Table Of Contents For This Page

For your easy finding the new design and big difference of NJP 1200D Capsule Filling Machine from the original ones,we have prepared a lot of information on this page for you to delve into. To make sure you can find the information you want quickly, we have prepared this content directory that will jump to the corresponding location when you click on it.

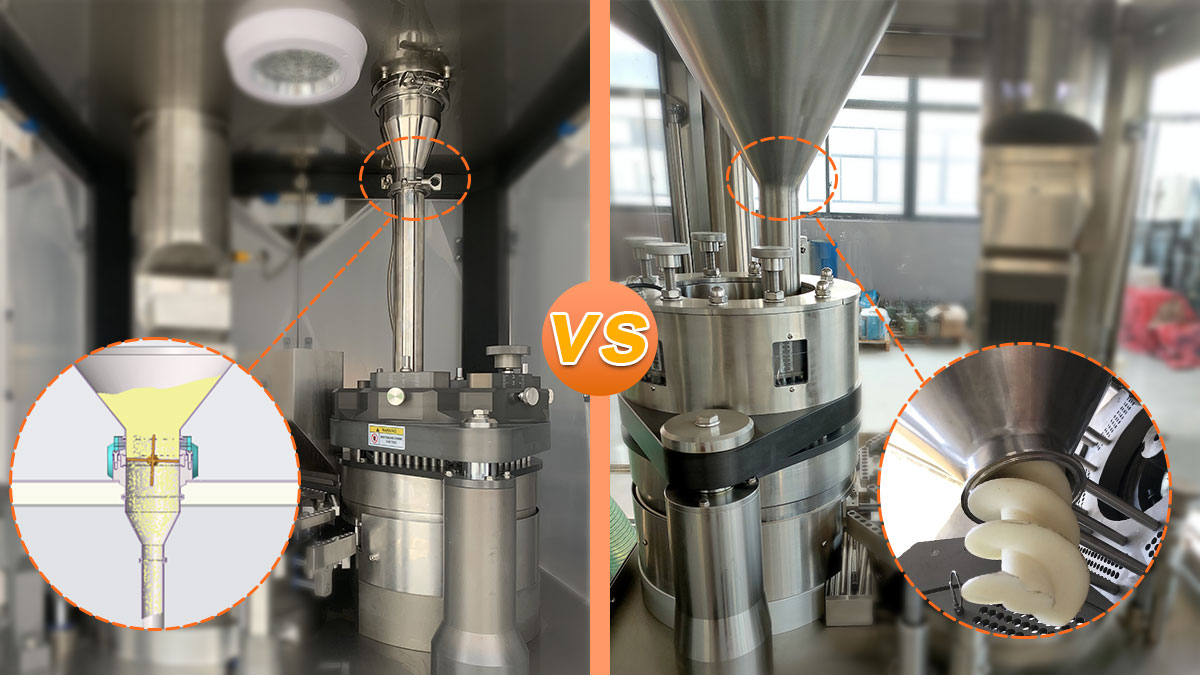

New Powder Hopper

New hopper adopts butterfly valve-type, powder feeding, and a pneumatic device ,is very suitable for drug powder with poor, liquidity, including Chinese herbal medicine and patent drug.

New hopper only takes about 8 minutes to disassembly,maintain and assembly.

Traditional hopper adopts screw feeding device, that the filling raw material may be hard to feed or adhere to the inner wall.And some powder may have poor liquidity,it is also hard to feed in powder.

Traditional hopper takes longer time to disassembly,maintain and assembly.

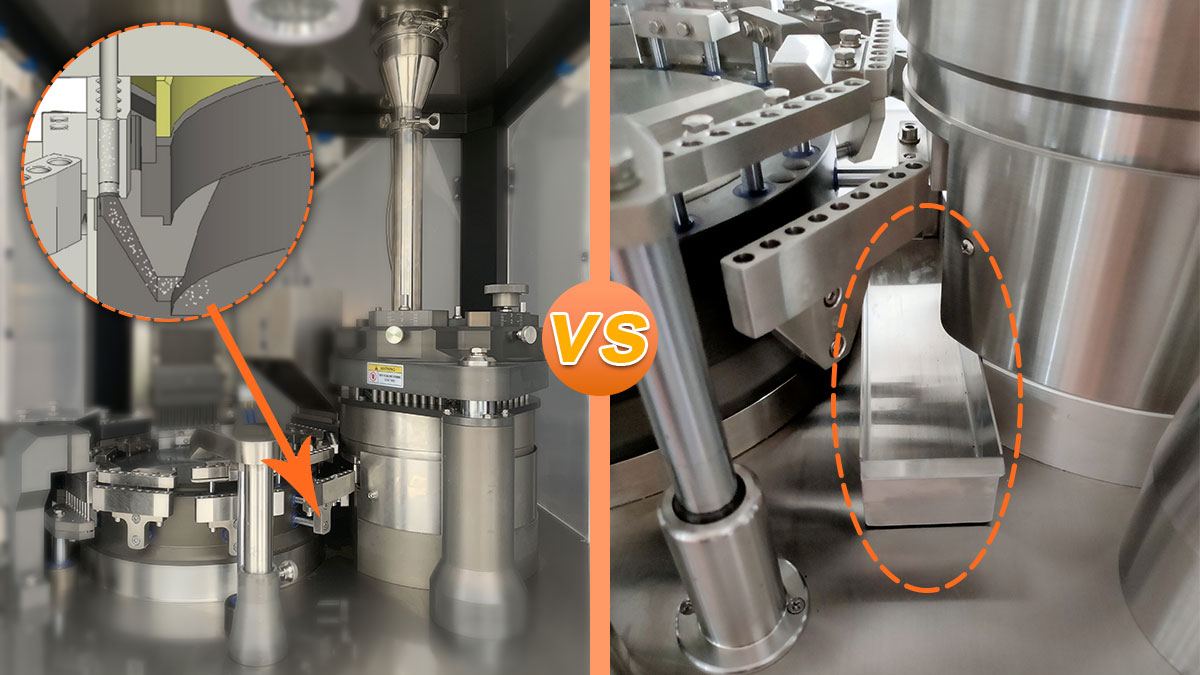

Capsule Feeder Rail

New capsule rail adopts linear guide transmission mechanism, with high operation precision and long service life. The enclosed design prevents waste capsule and dust from entering, ensuring the rapid and orderly seeder and accurate capsule orientation.

Traditional capsule rail adopts steel linear guide transmission mechanism,that is easy generating friction and broke the machine due to long time running.And no prevention from waste capsule and dust entering,continuous working cannot be guaranteed.

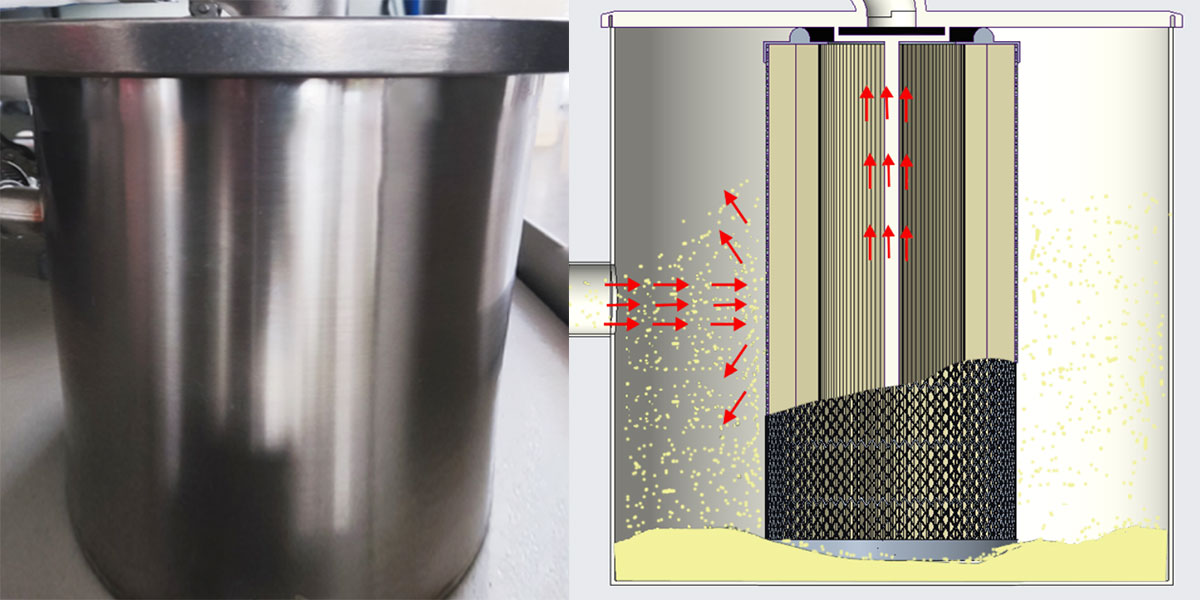

Anti-powder Leakage Device

New NJP 1200D was designed with a powder recycle bin inside the machine.

Traditional capsule filling machine doesn't has such device,that all the leaked powder just dropped on the worktable.

New NJP1200D adopts negative pressure technology, equipped with an independent powder diversion system, it can accurately recover the powder and avoid cross-contamination. The recovered powder can be directly used for production again, making it convenient and efficient.

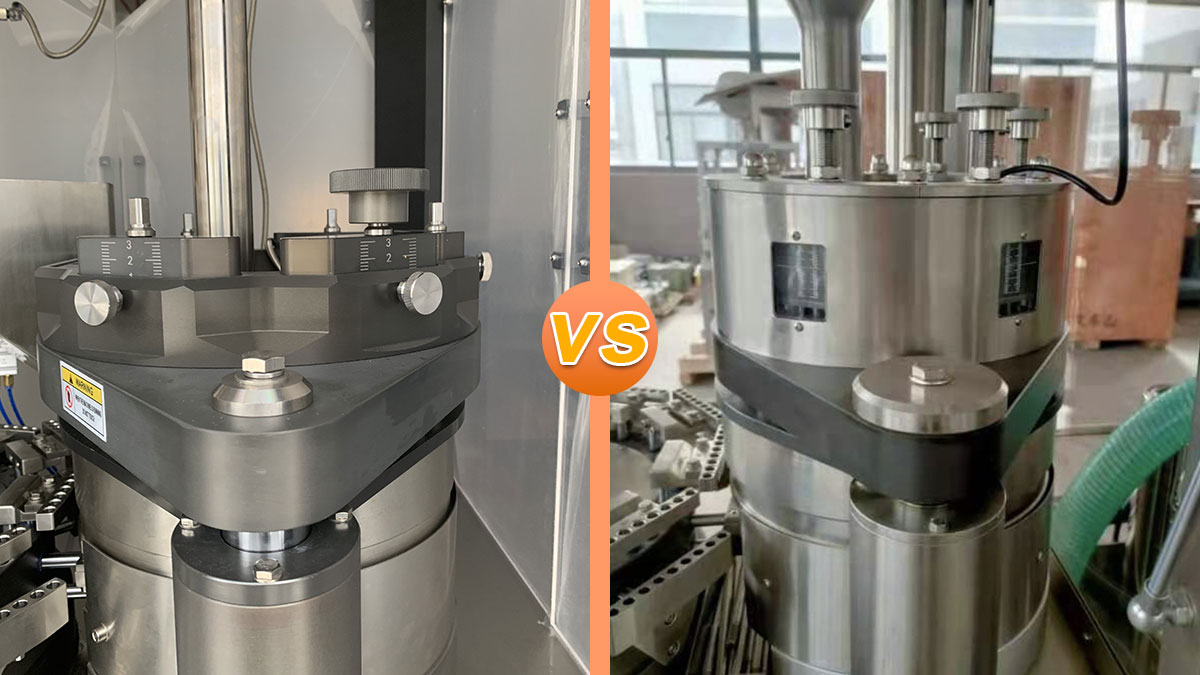

New Modular Design Unit

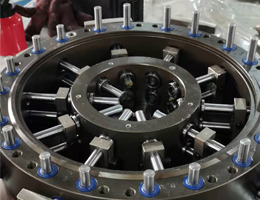

New Turntable

New structure turnable the upper and lower mold could move individually,with good sealing,that no powder entering into.

Traditional turnable the upper and lower mold couldn't move individually ,with good bad,that powders often enters into.

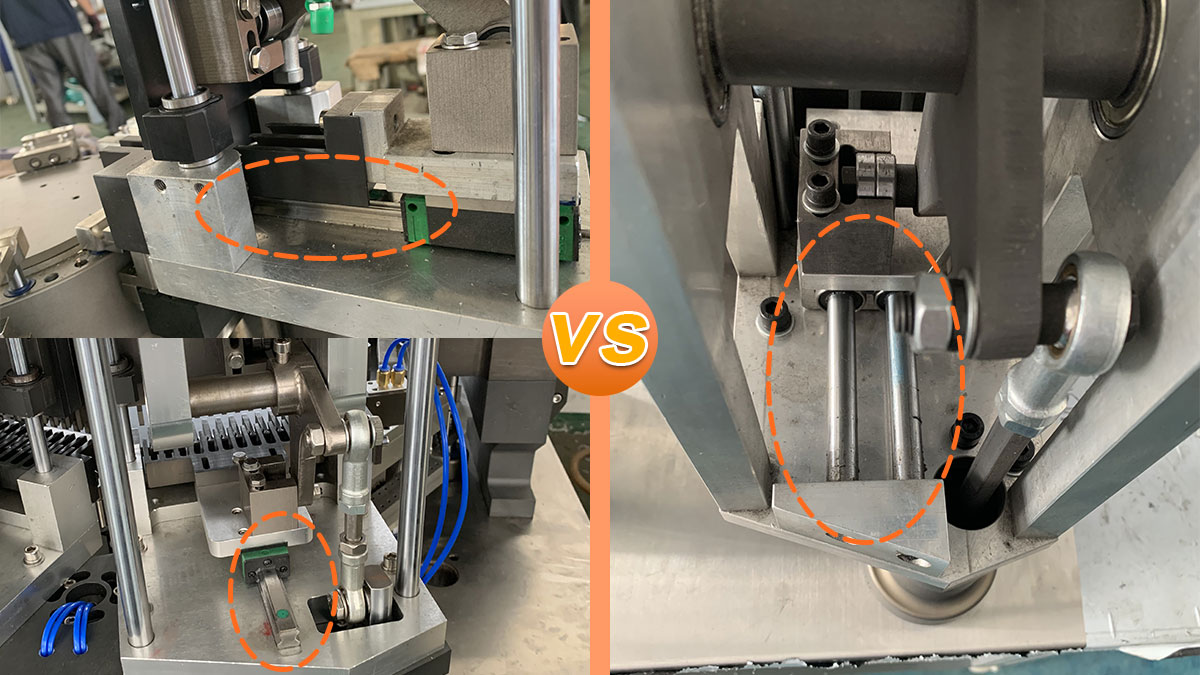

New Modular Filling Unit

New modular filing unit adopts modular design and filling gripper pin positioning, it is more fast and convenient to change for different types of mold.

Traditional filling unit adopts encircling sealing design and no filling gripper pin positioning,it is more complex to change for different types of mold.

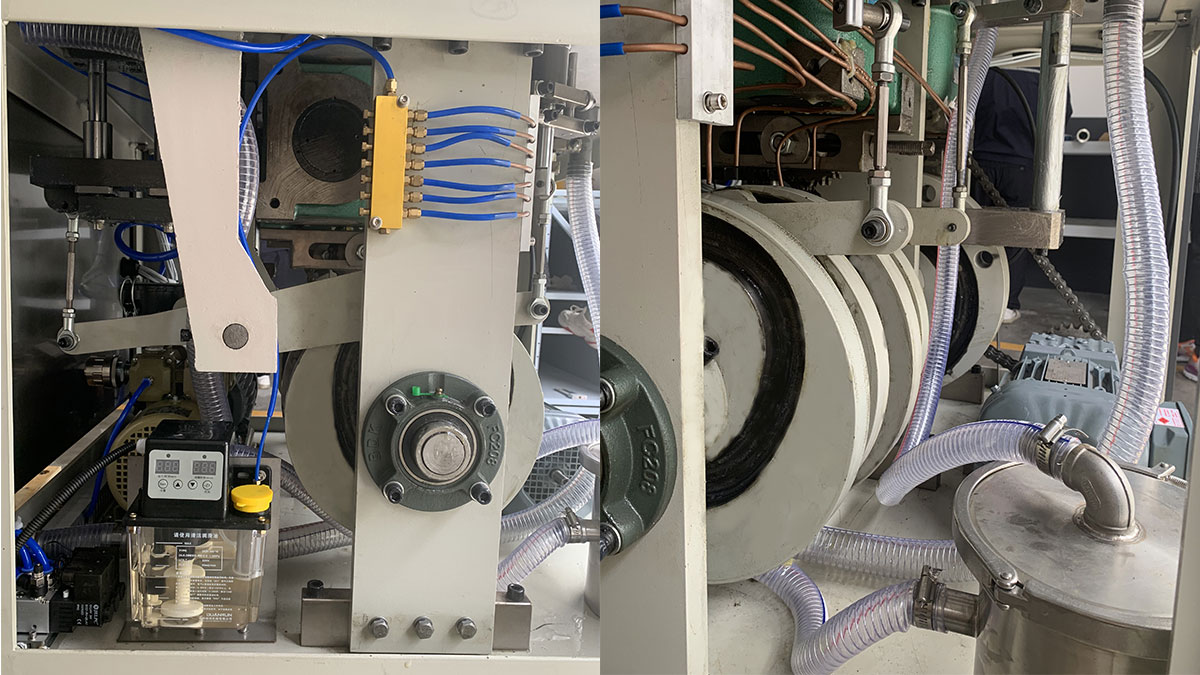

Automatic Lubricating System

Equipped with transmission mechanism automatic lubricating system, can achieve timing, quantitative, fixed point automatic oil supply. Make the transmission mechanism always maintain the lubrication state, improve the service life of the equipment, reduce the wear of accessories.

New Transmission System

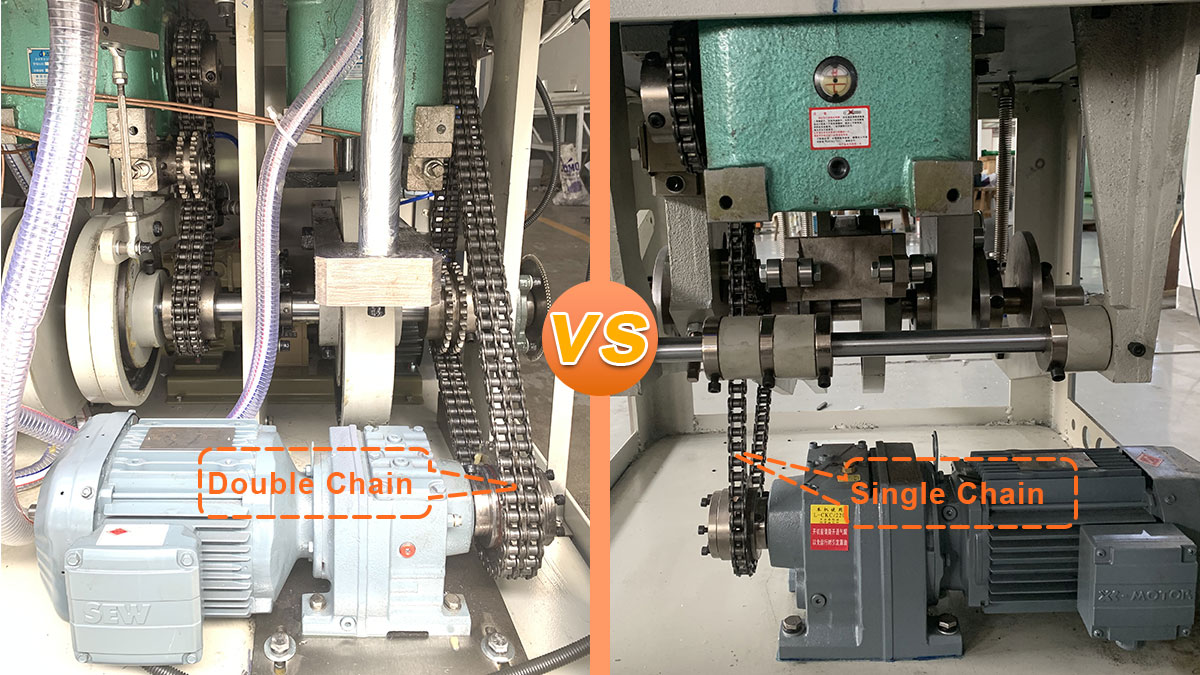

Double Chain System

New inner groove cam adopts double chain that makes the whole the machine's transmission have more power during long time running.

Traditional inner groove cam only has single chain that the machine will lack of transmission power during long time running.

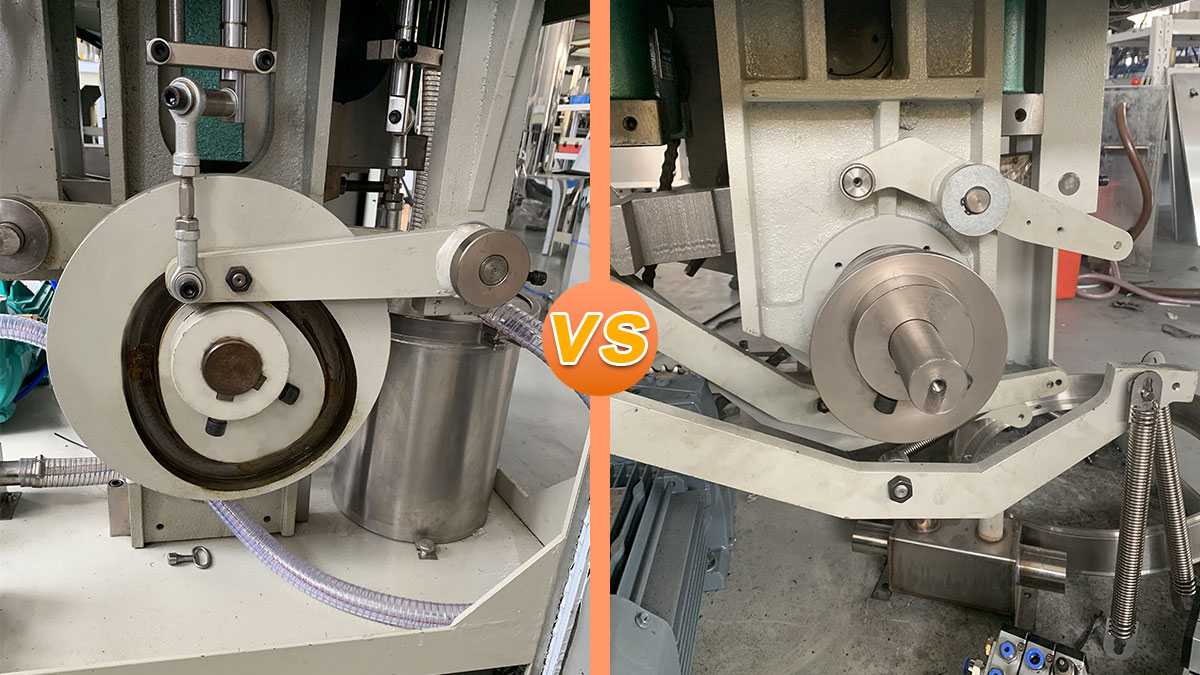

Internal Groove Cam

New NJP 1200D capsule filling machine added with internal groove cam that makes the machine's running and operation more stable and precise.

Tradition NJP 1200C capsule filling machine only has external groove cam that its working may become un-stable and un-precise during long time running.

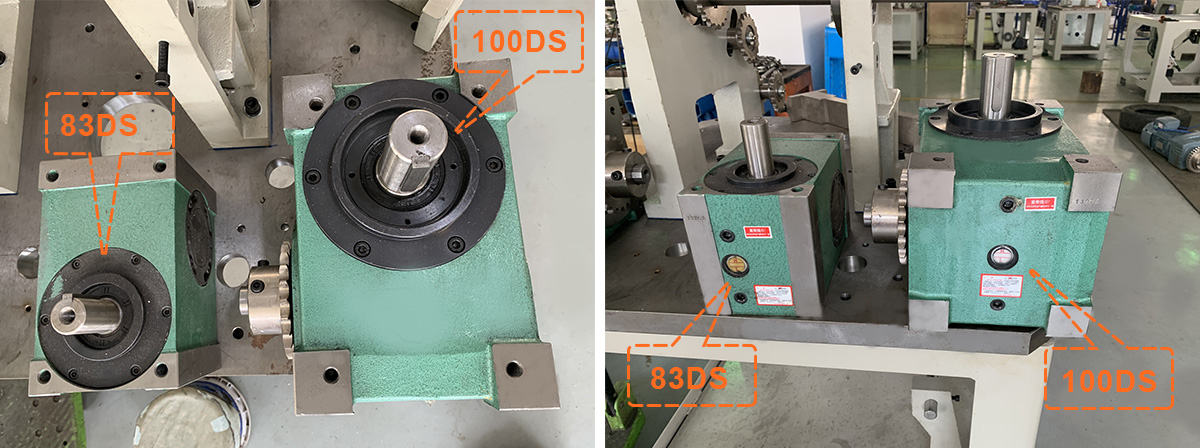

83DS Vs 100DS Cam Dividing Box

Adopts 100DS cam dividing box that the production cost increases, it also significantly enhanced the device’s production efficiency and service life. Its filling speed has been raised up to about 1100pcs capsule per minutes. Compared with the traditional 83DS cam dividing box whose filling speed is limited at about 900pcs capsule per minutes in proper working condition,If forcibly increasing the filling speed to about 1000pcs capsule per minutes and continuing the working condition for these machines that may cause breaking of the input and output shafts and the subsequent operation stopping.

Our company is at present the only enterprise in China to produce NJP 1200D full-automatic capsule filling machine with high-precision 100DS cam diving box.

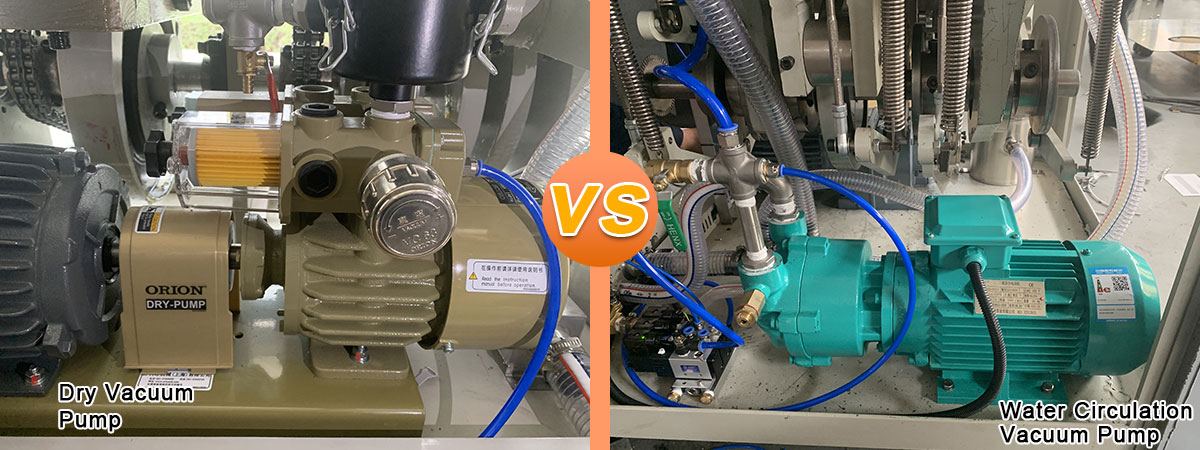

Dry Vacuum Pump

New NJP 1200D capsule filling machine adopts dry vacuum pump that is not only very quiet,but also will not generate heat and affect the temperature control of GMP workshop after continuous running.

Traditional capsule filling machine uses water circulation vacuum pump,that will not only generate noise,but also heat ,that makes the properties of the powder easy to change after long-term working.

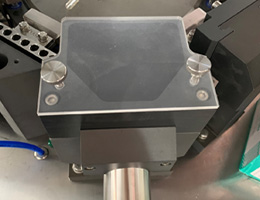

New Discharge Mechanism

New capsule discharge mechanism added with glass cover,effectively prevent dust entering and capsule contaminating and avoid the mechanical injury of the finished product capsule when it is discharging.

Traditional discharge mechanism has no prevention cover that dust is easy to enter and capsule may be injuried when discharging.

The Basic Knowledge About NJP 1200D Capsule Filling Machine

Get to know more basic knowledge about NJP 1200D capsule filling machine before making the final determination will help you boost your business and make the most suitbale choice.

What should be considered during the capsule filling process?

Specific factors must be taken into account during the filling of the capsule.First of all, The type of capsule you plan to fill will determine the type of machine you are using. You can use the fully automatic capsule filling device to fill different types of empty capsules.

What will you benefit from a capsule filling machine?

Using the capsule filling machine can save a lot of money that you can use it in other boring capsule filling practice.If you use the capsule filling machine domestically, it will save your money from the expensive capsules you buy on the counter.

What are different types of capsule filling machine available?

There are 3 types of capsule filling machines on the market now,they are Manual operated capsule filling machine, automatic capsule filling machine, semi-automatic capsule filling machine.

Learn more >

How many capsules can I fill per cycle?

It usually depends on the model that you buy.A manual capsule filling machine can fill and open capsule at the rate of 300 per cycle.For automatic capsule filling machine ,it depends on the capacity of the machine you buy.Like NJP 1200D,it can fill 72,000pcs capsule per hour.

Learn more >

Does the Capsule filling machine require regular maintenance?

Yes, it does. Capsule filling manufacturers suggest you regularly maintain the machine so that it works efficiently, especially if its left unused. There may be greasy lines left in the use of the machine that requires cleaning.

Learn more >

What are the important factors I need to consider when buying a Capsule filling machine?

To buy the right capsule filling machine for your business, you need to keep a few things in mind.The brand makes a huge difference, so consider buying from a trusted brand.

A Brief Self-nomination ,Why Choose AIPAK?

Tons of pharmaceutical equipment suppliers have been rising due to wordwide importance to health and drugs over time.AIPAK is one of the biggest names there is.Thousands of satisfied customers and clients testify that all AIPAK pharmaceutical machineries are above conventional products and one of the highest level when it comes to quality and actual manufacturing requirments.AIPAK always adhere “Quality First” “Technology innovation” as its targest service principle,all machines must have strict quality tests before exporting.

Leading Professional

Manned with industry-leading engineers and professionals.

Reliable Service

24/7 online customer support-have your concerns attended by our sales and support professionals.

Trusted Company

AIPAK has been partnered with many known clients for years and numbers just won’t stop.

High Quality

All machines must be tested and inspected for running before delivery.

Low Cost

AIPAK used cutting-edge technology allowing low-cost production for affordable products

Experienced

The company’s expertise has been taked advantages of by the global market for over 15 years now.

Try New NJP 1200D To See The Magic!