Your Premier Tablet Deduster

- All Kinds Tablets Suitable

- Quick Installed Connection Structure

- Stable Production Efficiency

AIPAK Tablet Deduster

AIPAK tablet deduster has unutilized many advanced technologies in its creation.The deduster machine is able to act as both elevating and dedusting machine ,which made it a usual combination with other tablet-compressing machine and metal detection machine and also made it extremely applicable in the filed of pharmacy chemical engineering,electronics and high quality dedusting with out damage to the table itself.Its advantages include long dedusting path, automatic tablet polishing of all sides/angles, and high quality dedusting without damage to the tablets. The machine is also employed many new designs and features to ensuring better and safer operations.

Furthermore, all AIPAK tablet deduster machines can act as a delivering device for any shapes and sizes of tablets that need to be dedicated in dedusting. It is designed and manufactured in conformance to cover GMP standard.

AIPAK Tablet Deduster Machines

APK-SZS230 Top rotation type tablet deduster

AIPAK APK-SZS230 model machine is an economical top rotation type tablet deduster .The tablet deduster has three functions such as tablet grinding, dust removing and lifting. The machine inlet can be connected with any model of tablet press and the outlet can be connected with metal detectors. It can realize the linked production mode including tablet grinding, dust removing, lifting and metal foreign matters detection.

meets GMP requirements

Quick installed connection structure

Stably with low noise

Get A Free Quote Now

APK-SZ300 Lower rotation type tablet deduster

AIPAK APK-SZ300 tablet deduster is suitable for dust removing of various shapes of tablets. The whole production process is direct and visual. Medicine and dust isolating devices are additionally mounted among all layers of sieve plates to realize effective separation of tablets and dust. The parts in the machine that contact tablets are all made of SUS316L/SUS304 stainless steel. It can work with any model of tablet press.

Effective separation of tablets and dust

Convenient use and cleaning

High efficiency and low noise

Get A Free Quote Now

APK-ZWS137 Horizontal rotary type tablet deduster

AIPAK ZWS137 high-speed tablet deduster adopts compressed air for scavenging, centrifugal dust removing and roller edge grinding principle to eliminate dust on the tablet surfaces and edge burrs, so as to make the tablet surfaces clean and the edges neat. The sieving box and power box are totally isolated from each other. The quick disassembled structure makes it convenient to disassemble, install and clean the machine. The parts that contact the medicine are all made of stainless steel, meeting the requirements for pharmaceutical equipment in GMP.

Quick disassembled structure

Meets GMP requirements

Convenient to clean

Get A Free Quote Now

The Buyer's Guide

Tablet Deduster:The Complete Buying Guide in 2024

Is dust prevalent in your tablet production room? Is dust pervasive in the packaging room that causes dusty packaging or equipment malfunctioning? Is delivered tablet free from dust particles?

If so, then this blog is for you!

This blog will help you to select the right choice for tablet deduster that will maintain your production area free from dust and make it to a cleaned environment.

A deduster, as its name shows eliminates the dust throughout the tableting process.

A tablet deduster is fairly simple equipment.

Its simplicity contradicts if the machine is improperly installed or specified.Want to know more?

Then read this informative blog to learn more about tablet deduster machines. For instance, tablet deduster principles, components, correct installation, failure, troubleshooting, and much more!

What to Expect?

After reading this blog we assure you: You will be able to select the right choice tablet deduster machine to run your business and production with a high profit margin.

1.What is a tablet deduster?

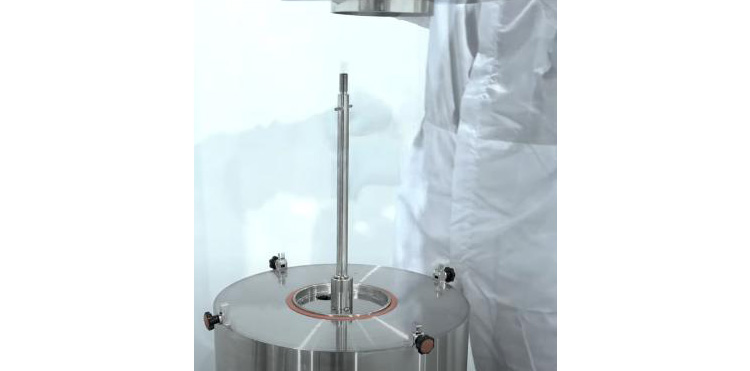

AIPAK tablet deduster

Tablet deduster is dedicated equipment employed for removing dust residue from the tablet soon after manufacturing.

A tablet deduster is the fastest equipment that generates the highest output ratio of more than a half-million tablets each hour.

Hence, this is an amazing and time-saving tool that gives perfect results to your business. A tablet deduster machine is extremely applicable in the field of a pharmaceutical manufacturing unit, chemical engineering, cosmetics, nutraceuticals, foods, and so on.

Tablet deduster can be integrated into a tablet press machine that ensures the formation of a professionally aesthetic tablet that is free from unsightly traces.

Tablet deduster is an advanced, innovative, and beneficial sort of equipment that offers extraordinary efficiency, high-level dust removal, easy maintenance, and low noise.

2.What is the tablet deduster working principle?

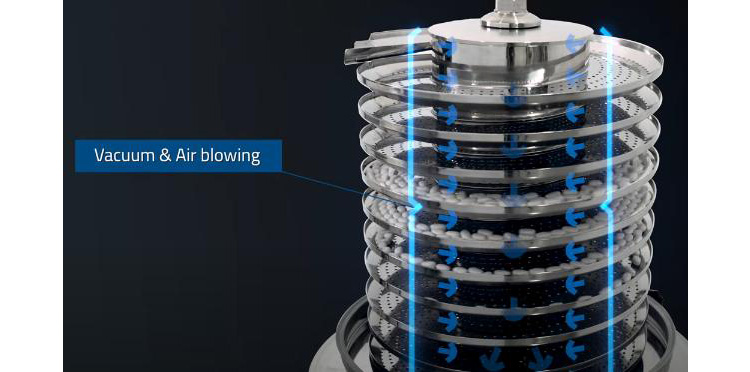

The tablet deduster machine employs electromagnetic and mechanical forces that result in the generation of vibratory motion.

The vibration or oscillation in a helical body of the tablet deduster machine creates significant vibration that allows an upward movement of tablets with a dedusting procedure simultaneously. In simpler words, the process of elevation of tablets and dedusting occurs at the same time.

Tablet Deduster Principle of Working- Vibratory Motion

Where EM= Electromagnetic Force, M= Mechanical Force, Deduster Machine

Working of Tablet Deduster Machine – Video Credit- PTK

3.What are the classifications of tablet deduster?

There are different types of deduster machines, each of them have their own structural and operational benefits.

1.Vertical/ Elevating Vibratory Tablet Deduster Machine

2. Horizontal Vibratory Tablet Deduster Machine

3. Brush Type Vibratory Tablet Deduster Machine

1. Vertical/Elevating Vibratory Tablet Deduster Machine

The vertical vibratory tablet deduster has two main types: ‘Downward convey tablet deduster’ and ‘upward convey tablet deduster’.

The working principle of both types of deduster is almost similar. Both of them consist of the perforated surface that vibrates or oscillate in order to dislodge the dust particles from surface of tablets.

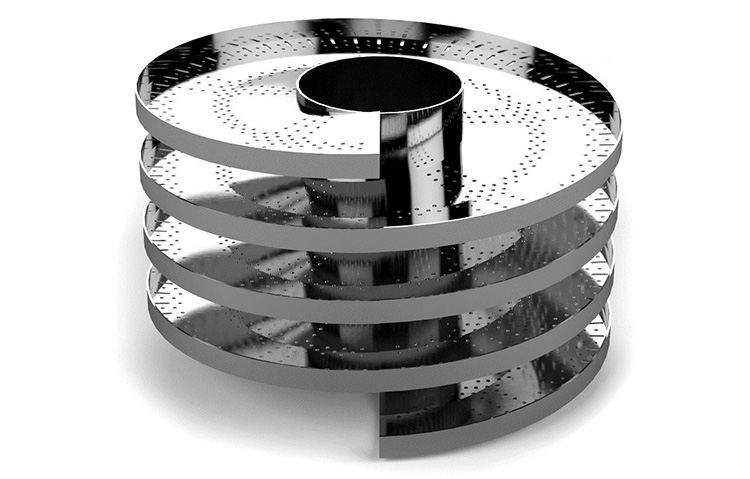

The tablet deduster rely on the helical punctured conveyor tray with attached central column.

A strong vacuum help in the drawing away dust from surface into a dust collection system.

AIPAK Tablet Deduster Machine

A Helical Perforated Plate

A vertical vibratory tablet deduster is broadly applicable to many industrial sectors. It moves tablets in ascending motion utilizing vibratory motion along a smooth perforated surface.

The principle of working depends upon the vibration of the perforated helical pathway. As the helical pathway vibrates the tablet spins and moves along with it that dust off from the surface. The dust extractor separates the dust from the surface and collects them into a dust collector bin.

2. Horizontal Vibratory Tablet Deduster Machine

The horizontal vibratory tablet deduster machine is similar to a vertical deduster machine except tablets move horizontally onto the flat perforated vibratory bed that continuously and gently shakes and dust off the momentary tablets.

Horizontal Tablet Deduster Machine

This machine is horizontal, but it slants downward which enables the tablets to fall when vibration conveys them from 1-meter distance.

Unlike the vertical tablet deduster machine, the perforated tray do not convey the tablets upward and can not reach the tall collection bin.

3. Brush Type Vibratory Tablet Deduster Machine

A brush-type vibratory tablet deduster machine is available in both forms either vertical or horizontal. This machine employs a motor-driven rotary brush that takes and sheds the dust particles from the tablets.

Brush-type vibratory tablet deduster machine is suitable to operate and dedust capsules as well.

This machine consists of a spirally mounted brush within a stainless steel tube which is controlled by an adjustable motor. When tablets are introduced into the feeder from the hopper brush pushes them into the tube that dedust the tablets and discharges them either at the top or bottom of the discharge chute.

Brush Type Vibratory Tablet Deduster Machine- Photo credit-Capplus

4.What are the basic parts of a tablet deduster machine?

The basic components of tablet deduster machine are as followed:

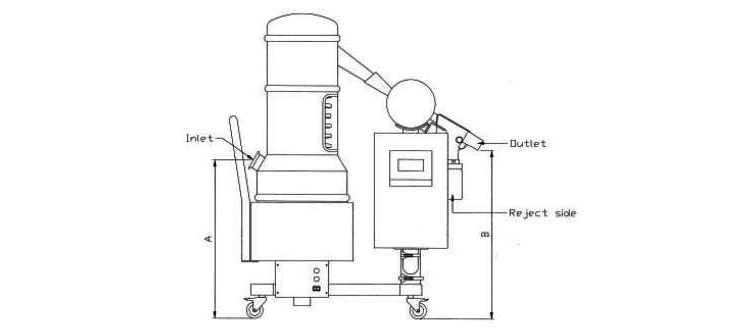

1. Tablets Inlet

A tablet inlet is present at either top or bottom of the tablet deduster machine. The location of the tablet inlet depends upon the classification of a deduster machine, for instance, vertical, horizontal, or brush type.

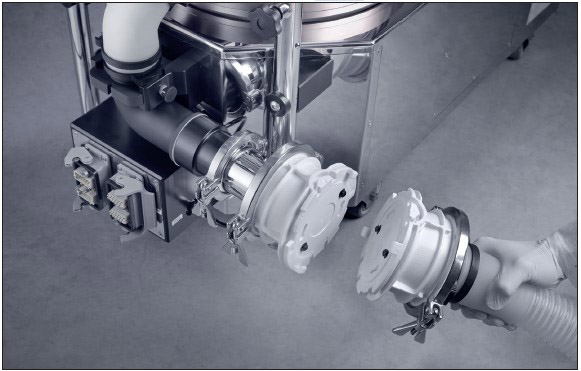

You can feed tablets either manually or directly integrate the equipment with the discharge chute of the tablet press machine.

2. Perforated Plate

A stackable perforated plate that allows vibratory movement to tablets allows the removal of residual dust particles.

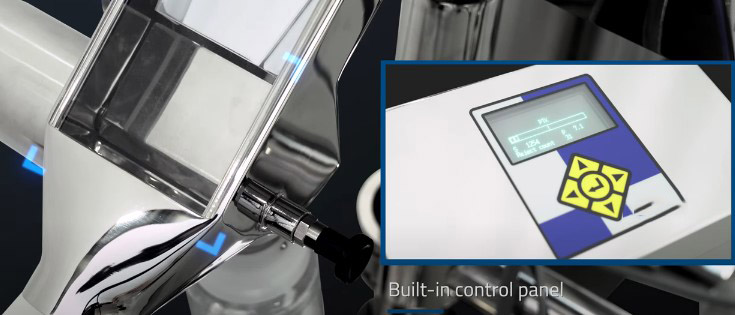

3.Digital Vibration Controller

Tablet deduster is composed of a digital vibrator controller that maximizes or minimizes the dedusting speed. This controller allows easy removal of dust for cleaning of tablets and ensures dust is properly removed using efficient dedusting properties.

4. Vacuum Suction Device

With a help of an air vacuum, suction device dust particles are easily dislodged from the surface of tablets. The intensity of the air vacuum suction device is entirely adjustable. The application of vacuum suction with vacuum chamber perforations ensures 100% dust aspiration of tablets.

5. Metal Detector

The metal detector offers identification of unwanted metallic traces on the surface of the tablet. It has a perfect identification system that rapidly rejects those tablets which are contaminated with unwanted metal.

6. Auto-Rejector

An auto rejector device is designed to recognize the unacceptable tablets and separate them automatically. Nowadays, tablet deduster machine has weight and size measuring sensors that help to evaluate the correct formulation.

7.Discharge Chute

A discharge chute or tablet outlet allows discharging of cleaned and dedusted tablets from the machine into the collection bin that could be different drums or containers as shown in the figure.

8.Dust Collector

With the help of the vibration of stainless-steel perforated plate and compressed air, dedusting is achieved and the dust is blown off using compressed air into a dust collector.

9. HMI

All basic operations, monitoring, and procedure adjustments are based on an HMI system that ensures easy utilization and optimizes the performance of the tablet dedusting process.

5.What are the industrial applications of tablet deduster machines?

1) Pharmaceutical Industry

Tablet deduster machine is of equal importance in the pharmaceutical industry as tablet press machine. This is well known that patient accepts those drug products that offer a physically aesthetic and clean appearance. Indeed, competitive pharmaceutical industry with high production demands for tablets must have to deliver perfect and quality tablet dosage form to achieve production targets. Hence, tablet deduster presents a reliable operating system even under the toughest conditions as well as applicable for all types, shapes, and sizes of tablet format.

2) Nutraceutical Industry

Nutraceutical items such as vitamins, dietary supplements, prebiotic, probiotics, etc have a challenging manufacturing process. The reason is the incorporation of highly sensitive material and environmental requirements. Tablet deduster machine is the most requiring equipment of the nutraceutical industry as it perfectly meets all quality standards approved for healthcare formulations with excellent protection.

Tablet deduster is ultra-speed equipment that is well-suited for larger-scale production of the nutraceutical industry for surface cleaning of tablets.

3) Food and Confectionery Industry

What if you find some metallic traces before adding sweeteners into the cup of coffee?

Similarly, when your child takes chocolate beans you must care for their health and safe eating.

That’s why you prefer those products that are manufactured by a competitive and well-trusted firm. Because they understand how your health is important to them.

Tablet deduster machines have been in demand in the food and confectionary industry for the last few years due to their safety and reliability outcomes.

So now, tablet dedusters are considered as well-suited machines for the food and confectionery industry that allows a safe, quicker, and consistent tablet manufacturing line.

4)Veterinary Industry

Home is full of joy with pets!

Every pet lover and veterinary medication manufacturer must know the importance of good and quality tablets. Thus, tablet deduster is of prime importance when it comes to delivering a veterinary tablet. A Tablet deduster machine is a perfect machine that can evaluate the behavior of the product, free of metallic traces, safe and quality tablet for poultry, farm animals, domestic or pet animals.

5) Chemical Industry

Manufacturing of chemical products is a highly sensitive procedure as minor failure can affect the whole chemical process and batch rejection.

That’s why good clinical and research laboratories opt for the excellent supplier to get well satisfactory chemical products.

The chemical manufacturing industry utilizes tablet deduster machines to give a good physical appearance and highly potent tablet products. For instance, pH tablets, buffers, sodium hydroxide, etc.

6.How a tablet deduster benefits a tablet production process?

The basic advantages of tablet deduster machine are as followed:

1.Compatible with All Formats of Tablets

Tablet deduster machines offer extensive compatibility features to deal broad category of tablets of various formats. The deduster machine can process approximately half a million tablets in an hour. Due to gentle agitation of spiral body, dedusting of tablets takes place with lesser harm to their surface.

2. Adjustable Speed Controller

The tablet deduster machine has an adjustable speed controller that allows you to select unique agitator control according to your choice. This property of the tablet deduster machine is flexible that fits to remove dust particles from tablets where speed is necessary to control.

3. Easy to Use

Tablet deduster machine is easy to operate and easy to integrate with other types of equipment such as tablet press machines. Using a built-in HMI touch screen controller or control knob, you can feed the acceleration, timings, and other parameters and start the machine. Hence, to operate the tablet deduster you do not require extensive user training and expertise.

4.Easy Maintenance

The entire making of the tablet deduster machine is of stainless steel. Therefore, this machine is not only approaching the safest zone but also easy to maintain. The Tablet deduster machine is accompanied by a vacuum cleaner, perforated or sieve plate that is easy to clean. Moreover, this equipment is comfortable to wash with purified water without having a risk of developing rust or corrosion.

5. Safe and Hygienic

The Tablet deduster machine is equipped with a metallic deduster which is an almost latest technology that offers a high degree of product safety and hygiene. High-performance tablet deduster not only by capturing unwanted dust particles using high vacuum and air blowing but can detect the presence of metallic traces that might be incorporated during the production process.

6.Reliable Operation- Auto Rejection System

A tablet deduster machine yields a reliable and adjustable work process that fits any type of tablet. This machine can handle a large production volume with unique acceleration. Therefore, the industry with a larger batch production trend toward tablet deduster machines. With the auto-rejection system, it enables to identify of deviant tablets and separate them from other tablets into the rejection cup.

7.Low Noise and Require Less Capacity

A Tablet deduster machine is a fairly simple machine that performs leading functions with low noise. Tablet deduster machine works efficiently to deal bulk quantity of tablets, with less maintenance, noise and occupies a lesser surface area for installation.

8. Cleaned Production Area

A tablet deduster removes dust particles from the tablet surface with the help of compressed air and a carefully vibratory mechanism. This, in turn, allows stable and undamaged tablet’s surface while dust particles are sucked away using a vacuum suction device that ensures the product cleaning as well as a production area.

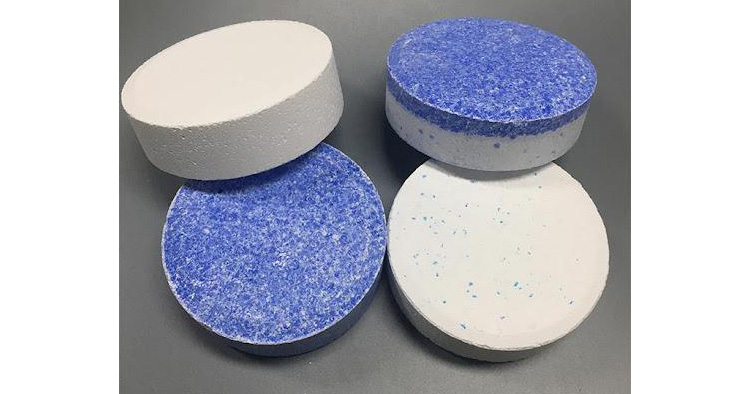

7.Can tablet deduster be utilized as a tablet polisher?

Yes, a tablet deduster machine can be utilized as a tablet polisher concurrently. The design and structure of the tablet dedusting machine are perfectly suitable for tablet smoothening and polishing especially for larger quantities.

The inlet of tablet deduster machine is integrated with tablet press machine while the presence of a metal detector, perforated plate, and elevating of tablets with continuous shaking not only offer dedusting but high- level of tablet polishing.

The tablet deduster machine not only benefits you with excellent polishing and dedusting performance but it also offers a safe and leaner production line to manufacturing goods.

8.How to operate a tablet deduster?

The below is a brief guideline for operating a tablet deduster machine. You may implement these operating points for most tablet deduster machines as a standard guideline.

Here we go!

Pre-Startups

- Before operating the machine, you should inspect if there is any remnant material in or around the deduster machine.

- Asses the machining process area that must be cleaner.

- Assess the relative humidity ( 40%-50%), and the room temperature (18-24) ℃.

- Equipment should be connected with the Power supply, also receiving a three-phase ‘alternate current (AC) if necessary.

- Monitor if dedusting is operational.

- The machine operator should properly wear a mask, pair of gloves, and goggles.

Start-Ups

- Replace the ‘Clean’ label with ‘Under Operation’ or ‘Processing’.

- Make sure ‘Tablet inlet’ or Feeding mouth of the tablet deduster machine is integrated with the ‘discharge chute’ of the tablet compression machine.

- ‘Switch ON’ the tablet deduster machine along with the tablet press machine if integrated.

- Connect the de-dust tablet container/ drum/ or polythene bag for tablet collections.

- Collect the dedust powder from the dust collector and treat them as recoverable form.

- Adjust the tablet's dedusting speed, and other parameters according to your requirement either ‘Setting Manually’ or using an HMI controller.

- Once the operation is completed, ‘Switch Off’ the machine.

- Remove the de-dust collecting cup which is mostly present at the sifter chamber.

- Gather weight and document the collected weight.

- Change the label from ‘Under Process’ to ‘To be Cleaned’.

9.How to clean and maintain a tablet deduster?

Discussed below are the following standard guidelines applicable for the cleaning and maintaining a tablet deduster machine.

Cleaning

- Remove the stuck powdery particles with the help of a ‘vacuum cleaner’ as well as a lint-free cloth.

A) Dis-assembling of Tablet Deduster Machine

For cleaning dis-assemble the tablet deduster machine in the following order:

1.Feeding Hopper

First, remove the tablet feeding hopper from the tablet deduster machine.

2. A food grade gasket

Dismantle the food-grade gasket by loosening the locking screws.

3.Perforated Plate

Remove the spiral perforated plate by loosening the tightening handle with the help of a screwdriver.

Loosening of tightening handle

Dismantling helical perforated plate

Carefully removing whole perforated plate for cleaning and maintenance purposes

- With the help of a Nylon brush, clean the residual foreign particles in the sifting areas.

- You may wash the equipment using 0.1% Teepol solution in raw water.

- After washing with Teepol solution, rinse the equipment with raw water to wash out Teepol solution from equipment.

Now rinse the equipment parts using purified water.

NOTE: Some machines are designed with inlet and outlet pipes for washing purpose that allows entry of rinsing and releasing of wastage water from the system. In this case, disassembling of the machine may not be required.

- With help of a lint-free cloth clean the vibratory or agitator base.

- Document the cleaning of equipment in the ‘logbook’.

B) Assembling of Tablet Deduster Machine

After cleaning the tablet deduster machine, assemble the unit in reverse order of disassembling. After assembling integrate the unit with the tablet press machine by connecting the discharge chute of the tablet press machine with the hopper of the tablet deduster machine.

2.Maintenance

A tablet deduster machine is a simple, robust, and reliable machine that requires low maintenance for efficient working. Somehow, you may inspect the following points to sustain the tablet deduster machine in a good condition.

- For routine maintenance, it is necessary to wipe the surface of the tablet deduster machine using 70% alcohol and then wipe it off with a dry and soft piece of cloth.

- Inspect and scrutinize the room temperature and relative humidity. The machine should not be operated at high temperatures for the long term that may affect the shelf life and working efficiency of the equipment.

10.What are the failure and pitfalls of a tablet deduster? How do you troubleshoot them?

Tablet deduster machine is easy and ultimate dedusting equipment that performs high- chores with effortless settings.

Sometimes, this machine may generate unwanted outcomes that need to be properly treated to sustain the working efficiency of the production line.

Discussed below are the following technical problems with possible troubleshooting of the tablet deduster machine.

1.Machine Doesn’t Work

Sometimes, when you operate the tablet deduster machine, it doesn’t respond.

- The possible reason for this problem might be a poor connection with the main ‘Power Supply’. Therefore, properly examine the main connection and repair where requires.

- The switch might be damaged or need replacement with a newer one.

2.Low De-dusting Speed

Tablet deduster is an ultra-high deduster machine. Sometimes, you may achieve the required speed that you fed in the system.

- The possible reason behind this problem might be an error in vibratory regulator or software that must need to be fixed by contacting the supplier.

- The parts of the tablet deduster machine might loosen during disassembling and assembling procedure. Hence inspect the machine and tighten the components of the tablet deduster machine properly.

3.Generation of Noise

This is a common problem of a tablet deduster machine, that is accompanied by the generation of unusual noises during the running of the process. The possible causes are:

- Loosening of basic components of the machine. Therefore, re-install the entire assembly.

- Tighten all loose components of the machine.

4.Machine Can’t Produce Vibration

This is an unusual technical issue that doesn’t occur in general routine. To deal with this problem:

- Improper electric supply.

- Improper signaling or data input

- Connection problems between the parts of a dedusting machine.

Therefore, you must disconnect and reconnect the device, and contact the technical team for a solution.

5.Tablets Drops into the Dust Tray

Sometimes, a tablet may drop into the dust collecting tray instead collection box.

Tablet Deduster

This problem might be arisen due to a change in the position of the Feed inlet or tablet outlet into the collection box. For this, you just need to tighten the sieve and check if it works properly or not.

6.Inadequate Vacuuming of Tablet Deduster Machine

Sufficient vacuum suction is compulsory to achieve a significant dedusting of tablets. Sometimes, the machine can’t create adequate vacuuming to carry out dedusting functions.

The cause of this problem might be when the vacuum cleaner is functioning properly hence it cannot create an optimized vacuum required for the tablet. Therefore, you must examine the vacuum cleaning and suction activities of the machine regularly. Clean the debris if it presents. Furthermore, replace the vacuum cleaner with a newer one.

11.What precautionary measures you should follow when operating a tablet deduster?

When operating a tablet deduster machine, the following precautionary measures should be considered:

1.Avoid working if electrical wires are being damaged or worn out. You must inspect before operating the system and replace them.

2. You must wear Personnel Protective Equipment for your and the product’s safety.

3. Never initiate the process if the machine is not properly cleaned or dried.

4. Always integrate the unit when it is completely powered off. Avoid integrating the machine with other equipment if it is already connected to the electrical power supply.

12.Why is a metal detector integrated with a tablet deduster? Why it is so important?

With a lot of advancements in tablet deduster technology, the integration of metallic detectors is introduced. This innovation is highly in demand for treating pharmaceutical, nutraceutical, food industry goods and is considered highly advantageous in this sector.

The detection of metal is very important in foods or orally administered drugs.

Tablet Deduster Machine with Metal Detector

The working principle of the metallic detector is based on electromagnetic induction. The induction of electromagnetic frequency automatically makes attractive forces that ultimately remove the metallic traces available in the formulation and rejects them from the manufacturing process. This metallic detector is easy to clean and compatible with all types of tablets.

13.Can dust re-enter into tablet deduster machine?

Most often when you operate tablet deduster machine, it yields a smooth and high-quality performance. In some cases, dust from dust collector re-enters into the system that interrupts the whole process, could cause dust to be blown out into integrated units such as tablet press, tablet collector.

As you know, removing dust consistently without fluctuation in optimum vacuum pressure is mandatory to run through out the procedure.

If tablet deduster is pressurized unreasonably it will cause interruption to whole process.

Tablet deduster is interconnected with tablet press and tablet collector. Thus, the entire series, although dust collection system of tablet deduster and tablet press is separate.

You must maintain the dust collection unit correctly. If they are not balanced, then tablet could be reversed back into tablet press machine.

Because, airflow of tablet press machine dust collection is much stronger than tablet deduster dust collection, so a balanced vacuum pressure is required.

14.What are the different types of vertical tablet deduster machines?

There are two basic types of vertical tablet deduster machines:

A) Vertical Downward Conveying De-duster

This type of deduster machine is considered as an older version deduster which is similar to horizontal type tablet deduster machine.

As its name shows tablets are introduced from the top of a machine that moves down from perforated plates and exits from the tablet outlet.

This type of deduster machine is also very noisy as a horizontal type machine and cost-effective too.

B) Vertical Upward Conveying De-duster

This type of machine is highly popular and extensively utilizes in a broad industrial sector.

A spiral perforated tray is mounted around a center column or tightening handle. This machine occupies a shorter surface as compared to a horizontal type of tablet deduster machine. Furthermore, working efficiency of vertical upward tablet deduster is far better than horizontal tablet deduster machine. The entry of tablets takes place from the bottom of the machine that ascends the tablet with slow agitation allows excellent dedusting process due to longer resident time.

15.Can you integrate a tablet deduster with a tablet press machine or pill press machine?

You can integrate the tablet deduster machine with the tablet press machine by connecting the ‘Feeding hopper’ of the tablet deduster machine with a ‘Discharge Chute’ of the tablet press machine’. The integration is done such as way, that it minimizes the chances of cross-contamination and low production.

16.What are the future trends and global business demands of tablet deduster machines?

The global business demand and future trends of tablet deduster machines highlight significant marketing growth opportunities and improvement in business optimization.

Tablet deduster performs elevating as well as dedusting procedures concurrently with ultra-high-speed is ideally needed for broad-scale pharmaceutical, chemical, food, and related sectors.

The market size of tablet deduster machines between 2021 to 2027 is expected to reach up to USD million. Thus, this increase in the future trend of tablet deduster machines will allow high-profit revenue.

Furthermore, this emerging trend is applicable for spiral perforated tablet deduster and elevated conveying tablet deduster machines.

17.What are the mandatory requirements that you must consider before purchasing a tablet deduster machine?

Before purchasing a tablet deduster machine, you must assess your requirements in the following points:

1. Identification of Batch Size

Before buying a tablet deduster machine, you must assess for minimum and maximum tablet sizes. Prior knowledge of the tablet sizes will help you to determine the capacity of the machine that is necessary to transport and dedust the number of tablets effectively.

2. Determination of Dedusting Capacity

Before going to decide on a tablet deduster machine, you must assess the output of the tablet press machine each time. The following information will let the vendor consider a suitable tablet deduster machine for your requirement.

3. Assessing Nature of Tablets

Not all tablet deduster machine is suitable for every manufactured tablet. You must assess the nature of the tablet before deciding on a tablet deduster machine.

For instance, effervescent as well as soft tablets may require different tablet deduster machines instead of too many vibratory deduster machines. Because too much agitation may affect the quality and stability of these tablets. Furthermore, you may need a dust-tight controlled system that restrains exposure of dust into the production room and protects the workers.

Nature of Tablets- Tablet Deduster

4.Considering Metal Detector

You must determine if the tablet deduster machine is accompanied by a metal detector. A metal detector is of prime importance when it comes to pharmaceutical, healthcare, and food products in order to offer a high degree of safety and purity of the delivered drug.

Tablet deduster- Metal Detector- Picture Credit- Powder and Bulk Solid

5. Determine Number of Collecting Containers

You must consider the number of collecting containers require for dedusted tablets. The number of diverters will be needed according to the number of dedusted tablets containers that will allow safe transport of tablets without a developing risk for cross-contamination.

6. Evaluating the Height of Tablet Inlet

By determining the height of the discharge chute of the tablet press machine, you will be able to decide the height of the tablet inlet. Furthermore, always prefer those tablet deduster machines that have adjustable tablets inlet and outlet orientations without the need of using tools.

7. Cost and Types of Machines

If you have a low budget then horizontal tablet deduster is beneficial for you. This machine has advantages and disadvantages too. For instance, high- noise, low tablet dedusting efficiency, and small capacity for tablet dedusting process.

Besides this, if you consider a vertical tablet deduster machine then it would be highly advantageous with a helical perforated plate that allows small bouncing of tablets.

Except for the high initial cost of vertical tablet deduster machines, this equipment is faster and efficient to run a small or large-scale batch of tablets.

18.Does tablet deduster comply with international quality standards?

Before purchasing a tablet deduster machine, you must look for the design of the machine that should be approved and upgraded in compliance with global quality standards.

Tablet deduster machine is widely managed and certified by the following organizations:

1.cGMP Compliance

Tablet deduster machine is manufactured and certified by cGMP that ensures high-quality standards offer for products and customer requirements.

2. CE Certified

Tablet deduster machine is CE certified equipment entails quality standards regulated by European directives and regulations.

3. FAT test

Tablet deduster machine verifies a currently manufactured and packed mechanical equipment is suitable and capable to meet production requirements.

4. FDA Compliant

Tablet deduster is FDA compliant machine that entails highly robust, effective, and safe features without any false aspects.

Conclusion

No pharmaceutical or nutraceutical oral dosage formulation is completed without being treated with a tablet deduster.

The global market of tablet deduster is rising at a very faster pace with considerable growth rate more than previous years and is expected to grow more in future years i.e., 2027.

Consequently, tablet deduster is a quality solution for tablet dedusting process. It ensures a smooth and high performance routinely operation at the site of hundred of pharmaceutical industries which ranges from small to larger multinational manufacturing units.

You get what you pay!

Apart from machine cost, you must opt for tablet deduster by judging their efficiency, and ability to handle the capacity of tablets at maximum acceleration- Always remember to pay for effectiveness and productivity level of machine to obtain a trouble-free production line for a longer term.

We hope, now you’re able to decide the right and high performance-tablet deduster machine as an ideal tool to improve your future business up to a high level.