Hammer Mill Machine: The Ultimate Buying Guide in 2024

A hammer mill machine is also termed as ‘hammer mill crusher and Pulverizer hammer. It is a perfect source of investment for food, pharmaceutical, and chemical processing.

It is a kind of multifunctional equipment that has encompassed with a broad industrial region such as medicine, foods, automobiles, chemical, paints, crushing glass beads, plastic material, hard rock, and so on.

Therefore, this is a kind of durable, highly profitable, high quality, user friendly, and low budget machine to serve the customers.

Are you planning to invest money in your business?

This is definitely the right place to be.

In this blog, we will give suitable recommendations and required guidelines about everything that you need to know regarding the hammer mill machine.

We will demonstrate the features, benefits, installation procedures, technical troubleshooting, and necessary buying guidelines.

All you need to give some quality time to read this guidance blog absolutely.

Let’s get into it!

1.What is a hammer mill machine?

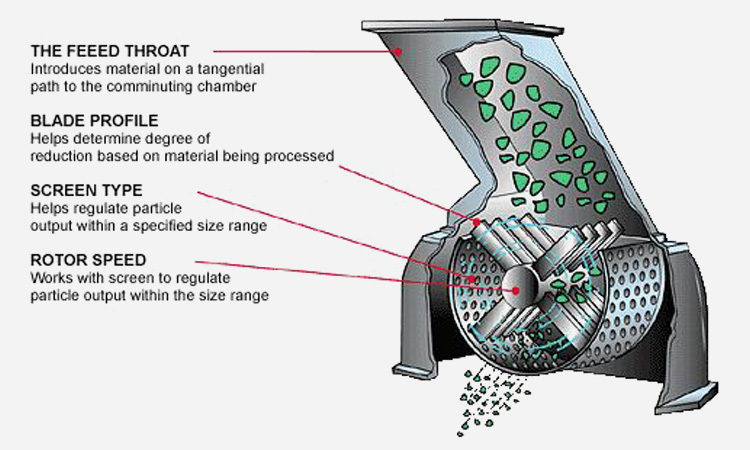

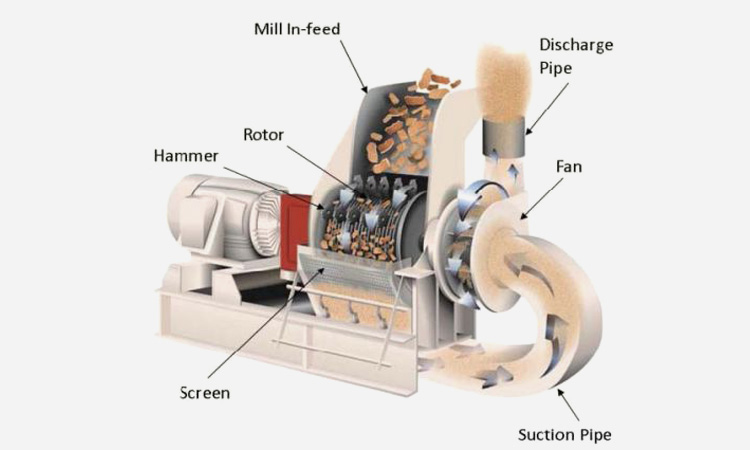

The hammer mill machine is one of the traditional and extensively used equipment for grinding, crushing, and aggregation of substances into smaller particles. This is a useful machine utilized in pharmaceutical, food, and chemical industries for the processing of various goods. The hammer rmill machine consists of multiple sets of hammers covered in a metal case. Due to high force, it helps in the size reduction of particles. The smashing of material takes place in various repeated phases. The excessive swinging of hammers from a focal shaft cause smashing of feed material with high precision.

Hammer Mill Machine

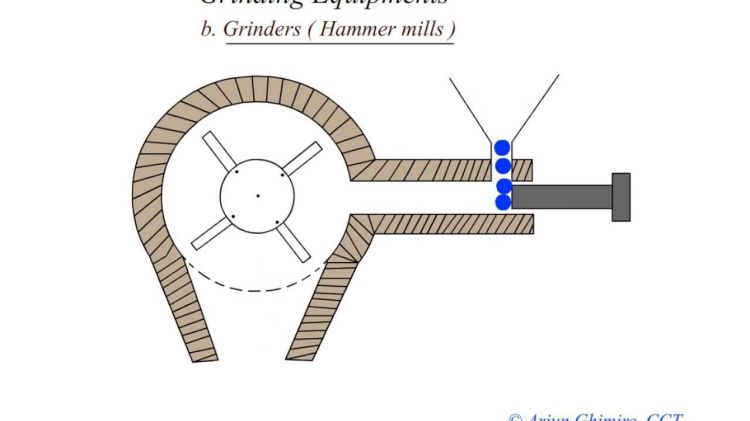

2.What are the types of mills used for grinding operations?

Grinding of raw materials for chemical, pharmaceutical, and cosmetic industries are conducted via the two most popular methods, air jet mills and impact mills.

The most used air jet mills are spiral jet pancake mill, oval ring mill, fluidized bed air jet mill, etc. The most used impact mills include pin mills, fixed hammer mills, etc. A brief description of each mill is given below.

- Air Jet Mills: It consists of a grinding chamber in the shape of a cylinder. Air nozzles are present to the circumference of the cylinder. The air jets form a grinding vortex that separates heavy particles from lighter particles and performs pulverization. The light particles are retained in the filter whereas the heavy particles are collected in the container. Particle size reduction takes place due to inter-particle collisions.

- Oval ring mill:As the name suggests the oval ring mill has a grinding chamber in the shape of an oval. Particle size reduction takes place at the inferior part of the grinder whereas separation of fine and coarse particles occurs at the superior part. Raw materials are introduced from the inferior end, where due to airflow inter-particles collision takes place leading to size reduction.

- Fluidized bed air jet mill: Like an air jet mill the grinding chamber of the fluidized bed air jet mill is in the shape of a cylinder. Air jets are present at the inferior end of the cylinder facing each other. With the help of a feeder raw material is introduced in the chamber. Particle size reduction takesplace by inter-particle collision due to airflow.

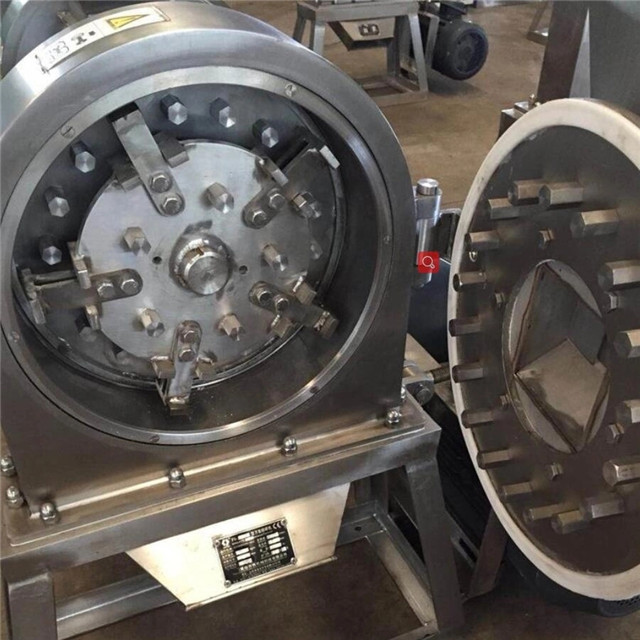

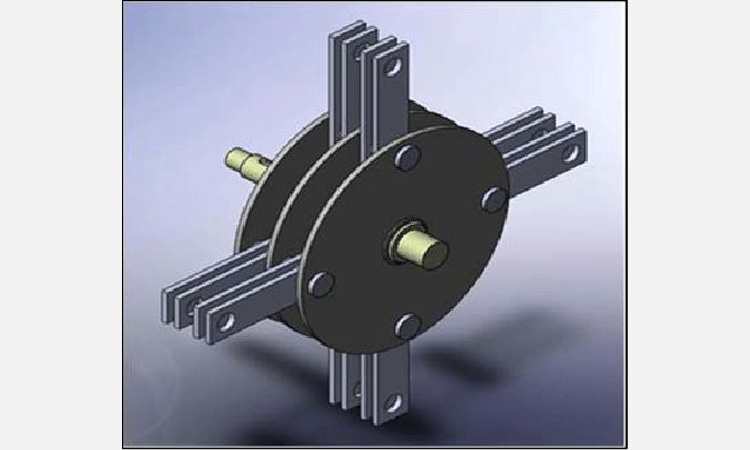

- Pin mills: It consists of two disks covered with overlapping pins. One disk is stationary and the other can move at a speed of 150 m/s. Materials for grinding are introduced by a feed screw, pulverized, and collected in a container. Particle size reduction takes place by both inter-particles’ collision and collision with the disks.

Pin mills- Picture courtesy-Millpowdertech

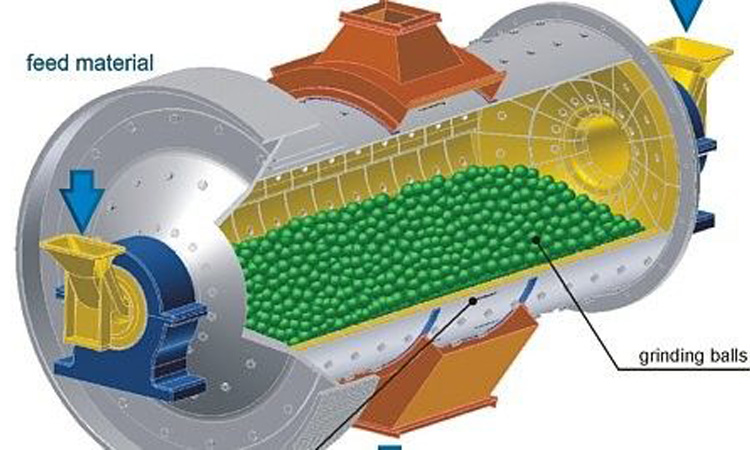

- Ball Mill

A ball mill grinds and blends the material into extremely finer nanosize balls. The working principle of the ball mill is impact and attrition via a rotating hollow cylindrical shell that contains grinding balls.

- Hammer mills:As the name suggests the grinding compartment contains hammers that can move at the speed of 50-100 m/s. Depending on the model of hammer mills different numbers of hammers are presently unique to that model. Raw materials are introduced by a screw feed mechanism. Particle size reduction takes place by the continuous impact of hammers on the grinding materials and inter-particles collision. The hammer mill machine is discussed in detail in the subsequent document.

AIPAK Pharmaceutical hammer mill machine

3.What are the important components of the hammer mill machine?

Hammer mill machine can be majorly divided into 06 individual units namely,

a) feed system,

b) Pulverizer unit,

c) drive unit,

d) support unit,

and e) control system.

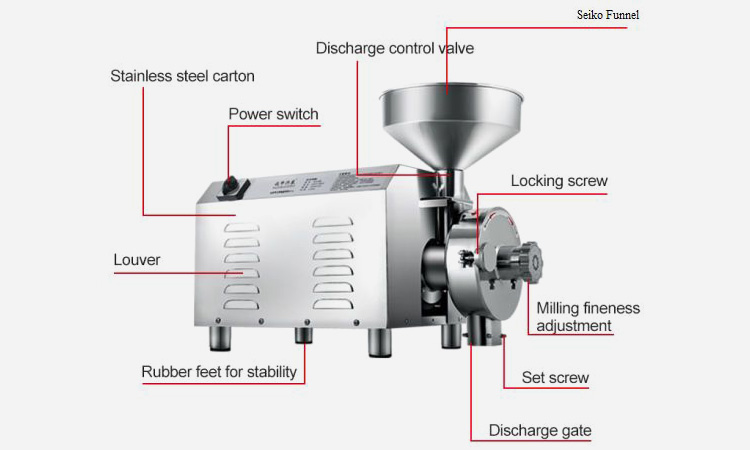

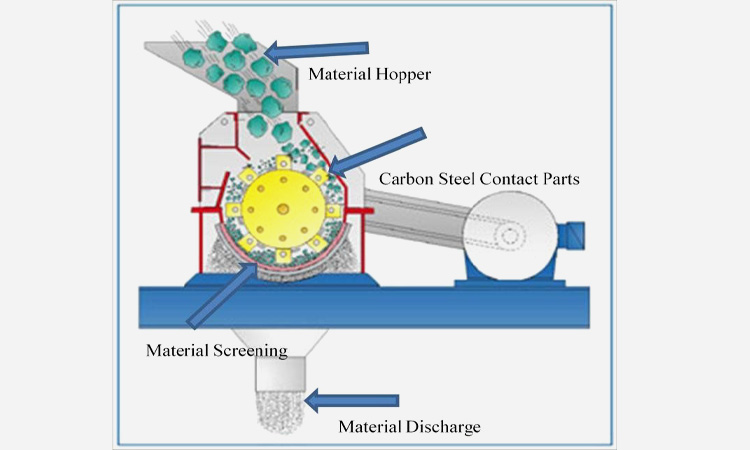

- Feed system:The feed system is subdivided into a hopper and feed screw mechanism.

Construction design of pharmaceutical hammer mill machine

- Hopper(A) with a capacity of 0.25 cubic foot is attached to the feed screw mechanism. The hopper comes in a range of 0.1-0.5 cubic feet.

- Feed Screw Mechanism(B) consists of a single screw (F) conveyer connected to a motor (C), gear reducer (D), and a speed drive (E) which can be adjusted.

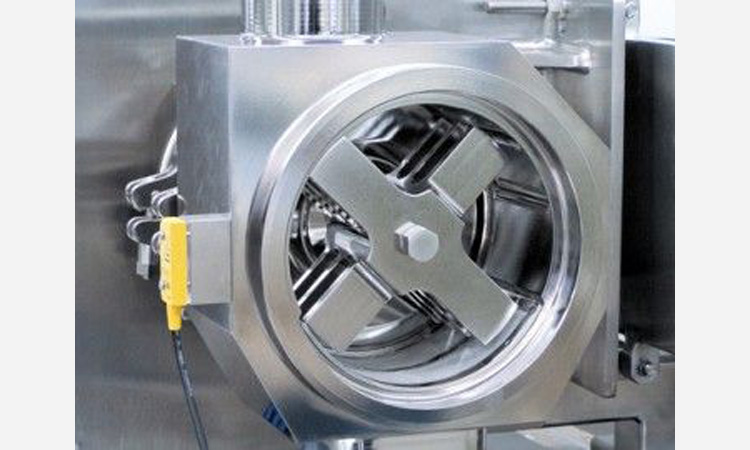

- Pulverizer unit:Pulverizer unit is divided into main body (H), rotor assembly (I), cover (N), and hammers (J).

- A pulverize unit is made of stainless steel ascreen(K)is attached and located to the walls of the main body with the help of retaining grooves. At each end of the screen rubber seals, namely end dust seals(Q) are present. The feed side rubber seal is held in place by the hold-down plate(R). Based on different models bottom is opened to discharge the pulverized material either into a container or air-controlled conveying system. An air relief pressure gauge (L) is present on the side of the main body which releases accumulated air developed during the rotation of rotor. A pressure gauge is further connected to an air filter that traps fine powder generated during pulverizing process. In an air-controlled conveying system the pressure gauge is replaced with a cover plate. The upper part of the main body is drilled to receive cover, pillow blocks (P) and end dust seals.

- On either side of the cover, two inlets (M) for controlling airflow are present. The purpose is to let air in during the process and remove any vacuum at the feed screwcaused due to rotation of rotor. Made up of stainless steel a multiple deflector liner (O) is bolted to the inside of the cover.

Hammer mill machine diagram

- Pulverizer drive unit:The Pulverizer drive unit is further divided into the driven sheave (S) mounted on the shaft connecting the rotor. Driven sheave is connected to the drive sheave (T) via V-Belt (U) covered by a safety guard (W). The drive sheave is connected to the motor, which in turn is mounted on the slide rails. The tension of the V-belt can be adjusted by moving motor along the rails.

Pharmaceutical hammer mill unit

- Support unit:The Pulverizer support unit consists of structural mill base(X) and supporting legs(Y). The main body, feed screw mechanism and both drives are bolted to a common structural millbase (X). The base stands on four legs, it is recommended to fix these legs to the foundation or suitable floor.

Hammer mill machine- Picture courtesy- AM Pharmaceutical

- Control system:The control system for the standard hammer mill usually consists of pushbuttons, a limit switch, and an ammeter. The pushbuttons are used to start the main drive motor and feed screw mechanism. Both the units are interconnected such that the feed screw cannot be activated unless the motor is running. The limit switch is for the housing cover. The limit switch prevents the operation of the mill if the cover is not properly placed. The ammeter is for the main drive motor. It displays the current drawn by the motor thereby, giving an idea of the loading and should be used to adjust the feed rate.

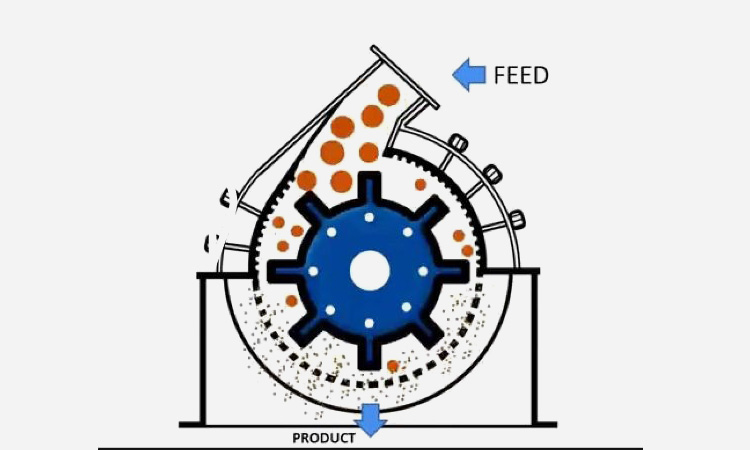

4.What is the working principle of the hammer mill machine?

The hammer mill machine carries out the particle size reduction or grinding by continuous impact of hammers with the raw material. The hammer mill machine is basically a drum that contains a shaft that can be vertical or horizontal, and on that shaft different sets of hammers are present. Based on the model the hammers are either fixed or free to move. The shaft is rotated at a high speed that ranges between 50-100 m/s that pulverizes the material which is collected in the container.

Hammer Mill Machine- Picture Courtesy- Hosokawa

Hammer Mill Machine Diagram

5.What are the basic types of hammer mill machines?

The types of hammer mills are based on their industrial applications. The function-based categories of hammer mill machines are discussed below.

- Gravity Discharge Hammer Mill

A gravity discharge hammer mill machine is also termed a bottom discharge hammer mill machine. In these machines, a set of hammers are mounted on a focal shaft. The reduction in particle size takes place by hammering force as well as particle forces. The final discharging of material is subjected to the force of gravity. That’s why this machine is known as a gravity discharge hammer mill. - Applications

The application of these machines is extensively operated for crushing ceramics, dry chemicals, and glass, etc.

- Pneumatic Discharge Hammer Mills

pneumatic discharge hammer mill machines almost have similar hammering capability as gravity discharge hammer mills despite the hammering set and the chamber wall’s structure is thin. a pneumatic discharge hammer mill machine has a dashboard that facilitates the size reduction process. The reduction in sizes is basically assisted by an air evacuation process. - Applications

As mentioned earlier, these machines are accompanied by light hammers, so they are used to deal lightweight materials such as greenwood, paper, etc.

Structure of Pneumatic Discharge Hammer Mill Machine

- Full Circle Screen Hammer Mills

Full circle hammer machines are suitable to deal with light-weight substances that mostly do not require excessive crushing. They feature a 300-degree rotating screen, that facilitates the improvement of particle evacuation.

Full circle screen hammer mill machines are utilized to hammer spices, grasses, and others.

- Applications

These mills are used for hammering spices, grasses, etc.

- Horizontal In-feed Hammer Mills

These hammer mills are designed in such a way that accept material from the horizontal side instead of from the top. Trim scrap grinder and pallet grinder are the prime features of these machines that perform hardcore functions on an industrial scale. - Applications

These hammer machines are considered as aggressive milling machines utilized to grind tough and heavy materials.

Horizontal In-feed Hammer Mills- Picture Courtesy- Technex

- Lump Breakers

The function of the lump breakers hammer mill machine is quite different from other hammer mill machines. these machines do not accompany the swinging of hammers, but they carried mixed functionalities such as a small, fixed hammer is mounted on the focal shaft. The purpose of these machines is not to grind but to smoothen the material such as powder to paste. It contains a hammer structure on shaft known as a ‘comb’. The purpose of the comb is to pass material of desirable size. - Applications

These machines are ideal to deal with sugars, dry chemical powders and cement, etc.

Lump-Breakers- Picture courtesy- Bulkinside

6.What are the benefits of hammer mill machines?

The benefits of hammer mill machines are discussed below:

- Simple Process of Crushing

Hammer mill is a simple machine with a flexible working principle. It generates specified top-size particles without need of having a closed-circuit-crushing unit. - Greater Size Reduction Ratio

It has an extensive size reduction ratio and a high capacity for various types of grinding.

- Optimum Energy Consumption

Hammer mill machines give maximum grinding output with less expenditure of energy.

- Ideal to Crush Brittle, Blunt, and Heavy Material

Hammer mill machines are ideally utilized to crush heavy, brittle, and blunt materials such as, glass, automobile components, etc.

- Ideal For Every Type of Material

Hammer Mill machines are ideal to deal with every type of material, such as from soft (food) to hardcore goods (steel/automobile) that ultimately result in significant fracture of materials.

- Easy to Install

Hammer mills are simple machines, and they are easy to install and operate. Furthermore, they occupy less space as compared to other manufacturing machines. - Accelerates the Dissolution Process

In the chemical, food and pharmaceutical sectors, hammer mills are primarily used for formulation and instant dissolution.

As you may know, during the dissolution process a small size particle swiftly dissolves as compared to larger particles. Thus, hammer mill machines are actively used for the rapid formulation process.

- Enhances Effectiveness of Active component

Many ingredients perfectly work when added into certain substances with slight grinding using hammer mill machines to initiate a chemical reaction. In this way, these machines are suitable to bring an effect of active components in a reaction mixture. - Mixing Solid and Fibrous Elements

Hammer mills are applied for the blending of two solid powders. Not only this, but they are also significantly used to yield a consistent form of fibrous ingredients efficiently.

7.What are the disadvantages of hammer mill machines?

The disadvantages of hammer mill machines are as follow:

- It is not recommended to deal with sticky materials because the material may stick over perforated screens and be difficult to swipe. Furthermore, plastic-like material may generate excessive heat during the grinding process therefore, a hammer mill machine is not ideal to grind such type of material.

- Hammer mill machines are not suitable for fine grinding of abrasive and hard material as it may result in excessive wear and tear of the machine.

- If the feeding rate is not properly controlled, it may result in the choking of hammer mill machines.

- A machine may encounter clogging of the screen.

8.What are the industrial applications of hammer mill machines?

There are a broad range of industrial applications of hammer mill machines. Some of the specific industrial applications of hammer mill machines are discussed below.

- Pharmaceutical and Chemical Industry

In the pharmaceutical and chemical industry, hammer mill is basically used for the following purpose:

1. Hammer mill machine is a mandatory tool for milling ingredients to form a powder. For this purpose, mostly all ingredients are combines and crushed together in hammer mills that result in the formation of the intermediate grade of powders. Additionally, it can also produce a precise grain-sized powdery material based on the type of machines and duration of crushing.

Hammer Mill Machine- Picture Courtesy- LB Bohle-Pharmaceutical

- The micronization of substances is necessary when it comes to preparing any pharmaceutical products. For instance, in capsule filling, you are required to fill the medicines or active substances in a fine powdery form. Therefore, hammer mill machines are used to micronize the pharmaceutical active substances.

- Food and Agriculture Industry

You may already know the dedications of hammer mill machines in the food and agricultural sector. The grinding of grains, legumes, and manufacturing of many food products frequently require hammer mill machines.Not only this, production of farming material or agriculture unit is unsatisfactory without the availability of hammer mill machine.

The hammer mill machines are mainly used to grind nuts and beans such as soya, nutshells, almond, coconut, etc. The grinding of this material ultimately provides us ready to use coconut powder, Choco-powders, almond powders, etc. in the market.

- Cosmetic Industry

In the cosmetic industry, the applications of hammer mill machines are of prime importance. For manufacturing of creams, lotions, body washes, soaps, facewashes, blush on, lipsticks, etc. requires ingredients in micronized form. Thus, uneven, or relatively large size particles interrupt the manufacturing batch. Hence, the hammer mill machine is a promising machine for manufacturing a good quality cosmetic product.

- Automobile Industry

Hammer mill machine is of prime importance when it comes to deal with scrapping and recycling of automobile and mechanical materials. Hammer mill machine is significantly used for the scrapping of automobile elements. Intense hammering results in a crushed metal which is then sent for the melting process. Finally, the finished product of molten material is sent for new production and recycling purpose.

9.What is the difference between a hammer mill machine and a ball machine?

- Hammer mill machine works by grinding material with the help of repeated hammering process that results in shred or crushed aggregation of substance. Whereas a ball machine grinds the material with help of rotating mills.

- A hammer mill machine is comprising of a set of hammers, while a ball machine does not comprise of hammers.

- Hammer mill is a faster machine that grinds materials instantaneously. Compared with the grinding type, a ball mill can excessively grind materials even finer, but its grinding time is usually longer.

- Hammer mill can be fixed or free flowing that is attached to a center of a rotor that crushed the fed material with high repeatedly impact. Whereas in ball mills, the rotation of steel balls helps to grind the materials. The mill rotates approximately once every couple of seconds.

- Hammer mill can move horizontally or vertically which is entirely based on system configuration, whereas ball mill rotates in its fixed position.

Ball Mill Machine- Picture Courtesy- S-Pharmatech

10. Is the hammer mill and the Pulverizer machine the same?

- Hammer mill machine grind the material and press them repeatedly against the screen opening. Whereas pulverize mill in the term of hammer mill demonstrate almost similar function, that has vanes and milli plates to achieve the grinding process.

- Pulverizer mahcine can grind substances into a very fine form which is almost difficult for hammer mill machines.

- The grinding size particles of hammer mill is less than 1.5mm, whereas grinding size particle of Pulverizer is extremely smaller such as less than 0.150mm.

- Hammer mills require low power consumption to attain the grinding process. In comparison to hammer mill machines, the power consumption of Pulverizer is almost higher.

A Pulverizer Machine

11.How can you install hammer mill machine?

It is recommended that the hammer mill machine installation be carried out by experienced and skilled personnel having previous sufficient knowledge of machine installations. Personal and equipment care is necessary to avoid any accidents during installation that may result in injuries or financial losses. The following requirements should be read carefully and met before installing hammer mill machine:

- Foundation, clearance, and unloading requirements

- Unload the hammer mill machine from the container and bring the machine to the site of installation with the help of a forklift. A 1000-pound capacity hoist can be used for unloading and assembling the machine. Special care should be taken to avoid accidents during movement of machine.

- Hammer mill machine approximately weighs 700 pounds therefore the installation site should have a level floor. The floor or foundation should be reinforced with at least 6 inches thick concrete and if concrete berths are used then they must be at least one square foot with a height not exceeding 6 inches.

- There should be a clearance of approximately six feet on all side of the hammer mill once installed. Special attention should be given in the placement of the machine so as to provide sufficient head space and ease in the replacement of containers. It should be noted that the hammer machine requires scheduled maintenance which can be done by attaching appropriate rigging, therefore the installation site should support proper head room for attachment.

- The hammer mill machine is provided in wooden crates. After receiving the machine visually inspect all the crates for damages incurred during transportation before opening them. Inspect all the components for paint and check hardware for any loose connections.

- In case of any damage, components report immediately to the manufacturer.

- Assembling instructions

The hammer milling machine is factory assembled. The parts that need to be assembled at the site of installations are the hopper and legs.

- Ensure with the help of level gauge the foundation is even and flat. Bolt the legs to the hammer mill base frame. Lift the frame along with the legs with the help of straps and bring to the foundation.

- Secure legs to the floor with the use of recommended bolts. Level and secure the hammer mill frame. Once secured tightened the bolts of the legs to the frame.

Installation Hammer Mill Machine

- After securing the hammer mill rotate the rotor with hand. The rotor should move freely. If the rotor does not move freely refer to the maintenance guidelines provided with the machine.

- Adjust the tension in the V-belt by moving the motor on the rails. Properly adjusted V-belt will deflect at 3/16” when a weight of 5 pounds at the centre of the sheaves is applied. Tighten the bolts on the motor and install V-belt safety cover.

- Install hopper and the feed screw mechanism keeping in mind that both the surfaces in contact are clean. Use of gasket is recommended for proper seal.

- Check all the moving parts are properly lubricated.

- The hammer mill machine should be cleared of any tools and objects before commencing start up. Connect the control to the main power supply and switch on the machine after making sure that all the bolts are properly tightened.

- The rotation should be in a specific direction. Consult the maintenance manual for change of rotation if it is not in the specified direction.

Hammer mill unit

- Install air relief bag and container for receiving crushed materials.

- Check the safety limit switch performs as per the requirement with the help of a multimeter. Cut the main power supply to the hammer mill check the terminals of the limit switch in the control panel. Slightly lift the cover and check the terminal once again, there should be no reading on the multimeter.

- Operate the hammer mill machine empty for half an hour to check for any unusual noise or sound and vibrations. Periodically start and stop motor and check the screw motor interlock functions properly.

- After the first operation tightens bolts and catches.

- Lubrication of the hammer mill machine

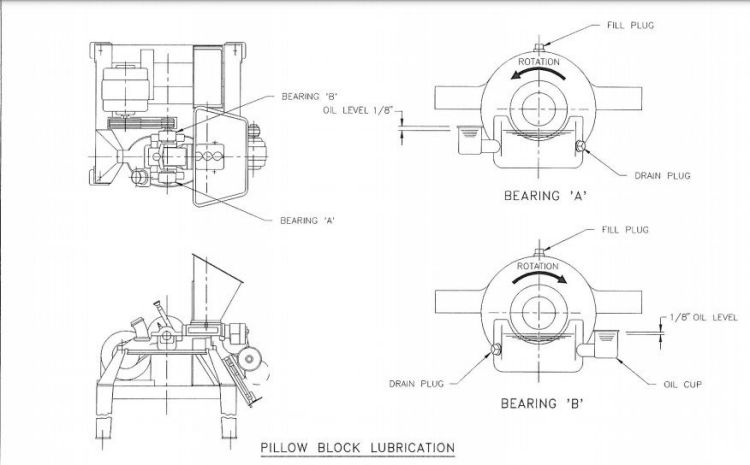

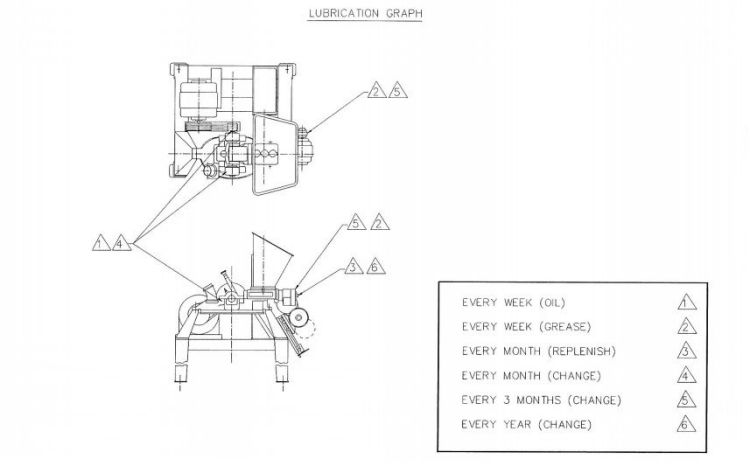

The hammer mill machine is lubricated prior to quality control testing at the manufacturing factory, further lubrication is checked and carried out after the installation. The parts that should be checked for lubrication on regular basis include the feed screw mechanism, gear reducer pulleys and pillow blocks.

- Precautions during installation

- A trained individual will carry out the installation of hammer mill machine.

- To avoid damage while moving or lifting the machine no straps or slings will be put around the rotor or screen.

- Avoid using swing bolts to lift the hammer mill machine.

- Once unpacked from the wooden crates avoid putting the rotor assembly on the floor.

- Avoid hitting and bouncing machines during transportation or lifting.

- Safety limits should never be verified while operating the machine, but the machine should be switched off and the main supply cut off and the safety limit checked via multimeter.

12.How to operate a hammer mill machine?

1.Pre-start up points

Before starting the hammer mill machine, a test run is important to determine if it works correctly or not. The purpose of checking is to obtain best results with reduced downtime. Discussed below are important pre-start up points:

- Operators are well equipped with personal protective equipment. These include safety shoes, safety goggles, helmet and working gloves. Operators should be well trained and experienced (hours) in handling the hammer machine.

- Make sure that all bolts are tightly secured.

- The housing cover should always be closed during operations. Use of excessive force is not recommended hand tight fastening will be sufficient enough to seal the components.

- Check whether the limit switch functions properly.

- Interlock between the main motor and screen mechanism is working properly.

- The screen should be properly installed, and the lubrication levels maintained.

- The inlets are opened as per requirement, these can be adjusted during operations.

- No tools have been left on the main body.

- The safety guards are in place and no safety measures by passed during operations.

- Vent ports are connected to air release bag.

- Start-Up Points

The hammer mill machine is easy to operate and requires normal concentration of an experienced operator.

- The grinding cycle is started by pushing the START push button for the main motor.

- Following the motor start-up, the screw mechanism is switched ON at the slowest speed as per manufacturer instructions.

- Once the motor and the screw mechanism are switched ON, start feeding the materials in the hopper.

- Keep a check on the ammeter present on the control panel. Adjust the feed rate accordingly by changing the screw speed. The maximum name plate amperage is 95% which should not be exceeded in any case.

- Stop the hammer mill machine to replace the container or air relief bag.

- End-Up Points

The hammer mill machine can be stopped at the end or during operations. Following points should be followed when stopping the machine after operations.

- Firstly, press the STOP push button to stop the feed screw mechanism.

- Do not stop the motor and continue till empty.

- When the ammeter on the control panel reads idle load stop the hammer mill machine by pressing STOP push button to switch OFF the main motor.

- Allow the machine to come to a complete halt before attempting anything.

- Once the rotor is stopped the machine should be started after removing the remaining materials in the grinding chamber. Also, the hopper and the feed screw should also be free from any visible particles.

- After changing the container or air relief bag start the hammer mill machine by following the above-mentioned start-up points.

In case of emergency shut down following points should be covered before operating the hammer mill machine.

- For emergency shutdown press STOP button on the control panel.

- Cut off the main power supply to the hammer mill machine. Remove the safety cover and open the mill. Remove any material in the rotor area before operating the machine.

- In case of power failure, the motor and the screw mechanism will stop functioning and will not restart by themselves when the power is restored. Before starting the operations make sure that the grinding chamber is emptied.

- Always cut off the main supply, remove the main electric cable before attempting to clean and open hammer mill machine.

13.What are the safety measures while dealing with hammer mill machines?

- Only trained individual will operate and carry out proper maintenance of the hammer mill machine. Proper training of the operator will be carried out under supervision, and it will be made assure that the operators have completely read and understood the working manual.

- No safety measures will be bypassed during the operation of a machine. No safety switches will be turned down during operation. No elements will be changed on the control panel during the working of the machine.

- If any error occurs during operation immediately stop the machine and remove the error. Make sure no tools are left on the main body of the machine before continuing with the process.

- Make sure there is a clear view of the machine and the area surrounding the machine is always clean.

- Place proper signs on the main body of the hammer mill machine before initiating maintenance or repair.

- Shut down the machine completely. Do not remove parts at least one hour after complete shutdown.

- Never try to slow down any moving part of machine with hand or direct tools.

14.What are the maintenance requirements of hammer mill machines?

Maintaining the hammer mill machine is easy and it requires minimal designated time for planned maintenance. Proper care and maintenance will increase the working life of the machine and will ensure efficient work output through the years. A brief overview is as follows, for detailed instructions such as changing of bearings and other part please refer to the manual provided with the machine.

- Lubrication:Follow the lubrication chart provided by the manufacturer with the machine.

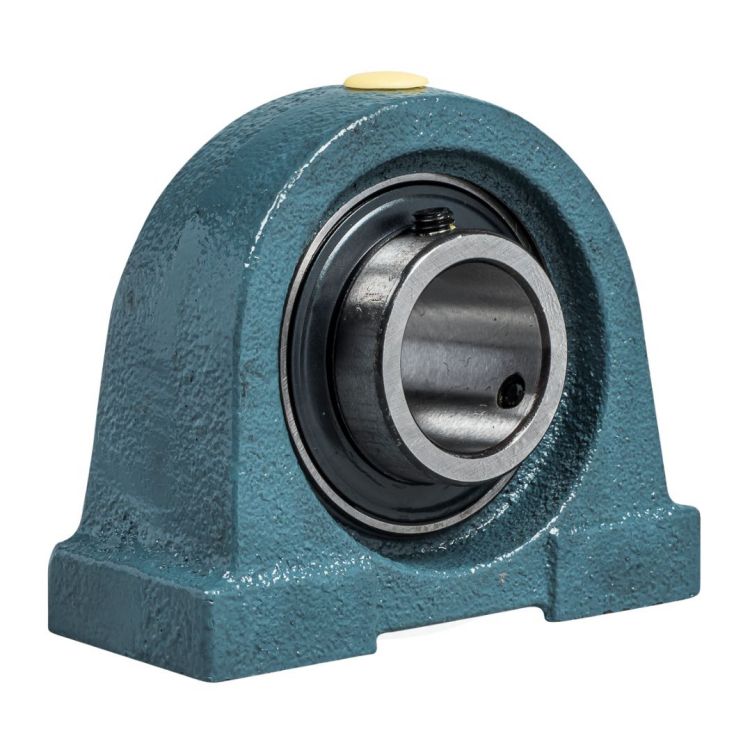

- Pillow Block: The pillow block in the mill should be lubricated every weak and fresh lubricant should be applied after thorough cleaning of the block not exceeding thirty days. The pillow blocks consist of oil cups provided with spring hinged covers. Oil is maintained at 1/8” from the top at resting position. During operations oil level may go down. Oil should never be added during operations the levels should be maintained after the machine is stopped. A drain is provided at the base of the pillow block for the oil to be changed every month. Use only manufacturer recommended oil cups, refer maintenance manual for lubricants and oil cups.

- Feed system/ Gear reducer:Before shipment, the reducer is greased at the factory. The reducer should be lubricated every week with a pressure gun and fresh lubricant should be applied every three months. Grease should be applied to the bushings and ball bearings.

- Pulleys: The pulleys should be lubricated every week with pressure gun.

- Daily maintenance: Check pillow blocks for any change in temperature. After an hour of operations carefully touch the pillow blocks. If you are unable to touch the pillow block or the temperature exceeds 140OF notify your supervisor. Be aware of any unusual noise or vibrations.

- Vibration limit:If under no load the vibration velocity limit (in/sec) is less than 0.15 in/sec, no need of taking any action. If under no load the vibration velocity limit is between 0.15 and 0.40 in/sec identify and correct the source of vibration. If under no load the vibration velocity limit exceeds 0.40 in/sec immediately shut down the machine and do not operate until the source is identified and corrected.

- Changing screens:

- Stop the feed screw mechanism but keep the hammer mill running so as to completely empty the grinding chamber.

- Once the chamber is empty stop the main motor and switch off the main electric supply.

- Remove the cover by loosening the clamp first followed by the removal of hold-down plate and end dust seal nearest the feed screw mechanism. Similarly, remove the end dust seal opposite the feed screw.

Screens of Hammer Mill Machine

- Remove the screen by simultaneously pulling up and pushing down by sliding out of its grooves. Clean the grooves before installing a new screen.

- Slide in the new screen carefully in the grooves. Clean grooves will aid in installation of the new screen.

- Check the end dust seals. Replace the seals if worn out.

- After installing the seals, install hold down plate followed by the installation of cover. Check the tightening of the bolts.

- Rotate the rotor with hand, it should move freely. Connect the main supply and start the machine.

- Changing rotors and hammers:

Hammers should be replaced as soon as signs of wear and tear appear. Worn out hammers significantly reduce the efficiency of the machine. The manufacturer recommends an extra set of hammers should always be at hand in case if unplanned replacement is required.

- Stop the feed screw mechanism but keep the hammer mill running so as to completely empty the grinding chamber.

- Once the chamber is empty stop the main motor and switch off the main electric supply.

- Remove the cover by loosening the clamp first followed by the removal of belt guard.

- Release the bolts on the motor and move the motor to remove the belts.

- Pillow blocks bolts are removed followed by rotor assembly. Use slings at both end of the shaft and rest the rotor assembly on pillow block.

Pillow Block Unit- Hammer mill machine- Picture courtesy- BMG

- Hammers are installed in proper position; each set contains six hammers. To remove stirrup hammers, remove the bolt and washer at the free end of the shaft. The pillow block assembly can be taken off the shaft once the bolt is removed. The king pin and hammer can now be replaced. Keep in mind that the manufacturer does not recommend a single hammer replacement. A new set contains 06 hammers, and it should be installed to keep the rotor balance. Once the hammers are installed, assemble the machine in the same manner in which it was dismantled. For further instruction refer to the installation manual.

- Changing screw mechanism

- Stop the feed screw mechanism but keep the hammer mill running so as to completely empty the grinding chamber.

- Once the chamber is empty stop the main motor and switch off the main electric supply.

- Power cut is followed by removal of hopper and belts and feed housing.

- Clean the pads before installing new feeder

- Assemble the machine in the same manner in which it was dismantled.

- Changing V-Belts

- Stop the feed screw mechanism but keep the hammer mill running so as to completely empty the grinding chamber.

- Once the chamber is empty stop the main motor and switch off the main electric supply.

- Power cut is followed by removal of hopper and belts and feed housing.

- Remove the guard covering V-Belt, then loosen the belt by sliding the main motor on the rails.

- Remove old belt and installed a new set. Adjust the belt tension as mentioned in the installation manual. Place the belt guard to its original position.

15.Why hammer mill machine is recognized as the most profitable equipment among manufacturing industries?

Nevertheless, hammer mill machine is identified as the most profitable unit behind successful industry due to following reasons:

- Hammer mill machine is a compact tool that performs huge functions but does not occupy a huge workspace. Hence, this is a very affordable source of income for those who have a smaller workspace.

- If we compared the cost of hammer mill machines with other manufacturing machines, it would have cost you less very with surprising functions.

- Hammer mill machine is almost considered a piece of safety equipment as it does not produce massive heat.

- Hammer mill machine is a highly preferred machine for any manufacturing unit as it yields an instant outcome soon after feeding the material, power supply, and required process feeding system.

- Hammer mill machine is sort of versatile equipment as it does not confine to specific types of material; although it helps you to deal the material with various shapes, sizes and compactness.

16.Does the hammer mill machine comply with international quality standards?

Globally assigned quality standards for manufacturing machines especially pharmaceutical, food and beverage industries are of prime importance and mandatory for every piece of equipment.

The Hammer mill machine demonstrates the following global quality standards.

1. cGMP Compliance

Hammer mill machines are high-quality equipment that conforming the requirement of cGMP ultimately makes it trusted and the most demandable manufacturing equipment.

As we mentioned above, the entire structure of the hammer mill machine is made up of stainless steel, hence it provides high level of hygiene and minimizes the chances of microbial or unwanted contamination.

- ISO Certified Machine

Hammer mill machine is labeled in EN ISO 140-6 standard, which is an entrusted milling machine that ensures quality assurance and standardization.

- FDA Compliant

Hammer mill machine is an FDA compliant equipment that ensures the product is highly robust, safe, effective, and properly manufactured with no misleading parameters.

Crusher Machine Related Products

Crusher Machine Related Posts

Crusher Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget,we'll reply you ASAP within 24 hours