Why Choose Our Cartoning Machine?

High-Speed & Efficient

Automate the process of folding cartons, inserting products, and sealing for thousands of units per hour.

Accurate & Reliable

Advanced control system ensures every product is correctly inserted and cartons sealed.

Versatile Applications

Ideal for capsules, softgels, tablets, bottles, sachets, and oral liquid cartons.

GMP & CE Compliant

Stainless steel construction designed for pharmaceutical and nutraceutical production.

AIPAK Cartoning Machine Applications

Capsule & Softgel Supplements

Tablets & Chewables

Oral Liquids & Syrups

Powders in Sachets or Bottles

Cartoning Machine FAQ

1.What types of products can the cartoning machine handle?

It can pack tablets, capsules, blister packs, pouches, stick packs, cosmetics, and small electronics.

2.Can the cartoning machine handle different carton sizes and shapes?

Yes, the cartoning machine is adjustable to accommodate a wide range of carton dimensions and product types.

3.What is the maximum output speed?

The cartoning machine can achieve up to 100 cartons per minute, depending on product type and carton size.

4.Is the cartoning machine fully automatic or semi-automatic?

Models are available in both fully automatic and semi-automatic configurations to suit different production needs.

5.How easy is it to change over for a new product?

The cartoning machine features quick-change tooling and pre-set parameters, allowing fast and efficient product changeovers.

6.Does the cartoning machine comply with GMP, CE, or ISO standards?

Yes, all the cartoning machines are designed and manufactured according to GMP, CE, and ISO 9001 standards.

7.Is the cartoning machine easy to operate?

Yes, it comes with a user-friendly PLC control system and touch-screen interface, making operation simple and intuitive.

8.How often does the cartoning machine require maintenance?

Routine maintenance is minimal; daily cleaning and periodic inspection are recommended to ensure optimal performance.

9.Are spare parts readily available?

Yes, AIPAK provides global spare parts availability along with technical support.

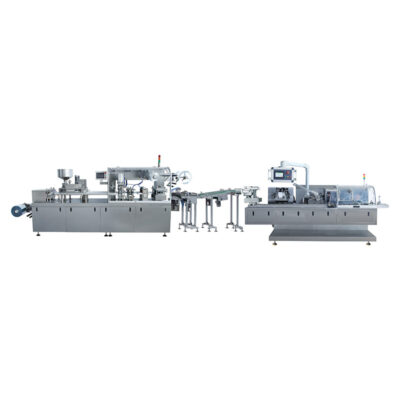

10.Can the cartoning machine integrate with other packaging equipment?

Yes, it can seamlessly integrate with blister machines, labeling machines, bottle fillers, and conveyors to form a fully automated line.

11.Does the cartoning machine handle fragile or delicate products?

Yes, it uses gentle feeding and handling mechanisms to prevent damage to sensitive products.

12.What are the electrical and space requirements?

Electrical requirements vary by model (220V/50Hz or 380V/50Hz), and space requirements are optimized for efficient factory layout.

13.Is training provided for operators?

Yes, AIPAK provides on-site installation, operator training, and detailed manuals.

14.What is the warranty period and after-sales support?

Standard warranty is 2 years, with remote support, on-site service, and spare parts supply.

15.Is the cartoning machine suitable for high-speed mass production or small batches?

Yes, different models support both high-speed continuous production and smaller batch runs, offering flexibility for various business needs.

Request Your Cartoning Machine Quote Today!

Fill out the form below and our sales team will contact you within 24 hours.