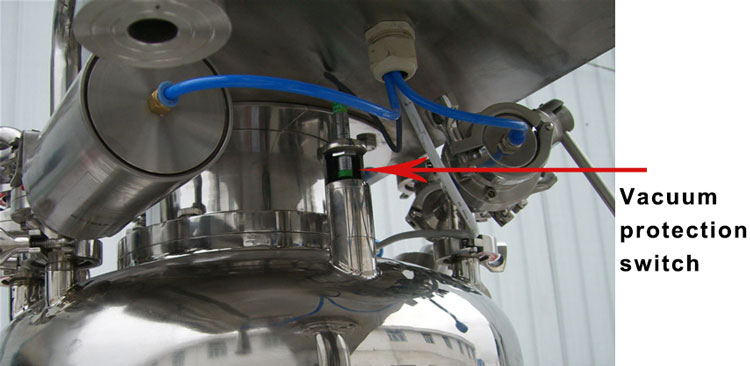

Vacuum protection switch

This vacuum protection switch is designed so that the cover can not be lifted when it is vacuum inside pot.

Safety system

Water inlet system and cooling system

13.What is the Working Principle of Vacuum Emulsifying Mixer?

Working Diagram of Vacuum Emulsifying Mixer- Photo Credit: yekeey

You have gone through the components and the kinds of Vacuum Emulsifying Mixer; it’s time for you to test how the machine works, i.e., the working principle. Now we'll check which part of the system plays which function.

Before starting anything, you have to heat the pots containing oil and water in separate pots.

Then through the emulsifying pump, each water and oil is used to suck into the emulsifying pot. This pot is positioned just at once under the two pots.

The device has a scraper that assists you in disposing of the substances caught in the mixer. When the system is about to mix or blend the substances, the primary mixer does the job. This results in the substances forming a brand new interface continuously.

During this procedure, the substances are compressed, cut, mixed, and blended. This occurs with the assist of a rotary vane. Using a high cutting wheel speed and fixed cutting cover, the process is repeated until the substances become 200nm- 2um.

The hydraulic shear takes place in masses because the centrifugal pressure effect is tearing and completely different outcomes. This ends in emulsification, and the very last product is fine, bubble-free, and reliable merchandise of excellent quality.

As the emulsifying pot is a vacuum, the air produced throughout the combination method fills the vacuum immediately. After that, the emulsified substances settle at the lowest portion of the pot, after which they get discharged from the emulsification pot.

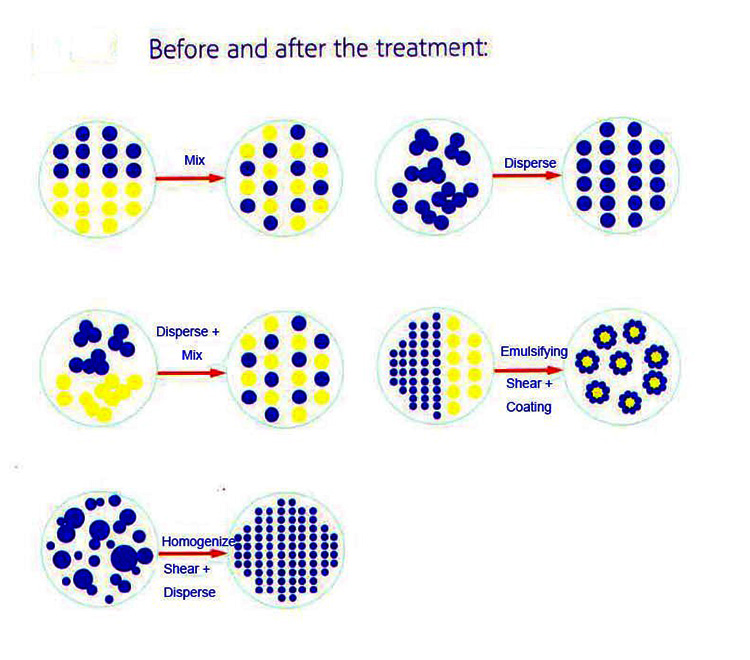

14.How does the Particle Size Change After the Treatment by the Vacuum Emulsifying Mixer?

The main function of the vacuum emulsifying mixer is to mix,disperse,emulsify and make homogeneous.

So ,on the micro,the scraping box stirrer and paddle mixer are to stir all the material indisde the tank in order to achieve the effect of mixing.

And on the microscopic,high speed homogeneous emulsification device is to make high-speed shear to the material so as to achieve the function of dispersion,emulsion, homogeneous.

15.What are the Main Features of AIPAK Vacuum Emulsifying Mixer?

Now we are going to discuss some salient features of AIPAK Vacuum Emulsifying Mixer, which are given below:

- The emulsification procedureof the primary pot is accomplished below the complete sealing condition, which prevents the pollutants of dirt and microorganism.

- The substance or the material usedinside the oil pot and water pot are brought to the primary pot through vacuum feeding. The immediate pot may be heated or cooled.

- The substance or the material inside thepot may be emulsified through high-pace inner stream shear of the homogenizer and may be blended clockwise or anti-clockwise. Clockwise blending is body scraping wall blending, and anti-counterclockwise blending is slurry blending.

- The scraper agitator has a centrifugal impactat some stage in function, making the PTFE scraper grasp to the pot's outer frame, which could successfully remedy the trouble of material staining at the wall of the pot and no lifeless.

- The frequency conversion rate regulating system can modifythe rate step shortly. Homogeneous blending and paddle blending may be used one after the other or at an identical

- Homogenization, material dispersion & emulsification, and combiningmay be finished in a quick.

- Emulsification technologyin the beginning from Germany is mainly designed for subtle and homogeneous products. The vacuum emulsifying mixer may be ready with wall scraping kind or ribbon kind and different agitation styles to effortlessly deal with substances with a 1-300000 CPS viscosity.

- Real-time dimensionand management components can effortlessly manipulate the temperature, pressure, pH range, and different.

- The essentialelements are manufactured from worldwide well known manufacturers, which can be quality substances.

- The shapeof the Vacuum Emulsifying Mixer is short and affordable with easy.

- The layoutand era of vacuum emulsifier are strictly met with GMP standards.

- Vacuum emulsifying mixers are suitablemachines for making lotion, cream, ointment, and suppository.

16.Why does the Vacuum Emulsifying Mixer Be Made of Stainless Steel?

Overall Structural Material:

The vacuum emulsifying blender is essentially made out of a water pot, oil pot, emulsifying pot, vacuum system, lifting structure, electric control structure, and action stage. It infers that when the materials are under vacuum conditions, it uses the high shear emulsifier to scatter one or a couple of stages to another predictable stage rapidly and impartially.

Process of Emulsifying Mixer Construction:

The materials will be set up in the restricted space among the stator and rotor. It works under the mechanical effects to produce strong energy of development.

By the action of water-controlled shearing, diffusive removing, influencing, breaking, and unevenness for in excess of 100 thousand times every second, the materials will be dissipated and emulsified quickly and consistently. At the time of reacting the whole course at high speed, the finely finished consequences of consistent and unrivaled evaluation without air pockets will be cultivated.

17. Is the Cosmetic Cream Vacuum Emulsifying Mixer Fully Automated?

The focal point of the China Emulsifying Mixer Machine is a cluster blender (emulsifier) that is comprised of a fully automatic fast rotor and a solitary holed stator. The rotor is driven by ABB or Siemens motor and pivots at the speed of 3000rpm, creating incredible attraction power. At that point, they are hurried to stream out through the openings onto the stator.

These mixers are popular because of their automatic features at the time of making cosmetic products like oils, creams, and many more. Moreover, it can help move the segments from the cream and oil directly from the tanks to the main emulsification plant. The small number of powders and creams can likewise be sucked by a vacuum cleaner to prevent all external dust. Security gadgets are worked to guarantee the blending part won't start if the cover is raised.

18. What are the Differences Between Different Homogenizer Vacuum Emulsifying Mixers?

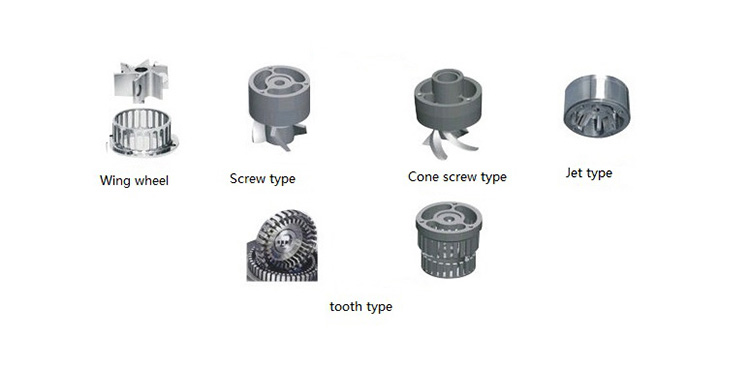

Various homogenizer types

The vacuum emulsifiers are provided by different associations, which fuses various combinations. The homogenizing structures join upper homogenization, lower homogenization, inside and outside orbiting homogenization. The mixing structures join single-way mixing, twofold way mixing, and helical strip mixing. The lifting structures join single-chamber lifting and twofold chamber lifting. Distinctive incredible things can be changed by customer necessities in various models, which include:

1. Triple mixing machines

In the triple mixing machines, there is an imported repeat converter for speed change. It can satisfy assorted imaginative requirements.

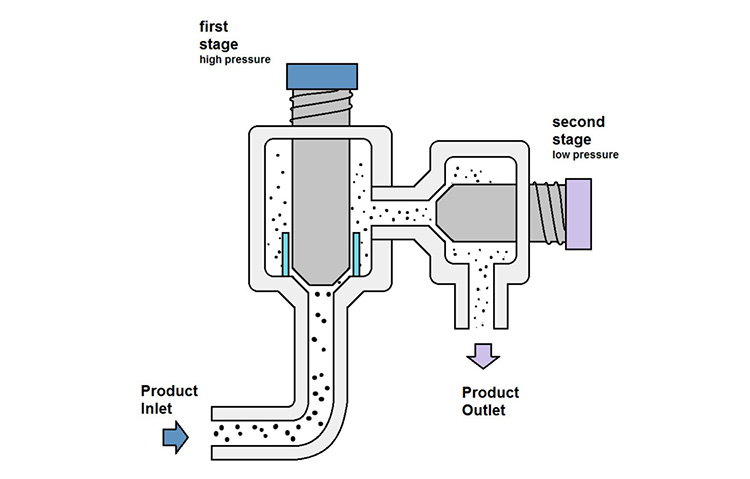

2. Pressurize homogenizers

The pressurize homogenizing structure in this machine is designed with German development for improving sealing productivity. The most authentic emulsifying insurgency speed can show up at 4,200rpm, and the most critical shearing fineness can show up at 5um. The warming modes fundamentally join steam warming or electric warming.

3. Vacuum deformers

It is the latest form of homogenizer and added up with the core features of a vacuum emulsifying mixer. The vacuum deformer can make the materials meet the need of being aseptic. A vacuum sucking system is gotten, and especially for the powder materials, vacuum sucking can avoid dust.

An imported three-layer tempered steel plate welds the pot body. The tank body and the lines embrace reflect cleaning, which totally changes with GMP necessities.

19. What Devices should be Included for A Complete Vacuum Emulsifying Mixer Production Line?

The overall Vacuum Emulsifying Mixer consists of several components. The vacuum composition is included with several sub-equipment that perform emulsification and agitation processes inside the vessel. Further, we will discuss all essential devices of this machine that play a unique role in every emulsification process for the production of any product.

1. Mixing Vessels

Mixing Vessels- Photo Credit: Whitemountain

The vessel's inner part is machined into the amazing round structure, so the scrubber works easily. Standard charge at an at once of the vessel limit, yet the material can be energized to the greatest 90%. We are prepared for the assembling of vessels with 1L-10000L limits as per your solicitation.

2. Standard Type

The Head plate at the base region of the Mixing tank is produced by presswork. It gives a huge warmth zone and alters the shape for the inside pressing factor, and it has a smooth surface at the inside mass of the Mixing Tank.

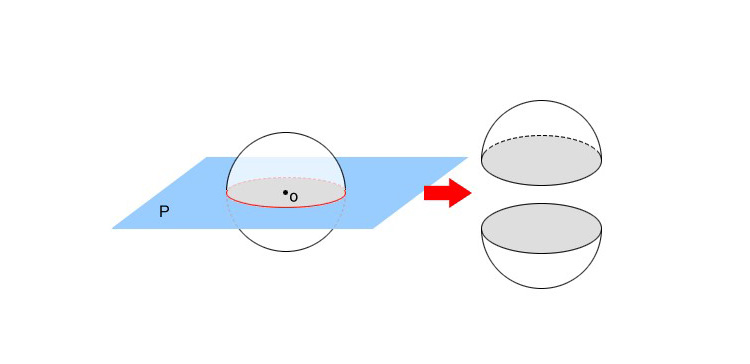

3. Hemispherical

Hemispherical-Photo Credit:math

High strength Agitating means the system proficiency is high. High Mixing Efficient Small measure of material can be fomented for the situation of the single cutting edge. Directly heat move territory is more modest than at any other time. Low Strength Agitating productivity is high. But it is conceivable to shuffle the items from limited quantity.

4. Agitating Mechanisms

Agitating Mechanism-Photo Credit:Goavec

Agitating Tools

You can easily select the type of blade and a rotation speed which totally depends on the use. You can also control the rotational speed that is a continuous variable available in a certain range. The rotation recorder and tachometer are attached to the control board. Also, a shaft part is equipped with high-quality sealing with oil under certain safety mechanics.

Scraping Tools

The automatic scraper should make the product heated or cooled by vessels inside the wall move or circulate to promote an effective heat exchange with a heat conductive surface. Also, the roundness inside the vessel made the scraping blade work more effectively and realized an excellent and constant heat exchange performance. The scraping blade can be dismounted with ease at a touch. Available as materials are Teflon, neoprene, nitrile rubber, etc. We will select among these materials the most suitable for your purpose of use.

5. Higher Shear Mixer

Do you know that uniform scattering and mixing without utilizing as least surface dynamic specialist as conceivable is the new propensity is item blending? Well! Most of the time, these rapid slashing blends are utilized. The state of blender edge contrasts one from another. However, the highlights regular to all models are described in a turbine-like cutting edge is turned at fast. A fine scattering is achieved in a relatively brief timeframe by incredible disturbance and percussion in this way created.

Homo Quick Mixer

Incredible shearing, effect, and cavitation as created when the liquid passes between the quick turning turbine vanes and the stator (freedom of 0.5mm) actualize emulsification and scattering. As a connection, the cutting edge can be supplanted basically with the scattering/blender sharp edge, as demonstrated on the following page. The photographs show the edges of the fast homo mixer is applied to the assembling of skin cream and salve.

If the ultimate slashing power is wanted, then it is conceivable to use an extraordinary seal. It will allow you to raise the blender turning speed up to the greatest 10000 rpm. In any case, this blender can be supplanted with the converse homo blender of suck-down type. For this situation, the circling motion in the vessel becomes fast, which is the success rate for the scattering of force with little explicit gravity.

Scattering Mixer

The scattering mixer has sharp edges, and the blades are made with circular disks. The powder is scattered easily into fluid, and chunks of powder are cleaved by this indented edge for turning it fast. Same as like that, they are pounded easily and equally. Also, it can scatter uniformly into the fluid. The powder is squashed, scattered by the serrated cutting edges to be uniform-atomized in the liquid.

Ultra Mixer

Ultra Mixer-Photo Credit: Enggnews

The ultra-mixer can suck down all sort of bad materials descending by own load into the blender. It will provide you high-level cavitation power as the scratching power of the turning hood. Also, the combination comes out from the side of the vessel. Since the ultra-blender, as opposed to the quick homo blender, which pummels the material by aberrant slashing power, pounds the material by direct hacking compel. It is generally reasonable for the scattering of powder. It tends to be utilized additionally for the incredibly high thick item and has an amazing cleaving power.

20. Are there any Environment Requirements during the Vacuum Emulsifying Mixer Working Process?

While working on the emulsifying mixer, you need to also focus on all major environment requirements that are necessary. The basic requirements include:

Temperature Control tools:

Cooling and Heating Equipment

At the time when you start the steam process, heated water, cool water, or saline solution is utilized for temperature control. The perplex plate is given inside the coat to prevent the development of a short way that this fluid might bring about. It is utilized to offer a strong turn joint that applies no unnecessary power to the wirings if the tumult vessel is slanted to the front. Since it can harm the hoses but in safe mode, it offers safety wellbeing, which is guaranteed.

Thermometer

Do you know that the item is totally settled in the vessel? Well! The item temperature is arranged precisely by methods for the thermometer gave inside the vessel. The temperature sensor can quickly embed through the upper cover or the base of the vacuum. Also, it can be placed on the side of the vessel. In addition, the interlocking of the thermometer with different control gadgets empowers programmed temperature control.

Inside-Pressure Control Tools

It is conceivable and good to utilize it under tension which is based on the motivation behind its usage.

Material Charging Mechanism

Considerably under a decreased tension, it is appropriate to charge the fluid or gas material from outside without ruining the vacuum condition. It is likewise conceivable to give a channel at the charging port. It can quickly charge the material while continuing with vacuum invasion.

Product Take-out Requirements:

The cover has an open and close lid in the gadget that is accessible as a manual system and fully programmed component.

Instigator Rollover Tank

Indeed, even high-range items can be taken out effectively by shifting the instigator's vessel. The cleaning within the vessel is additionally simple. At the same time, the vessel containing a modest quantity of material is to be shifted by manual handle activity. While containing a lot of items in one tank is not appropriate. So it is suggested for you to shift either electrically or to use pressurized water.

21. What Should You Pay attention to when Operating the Vacuum Emulsifying Mixer?

While taking out all heavy items from the tank is likewise suggested to start the safe cycle. Other than the above standard control board and tools for safety needed for item quality control can be mounted together. You can use the recorder, ammeter, Visco sensor, tachometer, pressure check, PIT sensor vacuum meter, and flowmeter.

Tools for Safety:

Most people prefer to use safety mechanism tools in the mixer. Mulling over the administrator's safety requires a basic security system that works as a supplier in standard hardware to the instigator. It will allow starting:

- The mechanism to stop water-driven siphon working as a vacuum activity is in advance.

- The mechanism to stop the revolution of the instigator is when the top is open.

- Produce safety valve

22. How to Choose the Most Suitable Way of Mixing & Homogenizer?

At the time of choosing homogenizers and mixers for your company, you need to check the type of product you want to emulsify. There are several homogenizers available in the market. The current market homogenizing method comprises of three different categories, which include:

1.Mechanical rotor-stator homogenizers

Mechanical rotor-stator homogenizers-Photo Credit: Homogenizer

Huge size rotor-stator homogenizers measure fluid examples in the 0.01 ml to a 20-liter reach. The limit of the rotor-stator ought to be coordinated to the consistency and volume of the medium and with the kind and measure of plant and creature tissue to be prepared.

The speed and effectiveness of homogenization are fully integrated by utilizing a small homogenizer. The volume ranges can go up around ten folds. Likewise, a large portion of the mechanical homogenizers works appropriately with fluid examples in the low to medium consistency territory.

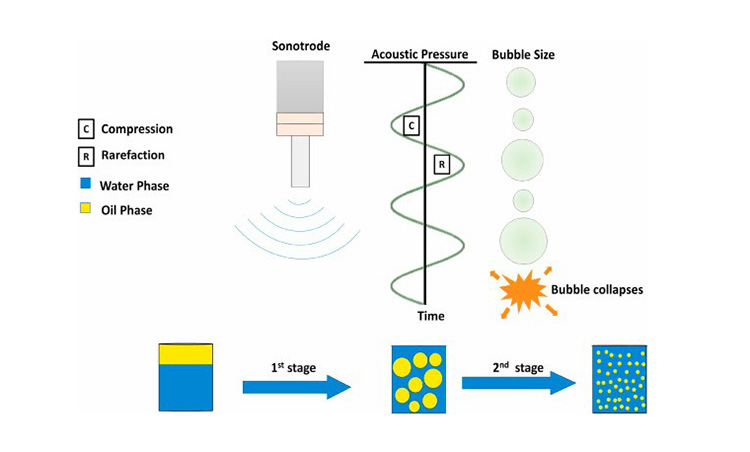

2.Ultrasonic homogenizers

Ultrasonic Emulsification- Photo Credit: Shemantic

These gadgets work by producing extreme sonic pressing factor waves in fluid media. The pressing factor waves cause gushing in the fluid and, under the correct conditions, the fast development of miniature air pockets, which develop and blend until they arrive at their thunderous size, vibrate savagely, and ultimately breakdown. The mechanism of emulsifying is called cavitation. The interactions of the fume with the product mixture create a stunning wave with high energy to break covalent bonds.

3.Pressurized homogenizers

Pressurized homogenizers-Photo Credit: MDPI

High-pressure homogenizers have been utilized to upset microbial cells for a long time. Except for profoundly filamentous microorganisms, the strategy has been discovered to be by and large reasonable for an assortment of microbes, yeast, and mycelia. Machines which incorporate the impingement configuration are more powerful than those which don't. But sometimes, disturbance of the blending quality happens at the time of blending heavy products and producing solid shearing powers.

23. Which Key Factors Determine the Efficiency of Vacuum Emulsifying Mixer?

As you have now perceived what a vacuum emulsifier is also as its motivation, you would now be able to investigate this rundown. We have arranged a few highlights of a quality vacuum emulsifier that you should consider while operating this mixer:

1.The blending of immiscible fluid stages:

There are fluids that will require additional exertion in the blending interaction. Take oil and water for a model, which are the essential fixings in creams and salves. Search for this factor in thinking about an emulsifier.

2.Emulsion consistency

Another trouble that you can experience in joining components is their consistency. The thickness and surface of your examples matter in the blending game. Thus, you better ensure that your machine is equipped for taking care of this thing.

3.Board unit adaptability

Your hardware must do the total and legitimate system of blending, emulsifying, warming, homogenizing, cooling, heating, and vacuum.

4.Testers for electrical warming

In principle, vacuum homogenizer machines, tests, and regulators for electrical warming ideally have a twofold temperature.

5.Efficiency Cooling framework

Your emulsifier produces a specific measure of warmth. IT makes everything a lot more convenient. In any case, you will require a more drawn-out homogenizing time. The more it goes, the more warmth it radiates. A cooling framework will clearly address this worry.

6.Moveable Pump

To make the release of the completed item simpler and way speedier, an exchange siphon is a trustworthy solution. Your homogenizer needs to likewise go about as an exchange siphon.

7.Homogenizer and fomenter versatile speed:

Successful homogenization depends on the homogenizer's speed and force. The higher the speed and force of it, the more it gets fit for chipping away at a lot greater molecule sizes in mass yields.

8.Lifting framework for oil pressure driven

Possessing a vacuum emulsifier requires legitimate support. On the off chance that it has an oil water-driven lifting framework, this won't be an issue. But do you ever think that why it happens? Since this component does cleaning and support less problem and easy. It mostly happens in managing the oiliness of oil.

9.High shear inline blender with pipes

Level high shear inline blender with pipes is an element that does outer emulsifying and homogenizing. By having this element, the temperature will be a lot simpler to control and oversee.

10.Vacuum framework

The vacuum framework is the feature highlight of a vacuum emulsifier. As referenced before, air circulation obstructs a better blend. Henceforth, the vacuum framework. It ensures the emulsification and blending are done altogether by taking out the air bubbles that are framed during the interaction. Additionally, it moves the fixings from any remaining parts to the primary emulsifier blender.

24.How will you Charge and Discharge Materials from a Vacuum Emulsifying Mixer?

Presentation of Emulsification-Photo Credit: Shematic

Process of charging

In the high thickness of emulsion, particularly the assembling cycle of cream, salve, emulsion items, generally the tricky is the scattered stage molecule size and blending the air blended in with items, grain size is too huge a wherever emulsion insecurity, need brilliance.

Different items into the air will make the items bubble, bacterial defilement, simple oxidation, and the appearance isn't smooth. For the two being referred to, our created ZJR arrangement vacuum emulsifying blender, by the quality instigator cutting edge blending, scratching the divider. The middle area has mixed their supplement one another and joined into a blending phase in an ideal way.

Process of Discharging

The whole process allows you to avail of the ideal blended items at the time of discharge. The tone and the vacuum siphoning mode are available for the creation for sending out in the blending interaction of no air bubbles. The first blending and discharging can deliver gleaming, fast purifying, and great malleability of excellent items.

Once you tackle all these two issues in this processing plant, you can use the vacuum emulsifying blender maker that had created the ZJR mixer. The whole system of discharging is comprised of a homogenizer and center edge stirrer and scrubber deposits stirrer to offer the best blending route.

The whole scenario can deliver the ideal blended material. By separating air from the material, the vacuum siphon can guarantee that the material and products will remain shiny, impeccable, and bendable.

25.How to Maintain Hygiene During the Vacuum Emulsifying Mixer Production Process?

Maintaining the hygienic environment is the need of every industry who are making food product or different ornaments. At the time of blending, all items are quickly cleaned from the tacky materials on the divider with the goal that the scratched materials will ceaselessly produce new interfaces.

At the time of collapsing the sharp edges and the turning edges, they should have blended and streamed down properly to the homogenizer underneath the pot body.

Since the emulsifying pot is in a vacuum express, the air bubbles produced during the blending interaction of the material are taken out on schedule. Thus, the material will turn out to be more sensitive, cleaned, and gleaming.

26.Is there Any Factory Installation for Vacuum Emulsifying Mixer?

After the system arrived at the client factory, the course within the proper area affirmed that the water, energy, and gas were installed. After arrival, your system will be installed in the following way:

- Check whether every valve and switch is in its unique and original function.

- Check whether the rotation path of homogeneous, sweep wall stirrer is in position and working correctly and whether the rotation function could be substantial.

- Check whether there may be water inside the heating interlayer and no longer switch on while the liquid stage is under the heating rod. If the consumer uses steam heating, make sure that the connecting pipes and valves among the steam generator and the vacuum emulsifier mixer are well connected.

- Check the electricity voltage, meters, indicators, etc., are operating correctly?

- In operation, consistent with the consumer's system and manufacturing process, the cloth must be heated and stirred at an equal time.

- When there may be fine cloth inside the pot, the homogenizer may become on and sweep wall mixed on an equivalent time. The sweep wall stirring pace has to be adjusted upward from least to required, i.e., zero to the preferred rate.

- If the homogenizer fails in function, the electricity delivery must be switched off fast and disassembled and repaired. When the vacuum pump is opened, it's far essential to extend the vacuum control switch earlier than opening the vacuum pipeline valve. First, close the vacuum valve, when closing, then flip off the electricity delivery. When the vacuum stress reaches negative – 0.05 MPa to – 0.06 MPa, open the feed valve to suck the substances inside the water pot and oil pot. And regularly test the integrity of the filter to keep away from contamination into the emulsifying pot to ensure the regular function of the homogenizer. The vacuum inside the emulsifying pot has to stay low. In general, it must be saved among – 0.05 MPa and – 0.06 MPa to keep away from boiling water.

- Machines should be cared for while they may be operating. Before leaving the place, you must have to stop operating.

- Before the system stops operating, it's far essential to regulate the frequency converter again to 0, then press the stirring stop button.

- Switch off the electricity transfer, test whether the water valves are closed, and then open the vacuum exhaust valve.

- 11.After discharging the products, maintaining the pot clean, clear the remains inside the pot with hot water

27.What Quality Standard should Vacuum Emulsifying Mixer Conform to?

Some Quality requirements must conform or comply with the Vacuum Emulsifying Mixer. These requirements are essential because organizations frequently gain higher earnings by meeting these satisfactory requirements and decreasing their losses. Those organizations that exceed exceptional standards stand out above their competitors and their capacity for income and customer loyalty.

The Vacuum Emulsifying Mixer has to comply with CGMP standards like Clean-In-Place (CIP) /Sterilize –in-place (SIP).

- The contact components need to be crafted from Stainless Steel 316Ll for all products. Besides, they have to be reflected polished.

- Components that haven't any touch with the goods must be crafted from stainless steel.

- For hydraulic pumps, vacuum, and their operators, it must have many protection devices.

- There should be a PLC panel in which operations and functions are pre-decided before operating the system. In case the fault is detected, the operator can stop the device from the emergency stop button on the PLC immediately. In this way, it is easier to operate.

- In a single unit of operation, the perfect or an ideal device must have the ability to finish the complete procedure, i.e.,

- Mixing

- Dispersing

- Emulsifying

- Homogenizing

- Vacuuming

- Heating

- Cooling of the materials.

Emulsifying-Photo Credit: khni.kerry

- For agitators and homogenizing, the system must have exceptional speeds.

28.What should you consider when choosing a Vacuum Emulsifying Mixer?

Before buying or having Vacuum Emulsifying Mixer, you need to keep in mind a few things that help you have a higher output or yield. Some of them are defined below:

First, it's far essential to clarify the central determinant of the standard of the emulsifying system- the homogenization effect, because the impact of emulsification and homogenization is the maximum important. What quality can the emulsifying system acquire through homogenizing the droplet length, generally among 200nm and 2um? The droplets have a smaller particle length and higher standard. The smaller the distance between the stator and the rotor, the smaller the droplet length obtained.

Secondly, can the vacuum emulsifying system can put together sensitive and bright face cream. This is likewise an index to decide the quality of the emulsifying system.

The reliability of the shape of the emulsifying system and the benefit of operation also are essential. The shape is extra dependable, and the carrier existence is longer. The process is less complicated, and there are very few problems. Stable machines make sure manufacturing performance and keep renovation time.

Some other things to consider are:

- This device is not so common. To enhance blending performance, it makes use of many features of a vacuum. This results in the proper product management and higher blending results.

- The vacuum controls the blending environment, which facilitates averting aeration, which might also cause blending blade degeneration.

- The blending in a controlled environment additionally helps you in getting void-free end products.

- It is suitable for generating different kinds of batches like small, medium, or large, and some massive portions of a product's powdery type. The reason behind this is that it comes with working capacities of between 30 Liters to 2000 Liters.

- It could be applicable for generating lotions and different fluid merchandise like syrups (cough).

- It saves your time because the manual technique takes quite a lengthy time. The computerized device offers a vast power input that quickens the whole process. The merchandise has advanced constancy with correctly managed viscosity.

- It reduces wastage that happened for the duration of manual blending. Hence it's far developing appropriate returns to the industry.

- The automated one has an in-constructed CIP, which ensures hygiene for the system and stops infection of the merchandise.

29.How to Troubleshoot Common Problems during the Vacuum Emulsifying Mixer Manufacturing Process?

There are some certain problems or issues you may face during the Vacuum Emulsifying Mixing, some of them are given below:

- You may face difficulty in mixing powder which is difficult to dissolve in water.

- There may be a problem of having two-phased emulsification to end up with a uniform product.

- Bottom sediments at the emulsification pot is a huge concern.

- For agitators it is very difficult to break down some materials form agglomerates.

A vacuum emulsification machine is a piece of easy non-preferred gadget equipment. Its satisfactory performance comes from the natural, technological layout and application of every part of the system and the correct functions and protection of the consumer. Improper functioning of the vacuum emulsification machine frequently reasons gadget failure. Suppose you want to save your device failure from inflicting incorrect manufacturing losses. In that case, operators have to be talented in learning the operations and the technique of the vacuum emulsifier and want to apprehend a few standard troubleshooting methods.

- You need to check whether the emulsifier's vacuum pipe is opened or closed and whether the sealing ring is leaking.

- Check if the vacuum valve is open or the vacuum pump is refueled, or the water tankof the vacuum pump is filled, and the rotation path of the vacuum pump is correct.

- You may check whether the energy delivery is smooth and any leakage in the electrical cord.

- You need to check whether the motor blades are operating smoothly and whether the motor is failing.

- Whether the homogeneous head is strong and whether any external frame jams the homogeneous head.

- Whether the relay of the electrical manages cupboard is tuning out and the restriction transfer is released.

- Whether the stirring shaft revolves and whether the scraper is worn slightly.

- Check whether there may be any external frame caught within the scraper wall, and it has to be no longer turned quickly.

Vacuum Emulsifying Mixer Related Posts

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 156 0710 8630