What Can You Get?

What Are Your Feeder Options?

Why Choose AIPAK Roll Plate Blister Packaging Machine?

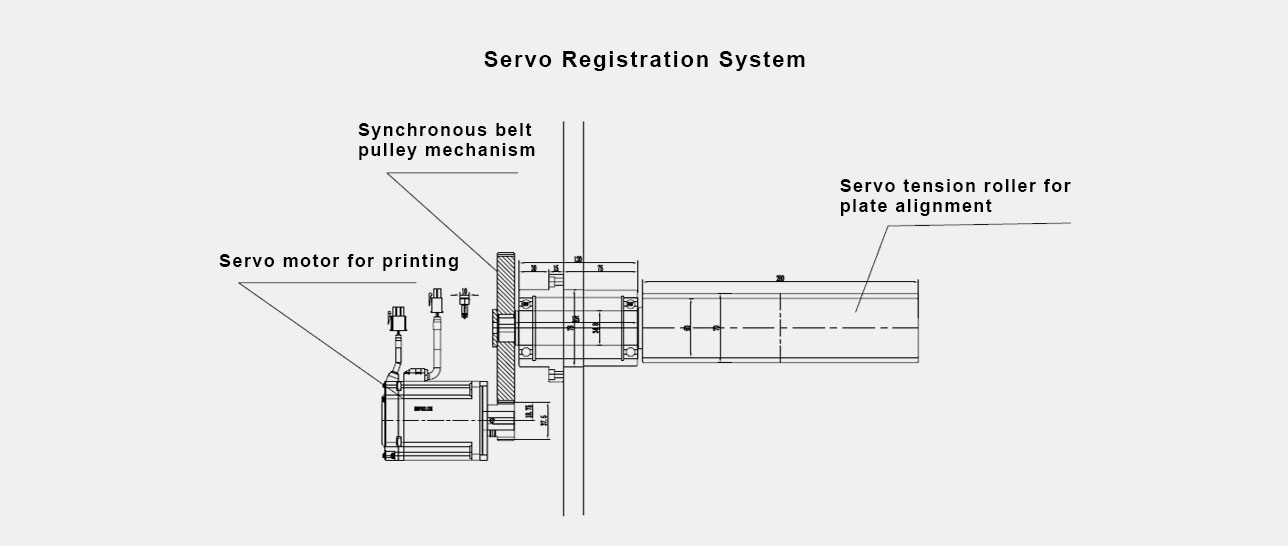

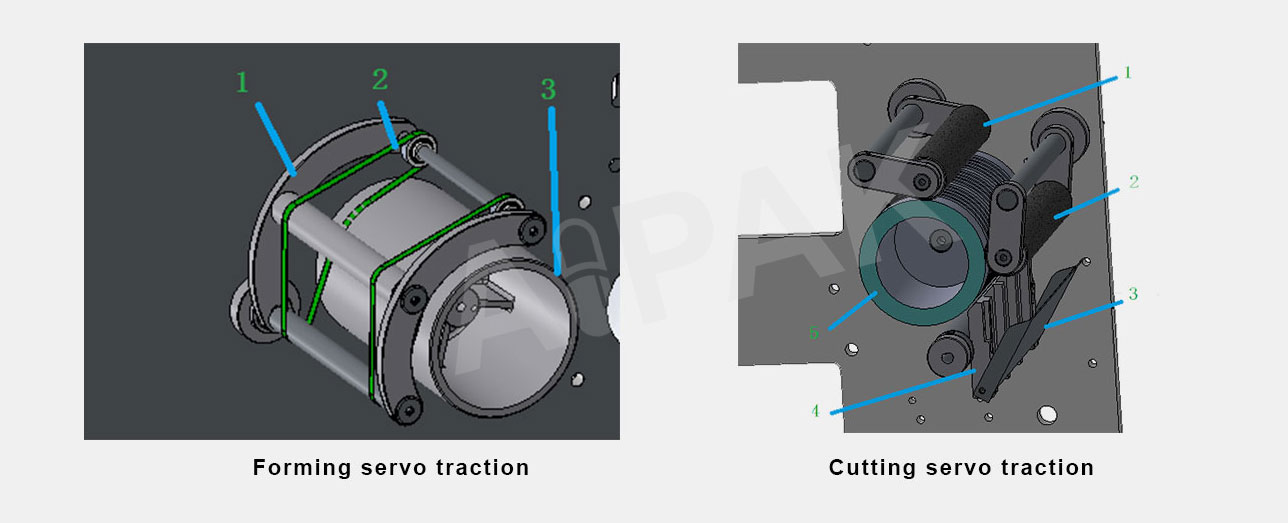

Full Servo Controls The Entire Operation

With 6 Servo Motor, full data-driven intelligent operation, you are able to complete all operations/variety adjustments on the touch screen or able to store operational data and you only need to retrieve your product name, no need for adjustment, you can also upload your servers, data communication and collection.

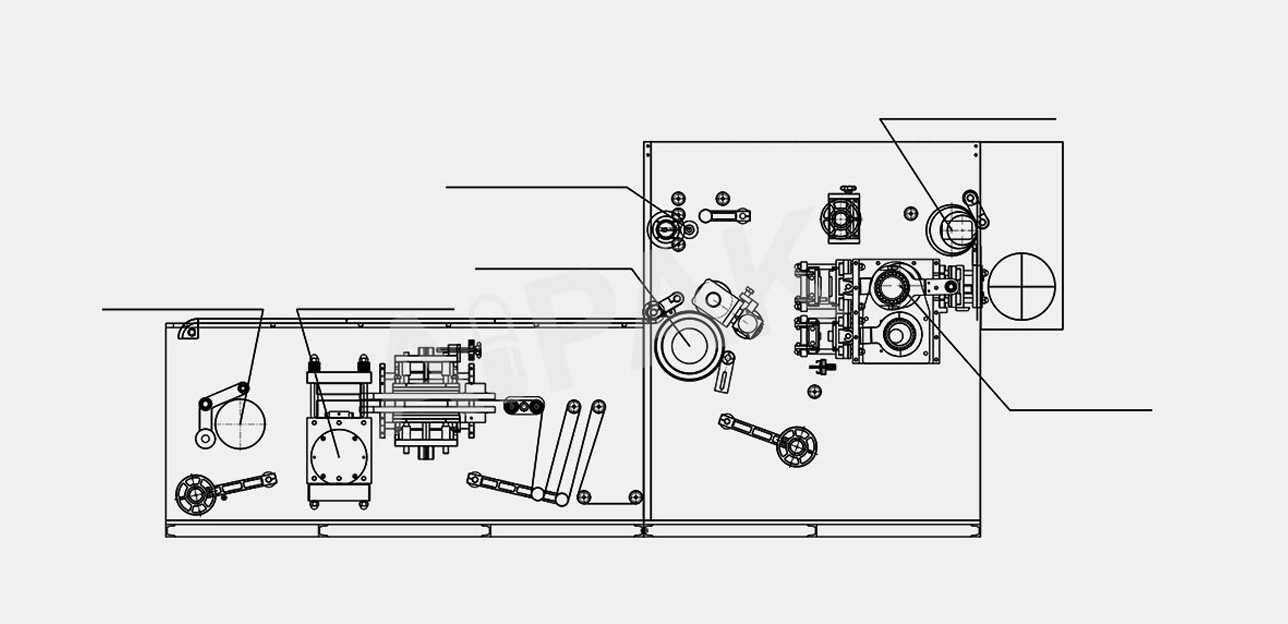

No Shaft, Chain, And Gear Connection

Everyone knows,the simpler structure of a machine ,the simpler the operation,the better use the machine is .

AIPAK roll plate blister packaging machine is simple in structure,no shaft, chain, and gear connection.You will no need to do any manual mechanical adjustment when changing the mold.

Full Touch Screen Parameter Settings

Can effectively alleviate the shortage of technical personnel in pharmaceutical companies.

And it has a one-click restore function to avoid human differences and interventions.

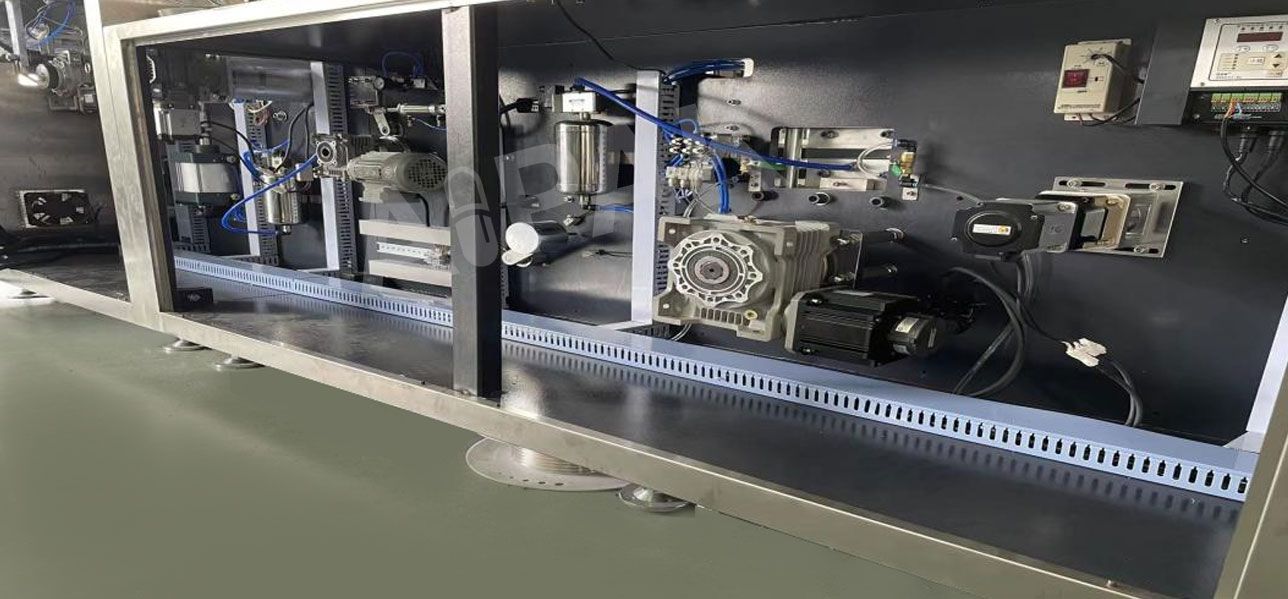

Independent Electrical Control Box

With independent electrical control box, as well as the Panasonic servo system and programming control framework of the same brand, completely solve the interference problem between servos. In addition, cooling, maintenance, and upkeep are safer and more convenient.

Advantages of AIPAK Roll Plate Blister Packaging Machine:

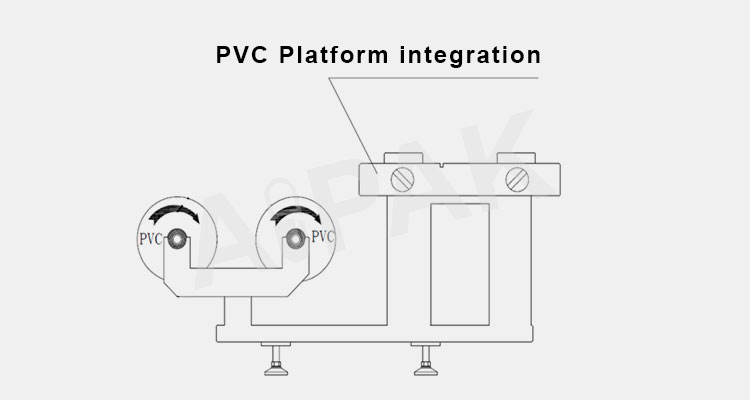

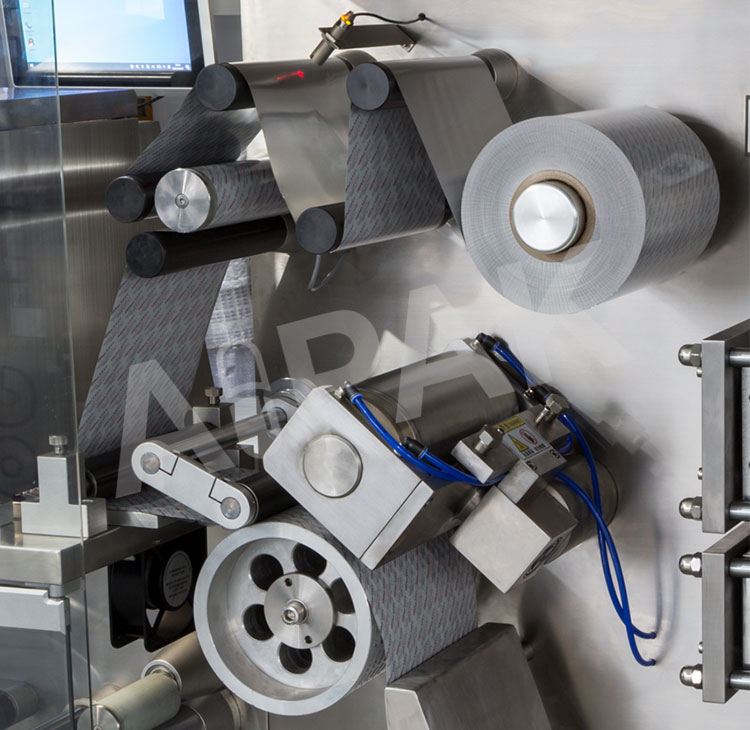

I.External PVC/Hard Aluminum Frame And Quick Docking Platform

External PVC roll holder can hold large rolls of PVC, reducing the need for material replacement and ensuring the production efficiency of the equipment.

Innovative design PVC quick docking platform, you will be more easier replace the PVC and PVC docking, greatly reducing your time for changing packaging materials, and will also reduce the technical requirements for your operators.

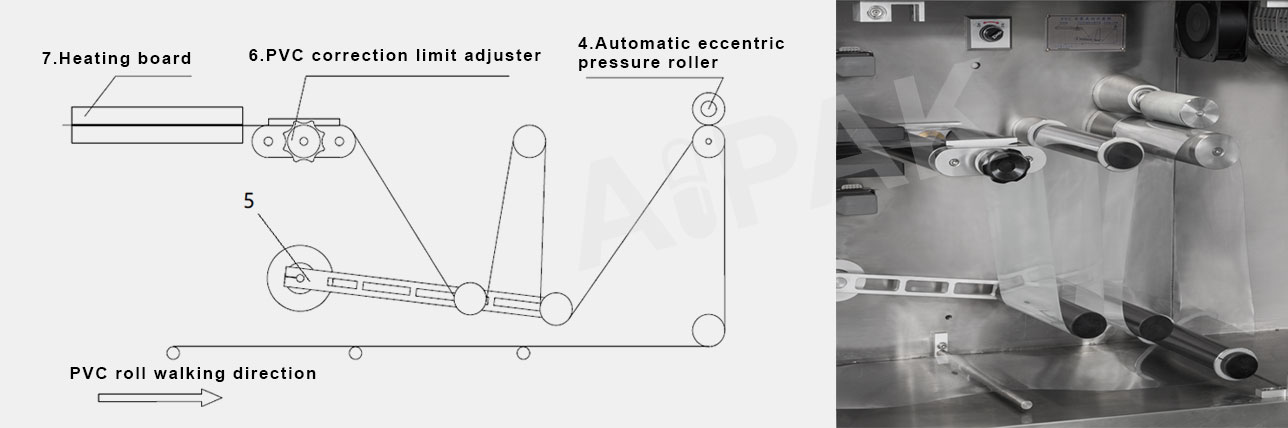

II.Material Active Output Mechanism and PVC /Hard Aluminium Correction Device

A. By using an automatic eccentric pressure roller (4) for synchronous active conveying with heating and forming, it avoids deformation of the softened packaging material due to passive transition stretching.

B. By using a balance pendulum (5) for material feeding, the feeding motor can be avoided from frequently starting and stopping, and vertical pressure can be applied to the material to ensure that it is laid flat without wrinkles.

C. Equipped with PVC manual adjustment and correction device (6) for PVC/hard aluminum strip, ensuring that the PVC/hard aluminum strip will not deviate, and the forming, heat sealing, and punching positions are correct.

III.Innovative PVC Heating Mechanism

A. The heating board adopts the PID pulse heating principle, which is uniformly heated and can delay the aging of the internal coils of the heating board.Its surface adopts imported composite coating to ensure even heating and wear resistance of PVC, with a 4-year warranty without damage.

B. Adopting upper and lower cylinder control, the upper and lower parts can be fully opened simultaneously or independently operated on the touch screen to avoid scalding for packaging material changing workers.

C. The heating board has a guided sliding structure as a whole. Can be horizontally moved left and right through the handle, ensuring more time-saving and labor-saving operation for changing molds and varieties.

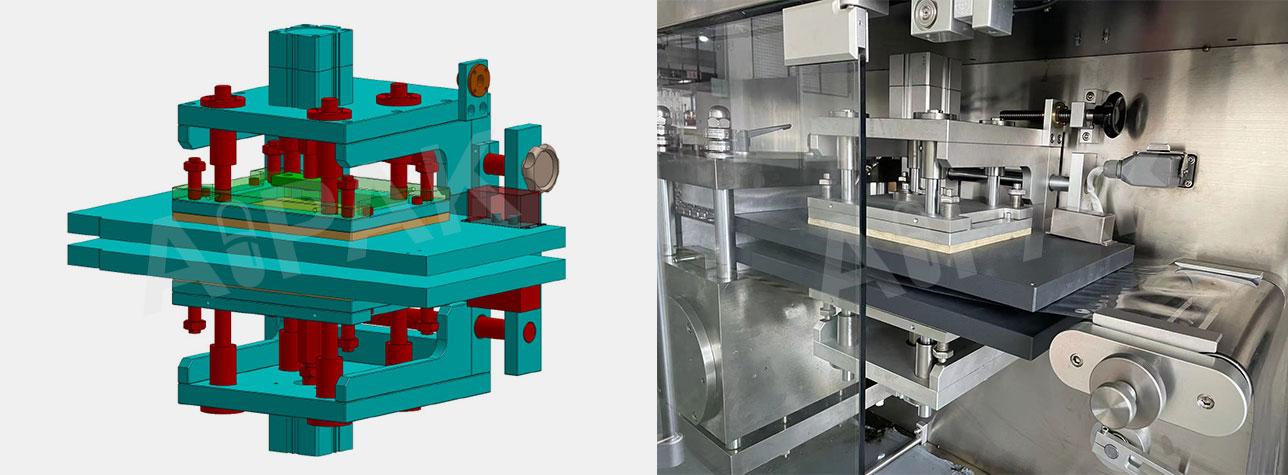

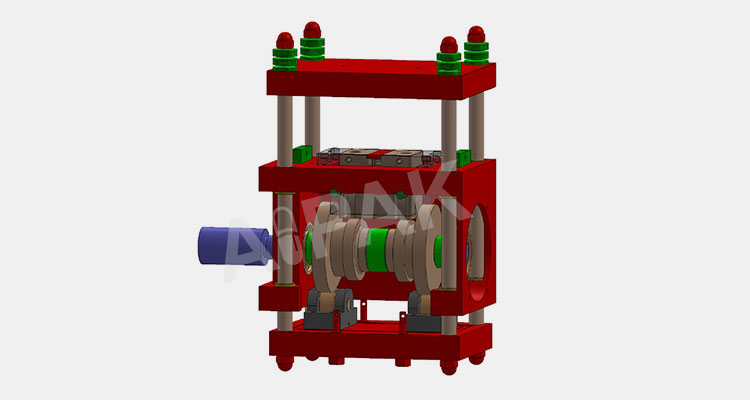

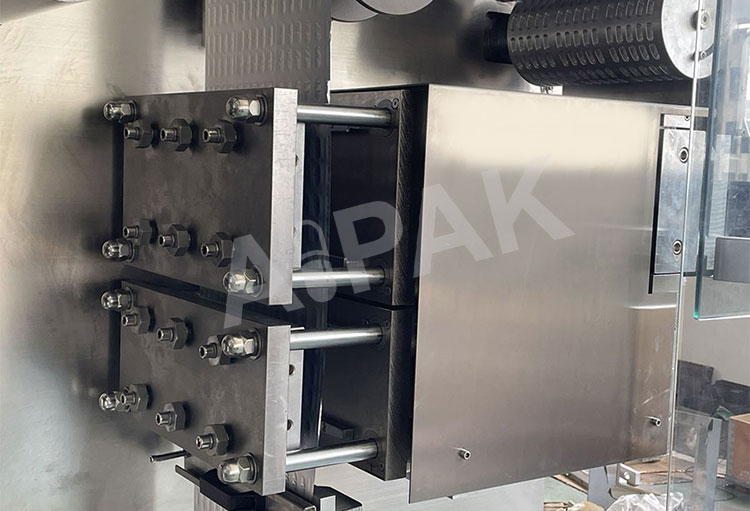

IV.Double Cam(traditional single cam)

A.Adopting hyperbolic double-cam structure, balanced force, designed pressure of 10T. The molding device is made of stainless steel and cast as a whole structure, ensuring no deformation for 10 years.

B.It can be blow molded into aluminum-plastic, or cold pressed into aluminum-aluminum, and the interchange is simple.

C.Built-in sunken oil tank, no manual intervention required.

D.The servo system is independently controlled, and the forming frequency and angle can be arbitrarily set. It can also operate synchronously with the entire machine.

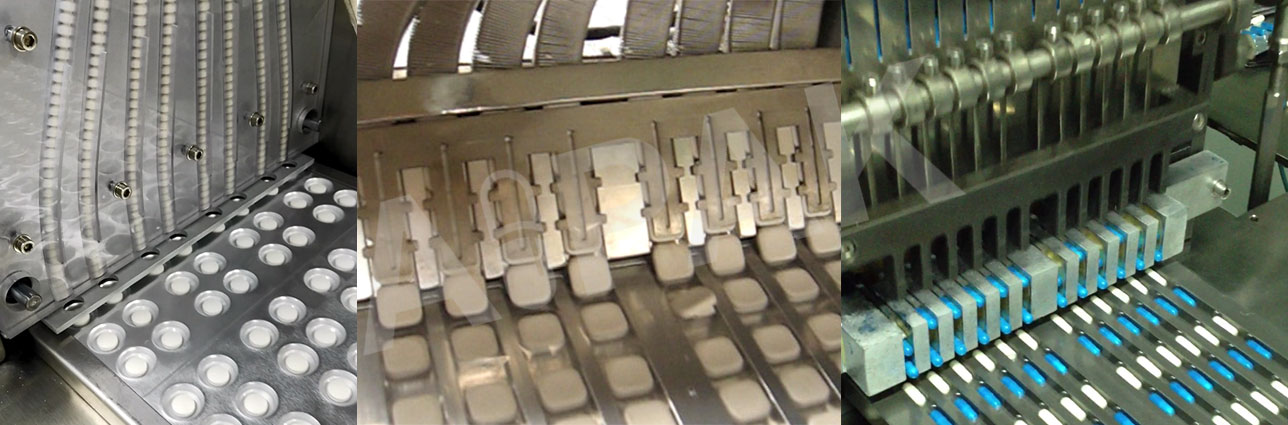

V.Adjustable High-level Track Feeder

A.Supported by multiple patents, this device is unique. It is not only suitable for capsule and round tablet cutting, but also for square and irregular-shaped tablet cutting under the hard aluminum bubble cover. There is also a dust-free packaging achieved through a separate screening vibrating feeder.

B.The adjustable high-position dedicated feeder ensures that the material feeding rate of the equipment always keeps up with the line speed of aluminum-plastic PVC forming. Changing molds and feeding can be easily adjusted and positioned using only a handle.

C.It eliminates the impact on overall punching frequency caused by insufficient feeding rate. Stable, efficient, without damage to materials, no manual intervention required.

VI.Aluminum Foil Graphic And Text Layout

Aluminum foil graphic and text board, to make the content on the board comprehensive, your patients will be effectively guided with correct medication usage, making the product more aesthetically pleasing.

VI.Aluminum Foil Graphic And Text Layout

A.Independent servo system accurately drives the heat sealing mechanism,

B.Large diameter embossing roller, equipped with 10 heating tubes, ensuring perfect sealing even at high speeds.

C.Precision cylinder constant tension control aluminum foil output, to avoid tension changes caused by roll diameter changes, and eliminate the phenomenon of wrinkling or breaking of aluminum foil during heat sealing.

D.The innovative use of aluminum foil wearing trend can effectively prevent problems such as pill jumping before heat sealing, ensuring the quality of heat sealing.

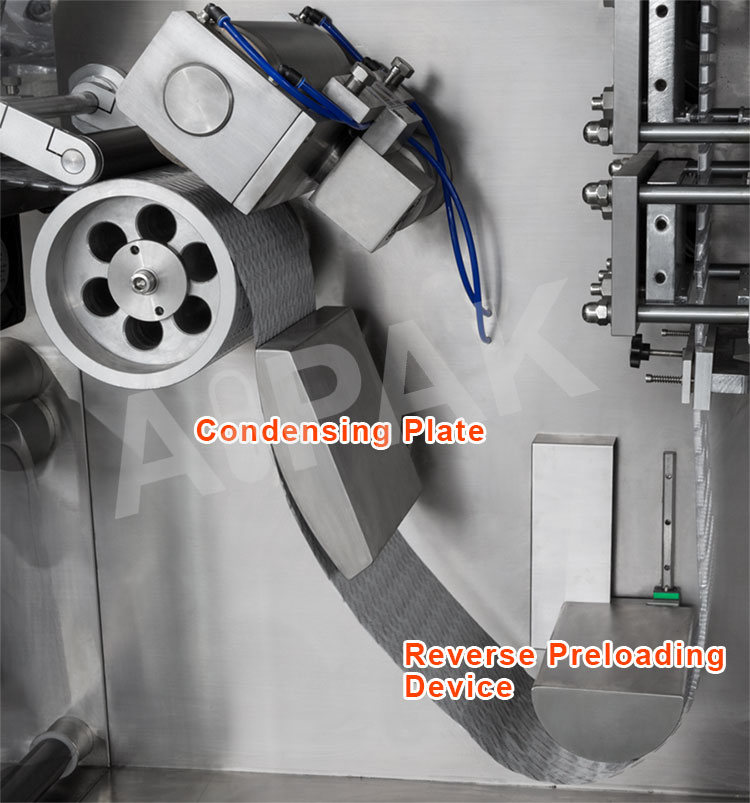

VIII.Thermoforming Board Leveling Mechanism

A.The post-sealed condensing plate has a fast cooling and shaping effect, and prevents the overheating failure of the tablets.

B.Reverse preloading device, with a corrective bubble cover belt to correct the bending after heat sealing (especially for better effect on cold aluminum strip), thus ensuring the stability of the subsequent interconnection.

IX.Buffer Type Batch Number And Tear Line

Segmented batch number and buffer tangent, efficient, stable, fine and beautiful seam, easy to tear.

Independent batch number adjustment mechanism for convenient adjustment of batch number clarity, abandoning the pad method and adopting a whole stepped structure for installing steel characters, making it more convenient and quick.

Adopting large camshafts and large bearings, batch printing is more powerful, stable, and advantageous.

XI.Punching And Cutting Adopts Independent Servo System

The punching and cutting mechanism has been upgraded to an independent servo system for precise control, ensuring synchronization and accuracy during the punching and cutting process. The noise is reduced, the equipment operation will be more smoothly, and the punching efficiency is faster and more efficient.

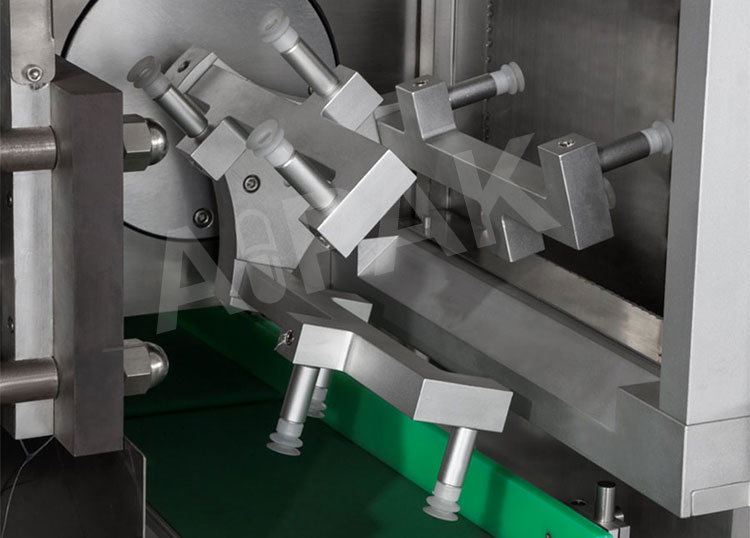

XII.Manipulator Mechanism

The newly designed manipulator has a modular structure, short stroke, simple structure, and more convenient disassembly. The efficiency of stabilizing the suction plate is increased by 50% compared to the old single manipulator. The suction plate is stable without shaking. The angle, time, and speed of the suction and discharge plate can be set arbitrarily.

Different Loading Device

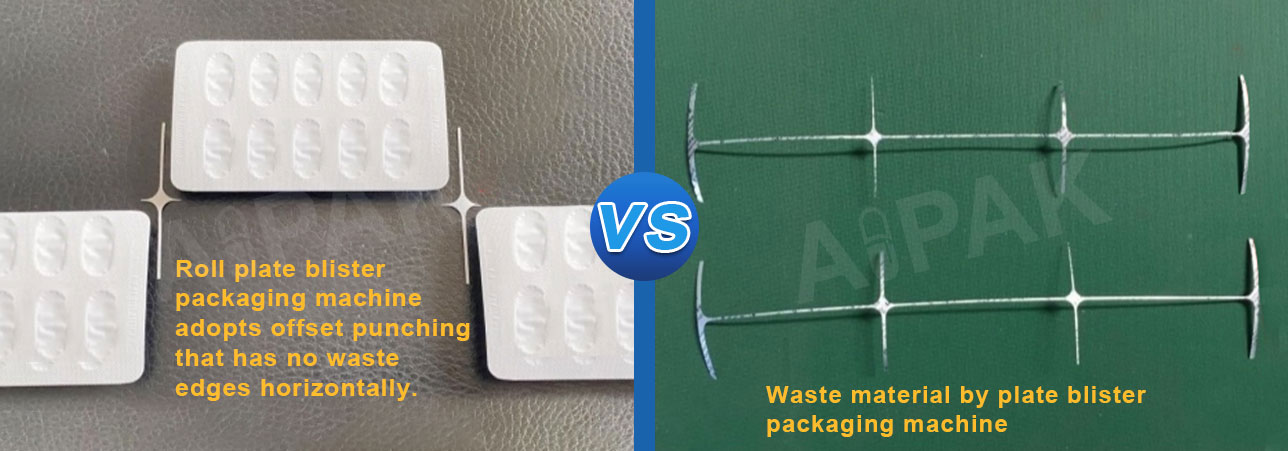

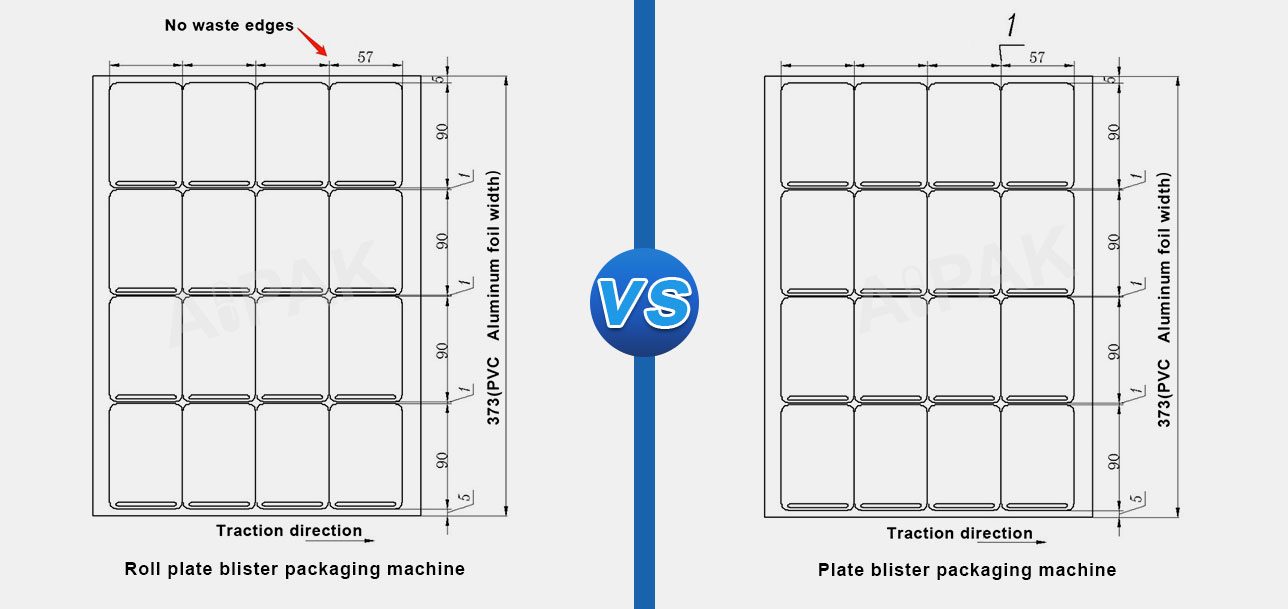

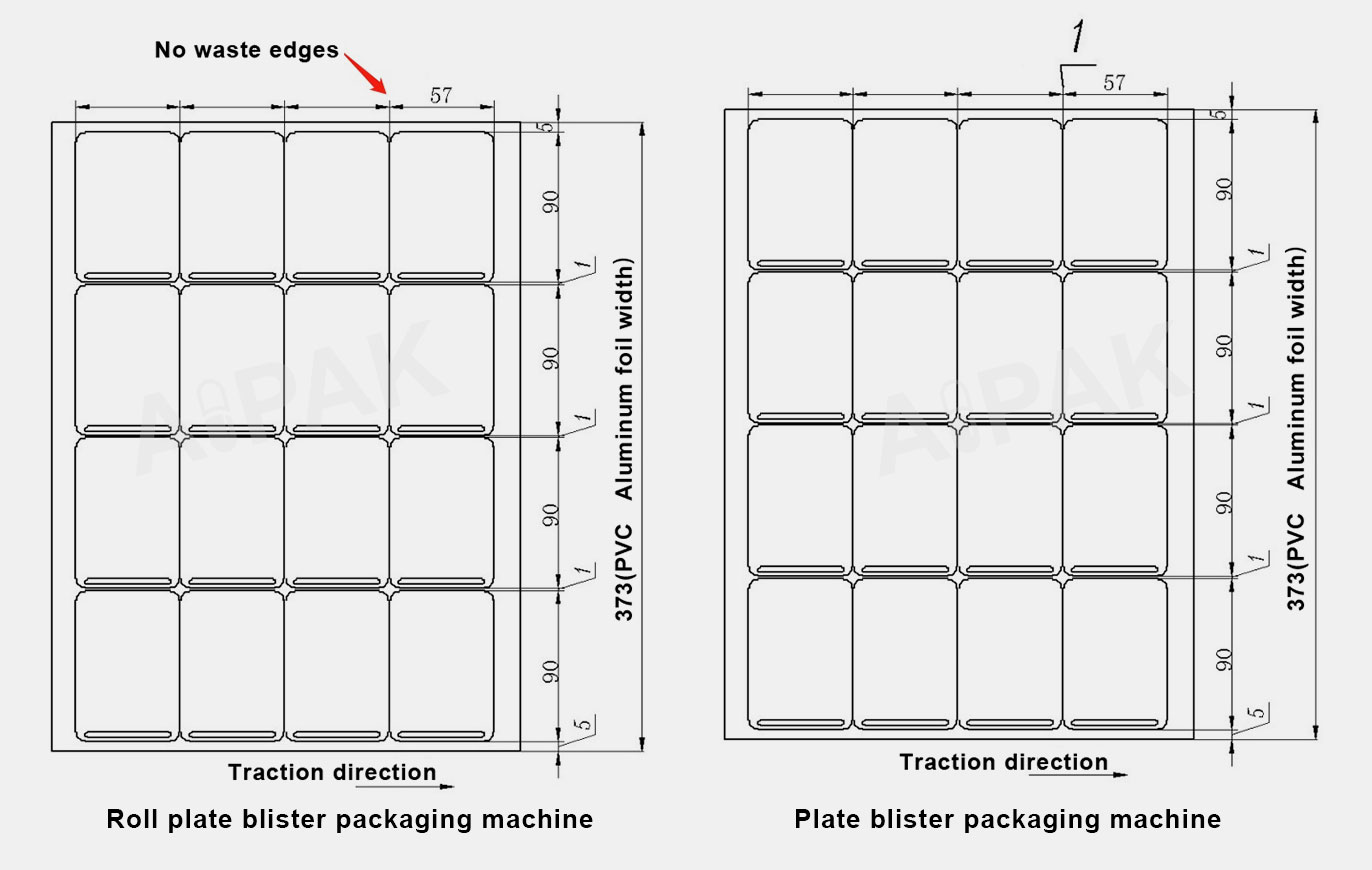

Plate Vs DPH Series Roll Plate Blister Packaging Machine

Omparing In Packaging Material Savings

Comparing In Packaging Material Savings

| PVC Plastic:Thickness:0.25mm, weight per square meter:337.5, price: RMB15/Kg

PTP Aluminum Foil: Thickness: 0.02mm, weight per square meter: 68, price: RMB53/Kg Cold-formed Aluminum: Thickness 0.16mm, weight per square meter 251.5, price: RMB80/Kg. Each board price = Length × Width × Weight per square meter × Price / Number of boards |

|||||||

| Model | Packaging Material | Forming Surface Length | Forming Surface Width | Weight per Square Meter | Price | Number of Boards | Price per Board |

| DPP-250 | PVC | 253 | 92 | 337.5 | 13.5 | 4 | 0.02651 |

| PTP | 253 | 92 | 68 | 56 | 4 | 0.02216 | |

| DPH-260 | PVC | 373 | 57 | 337.5 | 13.5 | 4 | 0.02422 |

| PTP | 373 | 57 | 68 | 56 | 4 | 0.02024 | |

| Boards per Minute | Cutting Time (Minutes) | Minutes | Minutes per Shift | Shift | Number of days | Annual Production (10,000 boards) | |

| 4 | 200 | 60 | 7.5 | 2 | 300 | 21600 | |

| Model | Annual Production | Price per Board (PVC + PTP) | Annual Material Consumption | Annual Material Savings | |||

| DPP-250 | 21600 | 0.04867 | 1,051.31 | -91.01 | |||

| DPH-260

no waste edges |

21600 | 0.04446 | 960.29 | ||||

| 1. Using model DPH blister packaging machine saves 91.01 thousand RMB per year in material costs

2. The scrap rate for DPP-250 increases by 3% per year. 3.DPP-250 requires 5 machines, in addition to other costs (such as workshop, labor, utilities, management, etc.). |

|||||||

DPH Roll Plate Blister Packaging Machine Material Saving Comparing With Other Manufacturers

| PVC Plastic: Thickness:0.25mm, square weight: 337.5, price: RMB15/Kg. PTP Aluminum Foil: Thickness:0.02mm, square weight: 68, price: RMB53/Kg. Cold-formed Aluminum: Thickness0.16mm, square weight: 251.5, price: RMB80/Kg. Price per board = Length × Width × Square weight × Price - Number of boards |

|||||||

| Model | Packaging Material | Molding Surface Length | Molding Surface Width | Square Weight | Price | Number of Boards | Price per Board |

| Other Manufacturer | PVC | 373 | 58 | 337.5 | 13.5 | 4 | 0.02464 |

| PTP | 373 | 58 | 68 | 56 | 4 | 0.02060 | |

| DPH No edges |

PVC | 373 | 57 | 337.5 | 13.5 | 4 | 0.02422 |

| PTP | 373 | 57 | 68 | 56 | 4 | 0.02024 | |

| Boards per Minute | Cutting Speed (pcs/min) | Minutes | Hours per Shift | Shifts | Days | Annual Production (Ten Thousand Boards) | |

| 4 | 200 | 60 | 7.5 | 2 | 300 | 21600 | |

| Model | Annual Production | Price per Board (PVC + PTP) | Annual Material Consumption | Annual Material Savings | |||

| Other Manufacturer | 21600 | 0.04524 | 977.14 | -16.85 | |||

| DPH No edges |

21600 | 0.04446 | 960.29 | ||||

| By using the AIPAK DPH roll plate blister packaging machine with edge-free technology, compared to competitors, the cost savings in packaging materials is 168,500 per year . | |||||||

Videos of AIPAK Roll Plate Blister Packaging Machines

Let's Stay In Touch!

Contact For Free Consultation

We're Here to Help! With just a few details we will be able to respond to your inquiry.